service solutions depending on the size, tool type

and demands in your operation.

•ToolScan RCM

Is your tool service level correct? Based on the

Reliability-centered Maintenance (RCM) process,

ToolScan RCM enables our service experts to

identify your precise needs in terms of tool ser-

vice. We'll help you optimize your existing service

program or, if necessary, develop a new one

•Full Coverage Service Agreements

Our full coverage option includes everything

needed for your tools’ regular corrective mainten-

ance. You delegate all service of your new or old

tools to Atlas Copco at a xed cost. Repairs re-

quired during the contracted period will be free

of charge, unless the tool has been misused

•Preventive Maintenance Agreements

Our standard preventive maintenance program.

Atlas Copco will maintain your equipment in peak

condition for a specied number of years at a xed

cost, with full documentation

•Fixed Price Repairs

A xed price repair program that ensures faster

turn-arounds and cuts administration costs at every

level. Combined with our Service Box concept,

it results in further reductions in administration

and handling costs

•ToolScan™

Identify problems before they occur. Ask for Tool-

Scan™ and an experienced Atlas Copco service

engineer will check the status of your tools on-site

for a xed price. A full report of the ndings on

each tool is provided after every ToolScan™

•Calibration Services

Let us handle your tool and equipment calibration.

We have experienced personnel, state-of the-art

equipment, and accredited calibration laboratories

operating in compliance with ISO 17025 standards

•ToolStart

We offer tool installation and start-up by qualied

Atlas Copco engineers at a xed price. The service

also includes: Programming, test running, and

operator training

•Training

Atlas Copco offers a wide range of training and

seminar programs relating to tools, systems and

software. Courses start with a theoretical platform,

and lead to instruction on practical implementation

in your business

For more information about these services, please

contact your Atlas Copco service sales representat-

ive.

Our Service Box concept cuts administration and

handling costs.

Service Kits

Even the best tool needs maintenance and overhaul.

Continous industrial use in tough working environ-

ments wear out some parts. Before a tool breaks

down it loses power and becomes less productive.

A gradual change can be difcult to detect. Atlas

Copco Service Kits will give new life to your tool.

Everything you need to recondition your tool is

contained in just one Kit. Instead of replacing an in-

dividual part i.e. vanes, as they wear out, recondition

the entire tool with an Atlas Copco Tools Service

Kit. This will guarantee a good function of your tool

and added assurance of dependability.

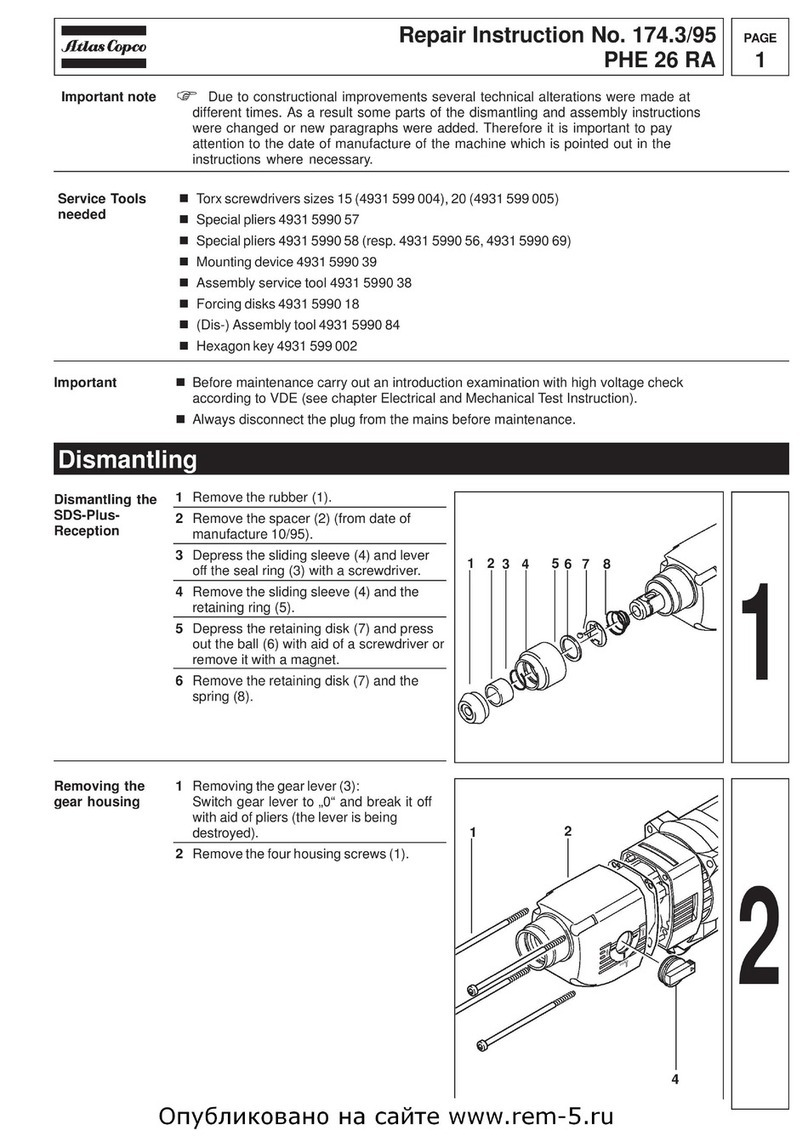

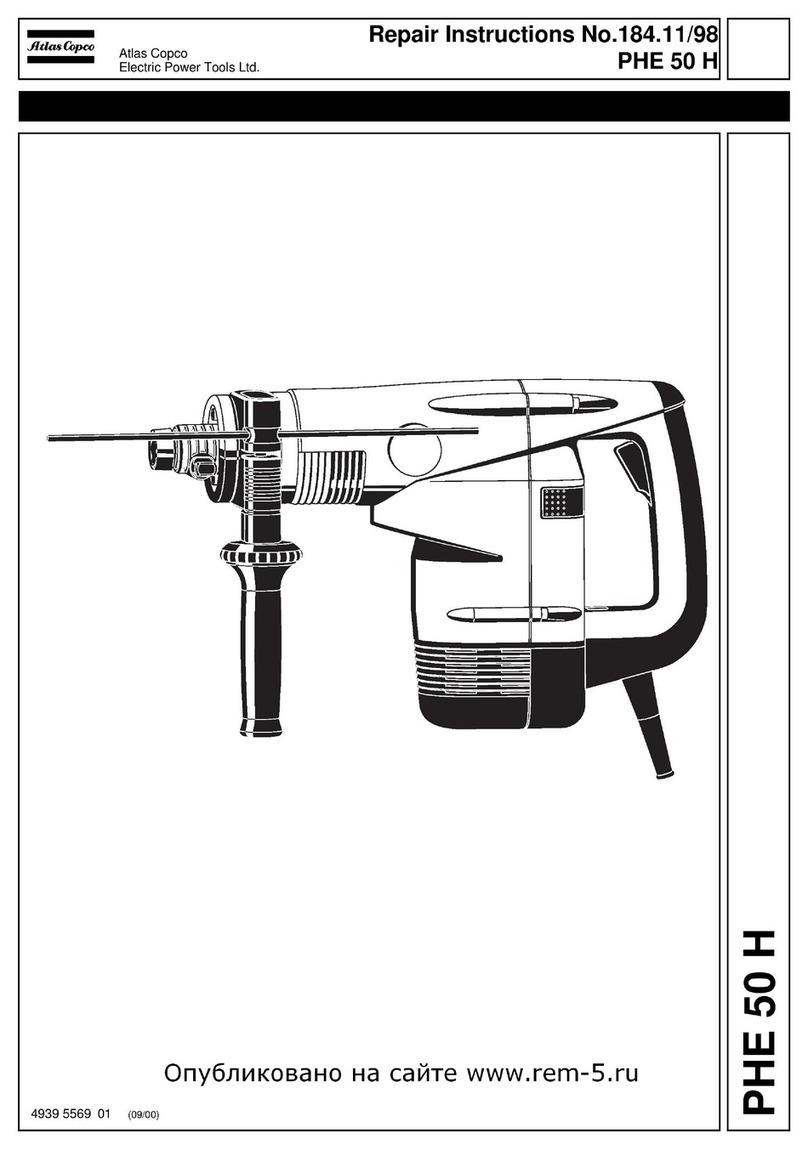

Service tools

The service tools which should be used to facilitate

rational and fast overhauling are listed in Service

instructions and in the exploded views.

Service boards and service tool sets

Besides the recommended service tools, for this

specic machine, we can offer complete service

boards with service tool sets. As optional equipment

we can also offer a "Board cabinet" which suits the

Service Boards. Boards and cabinet are in a yellow

colour. The size of the boards is

980×960×1.5 mm.The boards are equipped with tool

holders, transparent lm with black silhouettes of

the service tools (brackets to assemble the boards on

the wall incl.) For more information please read Atlas

Copco Service News concerning Service boards and

tools, Ordering No. 9835 5485 00.

Technical data

Noise and vibration emission

dB(A)Noise (according to PN8NTC 1.2)

81Measured sound pressure level

-Determined sound power level

3Spread in method and production

m/s2

Vibration (according to ISO 8662-1)

< 2.5Measured vibration value

-Spread in method and production

© Atlas Copco Tools - 9836 4880 00

6

LBB 36J H060-USafety and operating instructions