OPERATOR AND SAFETY MANUAL

1NO0035EN-00

Zebra 16

TABLE OF CONTENTS

Section 1. GENERAL DESCRIPTION................................................................................................................................... 8

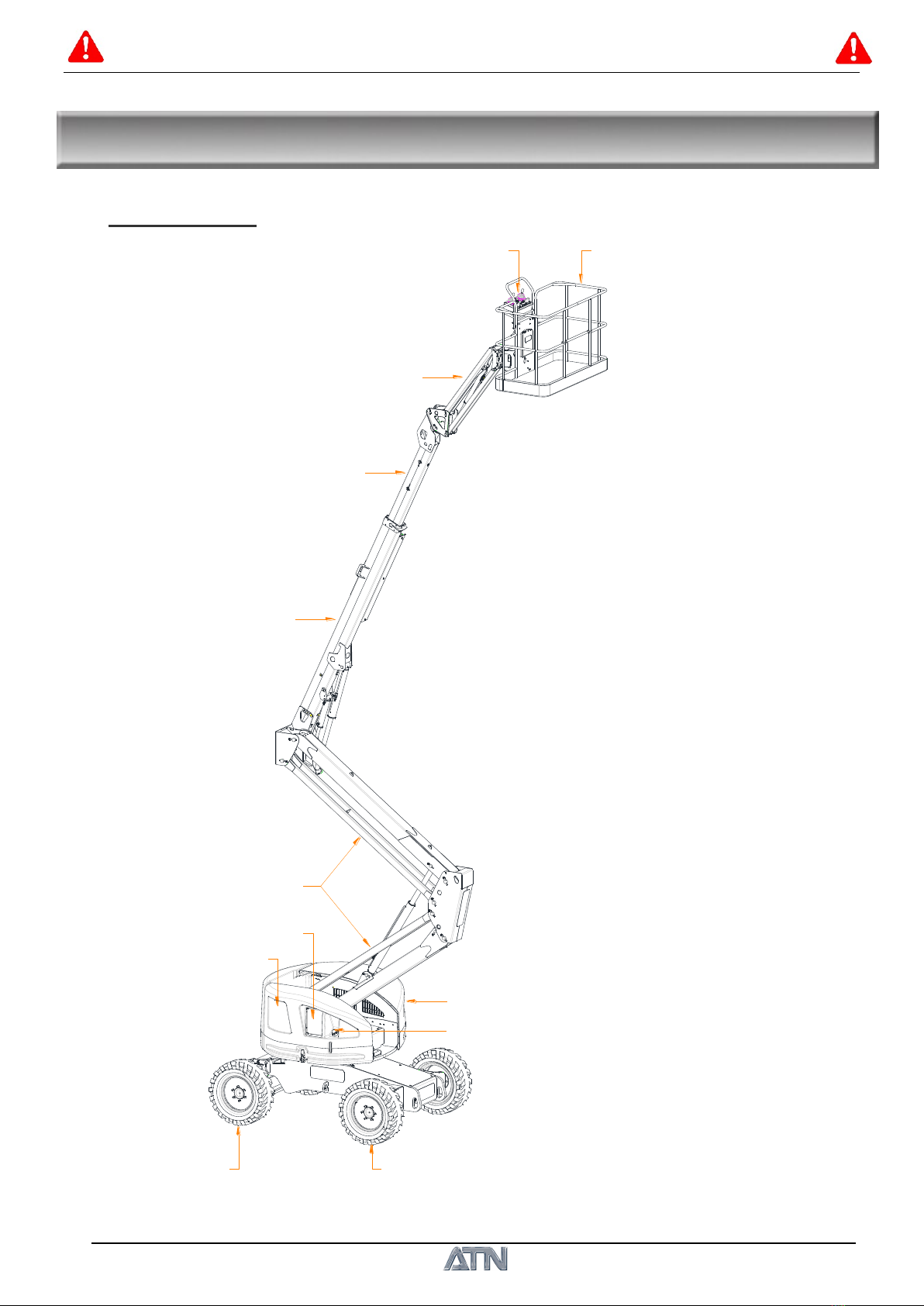

1.1. DESCRIPTION ................................................................................................................................................................. 8

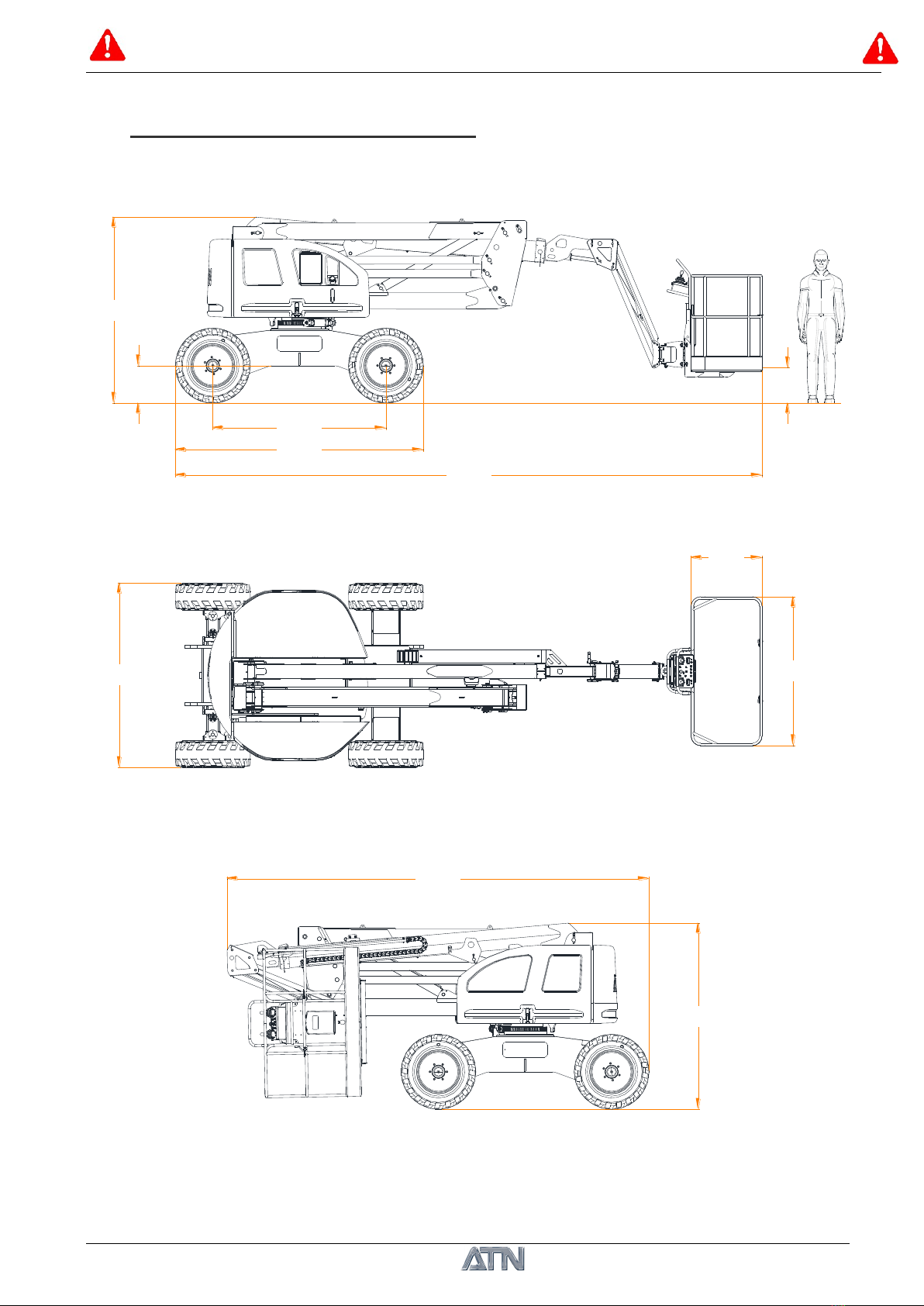

1.2. CARACTERISTICS - DIMENSIONS .............................................................................................................................. 9

Section 2. SAFETY INSTRUCTIONS .................................................................................................................................. 13

2.1. GENERAL INFORMATION .......................................................................................................................................... 13

2.2. TIPPING RISKS.............................................................................................................................................................. 14

2.3. CRUSHING AND COLLISION RISKS ......................................................................................................................... 15

2.4. ELECTROCUTION RISKS ............................................................................................................................................ 16

2.5. FALLING RISKS ............................................................................................................................................................ 17

2.6. OTHER RISKS ................................................................................................................................................................ 17

2.7. USAGE LIMITS .............................................................................................................................................................. 17

2.8. TOWING, LIFTING, TRANSPORT............................................................................................................................... 18

2.9. MAINTENANCE ............................................................................................................................................................ 18

Section 3. PREPARATION AND INSPECTION................................................................................................................. 19

3.1 INSPECTION BEFORE START-UP ............................................................................................................................... 19

3.2 INSPECTION TOUR ....................................................................................................................................................... 19

3.3 OPERATING CHECKS ................................................................................................................................................... 22

Section 4. USAGE ................................................................................................................................................................... 24

4.1. COMMANDS AND INDICATORS ............................................................................................................................... 24

4.2. DIESEL ENGINE OPERATION .................................................................................................................................... 32

4.3. SIDEWAYS MOVEMENT - STEERING ...................................................................................................................... 34

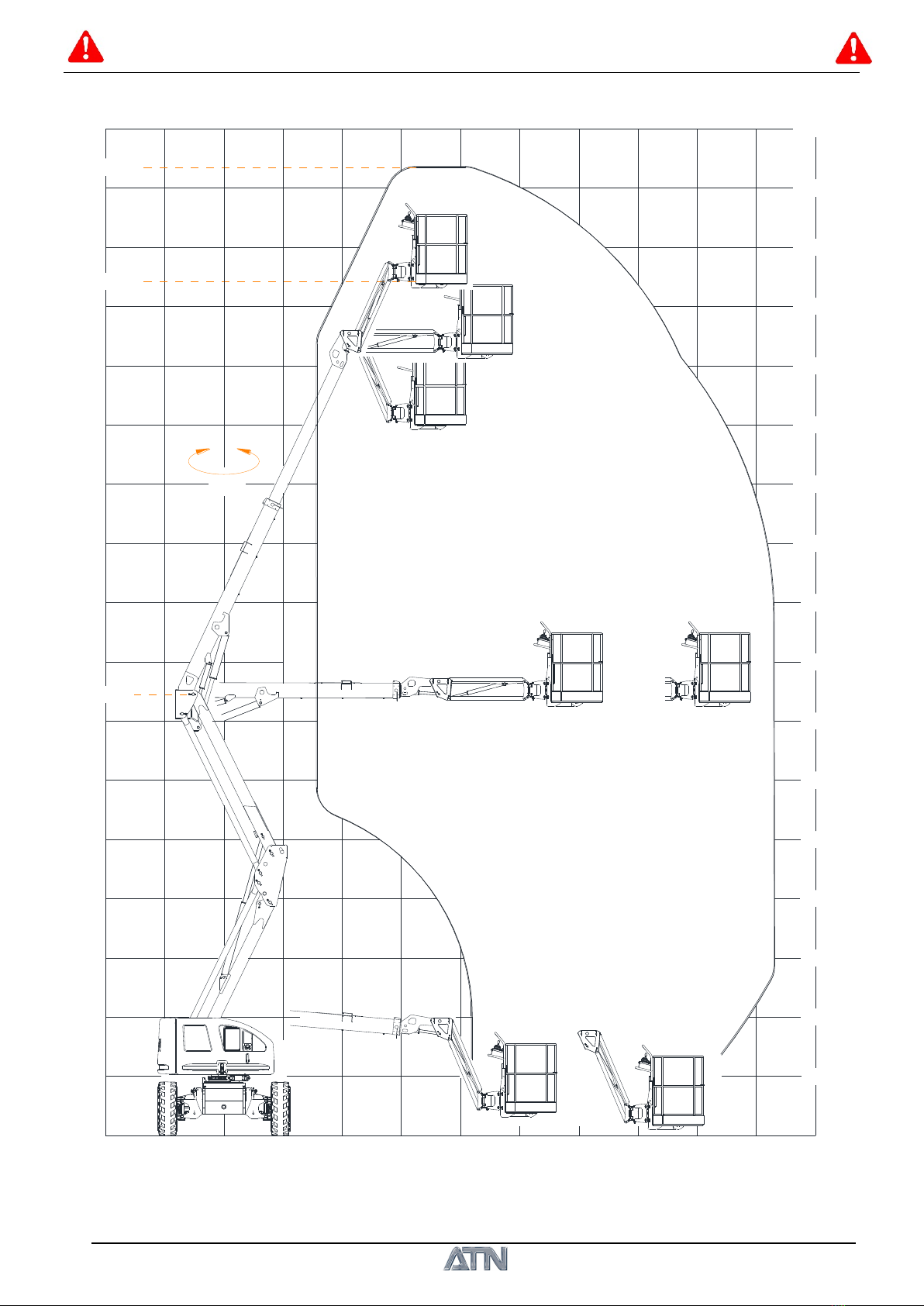

4.4. LIFTING STRUCTURE.................................................................................................................................................. 35

4.5. PARKING - STORAGE .................................................................................................................................................. 37

4.6. HANDLING - STOWAGE FOR TRANSPORT............................................................................................................. 39

Section 5. SAFETIES.............................................................................................................................................................. 40

5.1. INCLINE DETECTOR.................................................................................................................................................... 40

5.2. LOAD CONTROL........................................................................................................................................................... 41

5.3. SYSTEM FAULT ............................................................................................................................................................ 41

5.4. MOVEMENT ALARMS ................................................................................................................................................. 42

Section 6. EMERGENCY PROCEDURES .......................................................................................................................... 43

6.1. EMERGENCY COMMANDS ........................................................................................................................................ 43

6.2. EMERGENCY TOWING................................................................................................................................................ 43

6.3. AFTER AN INCIDENT .................................................................................................................................................. 44

Section 7. MAINTENANCE FOR THE OPERATOR ........................................................................................................ 45

7.1. DIESEL ENGINE ............................................................................................................................................................ 45

7.2. LUBRICATION .............................................................................................................................................................. 46

7.3. WHEELS ......................................................................................................................................................................... 47

7.4. BATTERY ....................................................................................................................................................................... 48

Section 8. CONTROL MODULE .......................................................................................................................................... 50

8.1. WELCOME SCREEN ..................................................................................................................................................... 50

8.2. MENUS ........................................................................................................................................................................... 51

8.3. SETTINGS - LOGS ......................................................................................................................................................... 63

8.4. FACTORY SETTINGS ................................................................................................................................................... 67

Section 9. DIAGRAMS ........................................................................................................................................................... 69

9.1. WIRING DIAGRAM....................................................................................................................................................... 69

9.2. HYDRAULIC DIAGRAM .............................................................................................................................................. 73