OPERATOR AND SAFETY MANUAL

1NO0027UK-05

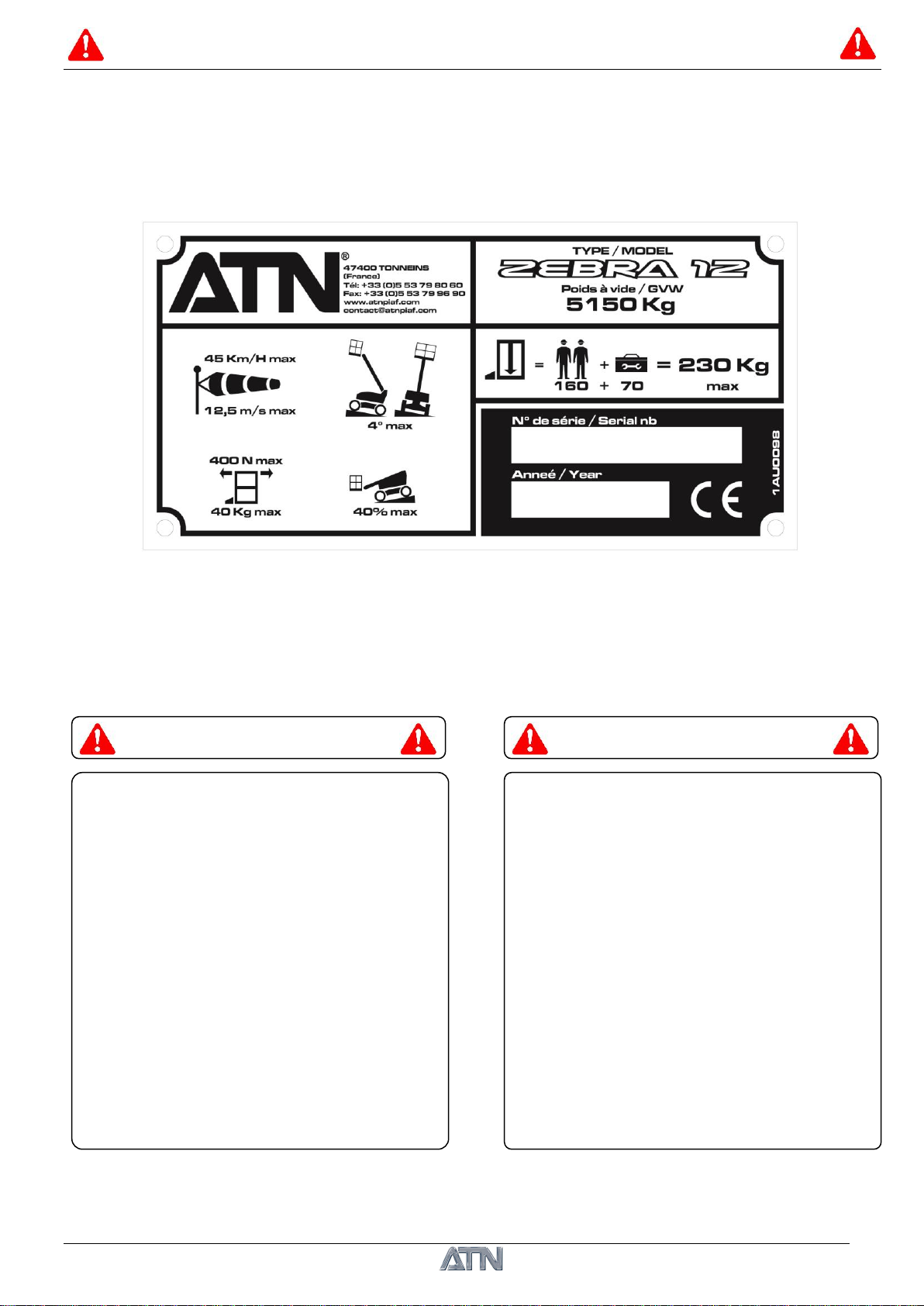

ZEBRA 12

TABLE OF CONTENTS

SECTION 1. GENERAL DESCRIPTION .........................................................................................9

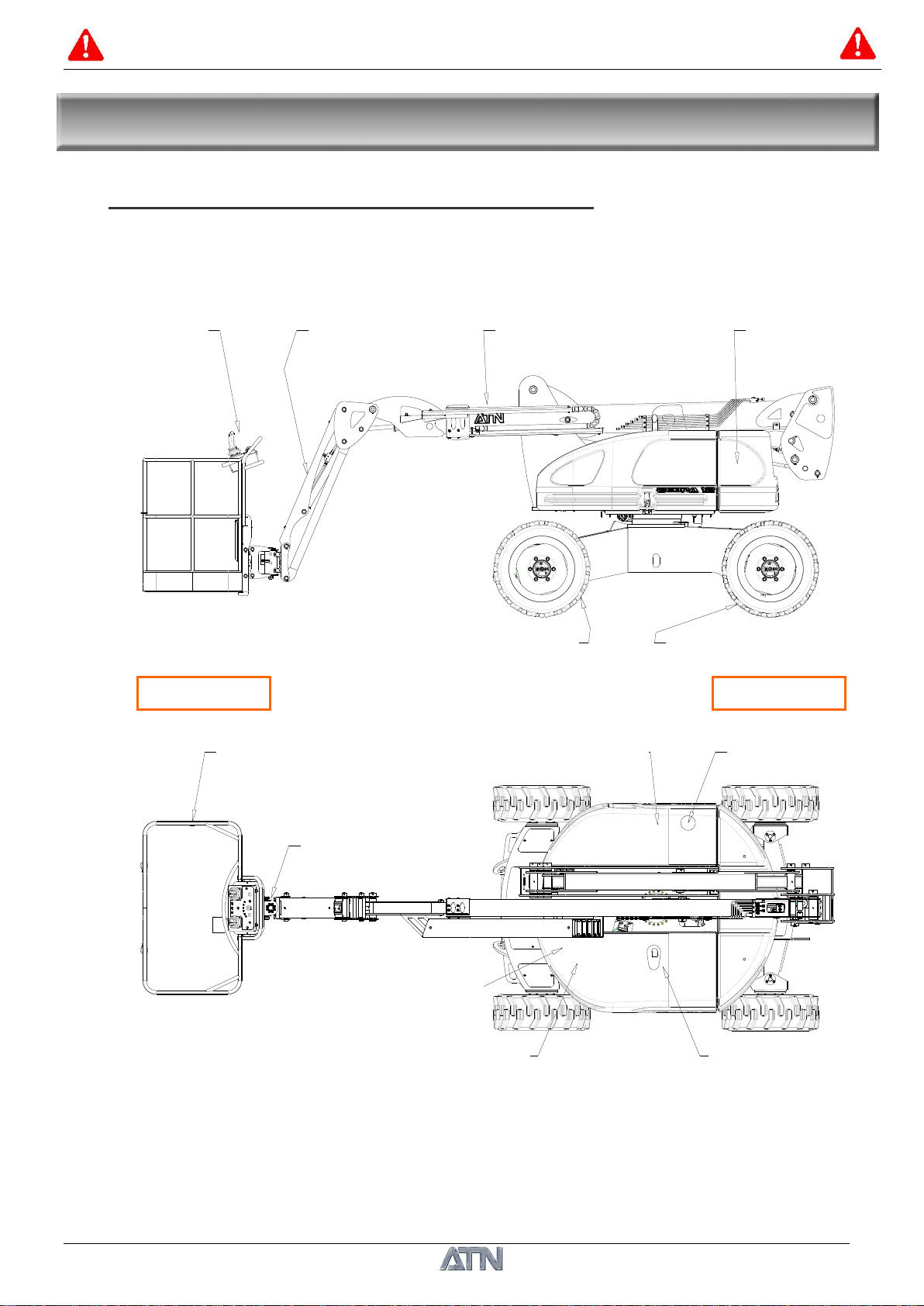

1.1. DESCRIPTION OF THE MACHINE, DIMENSIONS.........................................................................9

1.2. DIAGRAMS OF EVOLUTION..........................................................................................................10

1.3. TECHNICAL SPECIFICATIONS......................................................................................................11

SECTION 2. SAFETY INSTRUCTIONS ........................................................................................12

2.1. OPERATOR.......................................................................................................................................13

2.2. WORKSITE INSPECTION................................................................................................................13

2.3. STABILITY OF THE MACHINE.......................................................................................................14

2.4. CRUSHING HAZARD.......................................................................................................................15

2.5. ELECTRICAL HAZARD....................................................................................................................15

2.6. FALLING HAZARD...........................................................................................................................16

2.7. LIMITS OF USE................................................................................................................................16

2.8. MAINTENANCE...............................................................................................................................17

SECTION 3. USE...........................................................................................................................18

3.1. BASKET CONTROL STATION.........................................................................................................18

3.2. GROUND CONTROL STATION.......................................................................................................22

3.3. SAFETY DEVICE AND ALARMS.....................................................................................................24

3.4. START-UP.........................................................................................................................................26

3.5. PARKING AND STORING THE MACHINE ....................................................................................28

3.6. TOWING AND TRANSPORTING THE MACHINE..........................................................................28

3.7. STOWING THE MACHINE AND TRANSPORT INSTRUCTIONS ..................................................29

3.8. LIFTING THE MACHINE.................................................................................................................30

SECTION 4. REGULATIONS........................................................................................................31

4.1. CHECKS UPON FIRST COMMISSIONING....................................................................................31

4.2. PERIODICAL CHECKS IN FRANCE...............................................................................................31

4.3. APPROPRIATENESS........................................................................................................................31

SECTION 5. MAINTENANCE FOR THE OPERATOR ..................................................................32

5.1. GENERAL..........................................................................................................................................32

5.2. CLEANLINESS..................................................................................................................................32

5.3. ELECTRIC WIRES AND CABLES....................................................................................................32

5.4. SCREWS ............................................................................................................................................32

5.5. SEALING...........................................................................................................................................32

5.6. LUBRICATION POINTS...................................................................................................................33

5.7. WHEELS............................................................................................................................................35

5.8. STARTING BATTERY .......................................................................................................................35

5.9. BACKUP HYDRAULIC PLANT / SWITCH......................................................................................37

5.10. GENERAL INSPECTION GUIDE ..................................................................................................38

5.11. FACTORY SETTINGS.....................................................................................................................39

5.12. ACCESSING THE ICAN "DEFAULT VALUES" PAGE.................................................................40

5.13. ELECTRIC DIAGRAM....................................................................................................................41

5.14. HYDRAULIC DIAGRAM ................................................................................................................43