BEFORE USE

1. Inspect crane before each use. Do not use if bent,

broken or cracked components are noted. Ensure

that casters/wheels and boom move freely. Check

for and tighten any loose assemblies.

2. Verify that the product and the application are

compatible, if in doubt call for Technical Service

(888) 332-6419.

3. Before using this product, read the owner's manual

completely and familiarize yourself thoroughly with

the product and the hazards associated with its

improper use.

3. Open the release valve by turning the release valve

lever

counter-clockwise (no more than 1/2 full turn).

4.Withramfullylowered,removeoil¿llerplugandpump

handle 6 to 8 full strokes. This will help release any

trappedair within thereservoir. Ensure the oillevel is

justbelow the oil¿OOer hole. Reinstalltheoil ¿OOerplug.

&ORVHUHOHDVHYDOYHE\WXUQLQJLWFORFNZLVH¿UPOy.

5.Check to ensure that crane rolls freely, that the pump

andreleasevalve operate smoothly. Raiseandlower

the unloaded crane throughout the lifting range be-

fore putting into service.

6. Replace worn or damaged parts and assemblies

with Factory Authorized Replacement Parts only.

Lubricate as instructed in Maintenance Section.

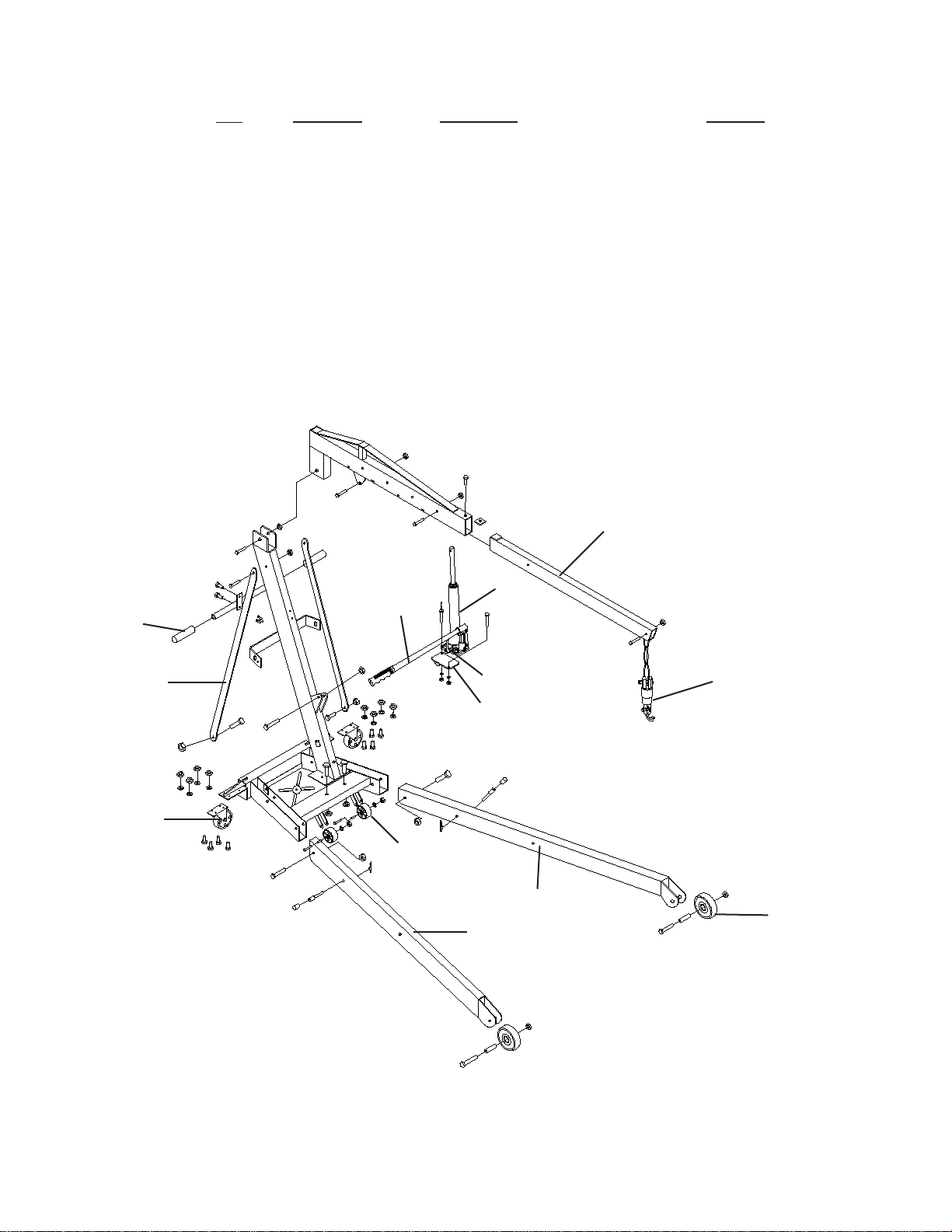

4Figure 3 - Assembly Illustration for model ATD-7484

ASSEMBLY

For ModelATD-7484: (See Figure 1)

1. Attach casters (#15) to rear extension legs (#24)

with M8x20 bolts, washers and nuts (#29, 33 &

34).

2. Slide front extension legs (#14) and rear extension

legs(#24)intobaseframe (#11),securewithM12x25

bolts (#13) in frame, tighten bolts.

Note: Do not tighten any bolts unless told to. Never

extend beyond mark on leg. Extend each leg extension

equal distance from frame.

3. Place post (#2) on the base frame and secure with

0[EROWV/HDYHEROWV¿QJHUWLJKW

4. Attach braces (#18) on each side of post at top and

secure with M12x100 bolt and nut (#4 & 19). Place

bottomofbraces on insideof base frame securewith

M12x90 bolts and nuts (#31 & 19).

5. Attach bracket (#32) to hydraulic unit (#1) with

M10x30 bolts, washers and nuts (#6, 25 & 26).

Then attach to post using M16x75 bolt and nut (#10

& 12).

6.Placeboom (#7) on topof post, secure withM20x120

bolt and nut (#3 & 20). Pump hydraulic unit using

handle (# 21) until ram is approximately 2" above.

Placefront mounting bracketon boom, ontop of ram

and secure with M16x90 bolt and nut (#9 & 12).

7. Slide boom extension (#8) to boom (#7), make sure

the slot for chain (#17) faces down and secure with

M16x90bolt and nut(#9 & 12). 4 positionsavailable:

1/2 ton, 1 ton, 1 1/2 ton and 2 ton.

8. Insert chain and hook(#17) to boom extension (#8)

with M12x75 bolt and nut (# 30 & 19).

Note: Checkall fasteners for tightness, including those

pre-assembled at the factory. Tighten where required.

Do not load beyond rated capacity.

WARNING

!

6WXGy, understand, and follow all instructions

provided with and on this device before operating

this device.

'RQRWH[FHHGUDWHGFDSDFLW\IRUHDFKERRPSRVL-

tion.

8VHWKHGHYLFHRQO\RQDKDUGOHYHOVXUIDFH

2QO\XVHFKDLQVDQGVOLQJVZLWKDFDSDFLW\HTXDO

to or greater than that of the crane.

,IORDGHGFUDQHPXVWEHPRYHGPDNHFHUWDLQWKDW

load is stable, is in lowest possible position and is

moved over a smooth, hard level surface.

Avoid shock loads caused by the rapid opening

and closing of release valve.

6KRFNORDGVPD\FDXVHWKHORDGWRVZLQJFDXV-

LQJWKHFUDQHWRÀLSYLROHQWOy, bend or break.

(QVXUHWKHERRPLVIXOO\ORZHUHGEHIRUHFKHFNLQJ

RUDGGLQJÀXLGWRWKHK\GUDXOLFXQLW

1HYHUH[WHQGERRPH[WHQVLRQEH\RQGOHJH[WHQ-

sion (Model ATD-7484).

'RQRWVWDQGRYHUORDGHGERRPQRULQLWVLQWHQGHG

line of travel.

'RQRWXVHDGDSWHUVRUDFFHVVRULHVWKDWDUHQRW

provided initially.

Do not use the device for any purpose other than

that for which it is intended.

1RDOWHUDWLRQVVKDOOEHPDGHWRWKLVGHYLFH

Failure to heed these markings may result in

personal injury and/or property damage.