2

Table of Contents

CRISP Continuous Autofocus System....................................................................................... 4

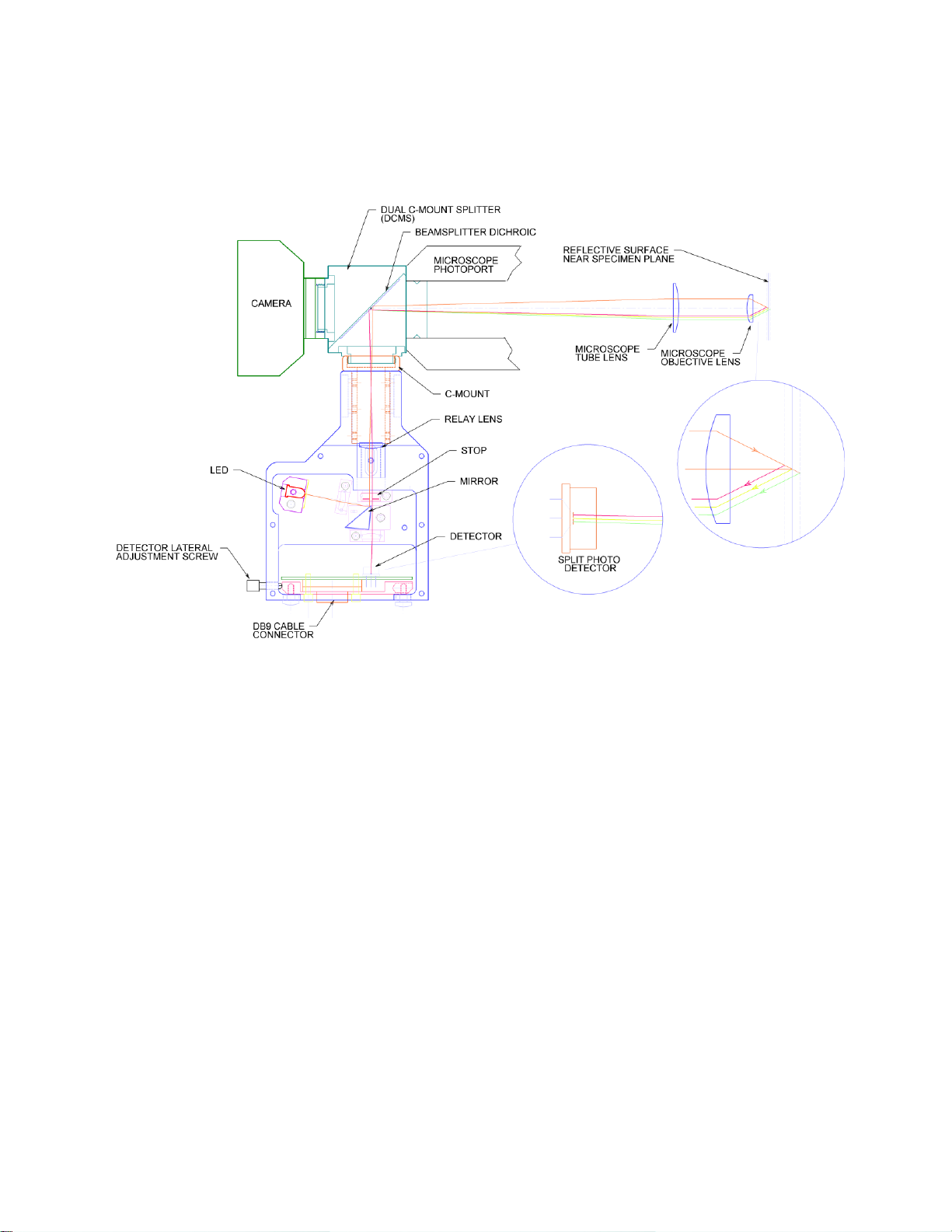

System Overview...................................................................................................................... 4

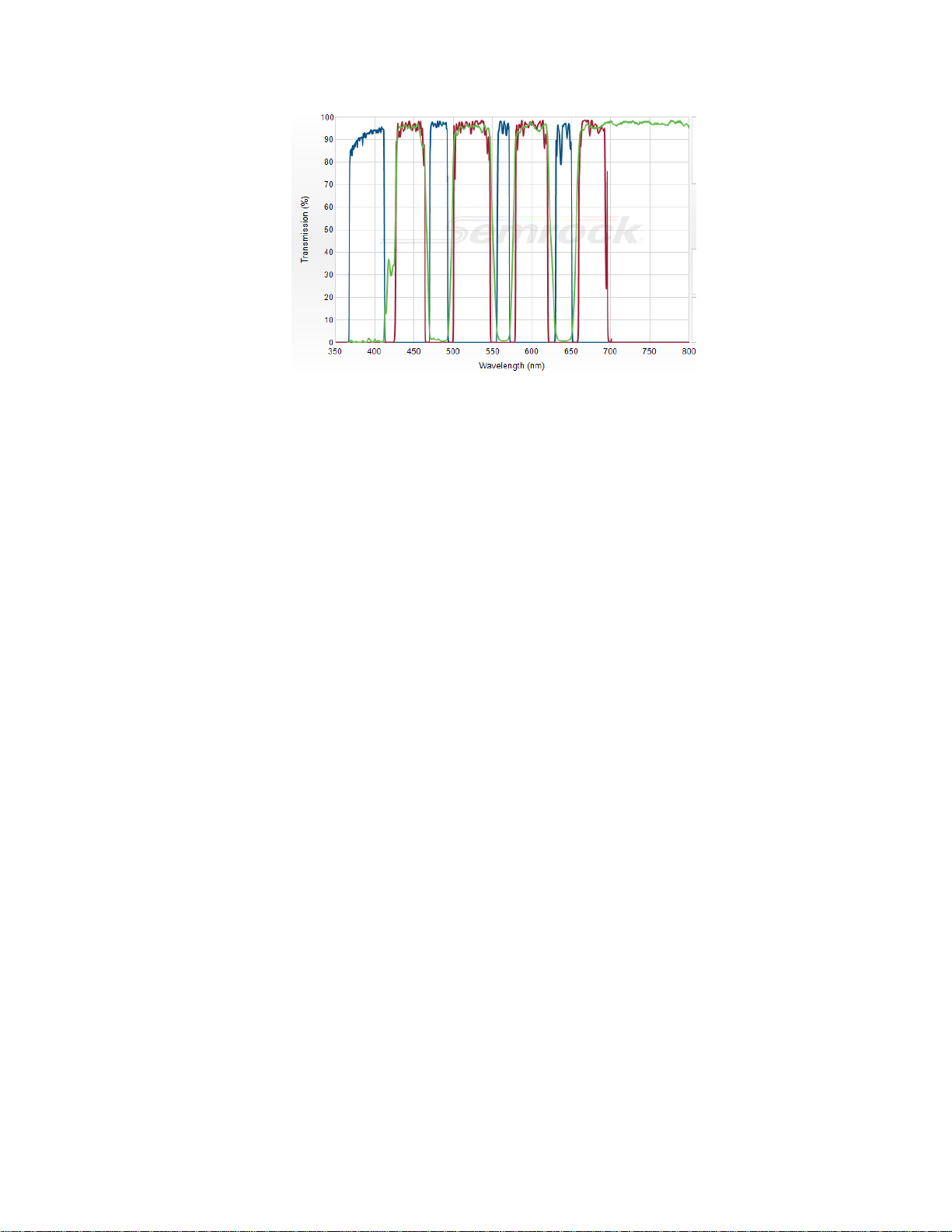

Fluorescent Filter Considerations.......................................................................................... 5

LED Characteristics and Filters ............................................................................................. 6

Commercial Filter Sets Suitable for CRISP........................................................................... 6

LED Power and Eye Safety..................................................................................................... 9

Installation.............................................................................................................................. 11

Theory of Operation.............................................................................................................. 11

Sample Considerations......................................................................................................... 11

Photodiode Displacement Signal.......................................................................................... 12

Control of the CRISP system ............................................................................................... 14

Button Actions...................................................................................................................... 14

CRISP System States............................................................................................................ 15

ASI Console support for CRISP ........................................................................................ 16

CRISP Operations................................................................................................................. 17

Quick Start Instructions Using ASI_Console....................................................................... 17

Quick Start Instructions Using Controller Only................................................................... 17

Engaging the LOCK for Normal Operation......................................................................... 18

Calibration Details................................................................................................................. 18

Optical Adjustment................................................................................................................ 20

Adjusting the Relay Lens position ....................................................................................... 20

Adjusting Position of the LED Light Source ....................................................................... 20

Adjusting the Primary Mirror............................................................................................... 21

Advanced Techniques............................................................................................................ 22

Troubleshooting Steps........................................................................................................... 25

Computer Control of the CRISP System .................................................................................. 26

TTL Control of the CRISP focus lock ................................................................................. 29