PC: Evolve Columns Operating Manual v2

Contents

Table of Figures .........................................................................................4

1. Column Hardware....................................................................................5

Mechanical Description: .............................................................................5

Design features: ......................................................................................5

Technical data........................................................................................6

Weights and Dimensions.............................................................................6

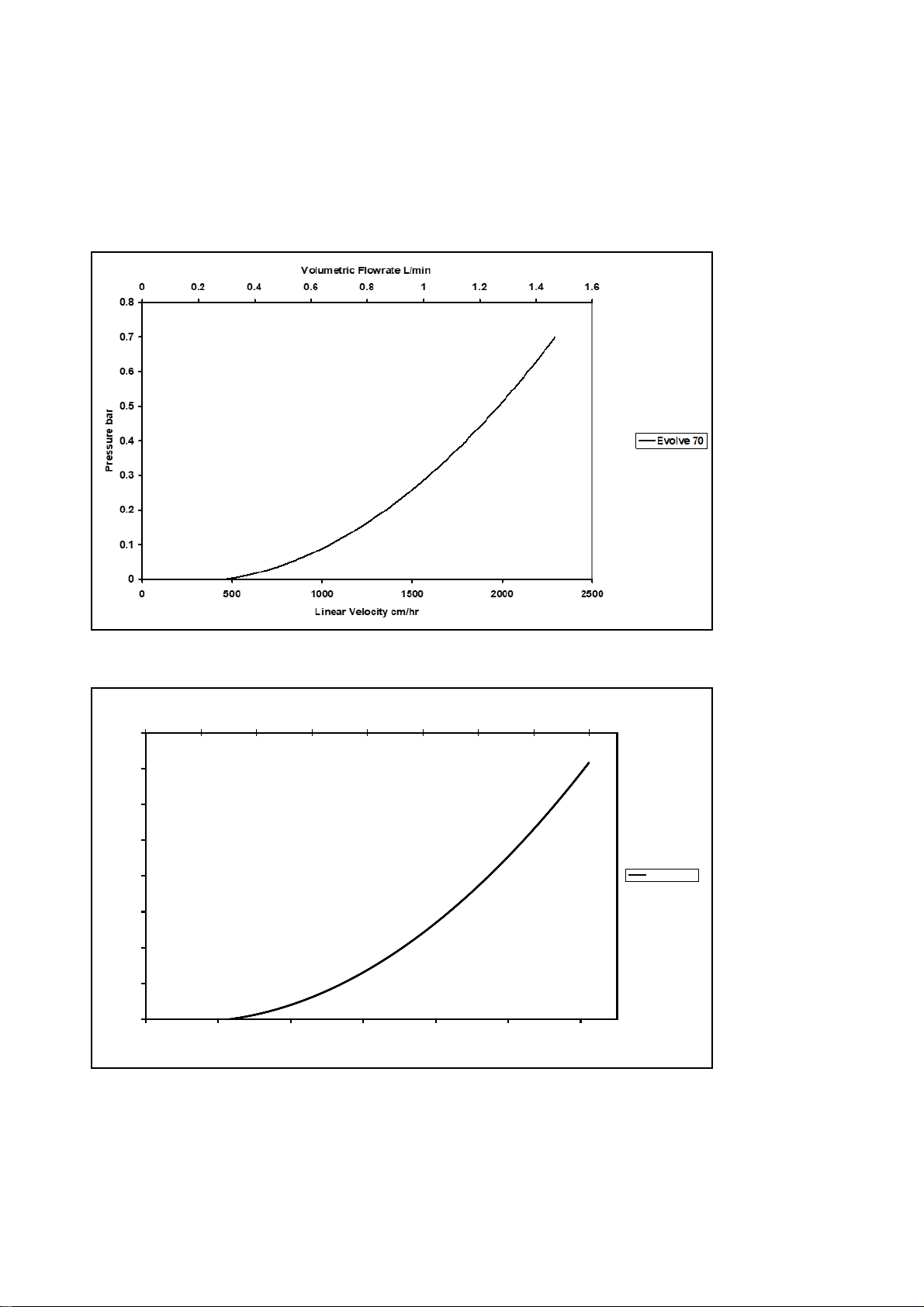

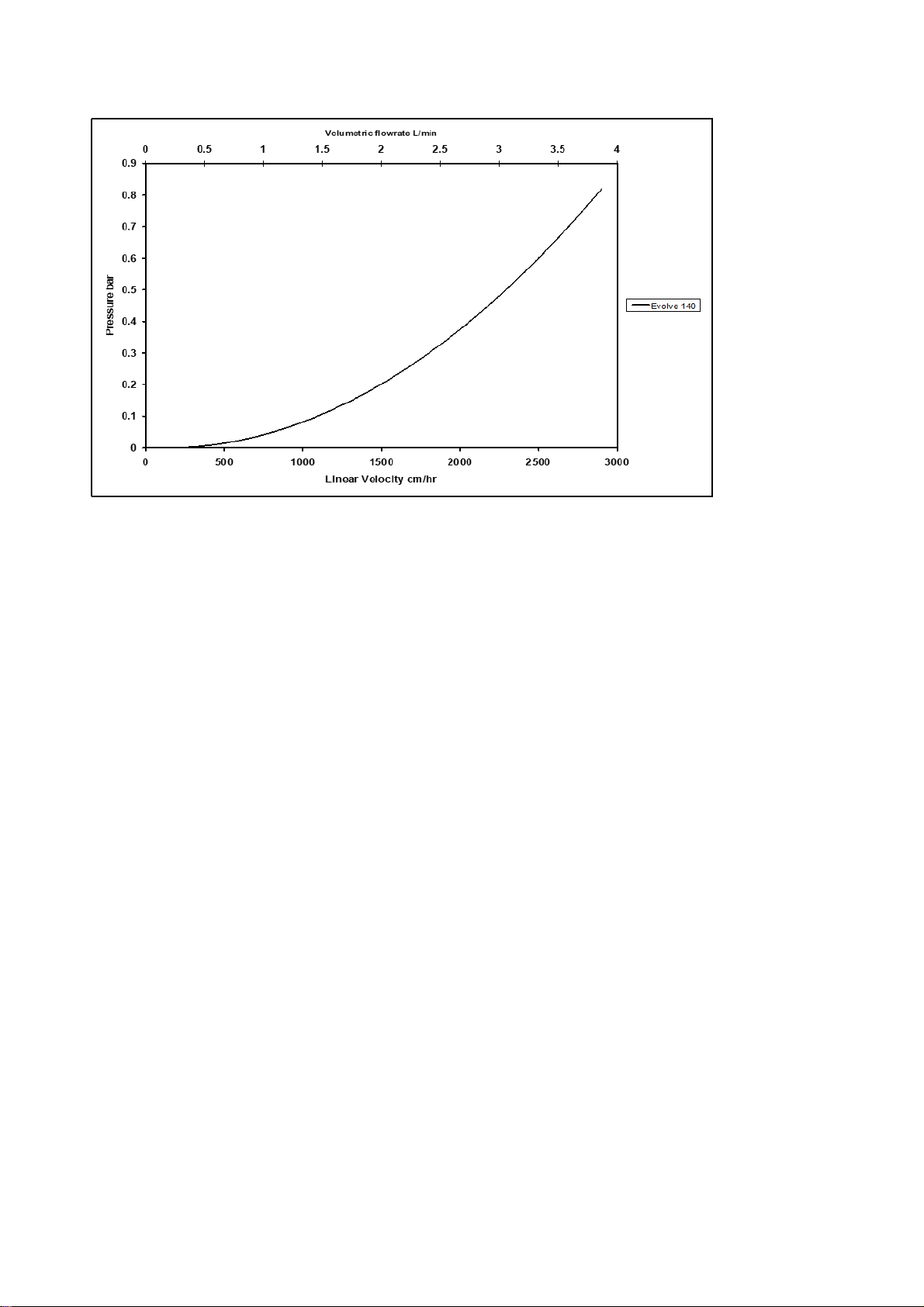

Pressure Drop .........................................................................................7

Material Conformity..................................................................................9

Materials of Construction – Process-Wetted Parts ............................................9

Materials of Construction – Non Process-Wetted Parts.......................................9

Chemical Compatibility.............................................................................10

2. Safety Guidelines ...................................................................................12

Safety considerations ...............................................................................12

Pressure Equipment Directive (PED)..............................................................12

Over-Pressurization .................................................................................12

Handling ..............................................................................................12

Chemical compatibility.............................................................................12

3. Column Installation and Operation...............................................................13

Column Installation..................................................................................13

(1) Installation of bed supports.................................................................13

(2) Installation of Fixed Bed Support ..........................................................13

(3) Levelling the Evolve™ Process Columns ...................................................14

(4) Installation of Adjuster Bed Support.......................................................14

(5) Setting the Bed Height.......................................................................15

4. Column Operation...................................................................................16

Hydrostatic Leak Test...............................................................................16

Column Packing (Constant Flow Rate Method)..................................................17

Unpacking ............................................................................................20

Cleaning...............................................................................................20

Storage................................................................................................20

5. Maintenance .........................................................................................21

Routine Maintenance Procedures and General Guidelines ....................................21

Disassembly of Evolve™ Process Columns ........................................................22

Adjuster Assembly ................................................................................22

Fixed Assembly....................................................................................23

Tube Assembly ....................................................................................23

Reassembly of Evolve™ Process Columns.........................................................24