Tecnodue I.T.S. PT 630 User manual

I.T.S. by Tecnodue

PT 630

Edition 1208

Operating Manual

I.T.S. Ital Trade Service PT 630 Operating Manual

2

22

2

The technical data and information contained on this manual can be changed without any notice

I.T.S. Ital Trade Service PT 630 Operating Manual

3

33

3

PT 630

The machine has been designed and constructed for the welding of PE, PP, PVDF and other thermoplastics pipes and fittings.

I.T.S. Ital Trade Service S.r.l.

Via Scar ellini 77 , 16149 Genova Italy

Phone : +39-010-6423396

Fax : +39-010-6423513

E Mail : info@it -tecndoue.com

Web Site : www.it -tecnodue.com

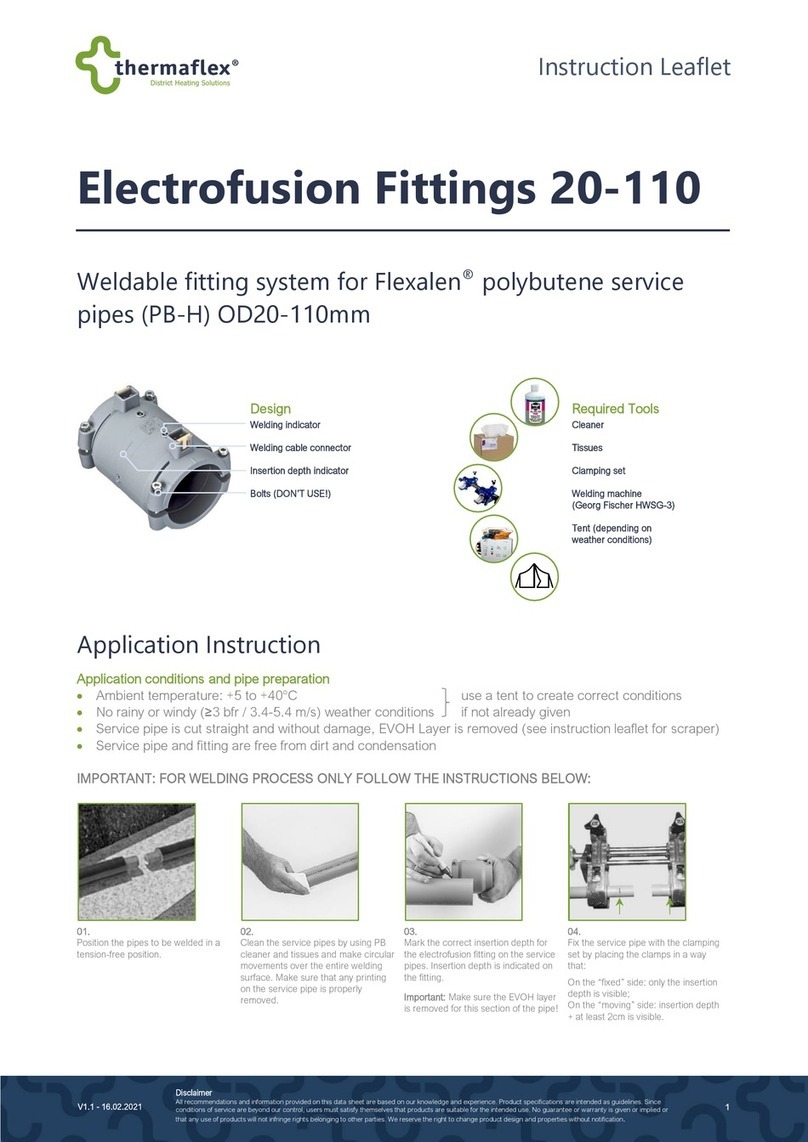

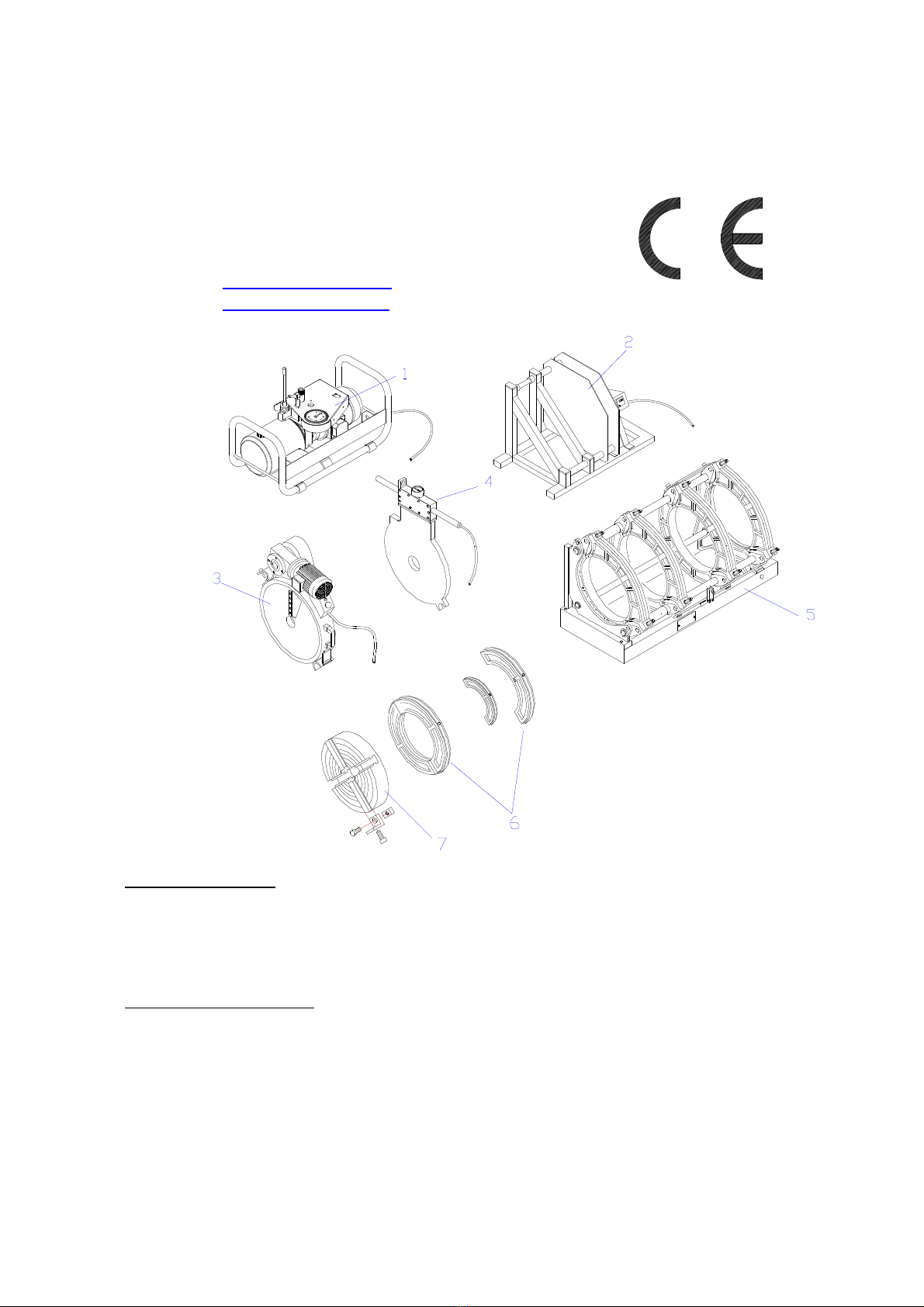

Standard Component

1. Hydraulic nit

2. Support for facing tool and heating mirror

3. Facing Tool

4. Heating Mirror

5. Basic machine

On reque t can be upplied:

6. Light weight alloy reducing rings for pipes and fittings d. 315,355,400,450,500,560mm

7. Stub End Device

• Wooden transport box according to ISPM 15

• LD (printing and storing data machine)

• Electric board with automatic circuit breaker

•

Rollers

•

Crane with electric hoist

I.T.S. Ital Trade Service PT 630 Operating Manual

4

44

4

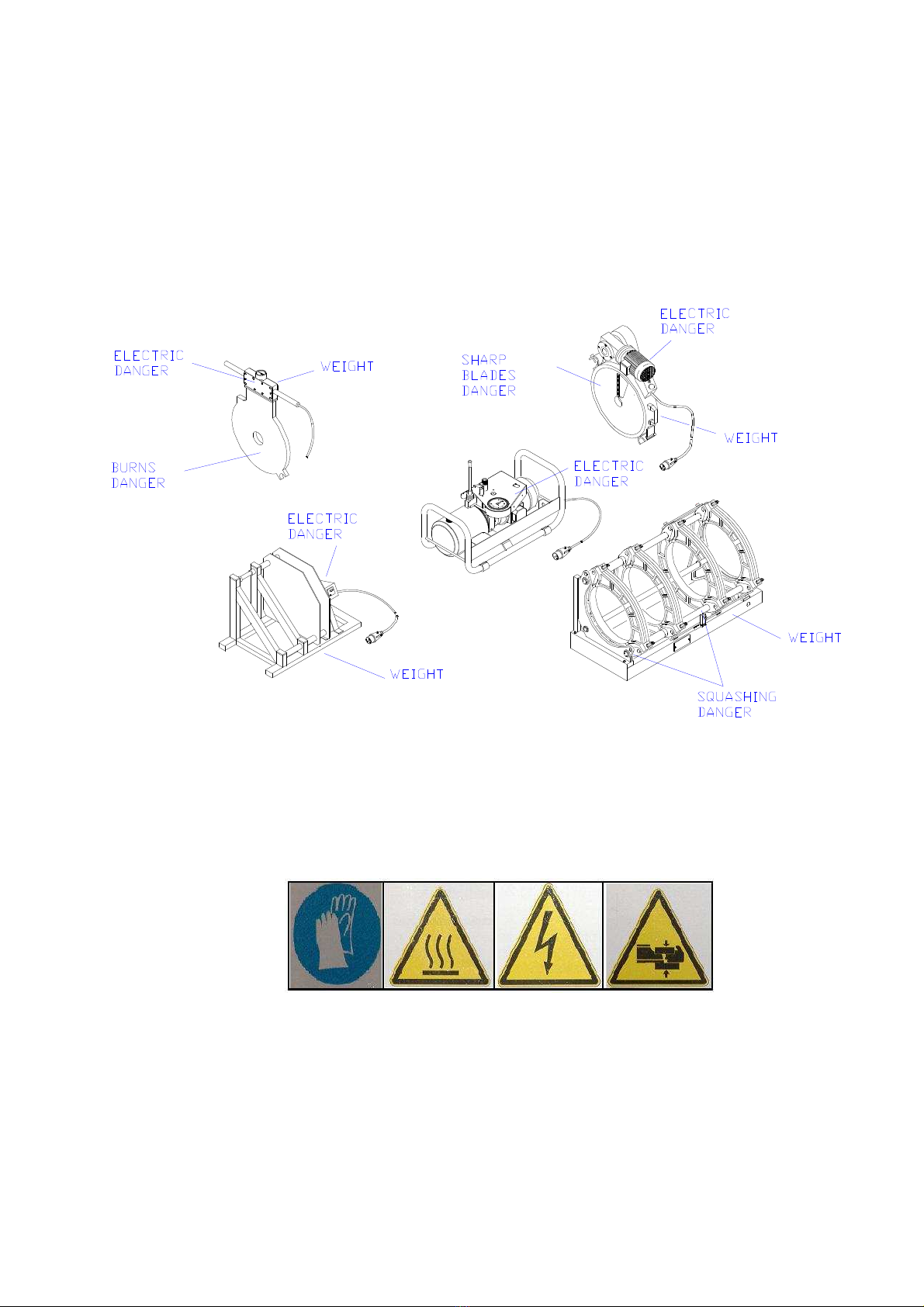

SAFETY RULES ACCORDING TO DIRECTIVES CEE

( To be read carefully and apply while utilizing the PT 630 )

Due to the specific use, this machine cannot be supplied with all kind of fix and removable protections suitable to avoid any risk of accident.

The machine, therefore, must be utilized, adjusted and keep in the perfect functioning conditions by skill operators.

Warning - Rule – Obligation

The use of machines composed by electrical components and movable parts, it's always a potential danger. In order to avoid any kind of accident caused by

electrical or mechanical sources it' strongly suggested to read and follow carefully the following safety rules before operating the machine.

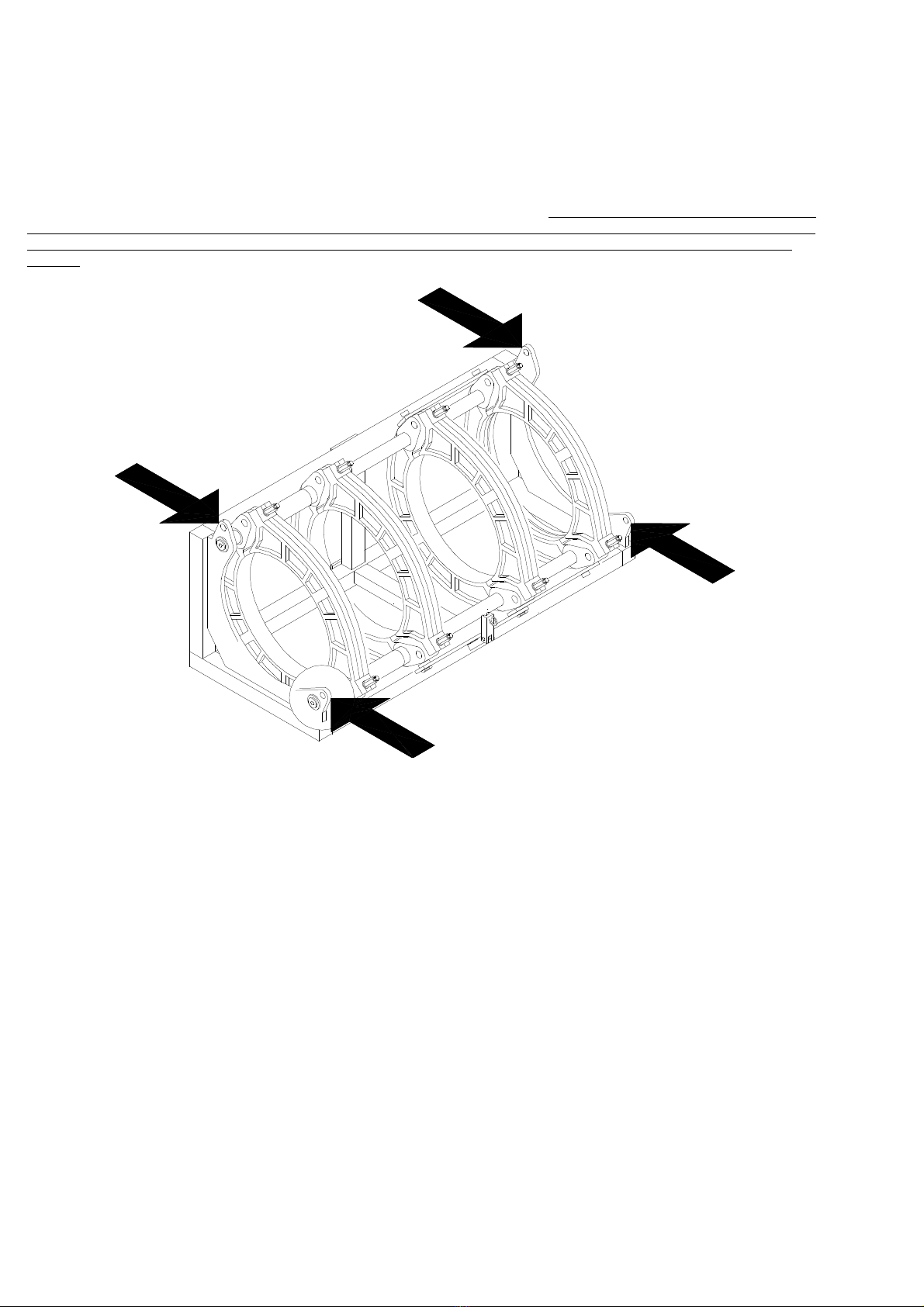

TRANSPORT/MOVEMENT

-.Basic Machine , Keep the maximum care while moving and it's suggested to utilize mechanical aids. ONLY MOVE THE BASIC MACHINE BY UTILIZING

THE HOOKS SHOWN IN THE FIGURE BELOW. IT IS COMPULSORY TO USE THE SAME HOOKS DURING THE STANDARD USE OF THE MACHINE.

DO NOT MOVE THE MACHINE BY HOOKING IT IN CLAMPS OR CYLINDERS. WHILE THE PIPES ARE FIT IN THE CLAMPS DO NOT MOVE THE

MACHINE

-.Facing Tool ,supplied with transport's hook.

Keep the maximum care while moving it and it's compulsory to utilize the handle also take care about the blades mounted in, it's compulsory use gloves.

-.Heating Mirror ,supplied with transport's handles

Keep the maximum care while moving it also keep the maximum care while utilizing it due to the high temperature involved always more than 200°C ,

it's strongly suggested to use suitable gloves.

In order to move from one working place to the other , the facing tool and the mirror must located into the special support , this support is heavy therefore

it's necessary to utilize the maximum care to move it

-.Hydraulic unit, supplied with transport's frame.

Keep the maximum care while moving it and in case utilize two person.

Avoid to transport the components by holding from the cable and remember to use suitable gloves.

ELECTRIC CONNECTIONS

The machine is operated by 400 Volts therefore be sure that the power supply plug is supplied with the safety devices according to the standard

requirements , also check that the power supply will be on the range of maximum 10% of the machine's nominal tension.

While the facing tool is connected to the power supply do not leave it into the basic machine but place it into the special support. In this position, even if the

start bottom is pushed the engine does not start.

Check regularly the cables and the plug and in case substitute by qualify personnel.

In case the heating mirror cable must be substitute the cable must be H07RN-F

Before carry out a reparation or maintenance all the plugs must with plug out from the power supply

ENVIRONMENTAL CONDITIONS

The working area must be clean and duly lighted. It's very dangerous to utilize the machine in case of rain or in wheat conditions or close to flammable agents.

CLOTHES

Keep the maximum care while utilizing the machine due to the high temperature involved on the heating mirror always more than 200°C , it's strongly

suggested to use suitable gloves. Avoid long clothes and avoid bracelets , necklaces that might be hooked into the machine.

CORRECT MACHINE'S OPERATION

Remember to check and read carefully the operating manual before utilizing the machine and the accessories.

KEEP ALWAYS THE MAXIMUN ATTENTION

After the heating mirror has been disconnected temperature will be hot for some minutes.

Keep the maximum care while utilizing the facing tool. Be careful to the blades , it's strongly suggested to use suitable gloves. During the facing operation

I.T.S. Ital Trade Service PT 630 Operating Manual

5

55

5

( facing tool in movement ) it's forbidden to take out the shavings

Avoid utilizing the machine after drinking or drugs use

Take care that all the people around the machine are at safety distance

While starting operating take care to avoid leave arms between the movable and fix trolleys.

SQUASHING DANGER

While starting operating take care to avoid leave legs or arms between the movable and fix trolleys. It's compulsory to be far from the basic machine

ACOUSTIC POLLUTION

The acoustic pollution of the drill engine is less than 85 dB ( value measured at 1 meter distance from the operator)

Due to some particular cases such as too much pressure during the facing the noise should be increased , therefore it's suggested to utilize some

protections.

IMPORTANT !!!!

Keep the maximum care reading and following the above Warning - Rules - Obligations the Ital Trade Services S.r.l. decline all responsibilities if are not

followed totally

Label on machine’ component

howing potential danger

WEAR BURNS ELECTRIC SQUASHING

GLOVES DANGER DANGER DANGER

I.T.S. Ital Trade Service PT 630 Operating Manual

6

66

6

1. Technical data

Operating data

Ambient temperature 0…50°C

Humidity (without condensation) 95 RH%

Transport and storing Temperature -10…60°C

Electrical data

Voltage 400 V 3 ph.

Frequency 50 Hz

Total power installed 11.5 KW 17 A

Heating mirror IP 54 9.3 KW

Facing tool IP 44 1.1 KW

Hydraulic unit IP 44 1.1 KW

Hydraulic data

Maximum working pressure 160 bar

Cylinder’s section 17,27 cm

2

Pressure gauge 0 - 160 bar

Pressure gauge precision class Cl. 1.0

Hydraulic unit engine revolutions 2800 rpm

Volumetric pump’s capacity 2 cc/rev.

Pump’s capacity 5.6 l/min

Hydraulic oil ISO 46

Oil tank’s capacity 7 liters

Mechanical Data

Facing tool transmission system Chain

Trolley maximum stroke 240 mm

Trolley slide bar diameter 50 mm

Distance between the cylinders centre 840 mm

Dimen ion

Basic machine 1460 x 1050 x 1040 mm

Facing tool 850 x 240 x 1050 mm

Heating mirror 1040 x 50 x 1050 mm

Hydraulic unit 700 x 360 x 400 mm

Support for facing tool and heating mirror 650 x 720 x 810 mm

Weight

Basic machine 229 Kg

Facing tool 107 Kg

Heating mirror 47 Kg

Hydraulic unit 41 Kg

Support for facing tool and heating mirror 36 Kg

Wooden transport box 154 Kg

Stub end device 41 Kg

Reducing inserts complete set 210 Kg

I.T.S. Ital Trade Service PT 630 Operating Manual

7

77

7

2. General de cription and application field

Hydraulic operated butt welding machines suitable for PE,PP,PVDF and other thermoplastics pipes and fittings.

The self aligning frame and the compact dimensions make the machines highly suited for working in road constructions, ditches , aqueducts,

gas ducts , sewers and irrigation systems.

Warning: The machine ha been equipped with one mobile trolley and one fixed trolley. Place the pipe to be welded on the mobile

trolley and and the pipeline end on the fixed trolley! Carefully check the pipe alignment before beginning to weld!

The machine is supplied complete of:

1) Basic machine d. 630 mm complete with a tools blue bag

2) Removable electric facing tool with safety switch

3) Removable PTFE coated heating mirror with a temperature control box.

4) Electro-hydraulic unit with accumulator and flexible hoses with quick couplings.

5) Support for facing tool and heating mirror

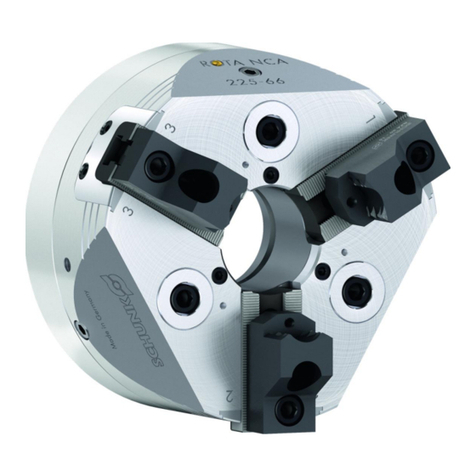

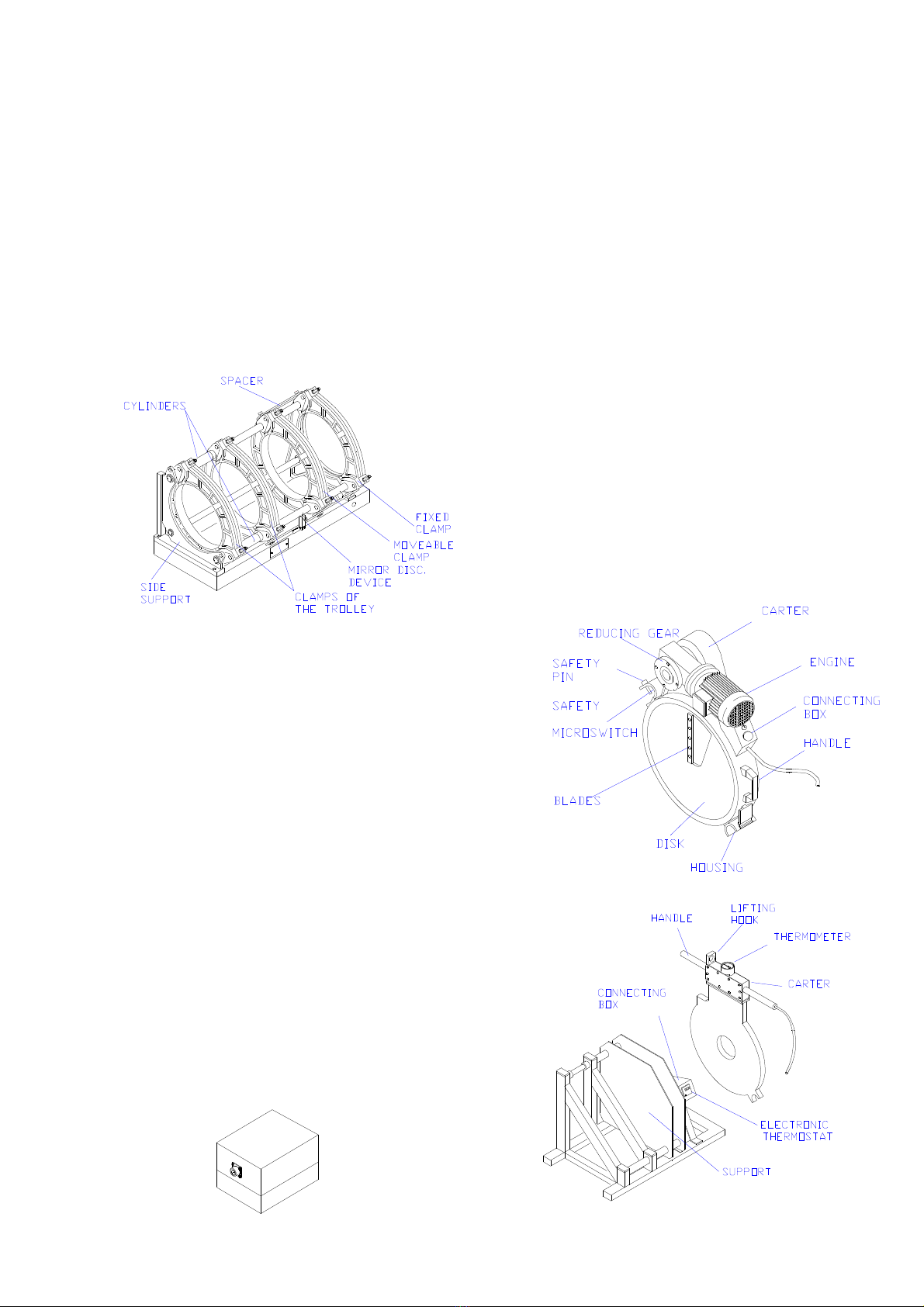

2.1 Ba ic machine

The basic machine is composed by:

• Two cylinders on which heads are mounted two complete

clamps d. 630 mm

• One movable clamp or d.630 mm sliding on cylinder's stem and

fixable in different positions by means of using the clamps spacers

• A stiffening bar

• Two side supports clamp d.630 mm

• A frame including the hydraulic circuit with the anti-drop

quick couplings.

• A heating mirror disconnecting device

2.2 Facing Tool

The electric facing tool is composed by:

• The facing tool body

• Two disks where are mounted the blades

• An engine with a reducing gear supplied with a safety pin

that , while connected keep the facing tool hooked to the

machine.

• A safety micro-switch allowing the engine starts only

when the facing tool is fit into the machine ,avoiding the start of

the engine out of this position.

2.3 Heating Mirror

The heating mirror is composed by:

• The heating mirror coated with green color PTFE complete with

thermometer (the thermometer does not depend upon the power

supply and always survey the real temperature of the heating plate)

and connecting box

• The support suitable for the heating mirror and the facing tool

where is located the connecting box

• The electronic thermostat located on the connecting box .

• LD connector. (The below figure shows where the LD connector

is located ).

LD Connector

I.T.S. Ital Trade Service PT 630 Operating Manual

8

88

8

2.3.1 Electronic thermo tat – different function

At each startup on the display will blink the writing ‘TEST’. This means that the

thermostat is testing the connection between the probe and the heating mirror.

If the test fails, the display will show 4 blinking upper scores (as per figure aside),

in this case the probe or the connection between the thermostat and the heating

mirror could be interrupted.

If the test success, the display will show the real temperature of the heating mirror and the heating mirror

warms up (the O T1 red led is switched on) until the set point value (the selected temperature) has been

achieved (central green light led).

To display the actual set point value of the temperature stored by the thermostat, push the key P. The display will show alternately the

writing ‘SP1’ and the et point value of the temperature. After 5 seconds the display will show again the real value of the heating

mirror temperature

To select a new value for the thermostat set point value (default value = 220°C):

1. Push the key P (The display will show alternately the writing ‘SP1’ and the et point value of the temperature)

2. By acting on the arrow keys P and DOWN it is possibile to increase or decrease the set point value.

3. When you reach the desired value push the key P to confirm.

4. The display will show again the real value of the heating mirror temperature

5. When the heating mirror will reach the set point value on the display the central green light led will be switched on.

Warning: On the thermo tat di play i alway hown the actual value of the heating mirror temperature (and never the et

point value!)

Temperature of the welding mirror for welding PE DVS 2207-1 norm

195

200

205

210

215

220

225

0 10 20 30 40 50 60 70

pipe wall thickne (mm)

Mirror temperature (°C)

PE100

PE80

0

Remember

W

hen welding PVDF, the temperature of the welding mirror should be adjusted for every wall thickness at 240°C +/- 8°C

When welding PP, the temperature of the welding mirror should be adjusted for every wall thickness at 210°C +/-10°C

I.T.S. Ital Trade Service PT 630 Operating Manual

9

99

9

2.4 Hydraulic Unit

The basic components of the hydraulic unit are the following:

• Electric engine

• Hydraulic pump

• Oil tank

• Hydraulic unit controls

• Pressure accumulator

• Pressure gauge

• Metal frame

2. 4.1 Hydraulic Unit Control

The control lever A open and close the machine's trolley according to the

position selected.

Bring the lever A into position A2 (position with automatic return) the trolley

is opening with the maximum pressure set up into the hydraulic unit

In position A1 the lever shut down automatically the engine ( release position ).

Bring the lever A into the position A3 ( position with hooking) the trolley is

closing, the hooking of such position allow the operator handling.

The hand wheel F of the pressure control allow the setting up of the

pressure at the requested values by turning anti clockwise the

pressure release , while turning clockwise the pressure increase .

The pressure by pass lever E allow ,by turning anti clockwise the

pressure releasing , while turning clockwise allow the pressure

increasing by means of using the hand wheel F and fixing. If you

completely clockwise turn the by pass valve, the pressure will be

blocked and the hydraulic unit will maintain the same pressure in case

of engine switched off.

I.T.S. Ital Trade Service PT 630 Operating Manual

10

1010

10

2.4.2 How to u e the hydraulic unit

Operating In truction

In order to make easy the learning we shall proceed to the description step by

step of all operations need in order to complete a welding according to the

following description:

Important !

Before begin the following operation be sure that:

- The lever A is fixed into the special housing

- Substitute the metal plug with the plastic black and red plug the

plastic plug is supplied with the machine into a plastic bag.

01. Fit the two pipes to be weld ( see relative instructions )

02. By turning the lever E anticlockwise bring the pressure to zero,

checking the pressure gauge D

03. Turn clockwise the lever E until closing ( please avoid using an

excessive strength )

04. Bring the lever A into position A3

05. By turning clockwise the hand wheel F achieve the inertial pressure

value ( value of pressure need in order to allow the trolley moving )

note the value of inertial pressure read into the pressure gauge D,

then by still operating the hand wheel F , increase the inertial pressure

value by the welding theoretical pressure value as per attached table.

06. Achieved the true welding pressure value ( inertial pressure plus

theoretical welding pressure ) bring the lever A into position A2.

07. Fit the facing tool (see relative instructions )

08. By acting on lever E anticlockwise achieve a pressure value of approx 5 bar more than the inertial pressure value checked and

then proceed to the facing tool operation (taking care that the engine's overloading).

09. At the end of the facing operation bring the lever A into position A3 and remove the facing tool.

10. Fit the heating mirror taking care that the temperature of the surfaces is the one selected (see relative instructions)

11. Bring the lever A into A3 in order to have the bead formation as per attached table, this operation must be done with the true

welding pressure value.

12. After bead formation act on lever E anticlockwise in order to bring the pressure to zero and proceed to the heating time as per

attached table.

13. Elapsed the heating time at pressure zero bring the lever A into position A2 and remove the heating mirror and immediately

bring the lever A into position A3 and acting on lever E clockwise put in contact the two pipes until achieving the true welding

pressure value by checking the pressure gauge D. These operations must be done according to the time indicated into the

attached table.

14. Bring the lever A into position A1 and keep such situation for all the cooling time indicated into the attached table, taking care

that the pressure will not decrease too much, in case bring for a little while the lever A into position A3 and put back into position A1

15. Elapsed the cooling time by acting on lever E anticlockwise bring the pressure to zero.

16. Take away the pipes welded

WE STRONGLY SUGGEST TO TRY MANY TIMES AND GET FAMILIAR TO THE UNIT BEFORE CARRYING ON WITH COMPLETE WELDING.

A WRONG USE OF THE HYDRAULIC UNIT COULD COMPROMISE YOUR WELDINGS..

Click

Click

I.T.S. Ital Trade Service PT 630 Operating Manual

11

1111

11

3. Heating mirror di connecting device

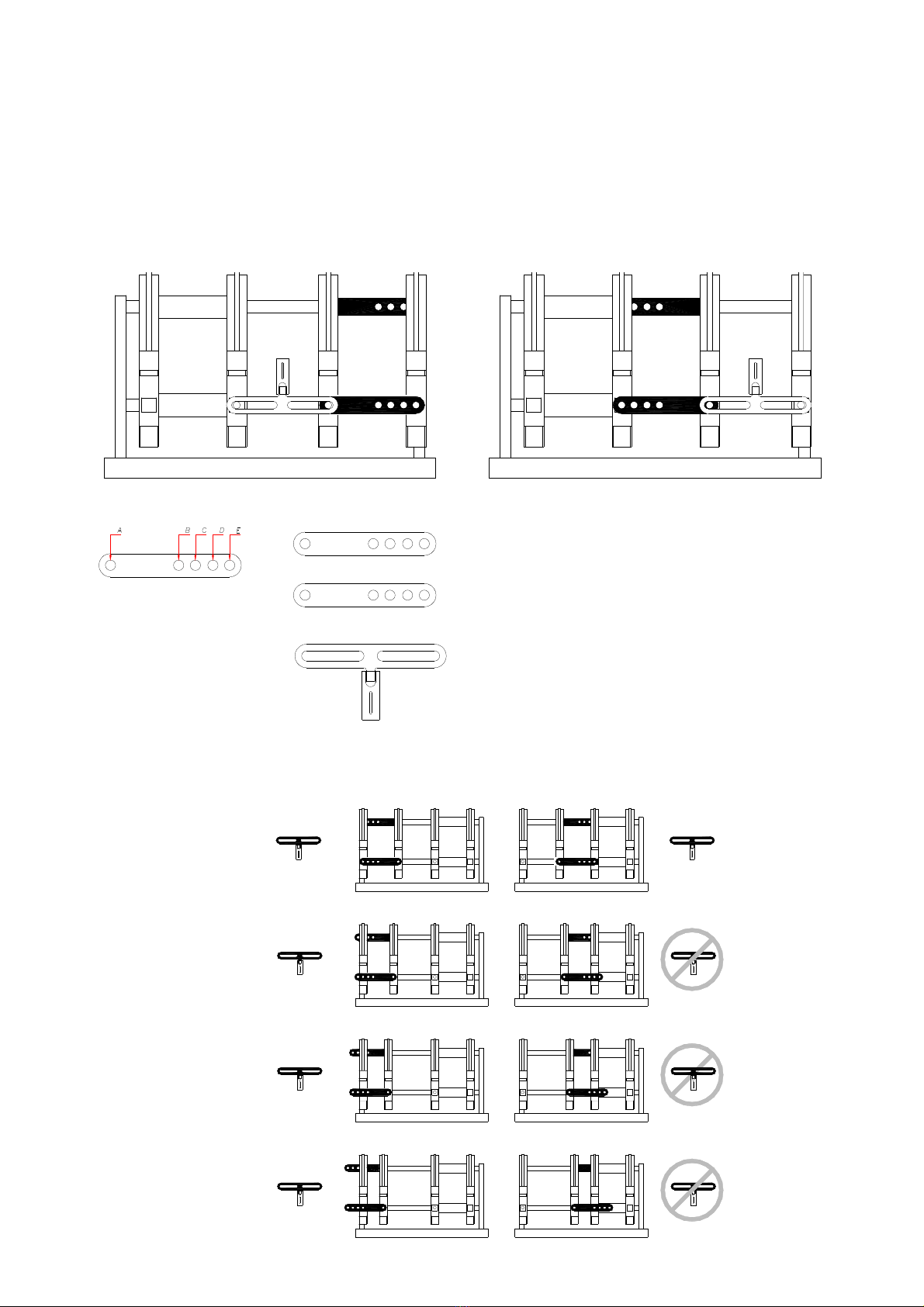

You can configure the machine according to the kind of welding to be executed as per the following different ways:

• Two fixed clamps and two moveable clamps Fig. 1

• One fixed clamp and three moveable clamps Fig. 2

You can change from a configuration to another in a quick way by simply acting on the two spacers and on the disconnecting device.

In the first configuration of the machine the disconnecting devices is between the two moveable clamps and the two fixed clamps.

The spacers are between the two fixed clamps.

In the second configuration of the machine the disconnecting devices is between the three moveable clamps and the fixed clamp.

The spacers are between the second and third moveable clamps.

Figure 1.Configuration 2 moveable clamp + 2 fixed clamp Figure 2.Configuratione 3 moveable clamp + 1 fixed clamp

Figure 3.

On the left: You can modify the distance between the clamps connected by

the spacers.

Fix the first clamp to the hole A and the second clamp in one of the holes

B,C,D,E

On the right (from above) pper and lower spacer (interchangeable) and

disconnecting device

WARNING !

Only in two confirguration you can u e the di connecting device with pacer! In the other configuration u e only the pacer to

avoid eriou damage to the ba ic machine!

I.T.S. Ital Trade Service PT 630 Operating Manual

12

1212

12

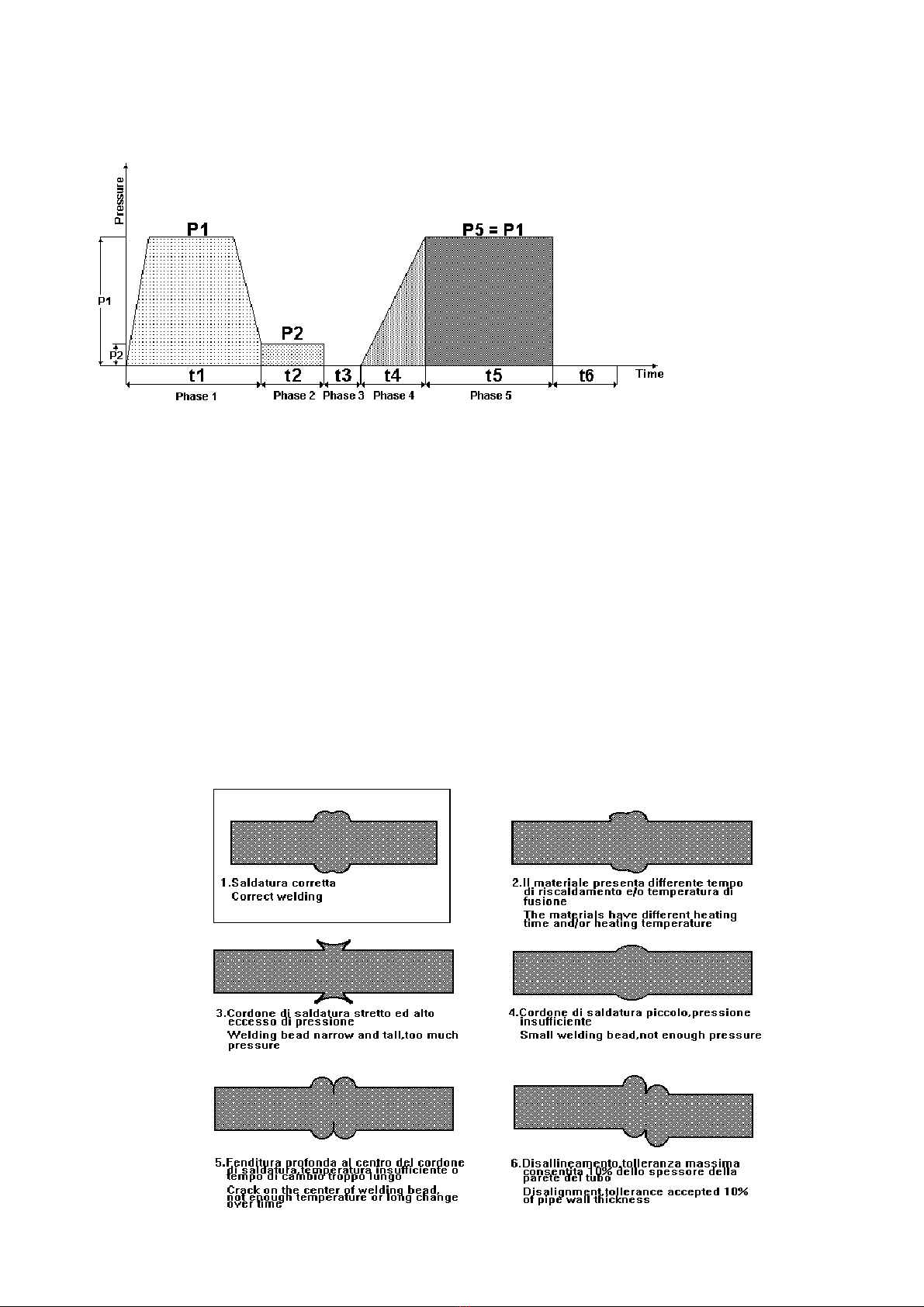

3. Butt welding in brief

3.1 Introduction

Stated that the basic machine it's suitable for all kinds of pipe, fittings and stub end available on the nowadays market. Here follows all the

different welding configurations of the machine:

1) Pipe with Pipe, standard configuration of the machine

2) Pipe with long spigot fitting, standard configuration of the machine

3) Pipe with short spigot fitting, to achieve this kind of welding it is strongly suggested to configure the machine with three moveable

clamps and 1 fixed clamp. Furthermore you must use the upper fittings clamp to fix better the fittings to the fixed clamp

4) Fitting with short spigot stub end, to achieve this kind of welding it is strongly suggested to configure the machine with three

moveable clamps and 1 fixed clamp. To fix the stub end you must use a special accessory called stub end device. Place the 4

brackets at the appropriate size punched on the stub end device. Fix the stub end by tighten the bolt of each bracket. The stub

end device is supplied with a fixing ring and you can install it on each clamp of the machine.

5) Pipe with short spigot stub end, to achieve this kind of welding you can use two different configuration of the machine (5 or 6)

6) Pipe with short spigot stub end, to achieve this kind of welding you can use two different configuration of the machine (5 or 6)

1. PIPE WITH PIPE 2. PIPE WITH LONG SPIGOT FITTING 3. PIPE WITH SHORT SPIGOT FITTING

4. FITTING WITH SHORT SPIGOT STUB END 5. PIPE WITH SHORT SPIGOT STUB END 6. PIPE WITH SHORT SPIGOT STUB END

3.2 Machine' preparation

It' trongly ugge ted to u e pipe roller for the liding of the pipe to be welded and if it' po ible po itioning the machine

with wooden table below, uch care will avoid additional effort to the machine.

a) Set up the working area so that welding is protected from the weather. Position the machine's components as per following figure

and eventually utilize wooden panels

b) Connect the flexible hoses of the hydraulic unit to the machine

I.T.S. Ital Trade Service PT 630 Operating Manual

13

1313

13

c) Connect the plugs to the power supply (Hydraulic unit, Facing tool and Heating mirror) after checking that the main power

supply is within a 10% of the specified one “ Warning Heating Mirror tart to warm up ! “

d) Select the correct temperature on the heating mirror

e) In case fit the inserts of the diameter to be welded into the machine

3.3 Pipe po itioning into the machine and facing operation

a) Open the movable trolley of the machine by means of acting the lever A (hyd. Unit) and take

it in position A2

b) Position the pipes into the machine taking care to leave enough space for the facing tool inserting

c) Check the pipes alignment, in case adjust it by means of tighten or loosing the clamps bolts.

The maximum misalignment could be lesser than 10% of the pipe or fittings wall thickness.

In any case the misalignment cannot be over than 2mm.

d) Clean the pipe ends

e) Fit in the facing tool between the two pipe's ends to be faced, by means of connecting the facing

tool into the special supports. Connect the safety pin and start the facing tool engine

f) On the facing tool there is a facer stopper (see the figure aside). In case of one of the pipe ends

has a small projection; the facer stopper let you select the only pipe to face. Put the facer stopper in

the left or in the right hole to prevent the right or left facing. To face all the pipes put the facer stopper

in the central hole.

Warning!!!: Alway check that the peed elector of the drill engine i in po ition 1 (lower peed)

g) Slowly approach the pipes ends towards the facing tool by means of acting on the hydraulic control unit (lever A Table V ) keeping

a value of pressure allowing the facing of the surfaces and avoiding an overload of the drill engine (a too much high pressure could

burnt out the drill engine). When shavings from both sides will appear continuous and homogeneous , the facing operation is

completed.

h) Put in contact the two pipes ends to be welded and check if the eventual disjunction is within the values of the following table:

In case the above values cannot be fulfilled the facing operation must be repeat.

3.4 Inertial pre ure mea urement

Before begin a welding cycle it is necessary to measure the inertial pressure. This value must be added to the pressure value shown in our

welding tables. The inertial pressure value depends on welding operating conditions (ex.: length and weight of the pipe to drag, general

condition of the machine, ambient temperature, etc.). To measure the inertial pressure follow these steps:

a) Completely open the movable trolley of the machine by means of acting the lever A and take it in position A2

b) By turning the lever F (Hyd. Unit) anticlockwise bring the pressure to zero, checking the pressure gauge

c) Turn clockwise the lever E (Hyd. Unit) until closing

d) Bring the lever A (Hyd. Unit) into position A3 (the trolleys do not move because there is no pressure)

e) By turning clockwise the hand wheel F note the inertial pressure value ( value of pressure need in order to allow the trolley moving ) by

reading it into the pressure gauge

Out ide diameter

mm

Port

mm

< 400 0,5

> 400 1,0

I.T.S. Ital Trade Service PT 630 Operating Manual

14

1414

14

3.5 Welding cycle

To obtain the be t re ult we trongly ugge t allowing the u e of the machine only to experienced operator

The welding phase is composed by 5 phases with 5 different times:

PHASE 1 = t1 = Time requested for the bead formation with the specified wall thickness

PHASE 2 = t2 = Time requested for the continual heating

PHASE 3 = t3 = Time requested for the change over

PHASE 4 = t4 = Time requested for bringing up the pressure

PHASE 5 = t5 = time requested for cooling down

Pre ure-Time diagram for butt welding

PHASE 1 = Heating up t1

a) Fit the heating mirror taking care that the temperature of the surfaces is the one selected

b) Bring the lever A (Hyd. Unit) into position A3 in order to have the bead formation as per attached table, this operation must be done

with the true welding pressure value: ( Inertial pressure + P1 ).

c) Check the Bead formation wall thickness according to the attached welding table

PHASE 2 = Heating up t2

a) After bead formation act on lever E (Hyd. Unit) anticlockwise in order to bring the pressure nearly to zero and proceed to the heating

time t2 at pressure P2

PHASE 3 = Change over t3

a) Elapsed the heating time at pressure P2 bring the lever A (Hyd. unit) into position A2 and remove the heating mirror and immediately

bring the lever A into position A3 and acting on lever E clockwise put in contact the two pipes

PHASE 4 = Bringing up pre ure t4

a) Achieve the true welding pressure value: (Inertial pressure + P1 = P5 ) by checking the pressure gauge, This operation must be done

according to the time indicated into the attached welding table.

PHASE 5 = Cooling Down t5

a) Bring the lever A into position A1 and keep such situation for all the cooling time indicated into the attached welding table, taking care

that the pressure will not decrease too much

b) Elapsed the cooling time by acting on lever E anticlockwise bring the pressure to zero.

c) Take away the pipes welded

Important !!!

In case of any doubt please refer to the specific instructions

I.T.S. Ital Trade Service PT 630 Operating Manual

15

1515

15

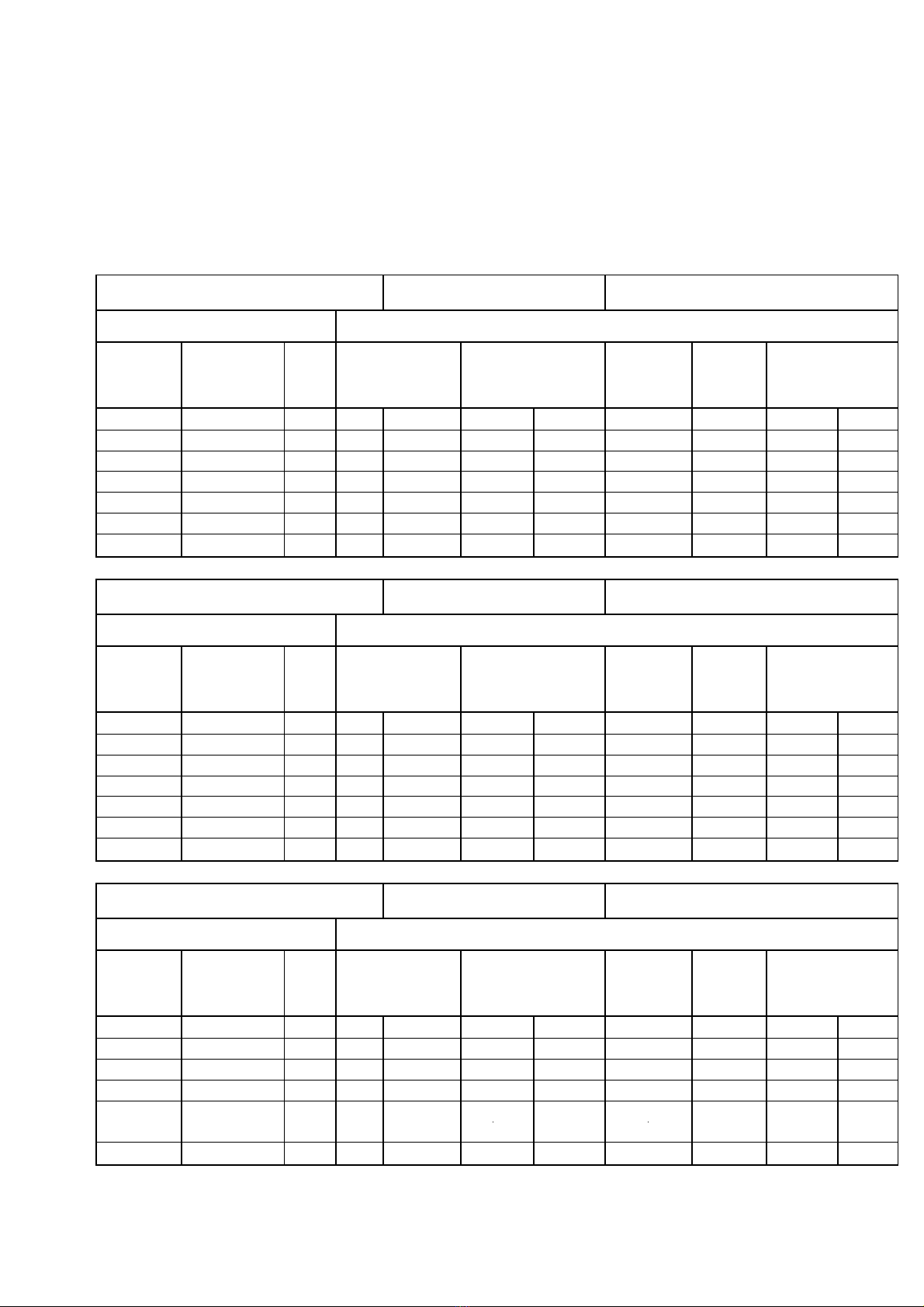

4. Welding Parameter for PE pipe & fitting DVS norm ver ion 2207-1

Pre ure-Time diagram for butt welding

t1 = Time requested for the bead formation with the specified wall thickness

t2 = Time requested for the continual heating

t3 = Time requested for the change over

t4 = Time requested for bringing up the pressure

t5 = time requested for cooling down

P1 = Pressure during the bead formation and the cooling down, this value is the result of the formula:

Pipe ection( cm2 ) x Material thru t coefficient( Kg./cm2 )

____________________________________________________________ = bar

Total machine cylinder ection( cm2 )

Material thrust coefficient for PE s 63 1,5 Kg./cm2

Material thrust coefficient for PP 1,0 Kg./cm2

Total PT 160 cylinders section 4,32 cm2

P2 = Pressure during the continual heating, this value either for HDPE and PP is 0,1 Kg./cm2.

Optical

checking of butt welding re ult

I.T.S. Ital Trade Service PT 630 Operating Manual

16

1616

16

4.1

Welding Parameter for PE & PP heet ,pipe & fitting according to DVS 2207-1 – 2207-11

Nominal Wall thickness

mm

Alignment

Bead height on heater

plate at the end of the

alignment time (alignment

under 0.15 N/mm

2

)

mm (minimum values)

Heating-up

Heating-up time= 10 x

wallthickness (heating-

up 0.02 N/mm

2

)

s

Changeover time

S (maximum time)

Joining pressure

s

Cooling time under

joining pressure p=0.15

N/mm2 0.01

Min (minimum values)

MATERIAL PE

ntil 4.5 0.5 45 5 5 6

4.5 … 7 1.0 45 … 70 5 … 6 5 … 6 6 … 10

7 … 12 1.5 70 … 120 6 … 8 6 … 8 10 … 16

12 … 19 2.0 120 … 190 8 … 10 8 … 11 16 … 24

19 … 26 2.5 190 … 260 10 … 12 11 … 14 24 … 32

26 … 37 3.0 260 … 370 12 ... 16 14 … 19 32 … 45

37 … 50 3.5 370 … 500 16 … 20 19 … 25 45 … 60

50 ... 70 4.0 500 … 700 20 … 25 25 … 35 60 … 80

MATERIAL PP

ntil 4.5 0.5 135 5 6 6

4.5 … 7 0.5 135 … 175 5 … 6 6 … 7 6 … 12

7 … 12 1.0 175 … 245 6 … 7 6 … 11 12 … 20

12 … 19 1.0 245 … 330 7 … 9 11 … 17 20 … 30

19 … 26 1.5 330 … 400 9 … 11 17 … 22 30 … 40

26 … 37 2.0 400 … 485 11 ... 14 22 … 32 40 … 55

37 … 50 2.5 485 … 560 14 … 17 32 … 43 55 … 70

Example on how to calculate the cooling down (t5) time following the DVS NORM

As per drawing above the time T corresponds to wall thickness value X in

mm. To calculate this time (t5 in minutes) please follow the formula below:

Example:

If you want to calculate the cooling down time for a 6mm wall thickness pipe, you must simply substitute the variable X with the value 6:

min,),(

,

T48546

547

6

10

6=−⋅

−

−

+=

To calculate the other times (t3 and t4) you must use the same principle of linear interpolation.

To obtain the t2 (in seconds) value use the formula below where the variable wt corresponds to the nominal wall thickness

)

mm

(

wt

(sec)

T

⋅

=

10

2

)5,4(

5,47 610

6−⋅

−

−

+= xT

I.T.S. Ital Trade Service PT 630 Operating Manual

17

1717

17

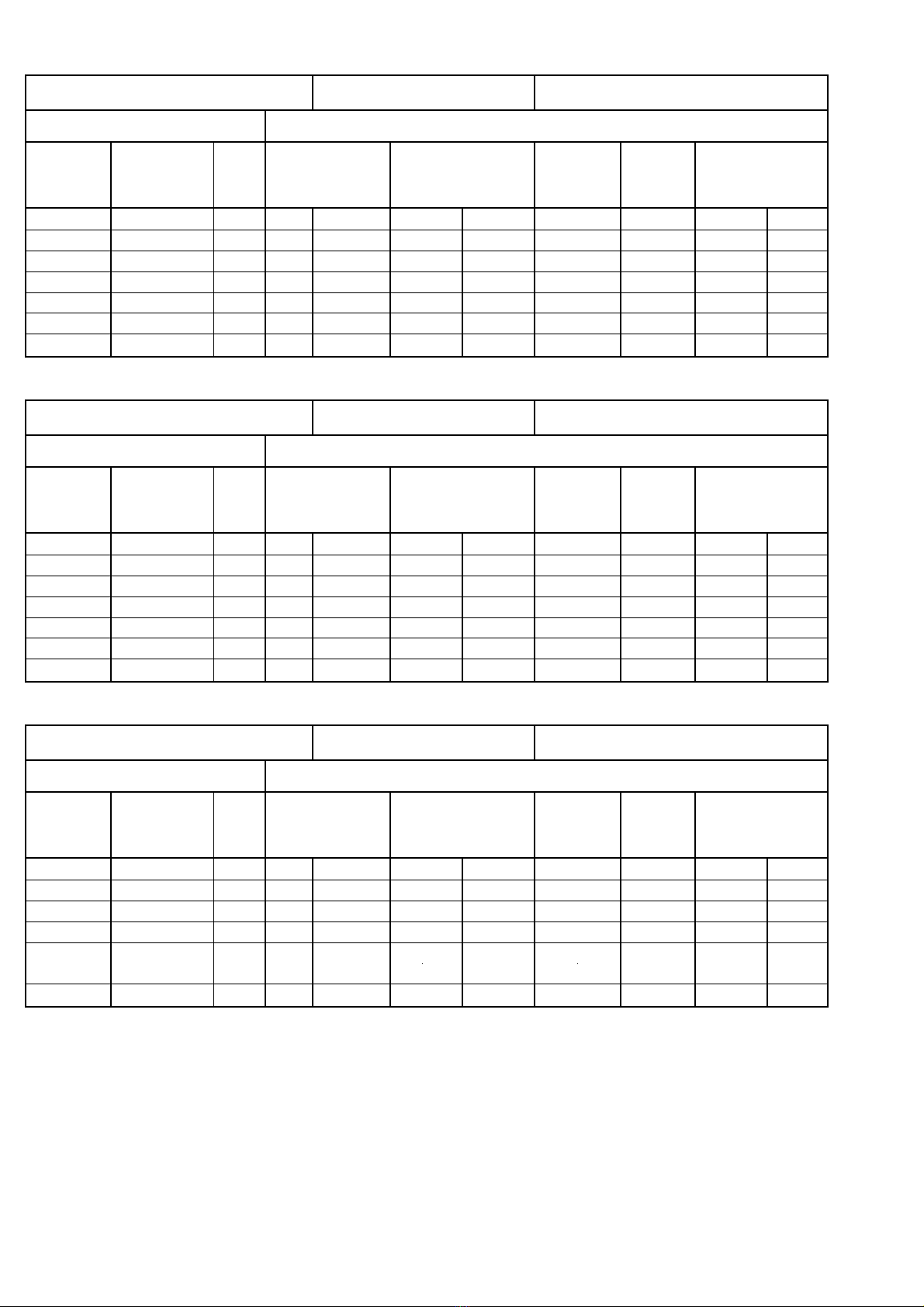

5. Welding Table for PE pipe DVS norm ver ion 2207-1

The following tables show the values to be applied during the welding cycle as per previous instructions and graph.

However in order to clarify once again the meaning of these values please kindly note:

t1 = Time requested for the bead formation to be done with pressure value = P1 + inertial pressure

t2 = Time requested for the continual heating to be done with pressure value = P2 + inertial pressure

t3 = Time requested for the change over

t4 = Time requested for bringing up the pressure at the value of pressure = P1 + inertial pressure

t5 = time requested for cooling down to be done with pressure value = P1 + inertial pressure

Important

Remember alway to add the value checked of inertial pre ure to the P1 and P2 value !!!!!!!

PT 630 - DVS 2207-1

Cyl. section cm

2

17,3

Welding range 315-630 mm

material PE80-100 SDR 41

D S T P1 bead P2 t 2 t 3 t 4 P5 t 5

DIAMETER WALL THICK. TEMP. BEAD FORMATION HEATING UP CHANGEOV. RAMP COOLING

mm mm °C bar mm bar sec sec sec bar min

315 7,7 215 6,4 1,5 0..

0,4 77 0.. 6 6 6,4 11

355 8,7 214 8,2 1,5 0..

0,5 87 0.. 7 7 8,2 12

400 9,8 213 10,4

1,5 0..

0,7 98 0.. 7 7 10,4 13

450 11,0 212 13,1

1,5 0..

0,9 110 0.. 8 8 13,1 15

500 12,2 211 16,2

2,0 0..

1,1 122 0.. 8 8 16,2 16

560 13,7 210 20,3

2,0 0..

1,4 137 0.. 8 9 20,3 18

630 15,4 209 25,7

2,0 0..

1,7 154 0.. 9 9 25,7 20

PT 630 - DVS 2207-1

Cyl. section cm

2

17,3

Welding range 315-630 mm

material PE80-100 SDR 33

D S T P1 bead P2 t 2 t 3 t 4 P5 t 5

DIAMETER WALL THICK. TEMP. BEAD FORMATION HEATING UP CHANGEOV. RAMP COOLING

mm mm °C bar mm bar sec sec sec bar min

315 9,5 213 7,9 1,5 0..

0,5 95 0.. 7 7 7,9 13

355 10,8 212 10,1

1,5 0..

0,7 108 0.. 8 8 10,1 15

400 12,1 211 12,8

2,0 0..

0,9 121 0.. 8 8 12,8 16

450 13,6 210 16,2

2,0 0..

1,1 136 0.. 8 9 16,2 18

500 15,2 209 20, 2,0 0..

1,3 152 0.. 9 9 20, 20

560 17,0 207 25,1

2,0 0..

1,7 170 0.. 9 10 25,1 22

630 19,1 206 31,8

2,5 0..

2,1 191 0.. 10 11 31,8 24

PT 630 - DVS 2207-1

Cyl. section cm

2

17,3

Welding range 315-630 mm

material PE80-100 SDR 27,6

D S T P1 bead P2 t 2 t 3 t 4 P5 t 5

DIAMETER WALL THICK. TEMP. BEAD FORMATION HEATING UP CHANGEOV. RAMP COOLING

mm mm °C bar mm bar sec sec sec bar min

315 11,4 212 9,4 1,5 0..

0,6 114 0.. 8 8 9,4 15

355 12,9 210 12, 2,0 0..

0,8 129 0.. 8 8 12, 17

400 14,5 209 15,2

2,0 0..

1,0 145 0.. 9 9 15,2 19

450 16,3 208 19,3

2,0 0..

1,3 163 0.. 9 10 19,3 21

500 18,1 207 23,8

2,0 0..

1,6 181 0.. 10 11 23,8 23

560 20,3 205 29,8

2,5 0..

2,0 203 0.. 10 12 29,8 25

630 22,8 204 37,7

2,5 0..

2,5 228 0.. 11 13 37,7 28

Warning!: in case of PE100 welding, temperature T must be increased to 220°c

I.T.S. Ital Trade Service PT 630 Operating Manual

18

1818

18

PT 630 - DVS 2207-1

Cyl. section cm

2

17,3

Welding range 315-630 mm

material PE80-100 SDR 26

D S T P1 bead P2 t 2 t 3 t 4 P5 t 5

DIAMETER WALL THICK. TEMP. BEAD FORMATION HEATING UP CHANGEOV. RAMP COOLING

mm mm °C bar mm bar sec sec sec bar min

315 12,1 211 10, 2 0..

0,7 121 0.. 8 8 10, 16

355 13,7 210 12,7

2 0..

0,8 137 0.. 8 9 12,7 18

400 15,4 209 16,1

2 0..

1,1 154 0.. 9 9 16,1 20

450 17,3 207 20,4

2 0..

1,4 173 0.. 9 10 20,4 22

500 19,2 206 25,2

2,5 0..

1,7 192 0.. 10 11 25,2 24

560 21,5 205 31,6

2,5 0..

2,1 215 0.. 11 12 31,6 27

630 24,2 204 40, 2,5 0..

2,7 242 0.. 11 13 40, 30

PT 630 - DVS 2207-1

Cyl. section cm

2

17,3

Welding range 315-630 mm

material PE80-100 SDR 22

D S T P1 bead P2 t 2 t 3 t 4 P5 t 5

DIAMETER WALL THICK. TEMP. BEAD FORMATION HEATING UP CHANGEOV. RAMP COOLING

mm mm °C bar mm bar sec sec sec bar min

315 14,3 209 11,7

2,0 0..

0,8 143 0.. 9 9 11,7 19

355 16,1 208 14,9

2,0 0..

1,0 161 0.. 9 10 14,9 21

400 18,2 207 18,9

2,0 0..

1,3 182 0.. 10 11 18,9 23

450 20,5 205 23,9

2,5 0..

1,6 205 0.. 10 12 23,9 26

500 22,7 204 29,5

2,5 0..

2,0 227 0.. 11 13 29,5 28

560 25,5 203 37, 2,5 0..

2,5 255 0.. 12 14 37, 31

630 28,6 203 46,9

3,0 0..

3,1 286 0.. 13 15 46,9 35

PT 630 - DVS 2207-1

Cyl. section cm

2

17,3

Welding range 315-630 mm

material PE80-100 SDR 21

D S T P1 bead P2 t 2 t 3 t 4 P5 t 5

DIAMETER WALL THICK. TEMP. BEAD FORMATION HEATING UP CHANGEOV. RAMP COOLING

mm mm °C bar mm bar sec sec sec bar min

315 15,0 209 12,3

2,0 0..

0,8 150 0.. 9 9 12,3 19

355 16,9 208 15,6

2,0 0..

1,0 169 0.. 9 10 15,6 22

400 19,0 206 19,8

2,5 0..

1,3 190 0.. 10 11 19,8 24

450 21,4 205 25, 2,5 0..

1,7 214 0.. 11 12 25, 27

500 23,8 204 30,9

2,5 0..

2,1 238 0.. 11 13 30,9 29

560 26,7 203 38,7

3,0 0..

2,6 267 0.. 12 14 38,7 33

630 30,0 202 49, 3,0 0..

3,3 300 0.. 13 16 49, 37

Warning!: in case of PE100 welding, temperature T must be increased to 220°c

I.T.S. Ital Trade Service PT 630 Operating Manual

19

1919

19

PT 630 - DVS 2207-1

Cyl. section cm

2

17,3

Welding range 315-630 mm

material PE80-100 SDR 17,6

D S T P1 bead P2 t 2 t 3 t 4 P5 t 5

DIAMETER WALL THICK. TEMP. BEAD FORMATION HEATING UP CHANGEOV. RAMP COOLING

mm mm °C bar mm bar sec sec sec bar min

315 17,9 207 14,5

2,0 0..

1,0 179 0.. 10 11 14,5 23

355 20,2 206 18,4

2,5 0..

1,2 202 0.. 10 12 18,4 25

400 22,7 204 23,3

2,5 0..

1,6 227 0.. 11 13 23,3 28

450 25,6 203 29,5

2,5 0..

2,0 256 0.. 12 14 29,5 32

500 28,4 203 36,5

3,0 0..

2,4 284 0.. 13 15 36,5 35

560 31,8 202 45,8

3,0 0..

3,1 318 0.. 14 17 45,8 39

630 35,8 201 57,9

3,0 0..

3,9 358 0.. 16 18 57,9 44

PT 630 - DVS 2207-1

Cyl. section cm

2

17,3

Welding range 315-630 mm

material PE80-100 SDR 17

D S T P1 bead P2 t 2 t 3 t 4 P5 t 5

DIAMETER WALL THICK. TEMP. BEAD FORMATION HEATING UP CHANGEOV. RAMP COOLING

mm mm °C bar mm bar sec sec sec bar min

315 18,5 206 15, 2 0..

1,0 185 0.. 10 11 15, 23

355 20,9 205 19, 2,5 0..

1,3 209 0.. 10 12 19, 26

400 23,5 204 24,1

2,5 0..

1,6 235 0.. 11 13 24,1 29

450 26,5 203 30,5

3 0..

2,0 265 0.. 12 14 30,5 33

500 29,4 202 37,7

3 0..

2,5 294 0.. 13 16 37,7 36

560 32,9 202 47,3

3 0..

3,2 329 0.. 14 17 47,3 40

630 37,1 201 59,8

3,5 0..

4,0 371 0.. 16 19 59,8 45

PT 630 - DVS 2207-1

Cyl. section cm

2

17,3

Welding range 315-630 mm

material PE80-100 SDR 13,6

D S T P1 bead P2 t 2 t 3 t 4 P5 t 5

DIAMETER WALL THICK. TEMP. BEAD FORMATION HEATING UP CHANGEOV. RAMP COOLING

mm mm °C bar mm bar sec sec sec bar min

315 23,2 204 18,4

2,5 0..

1,2 232 0.. 11 13 18,4 29

355 26,1 203 23,4

3,0 0..

1,6 261 0.. 12 14 23,4 32

400 29,4 202 29,7

3,0 0..

2,0 294 0.. 13 16 29,7 36

450 33,1 202 37,6

3,0 0..

2,5 331 0.. 15 17 37,6 40

500 36,8 201 46,4

3,0 0..

3,1 368 0.. 16 19 46,4 45

560 41,2 201 58,2

3,5 0..

3,9 412 0.. 17 21 58,2 50

630 46,3 200 73,6

3,5 0..

4,9 463 0.. 19 23 73,6 56

Warning!: in case of PE100 welding, temperature T must be increased to 220°c

I.T.S. Ital Trade Service PT 630 Operating Manual

20

2020

20

PT 630 - DVS 2207-1

Cyl. section cm

2

17,3

Welding range 315-630 mm

material PE80-100 SDR 11

D S T P1 bead P2 t 2 t 3 t 4 P5 t 5

DIAMETER WALL THICK. TEMP. BEAD FORMATION HEATING UP CHANGEOV. RAMP COOLING

mm mm °C bar mm bar sec sec sec bar min

315 28,6 203 22,3 3,0 0..

1,5 286 0.. 13 15 22,3 35

355 32,3 202 28,4 3,0 0..

1,9 323 0.. 14 17 28,4 39

400 36,4 201 36, 3,0 0..

2,4 364 0.. 16 19 36, 44

450 40,9 201 45,6 3,5 0..

3,0 409 0.. 17 21 45,6 50

500 45,5 200 56,3 3,5 0..

3,8 455 0.. 19 23 56,3 55

560 50,9 200 70,6 4,0 0..

4,7 509 0.. 20 25 70,6 61

630 57,3 200 89,3 4,0 0..

6,0 573 0.. 22 29 89,3 67

PT 630 - DVS 2207-1

Cyl. section cm

2

17,3

Welding range 315-630 mm

material PE80-100 SDR 9

D S T P1 bead P2 t 2 t 3 t 4 P5 t 5

DIAMETER WALL THICK. TEMP. BEAD FORMATION HEATING UP CHANGEOV. RAMP COOLING

mm mm °C bar mm bar sec sec sec bar min

315 35,0 201 26,7 3,0 0..

1,8 350 0.. 15 18 26,7 43

355 39,4 201 33,9 3,5 0..

2,3 394 0.. 17 20 33,9 48

400 44,4 200 43, 3,5 0..

2,9 444 0.. 18 22 43, 54

450 50,0 200 54,5 3,5 0..

3,6 500 0.. 20 25 54,5 60

500 55,6 200 67,2 4,0 0..

4,5 556 0.. 21 28 67,2 66

560 62,2 200 84,3 4,0 0..

5,6 622 0.. 23 31 84,3 72

630 70,0 200 106,7 4,0 0..

7,1 700 0.. 25 35 106,7 80

PT 630 - DVS 2207-1

Cyl. section cm

2

17,3

Welding range 315-450 mm

material PE80-100 SDR 7,4

D S T P1 bead P2 t 2 t 3 t 4 P5 t 5

DIAMETER WALL THICK. TEMP. BEAD FORMATION HEATING UP CHANGEOV. RAMP COOLING

mm mm °C bar mm bar sec sec sec bar min

315 42,6 201 31,6 3,5 0..

2,1 426 0.. 18 22 31,6 51

355 48,0 200 40,1 3,5 0..

2,7 480 0.. 19 24 40,1 58

400 54,1 200 50,9 4,0 0..

3,4 541 0.. 21 27 50,9 64

450 60,8 200 64,4 4,0 0..

4,3 608 0.. 23 30 64,4 71

Warning!: in case of PE100 welding, temperature T must be increased to 220°c

Table of contents

Other Tecnodue Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

SMC Networks

SMC Networks KF Series Operation manual

Siemens

Siemens acvatix MVI421 Series Mounting instructions

DROPSA

DROPSA MaXtreme Operation and maintenance manual

Peri

Peri UP Flex Stairs 75 Instructions for Assembly and Dismantling

REMS

REMS MSG 25 EE instruction manual

ABB

ABB HT610928 Operation manual