ASG, Division of Jergens, Inc.

15

7

0

0

S. Waterloo Road | Cleveland, OH 44110-3898 | Phone: (888) 486-6163 | Fax: (216) 481-4519 | Email: [email protected] | Web: www.asg-jergens.com 1Before Use

Please check for the following accessories before operating the machine:

Table of Contents

Overview .................................................................................................................1

Before Use ...............................................................................................................1

Operating Precautions .............................................................................................2

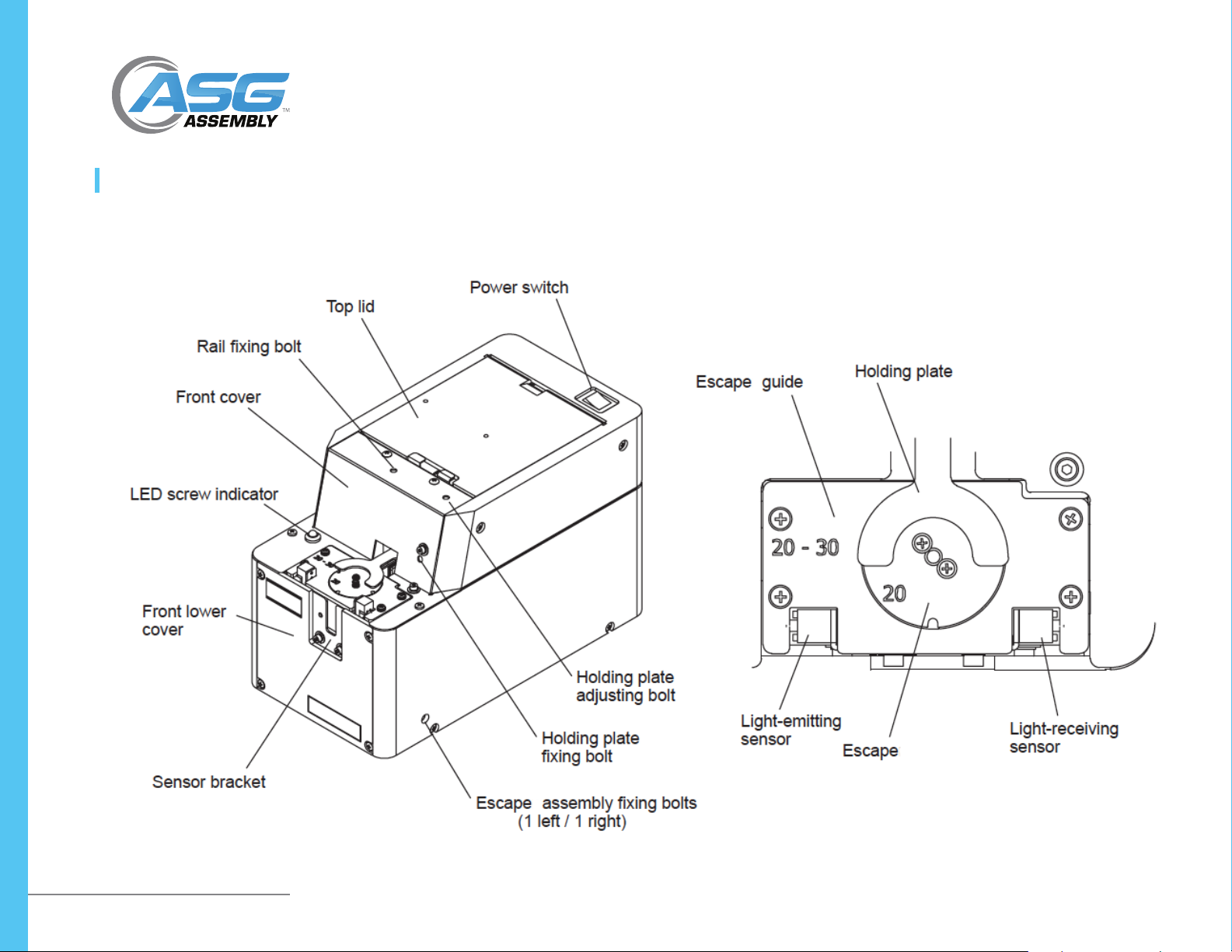

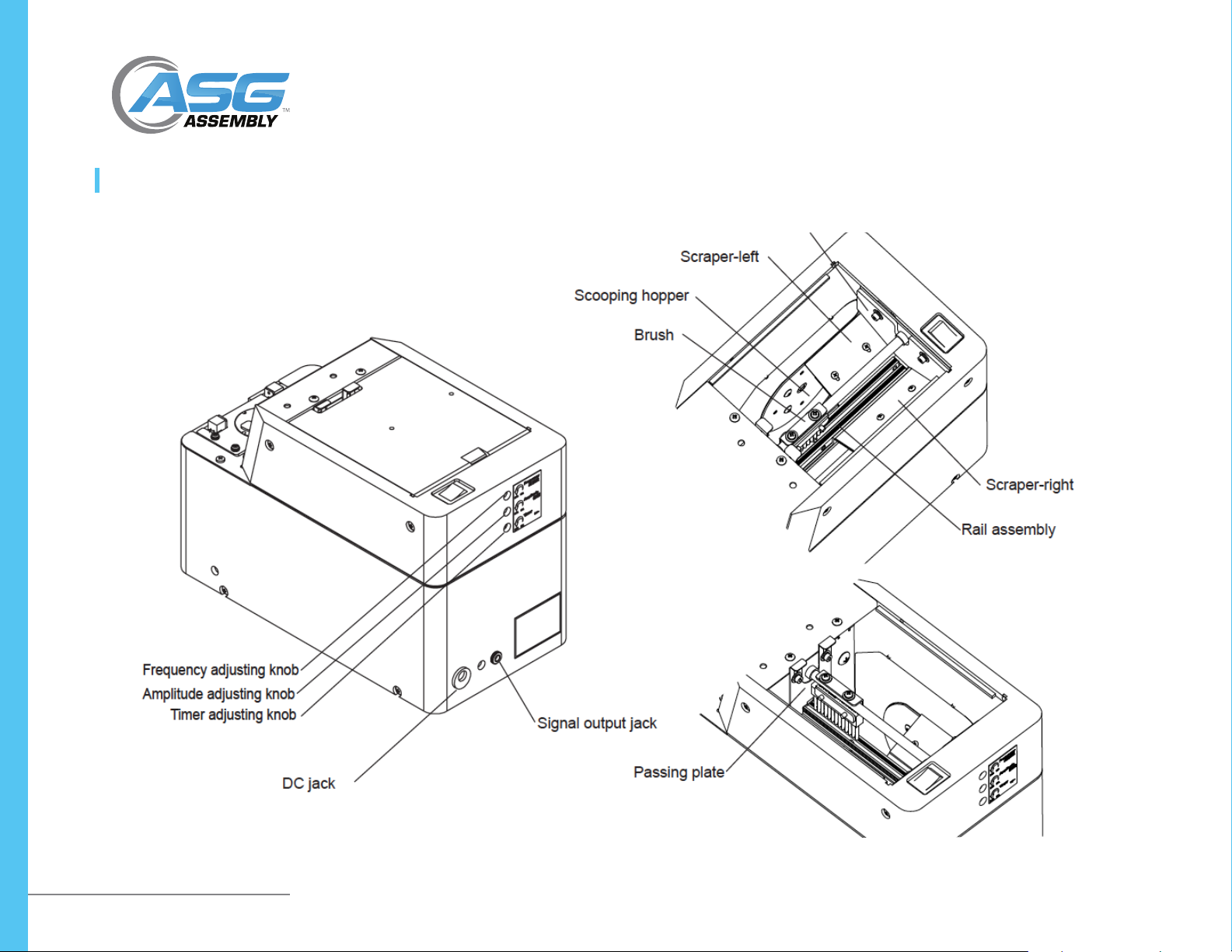

Names of Parts.........................................................................................................5

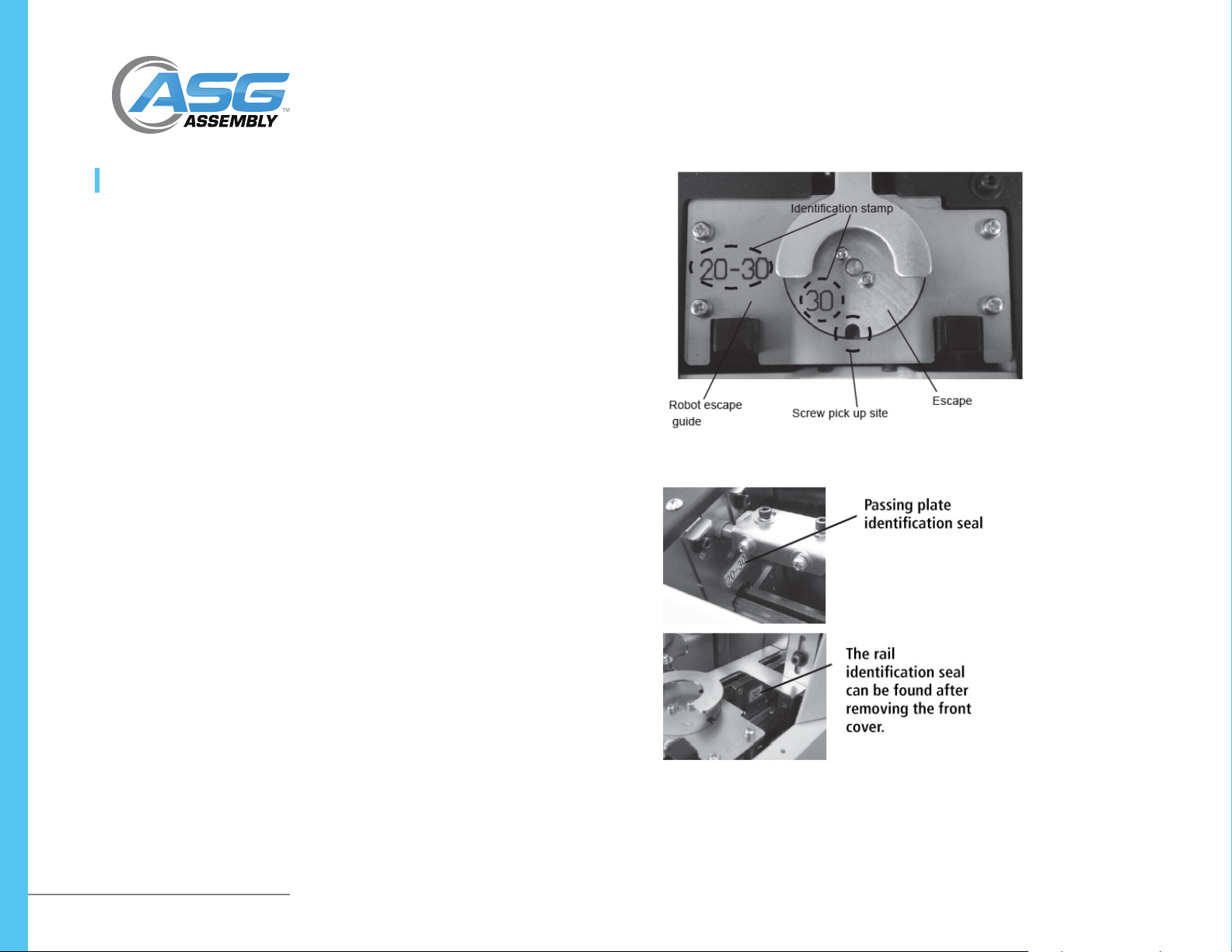

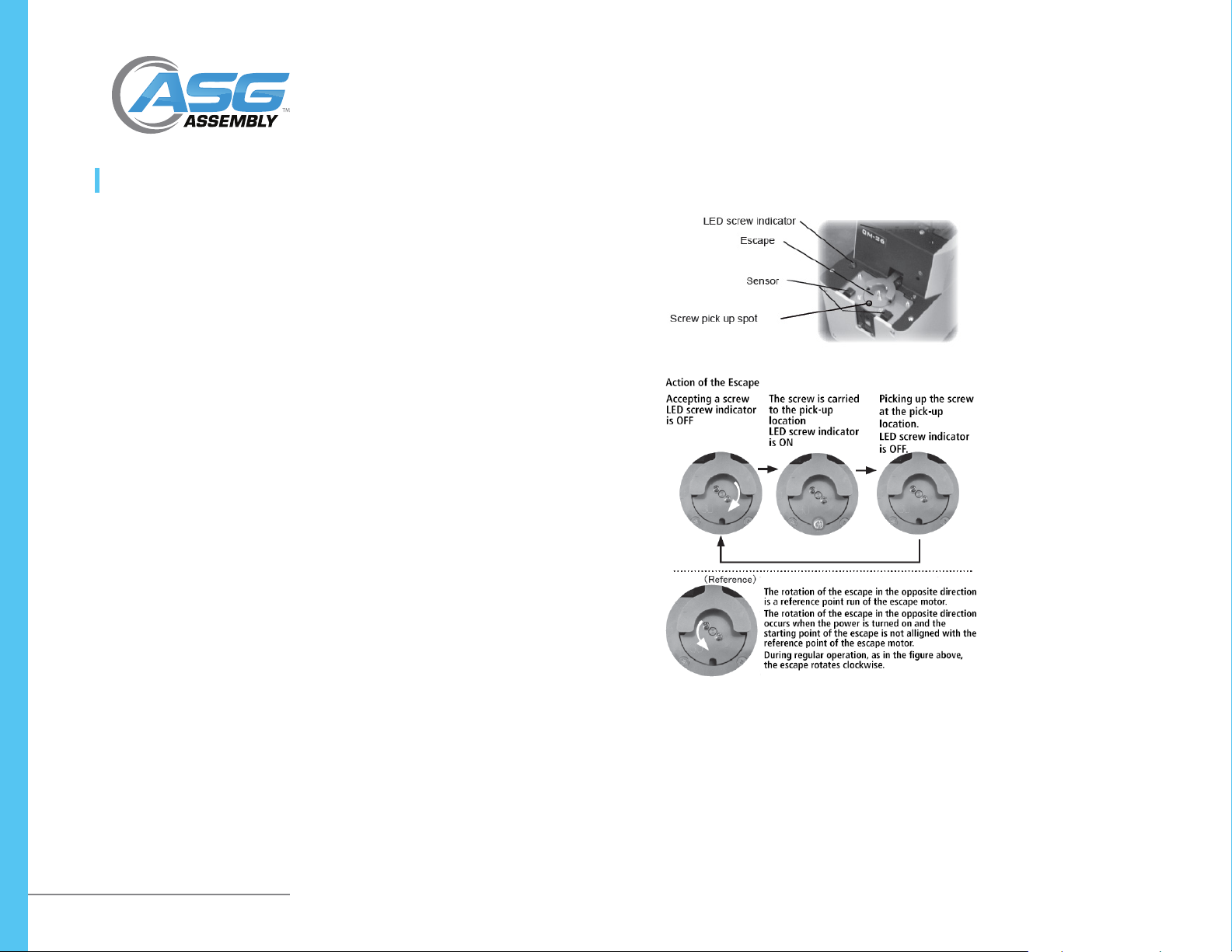

Adjustments and Checks Before Use........................................................................7

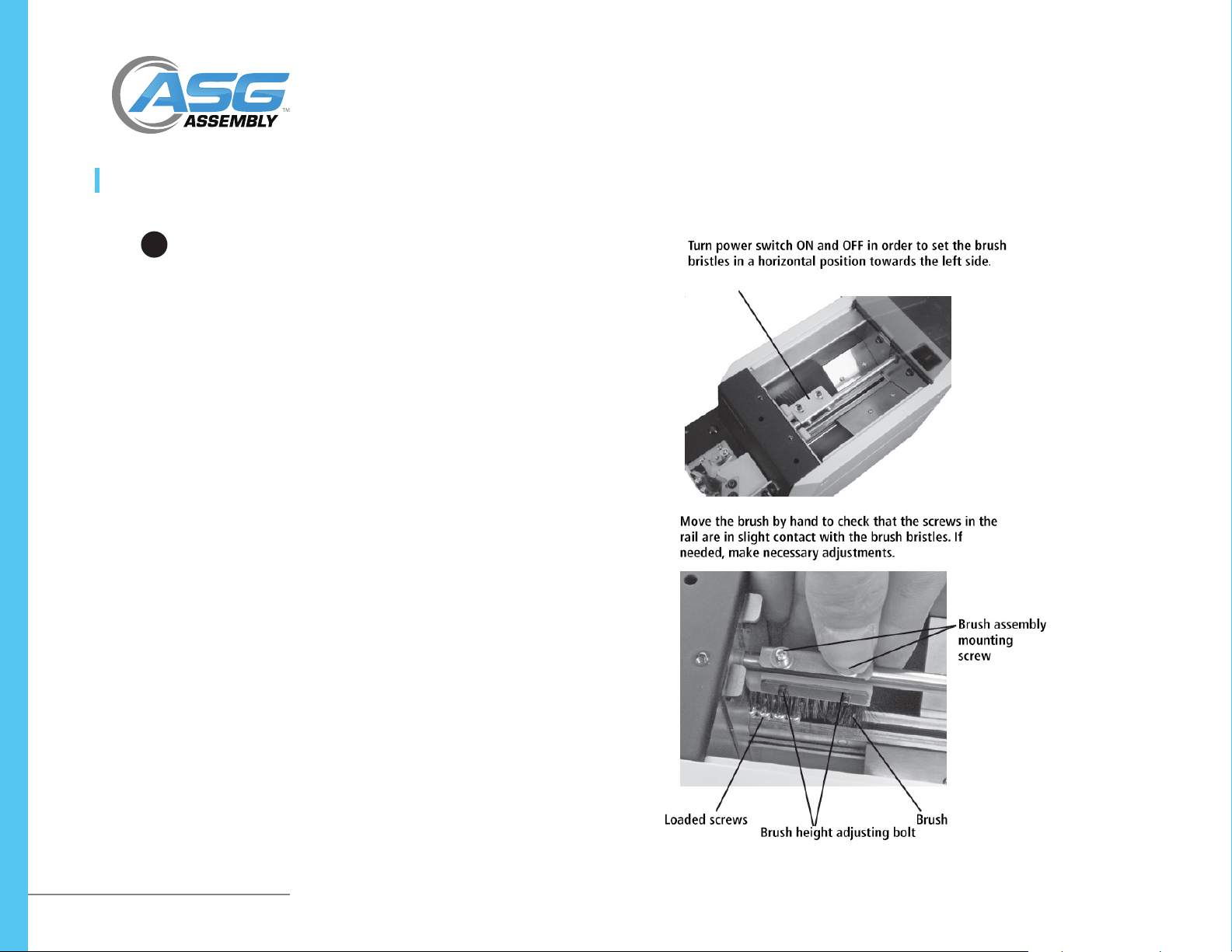

Maintenance..........................................................................................................15

Parts Adjustments and Replacements ....................................................................15

Application with Robotic System ...........................................................................25

Miscellaneous ........................................................................................................27

Troubleshooting .....................................................................................................29

Specications.........................................................................................................31

External Dimensions ..............................................................................................32

Warranty ................................................................................................................33

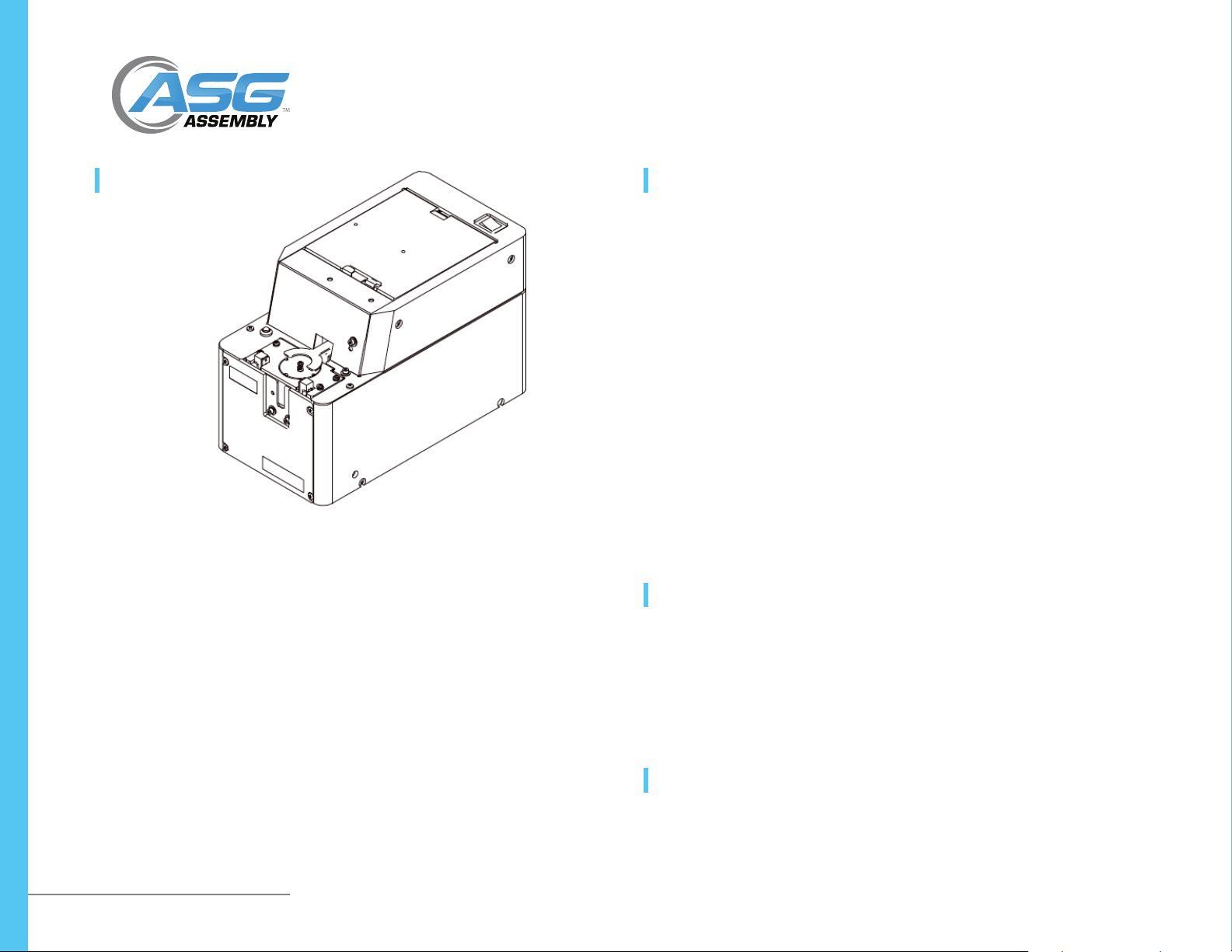

Overview

Thank you very much for selecting the OM Series Automatic Screw Feeder This machine

can line up screws (Type M2 - M6) and supplies them one by one to help the efciency

of screw fastening work. Different sizes of screws can be used by changing the rail and

parts of the escaper assembly. It can be used wherever there is a power source for an

AC adapter. Note: Only steel screws may be used with this machine. Stainless steel or

plastic screws cannot be used.

• (1) Instruction Manual

• (1) AC Adapter

• (1) Hexagonal Wrench

• (1) Screwdriver

• Read these instructions for the proper use of this machine.

• After having read these instructions, keep them in a convenient place so you or

the operator can refer to them whenever necessary.

OM-R Manual