10

10760B–AT42–03/12

Proximity Design Guide

5. Grounding

Proximity sensors are highly sensitive to ground loading as it adds directly to the natural

capacitance of the sensor, resulting in a decrease of the sensitivity (gain) of the sensor. Ground,

in this case, is anything that looks like an AC ground from the sensor view. It is recommended to

keep grounding as far away from the proximity sensor and the connecting trace of the sensor -

this connecting trace is essentially an extension of the proximity sensor.

When a ground plane is absolutely necessary, a hatched pattern is recommended which is

common practice for most standard QTouch layouts. When implementing proximity there are

some minor variations that have been proved to be best practices for achieving further proximity

ranges:

1. Avoid ground planes if possible. If necessary, for the sensitivity of the buttons, sliders,

or wheels, they are acceptable – just keep them away from the proximity sensor or at a

minimum separate the proximity sensor and its trace with a driven shield (See “Driven

Shield (E-field Directivity)” on page 12.).

2. Use a 33% mesh fill.

3. Use 45° angles in the mesh.

If a ground plane is used, the ground should be connected directly to the controller VSS pin to

provide a clean ground having no relative voltage spikes on it. Also, the proximity sensor and its

connection back to the processor should be separated by the maximum distance of air or

thickness of insulation as possible.

When designing with proximity sensors, or any QTouch product, remember that ground areas

near the sensor increases the capacitive loading resulting in a loss of sensitivity. Although this

capacitive loading effect can be compensated for by increasing CS when using QTouch,

increasing the oversampling rate when using QTouchADC, or increasing Rs when designing

with QMatrix, an overall decrease in signal-to-noise ratio (SNR) and an increase of power

consumption will occur.

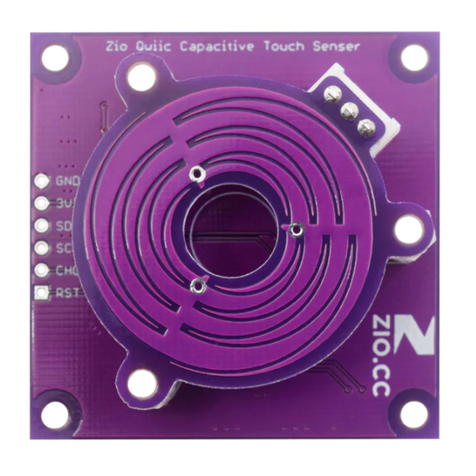

A proximity sensor is located along the left side of the figure below. As you can see there is no

ground plane near the proximity sensor – good practice. However a portion of the sensor trace

runs directly over the meshed ground plane. Even though there is separation between the trace

and the meshed ground plane (each on separate PCB layers) the proximity detector's range will

be reduced some degree due to signal absorption by the ground plane. In addition the ground

plane is meshed on a vertical instead of the recommended 45°. In this portion of the PCB design

the proximity sensors trace is at a right angle to the ground plane traces - standard practice for

reducing signal cross coupling, however there is enough coverage by the ground plane to cause

signal absorption.