Contents

Product Features . . . . . . . . . . . 4

Installation Requirement . . . . . . . 5

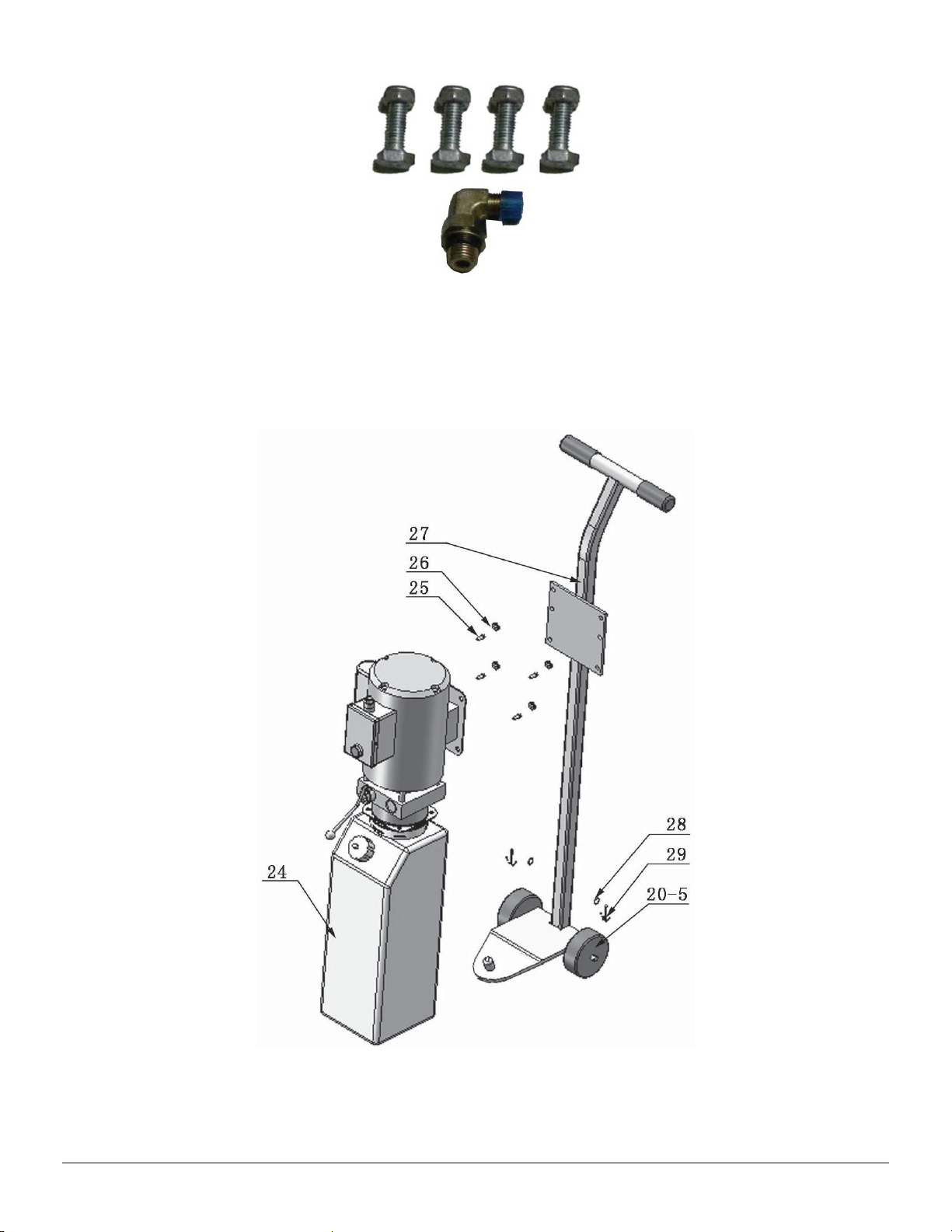

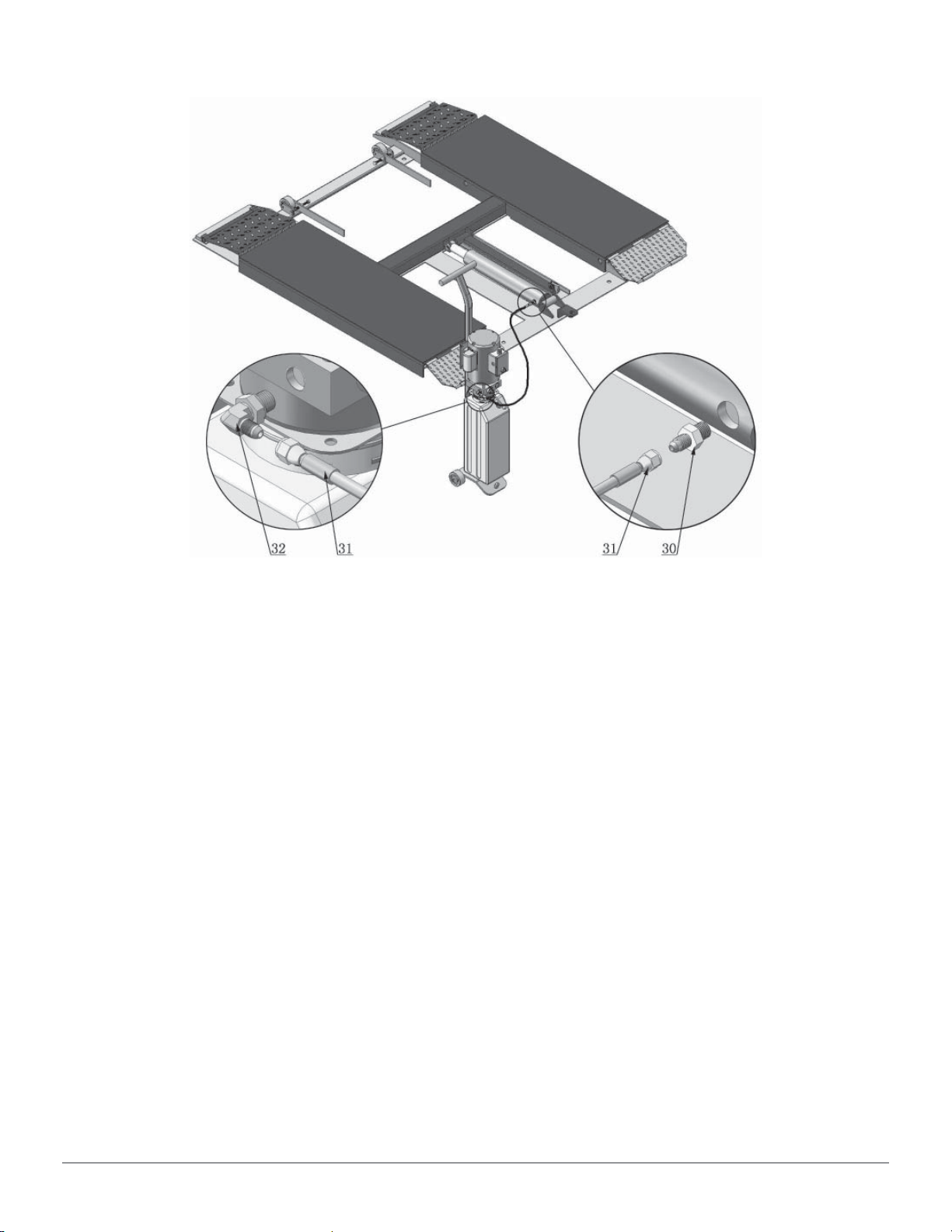

Steps Of Installation . . . . . . . . . 6

Exploded View . . . . . . . . . . . . 10

Operation Instructions. . . . . . . . . 14

Maintenance Schedule. . . . . . . . . 16

Trouble Shooting . . . . . . . . . . . 17

Parts List . . . . . . . . . . . . . . . 18

Warranty . . . . . . . . . . . . . . . 24