2920 1443 01 5

Instruct on book

1.2 Air drying circuit (Fig. 1.4)

Wet a r from the compressor aftercooler (2) enters the dryer

nlet, passes through nlet valve (5) and the nozzle of ejector

(11) nto a r nlet water separator (26). The a r leav ng the

aftercooler s normally saturated and has a temperature of approx.

10°C above that of the nlet cool ng water on water-cooled

compressors or above that of the amb ent temperature on a r-

cooled compressors.

In the dem ster (27), the water droplets are removed from the

a r. The a r s then led through rotor (12), wh ch adsorbs the

water vapour. The dr ed a r then flows nto a r outlet

compartment (30) and leaves the dryer through outlet valve (33).

1.2.1 Regeneration air circuit

Hot regenerat on a r s branched off from p pe (1) upstream of

the compressor aftercooler. Th s a r s unsaturated and has a

temperature of 130-190°C, depend ng on the operat ng pressure,

the cool ng water nlet temperature or amb ent temperature and

the a r nlet temperature.

The regenerat on a r passes through shut-off valve (7), throttle

valve (8) and stra ner (9) to nlet seal ng sector (10), and s

blown through the wet rotor channels. S nce the hot a r has a

lower vapour pressure than the wet rotor channels, t w ll dry,

.e. regenerate, the rotor.

The wet regenerat on a r leav ng the rotor s collected n outlet

seal ng sector (14).

The hot saturated a r s then cooled down n regenerat on a r

cooler (17) and passed to water separator (18), where the free

water s evacuated by the dra n system.

The regenerat on a r s then led to the suct on chamber (28) of

ejector (11), where t s m xed w th the wet compressed a r from

the compressor aftercooler. In the ejector the veloc ty of the

wet compressed a r s ncreased, result ng n a pressure drop n

the suct on chamber of the ejector and the ent re regenerat on

a r c rcu t up to throttle valve (8). The pressure drop prevents

regenerat on a r from enter ng the dry a r outlet compartment.

1.2.2 Rotor cooling air circuit

After regenerat on, the hot channels of the rotor are cooled by

a r from the dry a r compartment (30). The cool ng a r flow s

trapped by the regenerat on a r outlet seal ng sector (14) and

m xed w th the wet regenerat on a r.

1.3 Drain system

1.3.1 Description (Fig. 1.5)

The condensate enters the Electron c Water Dra n (EWD) v a

nlet (1) and accumulates n collector (2). A capac t ve sensor

(3) cont nuously measures the l qu d level. As soon as the

collector s f lled up to a certa n level, p lot valve (4) s act vated

and d aphragm (5) opens outlet (6), d scharg ng the condensate.

When the collector has been empt ed, the outlet closes qu ckly

w thout wast ng compressed a r.

When the controller reg sters a malfunct on, the red alarm LED

(F g. 1.7) starts flash ng and the electron c dra n valve w ll

automat cally change to the alarm mode, open ng and clos ng

the valve accord ng to a sequence as shown n (F g. 1.6). Th s

cond t on cont nues unt l the fault s remed ed. If the fault s not

remed ed automat cally, ma ntenance s requ red.

1.3.2 Testing the EWD

Functional test

Br efly press the TEST button (F g. 1.7) and check that the valve

opens for condensate d scharge.

Checking the alarm signal

- Press the test button for at least 1 m nute

- Check that the alarm LED flashes

- If an alarm dev ce s connected to the NO or NC contact

(see sect on 1.3.3), check ts operat on.

- Release the test button.

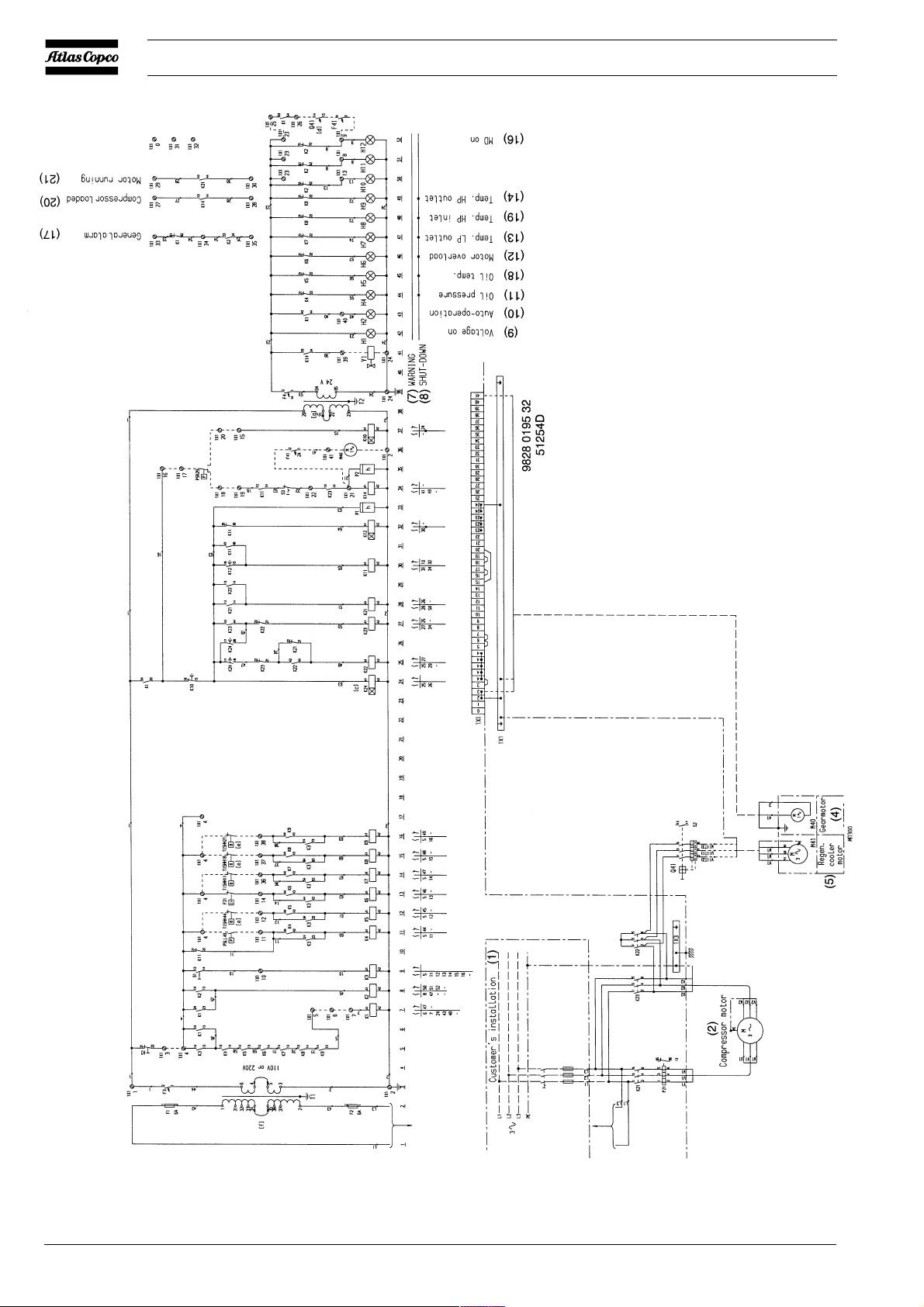

1.3.3 Electrical connections of the EWD (Fig. 1.8)

The nd cat ons on the data label must correspond to the ma ns

supply voltage and frequency. Connect the electr cal supply to

the EWD as shown n F g. 1.8. Never operate the EWD w thout

an earth conductor connected. An alarm dev ce can be connected

to the normally open or normally closed contact; see F g 1.8.