Page 2

TABLE OF CONTENTS

Maintenance and Servicing Instructions . . .3

Cleaning and Lubrication . . . . . . . . . . . . . . .3

Performance Verification . . . . . . . . . . . . . . .3

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Troubleshooting . . . . . . . . . . . . . . . . . . . . . .3-4

Disassembly, Repair, Replacement,

Reassembly, and Check Out . . . . . . . . . . . . .4-12

Compressor Chassis Removal . . . . . . . . . . .4

Compressor Removal . . . . . . . . . . . . . . . . . .6

Compressor Motor

Service Kit Installation . . . . . . . . . . . . . . . . .8

Aftercooler Fan Replacement . . . . . . . . . . .8

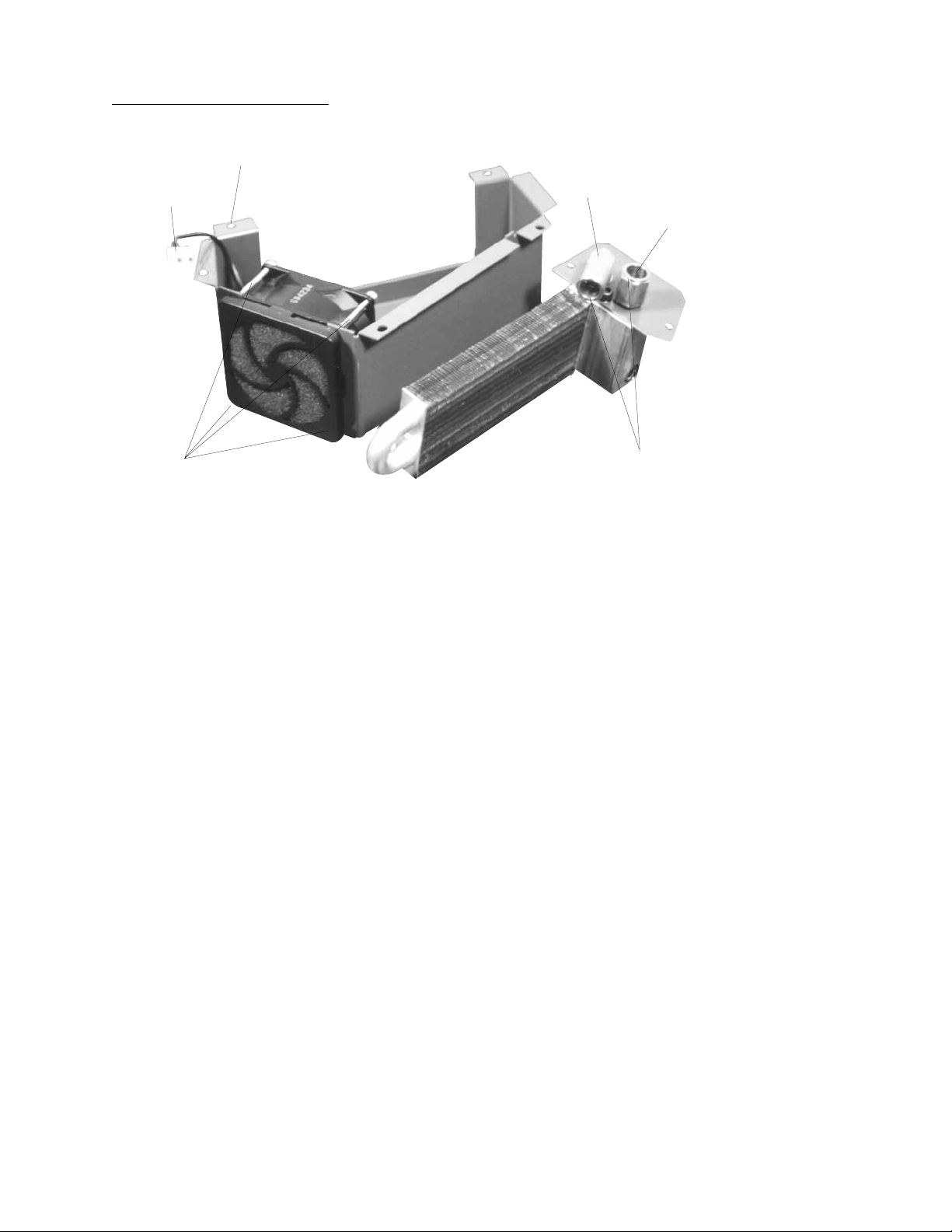

Aftercooler Assembly Replacement . . . . . . .9

Pressure Switch Replacement . . . . . . . . . . .10

Check Valve Replacement . . . . . . . . . . . . . .10

Removing the Air Storage Tank . . . . . . . . . .10

Replacing Pneumatic Tubing . . . . . . . . . . . .11

Removing Electronics Module . . . . . . . . . . .12

Removing the Intake Fan . . . . . . . . . . . . . . .12

Transformer Replacement . . . . . . . . . . . . . .12

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-26

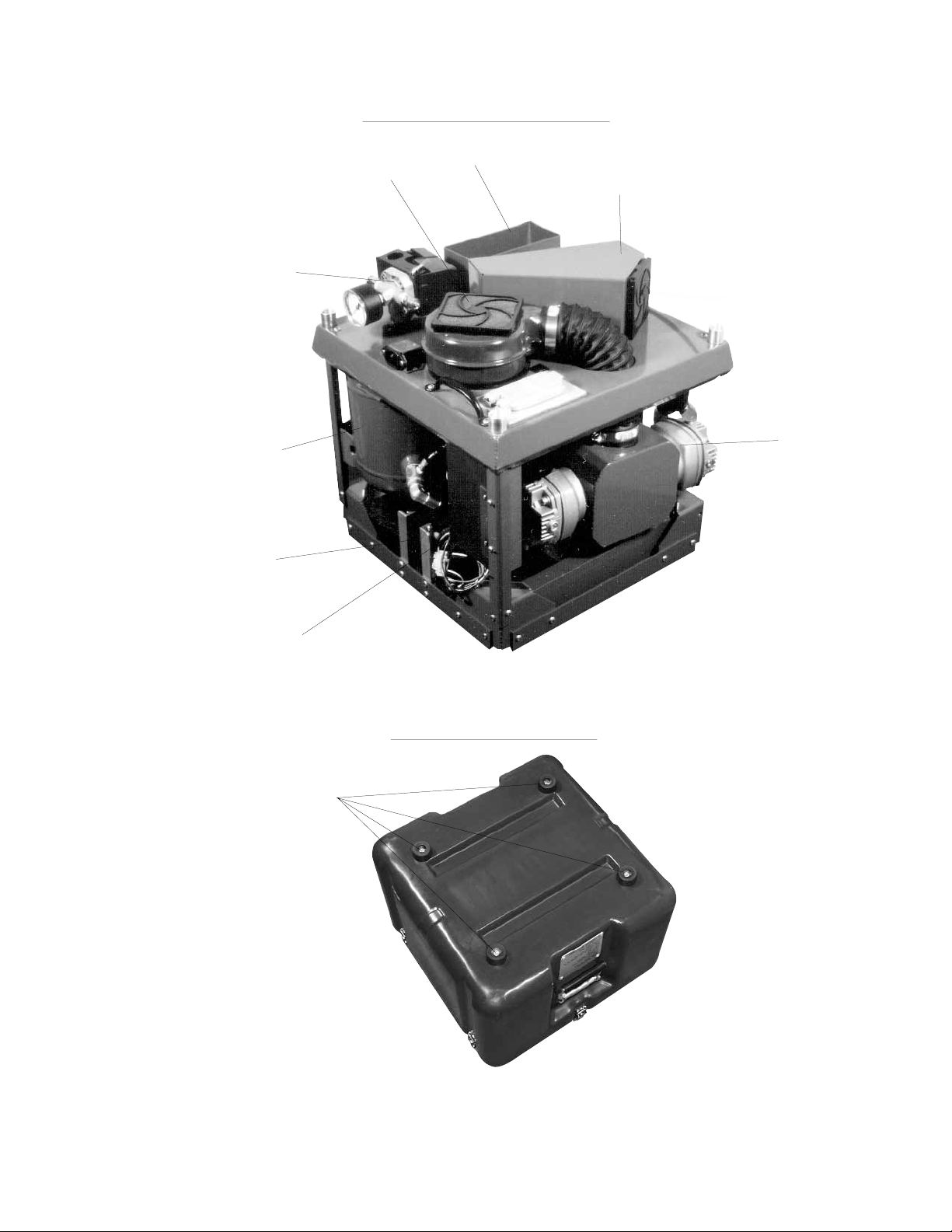

Case Base . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Case Top, Inside . . . . . . . . . . . . . . . . . . . . . .14

Case Top, Outside . . . . . . . . . . . . . . . . . . . . .14

Compressor Chassis . . . . . . . . . . . . . . . . . . .16

Air Storage Tank . . . . . . . . . . . . . . . . . . . . . .16

Transformer . . . . . . . . . . . . . . . . . . . . . . . . . .18

Compressor . . . . . . . . . . . . . . . . . . . . . . . . . .18

Intake Fan . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Aftercooler . . . . . . . . . . . . . . . . . . . . . . . . . .20

Motor Exhaust . . . . . . . . . . . . . . . . . . . . . . .22

Electronics Module . . . . . . . . . . . . . . . . . . . .22

Pressure Switch . . . . . . . . . . . . . . . . . . . . . . .22

Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Expendables . . . . . . . . . . . . . . . . . . . . . . . . .26

Table of Illustrations

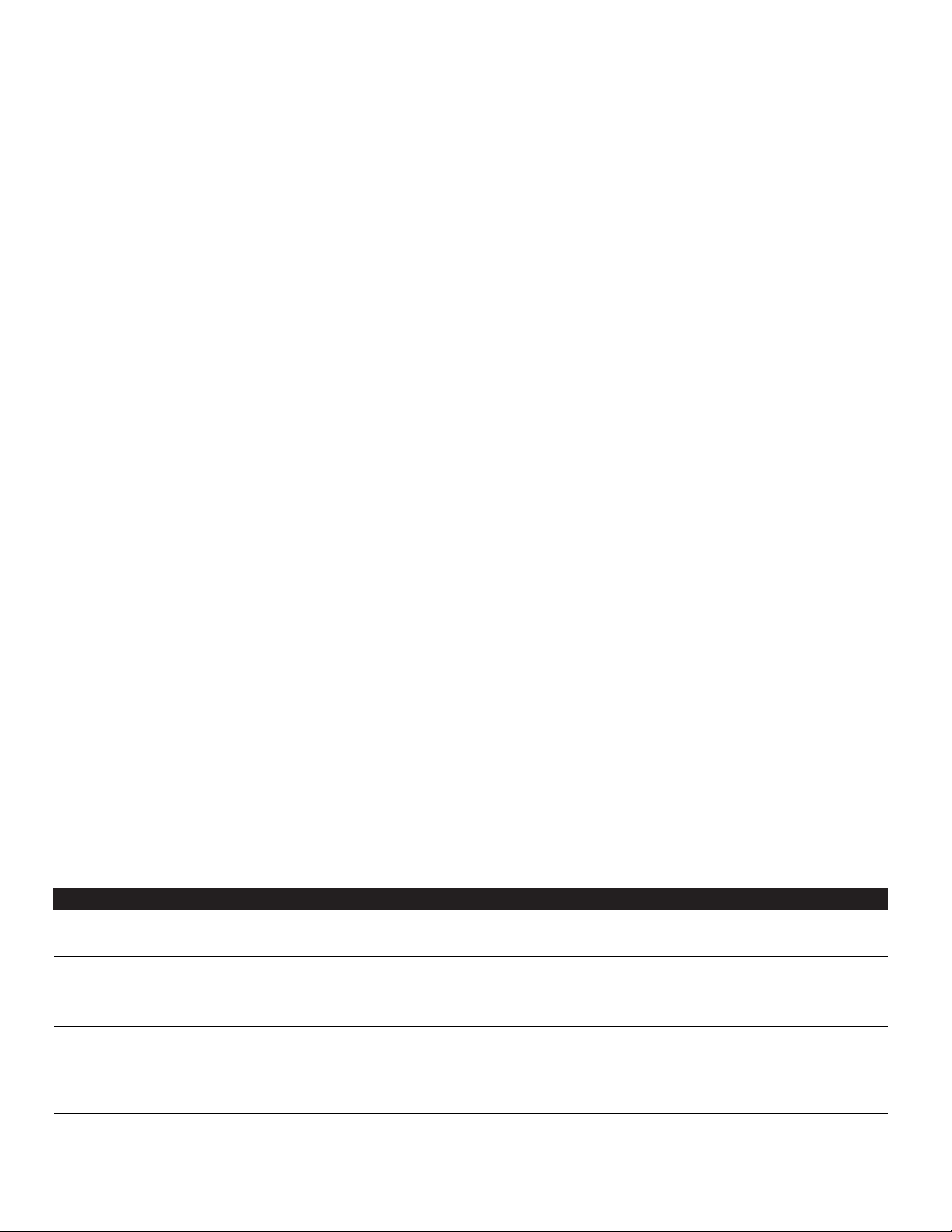

Figure A: AA-75CF

Component Identification . . . . . . . . . . . . . .5

Figure B: Compressor Chassis Removal . . .5

Figure Group C: Compressor Removal . . . .6

Figure D: Service Kit Installation . . . . . . . .7

Figure E: Aftercooler Removal . . . . . . . . . .9

Figure F: Pressure Switch Leads . . . . . . . . .11

Figure G: Tank Removal . . . . . . . . . . . . . . .11

Figure H: Intake Fan Removal . . . . . . . . . . .12

Figure I: Electronics Module . . . . . . . . . . . .12

Figure J: AA-75CF

System Wiring Schematic . . . . . . . . . . . . . . .13

Figure K: AA-75CF

System Pneumatic Schematic . . . . . . . . . . . .13

Figure 1: Case Base . . . . . . . . . . . . . . . . . . .15

Figure 2: Case Top, Inside . . . . . . . . . . . . . .15

Figure 3: Case Top, Outside . . . . . . . . . . . . .15

Figure 4: Compressor Chassis . . . . . . . . . . .17

Figure 5: Air Storage Tank . . . . . . . . . . . . . .17

Figure 6: Transformer . . . . . . . . . . . . . . . . . .19

Figure 7: Compressor . . . . . . . . . . . . . . . . . .19

Figure 8: Intake Fan . . . . . . . . . . . . . . . . . . .21

Figure 9: Aftercooler . . . . . . . . . . . . . . . . . .21

Figure 10: Motor Exhaust Chassis . . . . . . . .23

Figure 11: Electronics Module . . . . . . . . . . .23

Figure 12: Pressure Switch . . . . . . . . . . . . . .23

Figure 13A & B: Top Cover . . . . . . . . . . . . .25