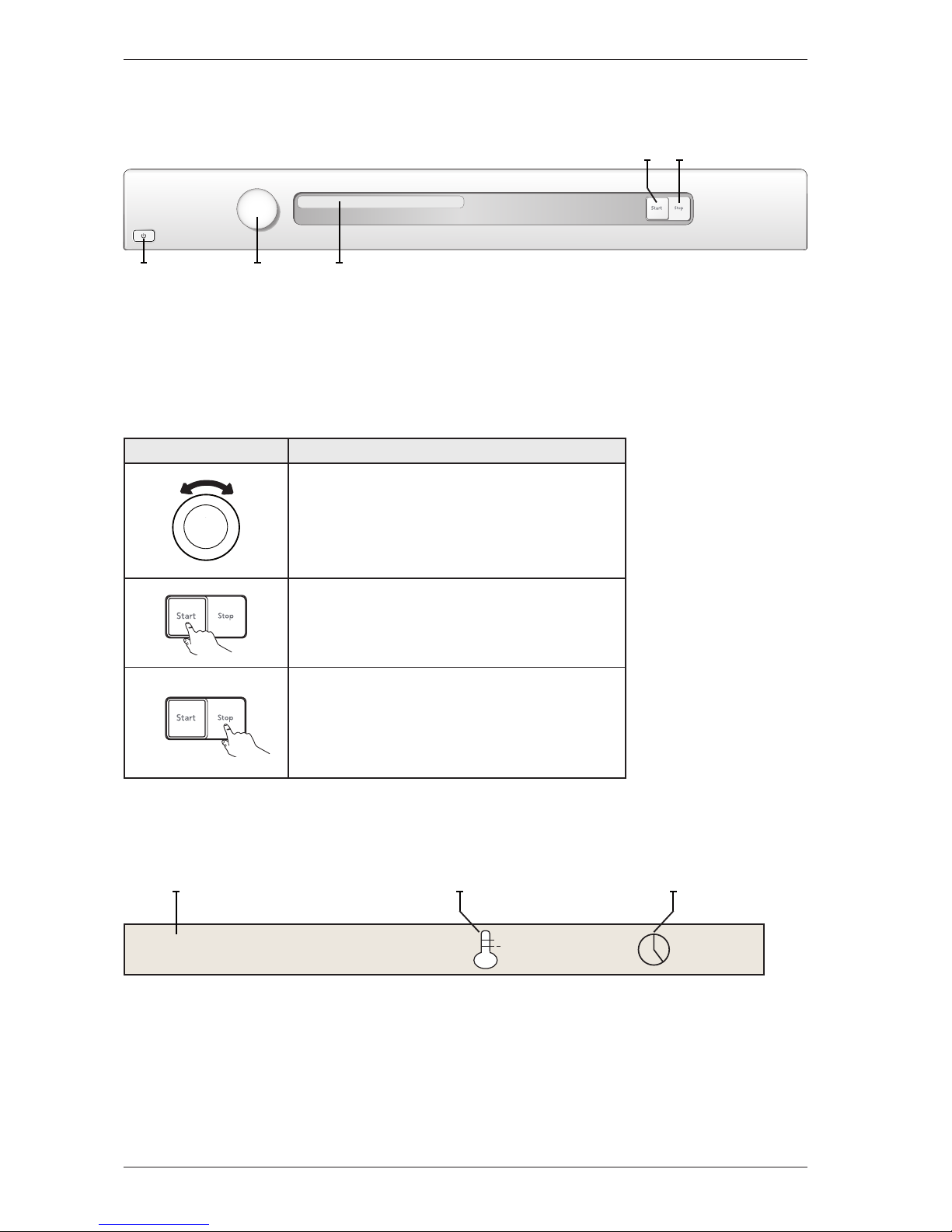

Component description

Components and measurement values

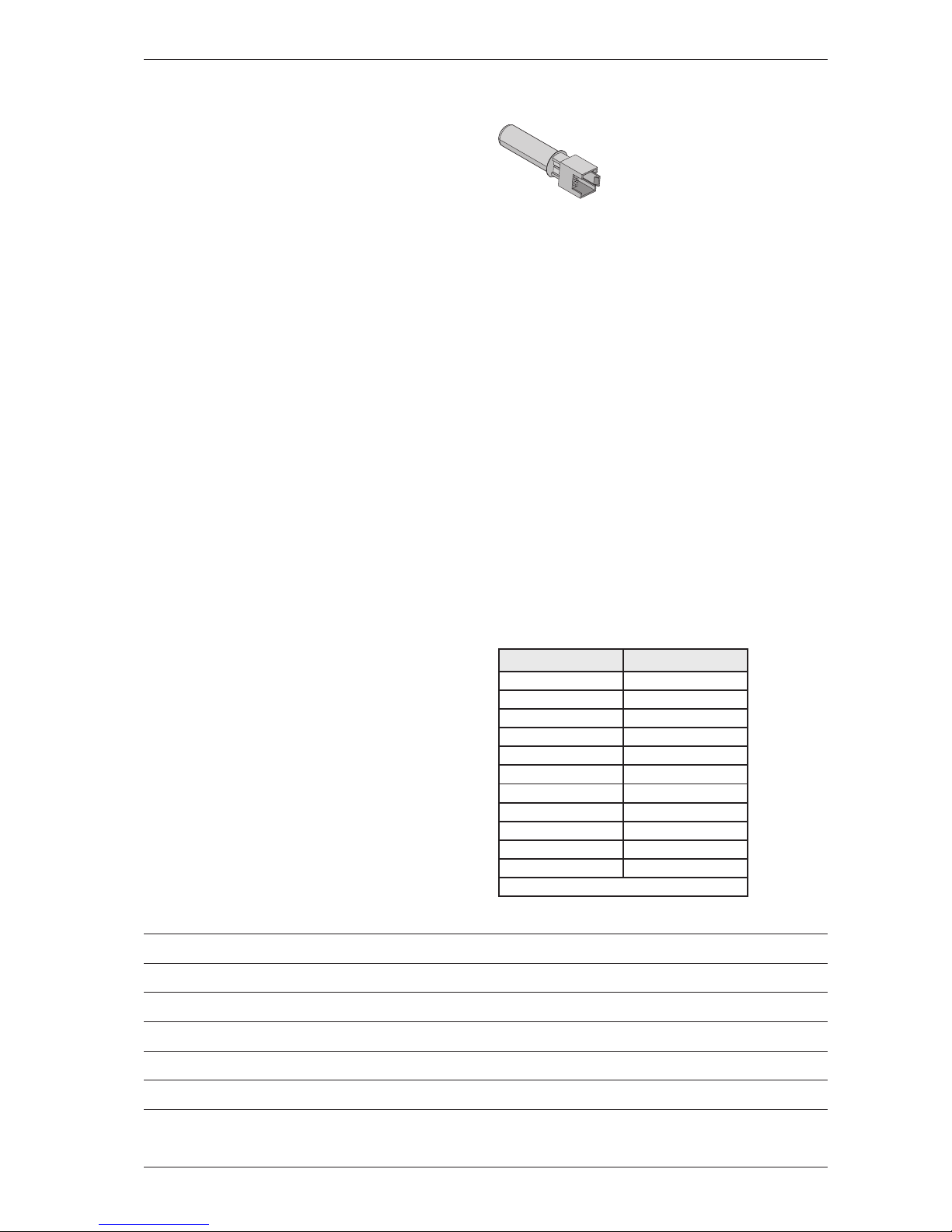

The specified resistance values apply at room temperature (about 20°C/68°F). Values within

±10% are considered normal.

Article no. Component Measurement value Comment

80 839 15 Motor 50 Hz,

220/240 V

Winding resistance:

cable colour red-white 26.5 Ω

cable colour red-blue 53.5 Ω

cable colour white-blue 27.0 Ω

Current: 0.7 A; 140 W; 2850 rpm

80 839 16 Motor 60 Hz,

220/240 V

Winding resistance:

cable colour red-white 26.5 Ω

cable colour red-blue 53.5 Ω

cable colour white-blue 27.0 Ω

Current: 0.7 A; 140 W; 3300 rpm

The motor is a 2-pin motor and is directly

connected to the fan for internal air and the

gearing for driving the cylinder. On condenser

dryers, the motor also drives the fan for external

air.

80 903 13 Capacitor 8 μF 50 Hz

80 903 14 Capacitor 6 μF 60 Hz

80 902 70 Capacitor heat pump 17 μF 50 Hz

80 902 71 Capacitor heat pump 60 Hz

80 821 28 Condensate pump 50 Hz

80 846 48 Condensate pump 60 Hz

80 762 02 EMC-filter with inductor The filter eliminates interference to and from the

machine.

80 833 44 Thermistor 4.8 kΩ(at 25°C) The thermistor controls temperature regulation. If

the thermistor is short-circuited or detaches from

the control unit, the programme is stopped.

80 773 85 Thermostat 150 150°C automatic The thermostat/overheating cut-out stops the

programme if the temperature becomes too high.

80 792 00 Thermostat 135 135°C automatic

80 902 24 Thermostat 110 110°C automatic

80 761 04 Door switch The front door triggers a door switch which stops

the programme when the door is open. If the door

has been opened and closed during the programme

the machine must be restarted using the Start/Stop

button.

80 761 03 Microswitch float

Overflow guard

If both containers in the tumble dryer are full the

programme is stopped by a float switch installed

in the lower container. “Over flow” is indicated

on the display.

Electrical connection Condenser 1950W/10A-2500W/16A

Vented 1950W/10A-3000W/16A

Heat pump 1300W/10A

Heating Water Circuit 1950W/10A

The machine is delivered as single phase and can

be switched between 10 A and 16 A. The control

buttons are used to make the switch via the software.

Does not apply to Heat Pump or Heating Water

Circuit.

80 824 92 Heating element 1950 W Heater 1: 1950 W, 24.5 Ω

80 915 90 Heating element 2500 W Heater 1: 1950 W, 24.5 Ω

Heater 2: 550 W, 91.4 Ω

80 824 91 Heating element 3000 W Heater 1: 1950 W, 24.5 Ω

Heater 2: 1050 W, 45.5 Ω

80 824 60 Heating element 3000 W Heater 1: 1950 W, 90.2 Ω

Heater 2: 1050 W, 167.6 Ω

Marine 440 V

80 824 61 Heating element 3000 W Heater 1: 1950 W, 24,5 Ω

Heater 2: 1050 W, 45,5 Ω

3-Phase

80 916 18 Heating element 2500 W Heater 1: 1950 W, 24,5 Ω

Heater 2: 550 W, 91,4 Ω

3-Phase

80 821 30 Cooling fan compressor heat

pump

637 Ω

80 821 22 Base heat pump complete 50 Hz

80 821 23 Base heat pump complete 60 Hz

80 88 415 Reversing valve 1.9 kΩ

80 841 00 Steam generator 68 Ω

Thermistor 61.4 kΩ

Steam pump 2.15 MΩ

Supplied with steam pump

80 902 22 Reed switch steam tank

80 889 37 Control unit compl. TD70.C The control unit contains microprocessors for

controlling programmes, the motor, the heating

elements etc.

80 846 49 LED-light compl. LED-technology for the machine’s internal light.

Service Manual TD70.C

9