Atmos MEDAP FINA FLOW User manual

OPERATING INSTRUCTIONS

FLOWMETER

MEDAP-FINA FLOW

MEDAP-FINA DFLOW

GA 5752 2804 GB 18

GA 5752 2804 GB 18

2

Subject to technical modification!

Illustrations and technical specifications may vary slightly from those in these operating

instructions as a result of ongoing product development.

V18 2020-07

4

GA 5752 2804 GB 18 3

Table of contents

Table of contents

1 Introduction ..............................................................................................................................................5

1.1 Foreword ....................................................................................................................................................5

1.2 How to use these operating instructions .................................................................................................... 5

1.2.1 Abbreviations ............................................................................................................................... 5

1.2.2 Symbols ....................................................................................................................................... 5

1.2.2.1 Cross-references ....................................................................................................... 5

1.2.2.2 Actions and responses .............................................................................................. 5

1.2.3 Definitions .................................................................................................................................... 6

1.2.3.1 Design of safety notes ............................................................................................... 6

1.2.3.2 Structure of notes ...................................................................................................... 6

1.2.4 Symbols used .............................................................................................................................. 6

1.3 Disposal......................................................................................................................................................8

1.3.1 Packaging .................................................................................................................................... 8

1.3.2 ATMOS products.......................................................................................................................... 8

1.4 Overview of FINA FLOW flowmeter ...........................................................................................................9

1.5 Basic requirements...................................................................................................................................10

1.5.1 Use in accordance with the intended purpose ........................................................................... 10

1.5.2 Applicable standards / directives ............................................................................................... 10

1.5.3 Intended purpose ....................................................................................................................... 10

1.5.4 Versions of FINA FLOW / DFLOW flowmeter ............................................................................ 11

1.5.5 Possible applications ................................................................................................................. 12

1.5.6 Interface description................................................................................................................... 12

1.5.6.1 Approved interface for compressed gas supply ...................................................... 12

1.5.6.2 Flowmeter outlet ...................................................................................................... 12

1.5.6.3 Connection tube ...................................................................................................... 12

1.5.6.4 Tube adapter for AIR and O2................................................................................... 13

2 Safety notes............................................................................................................................................14

2.1 General safety notes ................................................................................................................................ 14

2.2 Product safety notes.................................................................................................................................14

3 Initial operation.......................................................................................................................................16

3.1 Product testing .........................................................................................................................................16

3.2 Connection to the terminal unit.................................................................................................................16

3.2.1 General ...................................................................................................................................... 16

3.2.2 Version A.................................................................................................................................... 17

3.2.3 Version B.................................................................................................................................... 17

3.3 Mounting accessories...............................................................................................................................17

3.3.1 General ...................................................................................................................................... 17

3.3.2 Connection of the bubble humidifier (REF 5752 5315).............................................................. 18

3.3.3 Connection of disposable humidifiers from other manufacturers............................................... 18

GA 5752 2804 GB 18

4

Table of contents

4 Operation ................................................................................................................................................19

4.1 Function test.............................................................................................................................................19

4.2 Setting the flow for treatment ................................................................................................................... 19

5 Taking the unit out of operation............................................................................................................21

6 Cleaning and disinfection...................................................................................................................... 22

6.1 General.....................................................................................................................................................22

6.2 Cleaning ...................................................................................................................................................23

6.2.1 General ...................................................................................................................................... 23

6.2.2 Cleaning procedure.................................................................................................................... 23

6.3 Disinfection...............................................................................................................................................24

6.3.1 General ...................................................................................................................................... 24

6.3.2 Suitable disinfectants ................................................................................................................. 24

6.3.3 Disinfection procedure ............................................................................................................... 25

6.4 Special safety notes ................................................................................................................................. 25

7 Maintenance............................................................................................................................................26

7.1 General.....................................................................................................................................................26

7.2 Periodic tests............................................................................................................................................26

7.3 Malfunctions and troubleshooting.............................................................................................................26

7.4 Repairs.....................................................................................................................................................27

7.5 Service hotline..........................................................................................................................................27

7.6 Type plate position ...................................................................................................................................27

7.7 Sending in the device...............................................................................................................................27

8 Technical specifications ........................................................................................................................29

8.1 General.....................................................................................................................................................29

8.2 Ambient conditions...................................................................................................................................29

8.3 FINA FLOW O 15 / A 15 ........................................................................................................................... 29

8.4 FINA DFLOW O 15................................................................................................................................... 29

9 Approved accessories...........................................................................................................................30

9.1 Accessories..............................................................................................................................................30

9.2 Scope of delivery......................................................................................................................................30

Introduction

Foreword

GA 5752 2804 GB 18 5

1

1 Introduction

1.1 Foreword

Your facility has selected the leading-edge medical technology made by ATMOS. We sincerely

appreciate the trust you have placed in us.

1.2 How to use these operating instructions

These operating instructions are provided to familiarise you with the features of this ATMOS

product. They are subdivided into several chapters.

Please note:

• Please read these operating instructions carefully and completely before using the product for

the first time.

• Always proceed in accordance with the information contained herein.

• Store these operating instructions in a location near the product.

1.2.1 Abbreviations

EEC European Economic Community

VDE Verband der Elektrotechnik Elektronik Informationstechnik (Association for

Electrical, Electronic & Information Technology)

1.2.2 Symbols

1.2.2.1 Cross-references

References to other pages in these operating instructions are identified with a double arrow

symbol ‘’.

1.2.2.2 Actions and responses

The ‘’ symbol identifies an action taken by the user, while the ‘’ symbol identifies the reaction

that this will induce in the system.

Example:

Turn on the light switch.

Lamp lights up.

Introduction

How to use these operating instructions

6GA 5752 2804 GB 18

1

1.2.3 Definitions

1.2.3.1 Design of safety notes

Pictogram Descriptor Text

DANGER!

Indicates a direct and immediate risk to

persons which may be fatal or result in

most serious injury.

The text for the safety note

describes the type of risk and

how to avert it.

WARNING!

Indicates a potential risk to persons or

property which may result in health hazard

or grave property damage.

CAUTION!

Indicates a potential risk to property which

may result in property damage.

Tab. 1: Design of safety notes

1.2.3.2 Structure of notes

Notes not referring to personal injury or property damage are structured as follows:

Pictogram Descriptor Reference to

NOTE Supplementary assistance or further

useful information without potential

injury to persons or property damage

is described in the text of the note.

ENVIRONMENT Information regarding proper disposal.

Tab. 2: Structure of notes

1.2.4 Symbols used

Symbols are attached to products, type plates and packaging.

Symbols Identification

4

Labelling for products which were developed and are marketed in

compliance with the Medical Devices Directive 93/42/EEC. Class Is, Im, IIa,

IIb and III products are also marked with the identifying number of the

Notified Body.

Labelling in compliance with the ISO 15223-1 standard.

Symbol for ‘Product number’.

Labelling in compliance with the ISO 15223-1 standard.

Symbol for ‘Serial number’.

Introduction

How to use these operating instructions

GA 5752 2804 GB 18 7

1

Symbols Identification

Labelling in compliance with the ISO 15223-1 standard.

Symbol for ‘Name and address of the manufacturer as well as date of

manufacture’.

Labelling in compliance with the ISO 15223-1 standard.

Symbol for ‘Date of manufacture’.

Labelling in compliance with the ISO 15223-1 standard.

Symbol for ‘Follow operating instructions’.

Material designation for the plastic PA (polyamide).

Packaging label.

Symbol for ‘Keep dry’.

Packaging label.

Symbol for ‘Fragile! Handle with care’.

Packaging label.

Symbol for ‘Top’.

Labelling in compliance with the ISO 15223-1 standard.

Symbol for ‘Temperature limitations’.

Labelling in compliance with the ISO 15223-1 standard.

Symbol for ‘Relative humidity’.

Labelling in compliance with the ISO 15223-1 standard.

Symbol for ‘Atmospheric pressure’.

Labelling on type plate.

Symbol for ‘Oil- and fat-free’.

Tab. 3: Symbols

Introduction

Disposal

8GA 5752 2804 GB 18

1

1.3 Disposal

WARNING!

Infection hazard!

The product or some of its components may be contaminated after use.

Clean and disinfect the product before disposal.

1.3.1 Packaging

The packaging is made of materials compatible with the environment. ATMOS will dispose of the

packaging materials upon request.

1.3.2 ATMOS products

ATMOS will take back used products or those which are no longer in service.

Please contact your ATMOS representative for more detailed information.

Introduction

Overview of FINA FLOW flowmeter

GA 5752 2804 GB 18 9

1

1.4 Overview of FINA FLOW flowmeter

1

4

2

5

6

9

11

13

14

15

3

7

8

10

16

12

Fig. 1: Overview of FINA FLOW flowmeter

1 Flowmeter viewing tube 9 Version A

Tapping unit with integrated gas pin

2 Control valve

3 Flowmeter outlet (UNF 9/16") 10 Plug

4 Adapter for humidifier (UNF 9/16” – G 3/8") 11 Terminal unit

5 Tube adapter 4 mm, 6 mm, 8 mm (UNF 9/16") 12 Version B

Tapping unit with rail clamp and NIST connection

6 Tube adapter, plastic, 4 mm, 6 mm, 8 mm

(UNF 9/16") 13 Rail clamp

7 Connection tube 14 Equipment rail

8 Measuring scale 15 Locking lever

16 Connection tube

Introduction

Basic requirements

10 GA 5752 2804 GB 18

1

1.5 Basic requirements

1.5.1 Use in accordance with the intended purpose

Product

As per Annex IX to the Medical Devices Directive 93/42/EEC, this product belongs to class IIa.

In accordance with this directive, the product may only be used by persons who have been

instructed how to use this product by an authorised person.

This product is to be used exclusively for human medicine.

When employed in commercial or business use, this product must be entered in the inventory.

Accessories

Accessories or combinations of accessories may be utilised only as and when indicated in these

operating instructions.

Other accessories, combinations of accessories and consumable items may be used only if they

have a valid certification, are intended expressly for the particular use and will not adversely

affect performance, the prescribed ambient conditions or safety requirements.

1.5.2 Applicable standards / directives

The product satisfies the basic requirements set forth in Annex I to Council Directive 93/42/EEC

concerning medical devices (Medical Devices Directive) as well as the applicable national

(German) codes and the Medical Devices Act (MPG) in Germany. This has also been

demonstrated through the application of the corresponding standards which have been

harmonised with Directive 93/42/EEC.

1.5.3 Intended purpose

Name: FINA FLOW

FINA DFLOW

Main function: Designed for measuring the flow and determining the precise

dosage for the supply of oxygen and compressed air. In conjunction

with a hand-held nebuliser, the FINA FLOW is used to provide

metered administration of medication aerosols.

Medical indications /

application:

Inhalation and insufflation of oxygen within the scope of oxygen

enrichment via an inhalation mask or nose latch for patients who

can breathe independently.

Together with a hand-held nebuliser, administration of water-soluble

medications via an inhalation mask.

Specification of the main

function:

Supply of oxygen or compressed air. For oxygen / compressed air

supply, FINA FLOW is connected to a terminal unit for oxygen /

compressed air of a central medical gas supply system with a

pressure of 500 kPa ± 10%. For humidification of oxygen from the

central gas supply system, a humidifier may additionally be

connected. Supply of oxygen to the patient takes place via

connection tubes and an inhalation mask or a nose latch. The

administration of medication aerosols via compressed air takes

place via connection tubes to a hand-held nebuliser. The patient

presses the inhalation mask of the hand-held nebuliser onto the

mouth and nose.

User profile: Doctor, medically trained staff

Introduction

Basic requirements

GA 5752 2804 GB 18 11

1

Patient groups: Patients of all ages

Application organ: Lung

Application time: For continuous operation; in practice, short-term use on the patient

(< 30 days)

Application site: The application site is the clinical environment and doctor’s

practices which have a central oxygen / compressed air system.

The application of the product may only be performed by medically

trained and instructed staff.

Contraindications: The FINA FLOW may not be used for the following purposes:

• Outside the medical sector

• In MR areas

• In the home care sector

• Being operated directly by the patient

• For exclusive respiration

• With central gas supply systems having supply pressures other

than 500 kPa ± 10%

• When applying oxygen in its function as a medication, it is abso-

lutely necessary to measure the flow rate.

The product is: Not active

Sterility: Not a sterile product

Single-use product /

reprocessing:

The device and parts of the accessories are reusable. For

information on reprocessing, cleaning and disinfection, please see

the operating instructions.

1.5.4 Versions of FINA FLOW / DFLOW flowmeter

The connection of the tapping unit to oxygen or compressed air depends on the model being

used:

Version A: Tapping unit with integrated gas pin

• FINA FLOW is fitted directly to the terminal unit.

Version B: Tapping unit with rail clamp and NIST connection

• FINA FLOW is designed for mounting onto a 25 x 10 mm equipment rail and is supplied via a

NIST connection with oxygen or compressed air from a terminal unit connected using a con-

nection tube with gas probe.

Products and accessories are only permitted with the ISO colour coding. In Germany, Austria and

Switzerland, products with neutral colour coding are also permitted.

NOTE

The products are supplied with ISO coding. The scope of delivery includes a label

for neutral colour coding.

Introduction

Basic requirements

12 GA 5752 2804 GB 18

1

The product is available in the following versions:

• FINA FLOW O 15 Wall DIN (REF 5752 3681)

• FINA FLOW O 15 NIST connection, equipment rail (REF 5752 3682)

• FINA FLOW O 15 Wall MEDAP (REF 5752 3680)

• FINA DFLOW O 15 Wall MEDAP (REF 5752 3688)

• FINA DFLOW O 15 Wall DIN (REF 5752 3689)

• FINA DFLOW O 15 NIST connection, equipment rail (REF 5752 3690)

• FINA FLOW A 15 Wall MEDAP (REF 5752 3696)

• FINA FLOW A 15 Wall DIN (REF 5752 3697)

• FINA FLOW A 15 NIST connection, equipment rail (REF 5752 3698)

1.5.5 Possible applications

The following usage options are made possible by connecting products or accessories which are

contained in the list of accessories or which satisfy the specifications of the interface description.

• A metal tube adapter (REF 5752 2746) or plastic one (REF 5752 5316) can be used to con-

nect suitable connection tubes with inner diameters of 4 mm, 6 mm and 8 mm to the flowme-

ter.

• With the bubble humidifier (REF 5752 5315) for humidifying oxygen. The bubble humidifier is

intended for inhalation. The bubble humidifier is connected directly to the flowmeter.

• Sterile water systems / disposable humidifiers with a UNF 9/16" input may be connected

directly.

1.5.6 Interface description

All devices and accessories which are combined with the tapping unit must be listed in the

accessories list or meet the specifications of the interface description. Configuration of the overall

system as well as functional testing are subject to the overall responsibility of the medical staff.

Functionality and suitability of the connected accessory for each intended application must be

checked by the operator before every use. This includes the functionality of the connector

components, airtightness and suitability regarding material properties, working pressure and flow

rate.

1.5.6.1 Approved interface for compressed gas supply

In order to supply compressed gas, the tapping unit is connected to the central medical gas

supply system (CGSS) with a pressure of 500 kPa ± 10%.

The pressure in the supply line must be indicated and in the event of improper functioning must

be limited to 1000 kPa by an integrated pressure relief valve.

1.5.6.2 Flowmeter outlet

The internal thread on the accessory must match the external thread on the flowmeter

(UNF 9/16" 18 gear). Ensure that the connection between the flowmeter and the accessory is

leak-free.

1.5.6.3 Connection tube

The connection tube with an inner diameter of 4, 6 or 8 mm is connected with the tube adapter.

The connection tube may not collapse or must be pressure-resistant and must comply with the

hygiene standard of the hospital. The inner diameter of the connection tube must match the outer

diameter of the tube adapter.

Introduction

Basic requirements

GA 5752 2804 GB 18 13

1

1.5.6.4 Tube adapter for AIR and O2

The tube adapter is used to connect the tapping unit and the connection tube. The internal thread

of the tube adapter must match the external thread of the tube connector of the flowmeter outlet

(UNF 9/16").

Safety notes

General safety notes

14 GA 5752 2804 GB 18

2

2 Safety notes

2.1 General safety notes

DANGER!

Incorrect use can result in fatalities!

Instructions for using components made by other manufacturers are not part of

these operating instructions.

Ensure that the manufacturer's instructions are followed.

DANGER!

Observe hygiene guidelines!

Contaminated components may be hazardous to the patient's health.

Prepare the product according to the hygiene guidelines before using it for the first

time. Clean and disinfect the product.

DANGER!

Fire/explosion hazard!

Air, oxygen and oxygen compounds react explosively with oils, greases and

lubricants. Fire and explosion hazard due to compressed gases.

Always keep the product free of oils, greases and lubricants.

DANGER!

Fire hazard!

Fire hazard as a result of escaping oxygen.

Never smoke near equipment which carries oxygen and avoid using open fires or

glowing objects. Check the connector for leaks and tight fit when mounting

accessories.

DANGER!

Defective product!

Using incorrect spare parts and accessories can cause injuries or equipment

failure.

Only use original accessories or spare parts.

WARNING!

Risk of injury!

Hazard resulting from incorrect handling.

Follow the operating instructions for all accessories.

2.2 Product safety notes

CAUTION!

Malfunction!

Ensure that the connection between the product and the accessory is leak-free.

Safety notes

Product safety notes

GA 5752 2804 GB 18 15

2

CAUTION!

Property damage!

Exposure to UV rays can cause material fatigue. The stability would no longer be

ensured.

Do not expose the product to strong UV light.

CAUTION!

Observe ambient conditions!

The precision, operation, mechanical stability and tightness of the product cannot

be guaranteed if the ambient temperature range is undercut or exceeded.

WARNING!

Impacts!

Impacts may cause damage to sensitive, precision mechanical components.

Do not expose the product to impacts.

WARNING!

Non-permissible load!

If the permissible load is exceeded, leakages may occur at the connection between

the terminal unit and the gas probe.

In accordance with DIN EN ISO 9170-1, the overall weight of the product and

accessories may not exceed 2 kg.

Initial operation

Product testing

16 GA 5752 2804 GB 18

3

3 Initial operation

3.1 Product testing

DANGER!

Imprecise display in the event of deviations in system pressure!

If the system pressure of 500 kPa ± 10% is undercut or exceeded, it will no longer

be possible to accurately display the measured values of the flowmeter.

DANGER!

Fluctuations in flow rate!

Flow accuracy may be influenced by the following factors:

• Fluctuations in the supply pressure (terminal unit)

• Fluctuations in the back pressure (accessories)

• Fluctuations in the ambient temperature

DANGER!

Product testing!

Only product parts which are in perfect condition can ensure proper functioning of

the product. The product parts will thus have to be carefully inspected before

mounting.

WARNING!

Measurement accuracy!

The product may only be operated in a vertical position.

Pay special attention to the firm fit of the flowmeter viewing tube and to any possible cracks in

the flowmeter viewing tube. Do not use the product if there are any signs of cracks.

Check whether the connection tubes are undamaged.

Check whether the product has been properly cleaned and that there are no residues or

soiling.

Do not use damaged components.

3.2 Connection to the terminal unit

3.2.1 General

NOTE

Please refer to the manufacturer’s instructions for the particular terminal unit for

information on connecting the gas probe to the terminal unit.

Initial operation

Mounting accessories

GA 5752 2804 GB 18 17

3

3.2.2 Version A

1

1

2

2

Fig. 2: Version A

Tapping unit with integrated gas pin

The tapping unit (1) is plugged directly into

the terminal unit (2).

3.2.3 Version B

2

2

1

1

4

4

6

6

5

5

7

7

3

3

Fig. 3: Version B

Tapping units with rail clamp and NIST

connection

With the upper edge of the guide groove at

the front, position the rail clamp (1) at a

slight angle on the equipment rail (2) and

then press it against the equipment rail and

allow it to click into place.

Make sure that the rail clamp is correctly

secured and that the tapping unit is in a

stable position on the equipment rail.

Insert the NIST nipple (3) of the connection

tube into the NIST connection (4) of the

tapping unit and tighten down the NIST

screw connection (5) by hand.

Plug the gas probe (6) into the terminal unit

(7).

3.3 Mounting accessories

3.3.1 General

WARNING!

Tensile forces!

The connected accessories must not exert any mechanical forces which could

adversely affect the secure fit of the product.

Initial operation

Mounting accessories

18 GA 5752 2804 GB 18

3

WARNING!

Tensile forces!

Hold the basic unit with one hand when installing or removing accessories in order

to compensate for the tensile forces which are created.

3.3.2 Connection of the bubble humidifier (REF 5752 5315)

1

1

2

2

Fig. 4: Connection of the bubble humidifier

Connecting the bubble humidifier

Ensure that the tube connector of the

bubble humidifier has two seals.

Fill the humidifier bottle up to the marking

‘Filling level’ with distilled water and screw

the bubble humidifier cap into place.

Screw the bubble humidifier cap (1) directly

onto the flowmeter outlet (2) and tighten

finger-tight until it stops.

Pay attention that no tensile forces affect

the bubble humidifier.

3.3.3 Connection of disposable humidifiers from other manufacturers

Disposable humidifiers complying with the interface description may be connected to the

flowmeter outlet.

Screw the disposable humidifier directly onto the flowmeter outlet and tighten finger-tight until

it stops.

Operation

Function test

GA 5752 2804 GB 18 19

4

4 Operation

4.1 Function test

DANGER!

Function check!

The product is used in the treatment of patients. Any restriction in the unit's

performance can result in serious complications in treatment.

Perform a complete function check every time before using the unit.

Perform a complete function check of the tapping unit prior to use. During functional testing, pay

attention to the following conditions:

Version A: Tapping unit with integrated gas pin

• The tapping unit is correctly plugged into the terminal unit.

Version B: Tapping unit with rail clamp and NIST connection

• The gas probe of the connection tube is correctly inserted in the terminal unit.

• The NIST nipple of the connection tube is correctly secured in the NIST connection of the

tapping unit.

• The NIST screw connection is tightly fastened.

• The tapping unit is locked firmly to the equipment rail.

All versions:

• The tube connectors are firmly secured and tightly sealed, and no mechanical forces are act-

ing on the tubes.

• The plastic and rubber components are in perfect condition and show no signs of ageing.

• The accessories are correctly connected.

• The product is leak-free.

• It is possible to variably adjust the flow rate from zero to the maximum flow.

• The product is in good hygienic condition.

4.2 Setting the flow for treatment

DANGER!

Over-pressure!

The product is under pressure whenever it is connected to the terminal unit, even if

the valve is closed.

The flowmeter viewing tube may not be unscrewed when the product is connected.

WARNING!

Compressed gas setting!

The regulating mechanism is sensitive. Make the compressed gas settings very

carefully!

NOTE

The rate of gas flow is displayed on the flowmeter viewing tube in the centre of the

indicator ball.

Operation

Setting the flow for treatment

20 GA 5752 2804 GB 18

4

NOTE

When applying oxygen in its function as a medication as per the monograph in the

European Pharmaceuticals Reference, it is absolutely necessary to measure the

flow rate.

NOTE

The product only provides the patient with additional oxygen. The monitoring of the

patient is the responsibility of the user.

1

1

Fig. 5: Working with the tapping unit

Setting the flow for treatment

Open the control valve (1) by turning it

anticlockwise. Use the control valve to set

the gas flow rate to the required value for

the treatment:

Increase the gas flow rate

Turn the control valve anticlockwise.

Reduce the gas flow rate

Turn control valve clockwise.

This manual suits for next models

1

Table of contents

Popular Measuring Instrument manuals by other brands

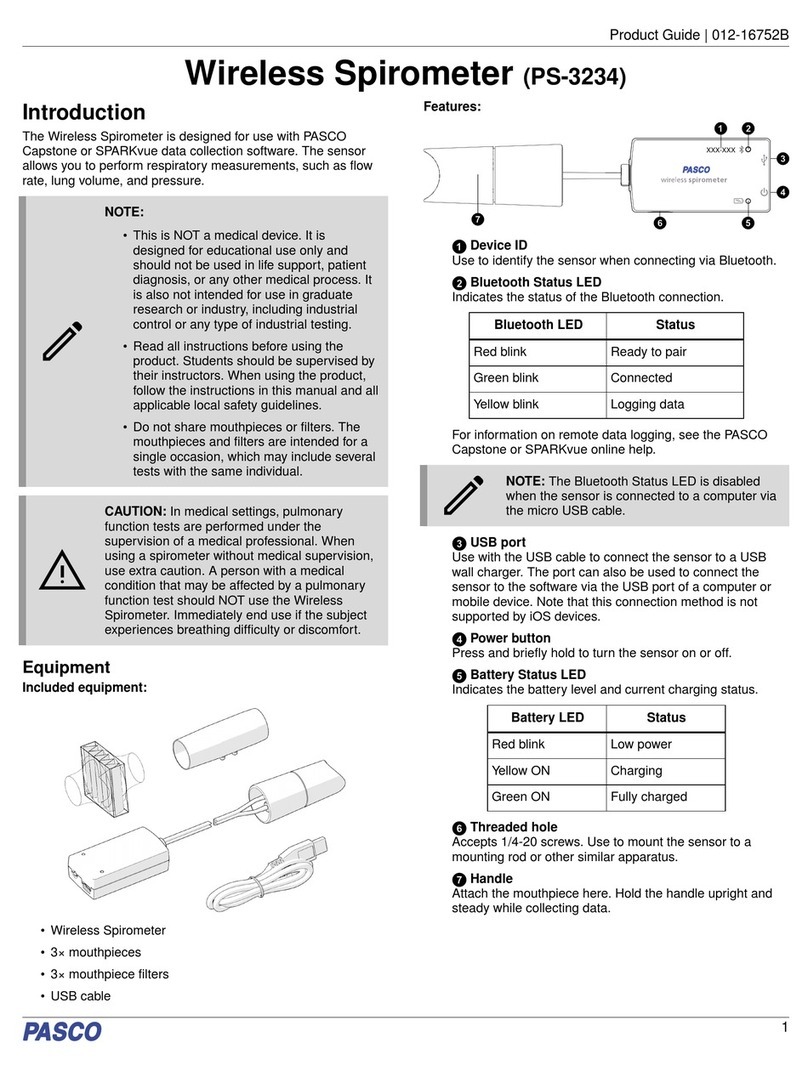

PASCO

PASCO PS-3234 Product guide

Badger Meter

Badger Meter Data Industrial 3000 Series user manual

Ecom

Ecom DP3 operating instructions

Elektro-Thermit

Elektro-Thermit RAILSTRAIGHT WAVE instruction manual

VOLTCRAFT

VOLTCRAFT LZG-1 operating instructions

International Light Technologies

International Light Technologies CureRight ILT800 instruction manual

Dateq

Dateq SPL-D2 manual

Analytik Jena

Analytik Jena compEAct N operating instructions

Nokeval

Nokeval 201 user manual

Agilent Technologies

Agilent Technologies 16800 Series Installation & quick start guide

B+K precision

B+K precision 302 instruction manual

Centrodyne

Centrodyne S610 Installation, operation, & programming manual