2/ 13

Contents

Assun Motor...........................................................................................................................................................1

Product Manual......................................................................................................................................................1

1. About the Manual...........................................................................................................................................3

1.1 Validity of This Document .........................................................................................................3

1.2 Using This Document..................................................................................................................3

1.3 Definition of Terms ......................................................................................................................4

1.4 Definition of Symbols..................................................................................................................4

2. Product Safety..................................................................................................................................................5

2.1 Intended Product Usage...................................................................................................................5

2.2 Product Usage Safety ........................................................................................................................5

2.3 Product Disposal/Recycling .............................................................................................................7

3. Product Series Information..........................................................................................................................8

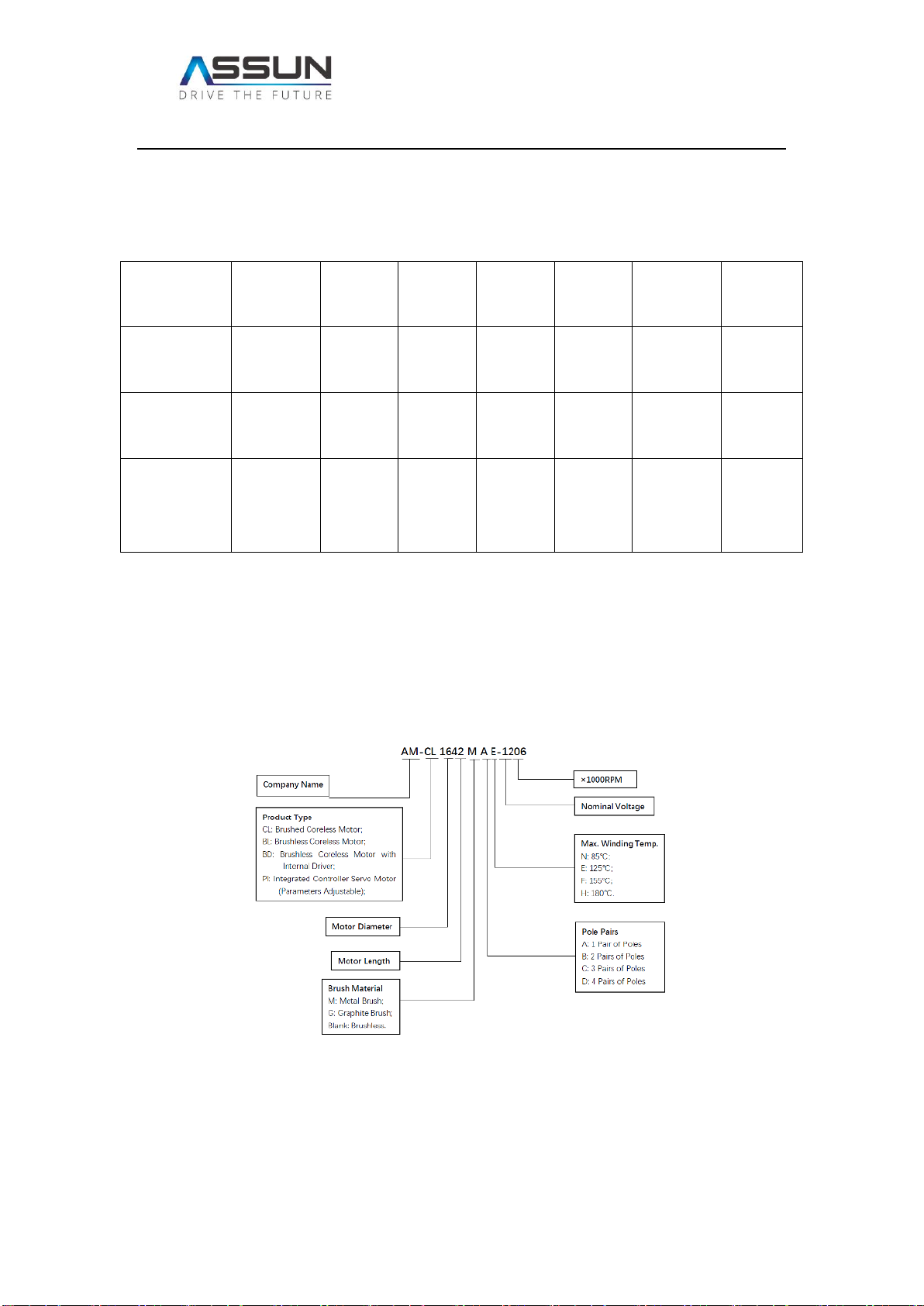

3.1 Product Series Structure Introduction..........................................................................................8

3.2 Product Model Information.............................................................................................................9

4. Product Function and Usage ................................................................................................................... 10

4.1 Motor Installation and Power Connection............................................................................... 10

4.2 Pulse input.......................................................................................................................................... 11

4.3 CW/CCW Control............................................................................................................................. 11

4.4 Feedback Pulse ................................................................................................................................. 11

5. Maintenance.................................................................................................................................................. 12

Appendix ............................................................................................................................................................. 12

Appendix 1. Series Product Parameters .......................................................................................... 12

Appendix 2. Specified Product Drawing and Parameters ......................................................... 12

Contact................................................................................................................................................................. 12