DW 950 / 951 / 952 / 95C

WATER SOFTENING

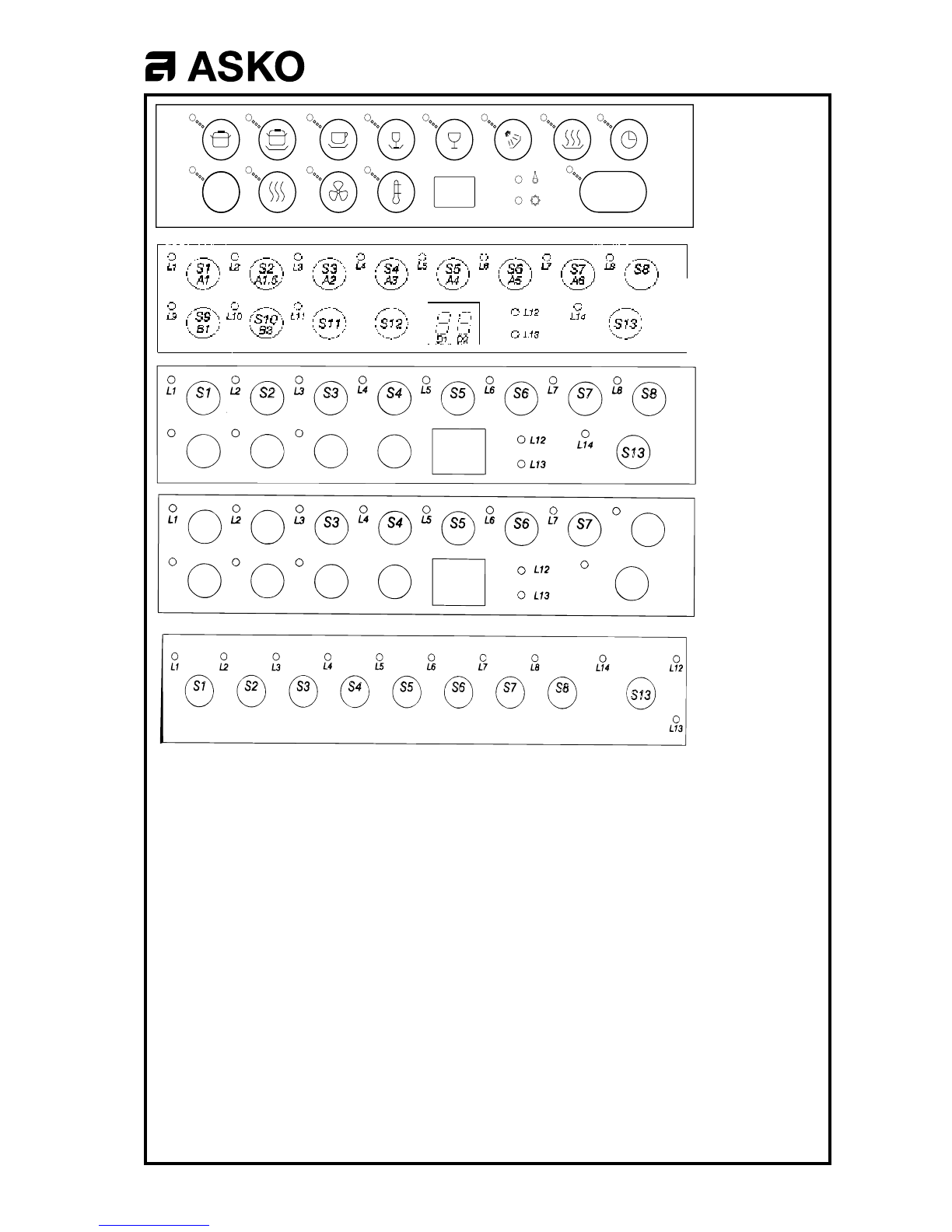

Thewatersofteneroperatesasfollows:

During rinse, pre-wash and main wash:

1. Inletvalve1opensandadmitswater.

2. Thewaterflows

•through hose 3 to air-brekdevice, no1

• passes an airgap

•leavesthe air-breakdevicethroughno.3

•passes hose 7 to theresin containerof thesofte-

ner,no3.

Therethewaterissoftenedandthesoftwaterflows

•outthroughno.4

• through hose 8 back to the air-break device no. 4

•entersthemachinethroughno.6.

1 Inletvalve1

2. Inletvalve2(regenerationvalve)

3. Hose IV1 - air-break device

4. Hose IV2 - air-break device

5. Air-break device

6. Inletopening

7. Hose air-break device no. 3- resin

containerno.3

8. Hose air-break device no. 4 – resin

containerno.4

9. Hose air-break device no. 5 - salt

containerno.5

10.Saltcontainer

11.Resincontainer

Hard water, containing lime,

Ca(HCO3)2flows into the resin

container. The Ca ions are

replaced by Na. Soft water,

containing Na(HCO3) flows

into the machine.

Regeneration during the main wash:

3. Whenthemachinehasadmittedwater,asdescribedabove,forthemainwash,inlet

valve2opensfor20,30or50seconds, dependingon thesetting.Thewaterflows

throughhose4totheair-breakdevice5,onthroughhose9andintosaltcontainerno.5.

Thesalt-saturatedwaterflowsintotheresincontainer,whereitregeneratestheresin,so

thatitcansoftenfurtherwater.

Ca

Na(HCO )

3

Na

Ca(HCO )

32

Resin container

1

3

4

2

5

7

8

6

9

10

11