® Copyright by ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprint and technical changes reserved / Issue: 2019/02

- 2 -

INHALT

INTRODUCTION .............................................................................................................................- 4 -

General information’s ..................................................................................................................- 4 -

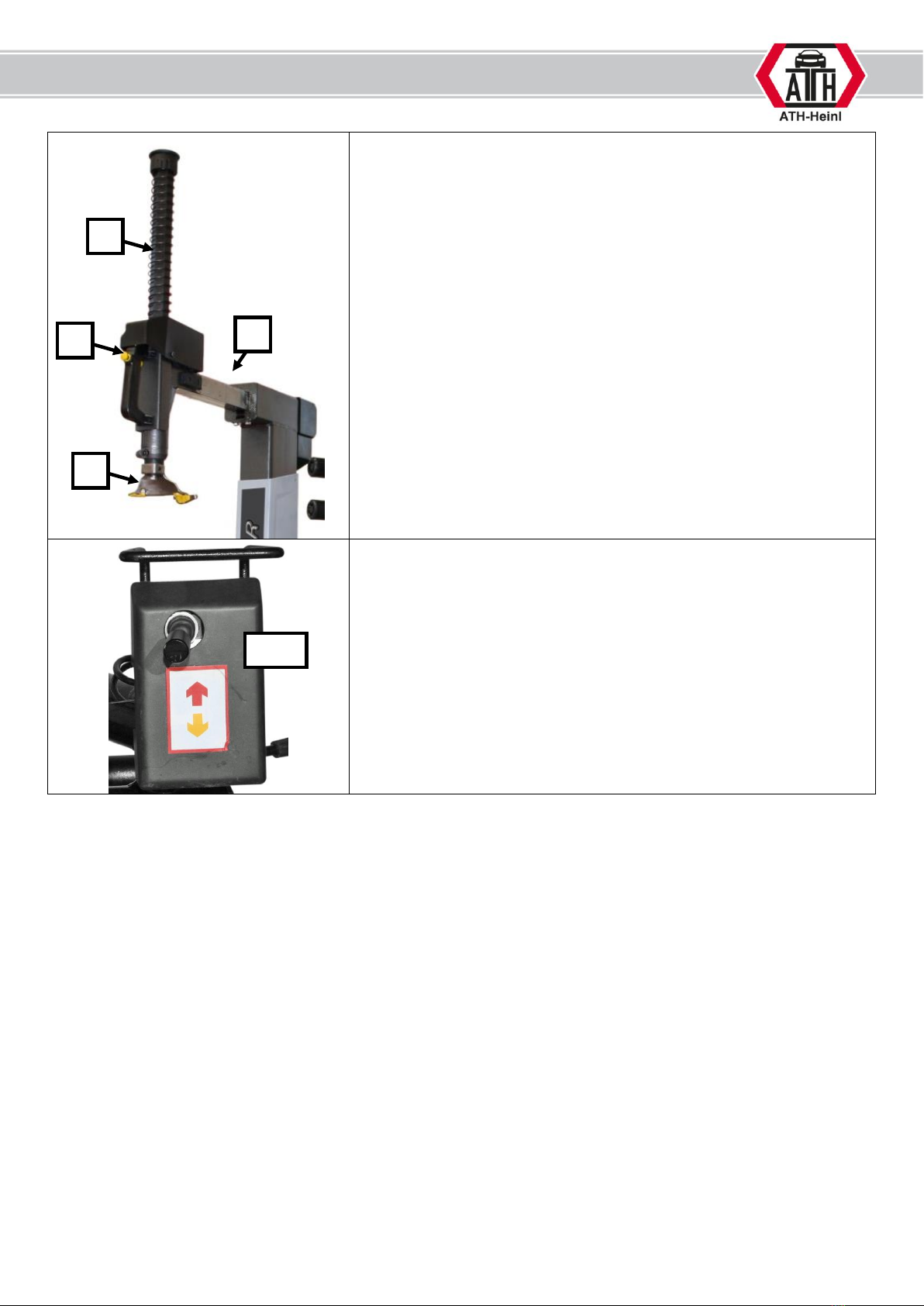

Description of tire changer...........................................................................................................- 5 -

Operation of tire changer.............................................................................................................- 6 -

Technical data ............................................................................................................................- 8 -

Dimension drawing......................................................................................................................- 9 -

INSTALLATION.............................................................................................................................- 10 -

Transport and storage ...............................................................................................................- 10 -

Unpacking of machine ...............................................................................................................- 10 -

Scope of delivery.......................................................................................................................- 11 -

Place of installation ...................................................................................................................- 12 -

Fixing.......................................................................................................................................- 13 -

Electrical connection..................................................................................................................- 13 -

Pneumatic connection................................................................................................................- 14 -

Final works...............................................................................................................................- 14 -

OPERATION .................................................................................................................................- 15 -

Operation instructions ...............................................................................................................- 15 -

General instructions...................................................................................................................- 16 -

Bead breaking of a tire ..............................................................................................................- 18 -

Preparation for clamping of wheels.............................................................................................- 19 -

Clamping of the tires .................................................................................................................- 22 -

Adjustment of the mounting head ..............................................................................................- 23 -

Demounting of a tire .................................................................................................................- 24 -

Mounting of a tire .....................................................................................................................- 25 -

Filling of a tire...........................................................................................................................- 27 -

MAINTENANCE .............................................................................................................................- 29 -

Consumables for installation, maintenance and care.....................................................................- 29 -

Safety regulations for oil............................................................................................................- 30 -

Notice ......................................................................................................................................- 31 -

Maintenance plan or care plan....................................................................................................- 31 -

Troubleshooting........................................................................................................................- 32 -

Maintenance and service instructions ..........................................................................................- 33 -

Disposal ...................................................................................................................................- 36 -

KONFORMITÄTSERKLÄRUNG / DECLARATION OF CONFORMITY ......................................................- 37 -

APPENDIX....................................................................................................................................- 38 -

Pneumatic diagram ...................................................................................................................- 38 -

Electric diagram ........................................................................................................................- 39 -

WARRANTY NOTE.........................................................................................................................- 40 -

Product warranty ......................................................................................................................- 41 -

INSPECTION AND CERTIFICATION BOOK.......................................................................................- 42 -

Inspection ................................................................................................................................- 42 -

Scope of the inspection..............................................................................................................- 42 -

Technical data ..........................................................................................................................- 42 -

Name plate...............................................................................................................................- 42 -

Installation and handover certificate ...........................................................................................- 43 -

Inspection plan .........................................................................................................................- 44 -

Visual inspection (Authorized specialist) ......................................................................................- 45 -

ERSATZTEILBUCH / SPARE PART BOOK..........................................................................................- 49 -

Gehäuse / Machine body............................................................................................................- 50 -

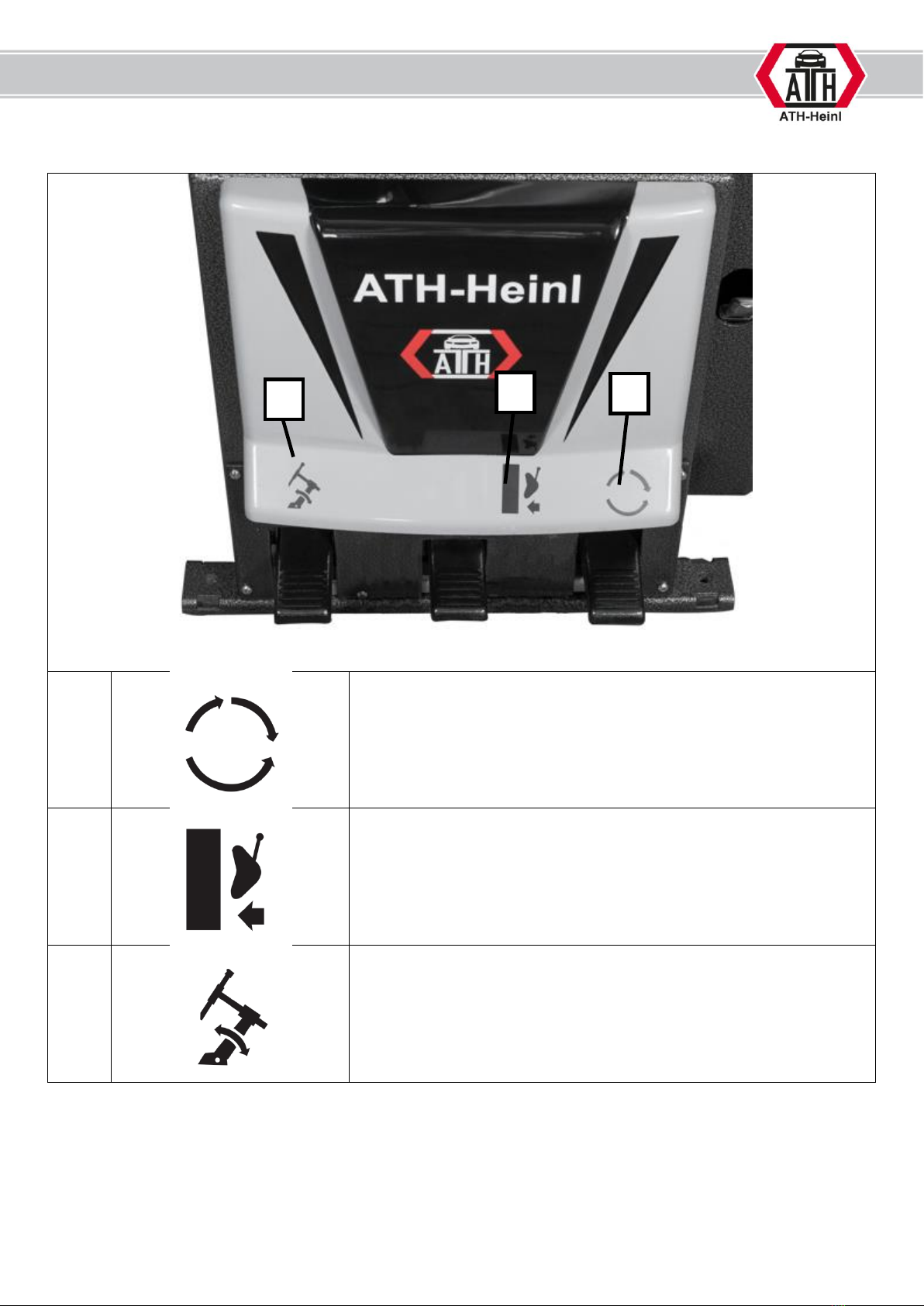

Pedaleinheit / Pedal assembly ....................................................................................................- 52 -

Drehteller / Mainshaft................................................................................................................- 54 -