9

Navigating T o “Set Gate T ravel Menu”

a. Press PREV to navigate to Menu 10.

b. Press SET to display MENU 10.1.

c. Press SET two times to enter the limit setting procedur e.

Follow LCD pr ompts.

8.2 Setting the left/right installation side settings

a. Select left or right installation side by pressing open button

for the corr ect side (Fig. 8.2).

b. Press SET to confir m.

8.3 Setting close travel limit

a. Press and hold Button 4 on the transmitter to close the gate

i. If the gate is closed too far, press Button 1 to “inch” the

gate towar ds open.

ii. When happy with the close limit position, press Button 2

to stor e this in the memory .

NOTE: Limit will not be accepted unless the gate is driven in

the close direction.

8.4 Setting open travel limit

a. Press Button 1 to open the gate.

b. If the gate is opened too far, press Button 4 to “inch” the

gate towar ds close

c. When happy with the open limit position, press Button 2 on

the transmitter to stor e into memory ..

NOTE: Limit will not be accepted unless the gate is driven in

the open dir ection.

WARNING: The gate will automatically close and

open once next step is performed. Ensure that no

persons or objects are in the gates path

d. The gate will now automatically close and open to calculate the

safety obstruction settings.

8.5 Automatic limit adjustment and load profile

After a brief pause, the controller will automatically close and

open the gate several times. This adjusts the speed at which

the limits are appr oached and helps to lear n the normal load

profile of the gate. When the setup is complete, the MAIN

SCREEN will be displayed with the gate shown to be OPEN.

The Gate can now be used.

NOTE: Do not press transmitter during limit adjustment

process.

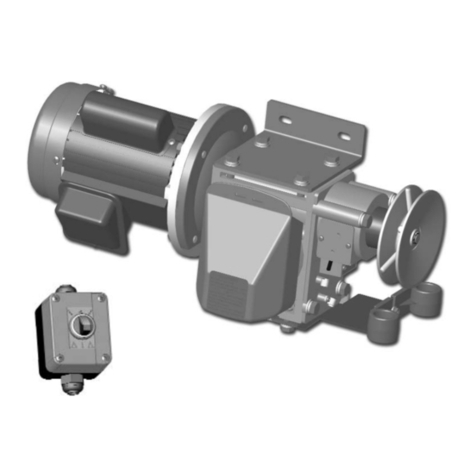

Fig 6.2

8. Setting Limits

The NeoSlider TM has the alter nate ability to set travel limits using a TrioCode TM128 transmitter , allowing free movement

around the gate to better assess the desir ed limit positions. In order to use a transmitter , it must first have at least one of

its buttons coded to the gate contr oller. The function assigned to the transmitter’ s buttons is of no concer n here as the

buttons ar e temporally assigned to OPEN, CLOSE and SET (Fig. 8.1).

Fig 8.1

Button 1

(Inch

Open)

Button 4

(Inch

Close)

Button 2

(Set)

NOTE: Gate should be moved manually to fully open position. When

re-engaging opener , nudge gate until click is hear d to confirm pinion

gear has engaged fully .

8.1 Setting Travel Limits

Navigating to “code transmitter” menu

a. Press NEXT to navigate to Menu 1.

b. Press SET to enter the code set pr ocedur e .

Storing T ransmitter Code

c. Controller will pr ompt to pr ess one of the transmitter’ s Button.

d. Press the transmitter button you wish to use to operate the gate

opener (e.g. button 1) .

e. Press the same transmitter button again as pr ompted by display .

f. Press the SET button to stor e the transmitter .

IMPORTANT NOTE:

Only TrioCodeTM128 Technology Transmitters

are compatible with this product.

8.6 Pedestrian access position

After completing the above procedur e, the Pedestrian

access position is automatically set to a position which

is five (5) seconds from the fully closed position of the

gate. The position can be manually set by following

the SETTING PEDESTRIAN POSITION procedur e (See

Section 12).

8.7 Errors during setting of travel limit

During the above procedur e, many error checks are

prefor med. If an error is detected, a message will be

displayed indicating the err or.

8.8 Recalculate Force Margins

a. Repr ofiling is a simplified way of re-lear ning the travel

characteristic of a previously setup Limit Switch travel

installation. Re-profiling can be used when the travel

characteristics of the gate change due to mechanical

adjustments etc.

b. To initiate a re-pr ofile simply locate “MENU 10.2

Repr ofile Travel”

WARNING: The gate(s) will automatically

close and open. Ensure that no persons or

objects are in the gates path.

c. Press SET then follow the prompts. The gate will start

to move and re-calculate force margins. The gate can

move between the open and close limit positions up

to two (2) times (depending on the position of the gate

and the power up condition).

d. A single beep will be hear d once the process is

complete and setup complete message will be

displayed