TABLE OF CONTENTS

Section 1. GENERAL DESCRIPTION................................................................................................................................... 8

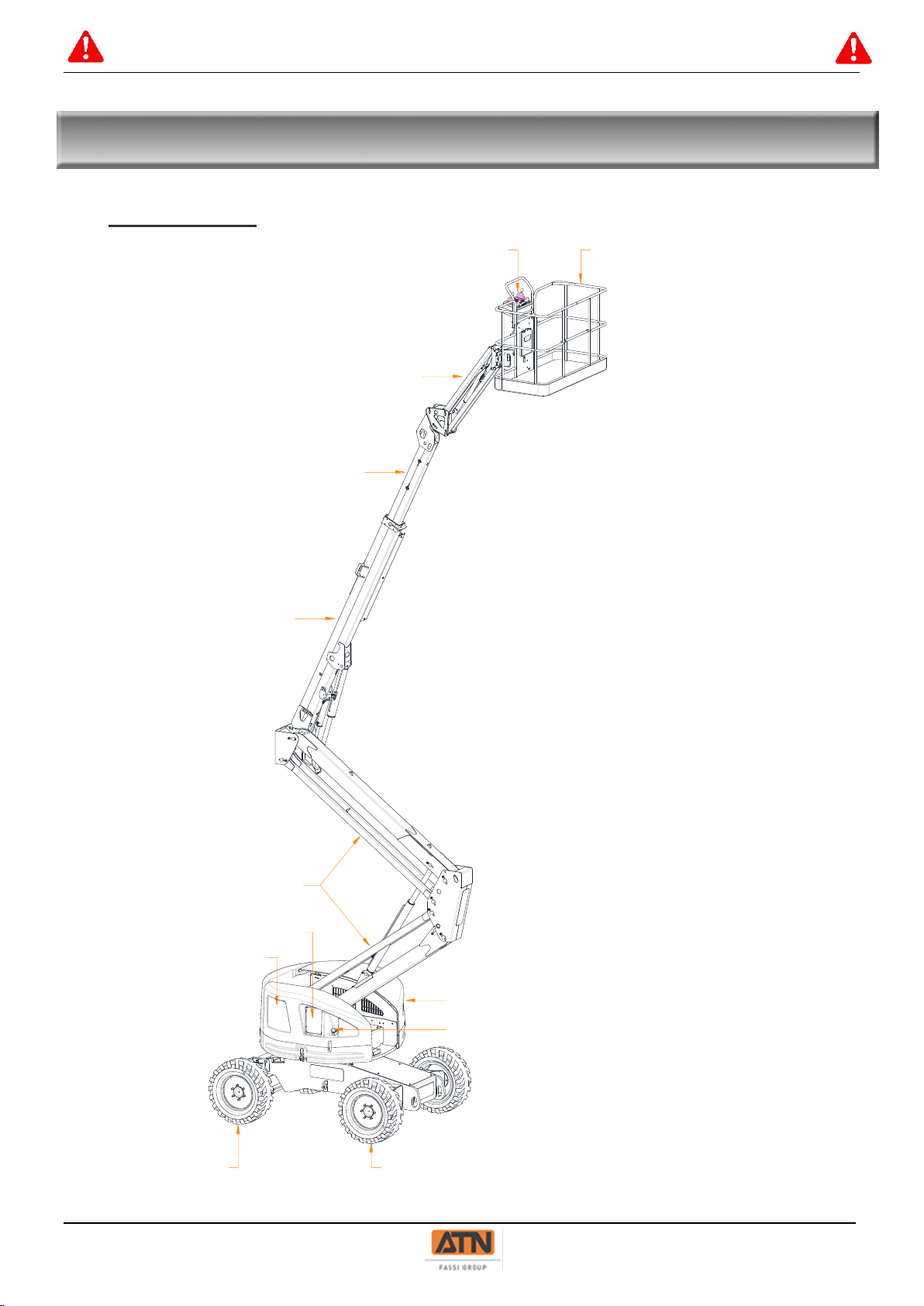

1.1. DESCRIPTION ................................................................................................................................................................. 8

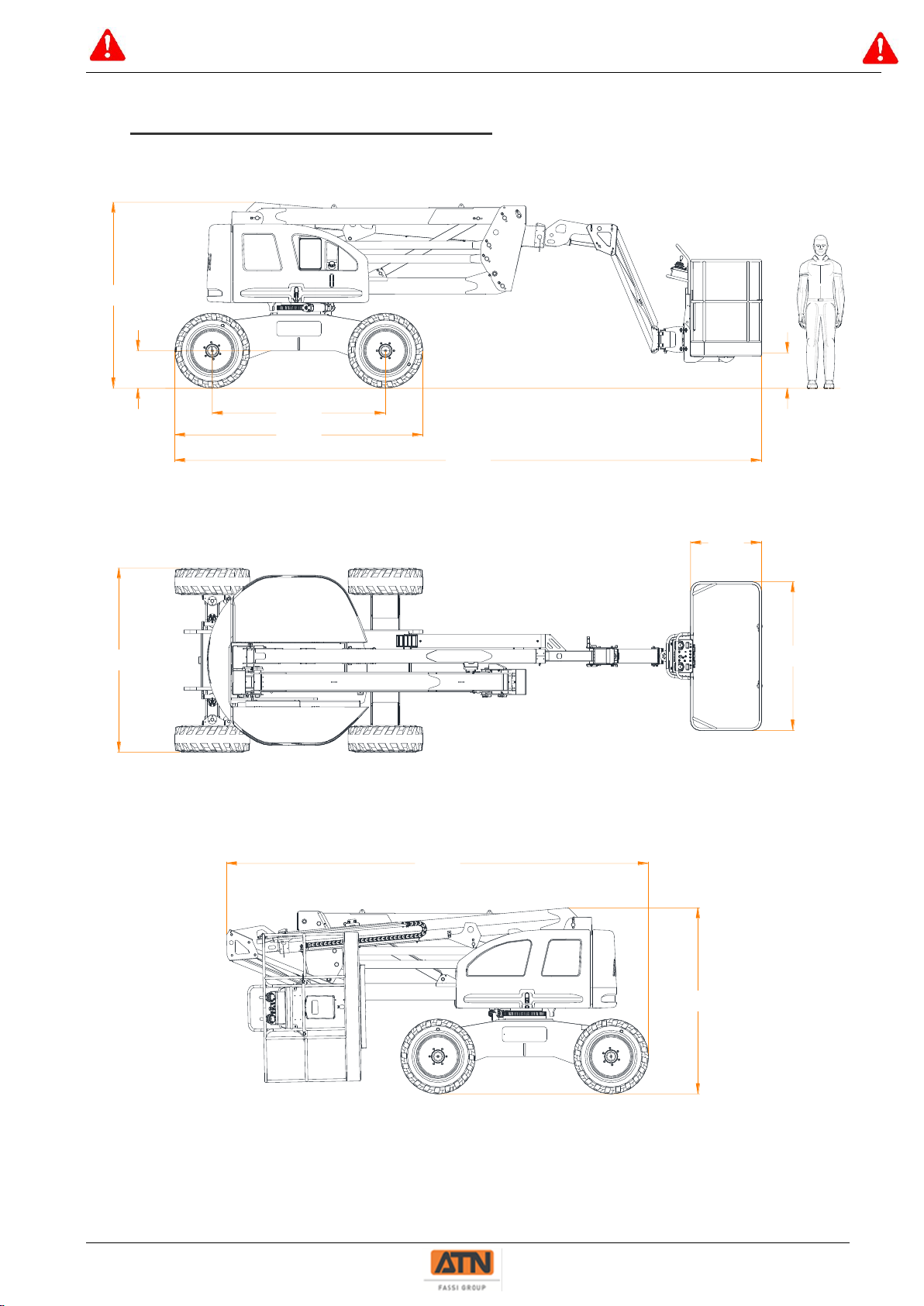

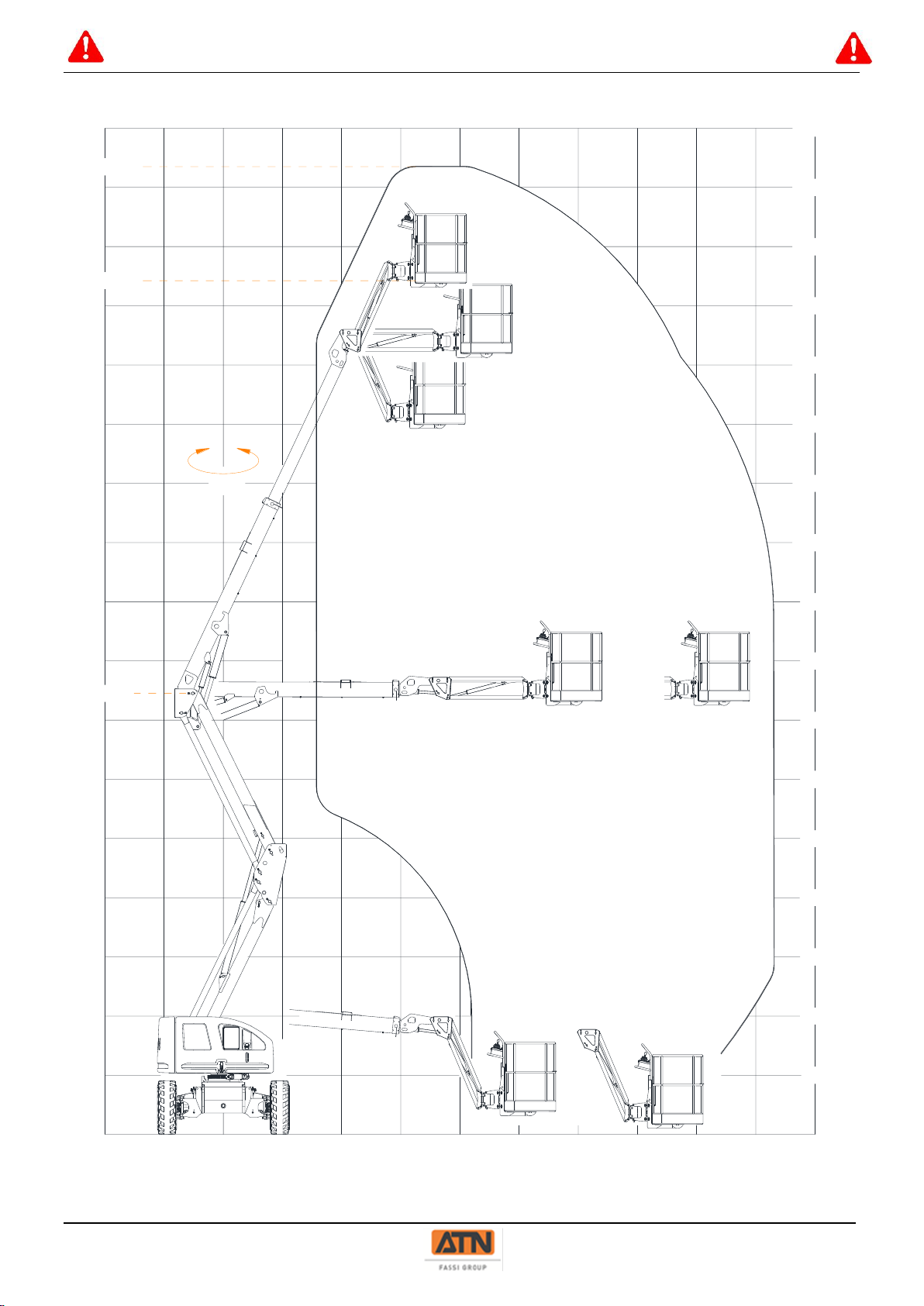

1.2. CHARACTERISTICS - DIMENSIONS ........................................................................................................................... 9

Section 2. SAFETY INSTRUCTIONS.................................................................................................................................. 13

2.1. GENERAL INFORMATION.......................................................................................................................................... 13

2.2. TIPPING HAZARDS ...................................................................................................................................................... 14

2.3. CRUSHING AND COLLISION HAZARDS.................................................................................................................. 15

2.4. ELECTROCUTION HAZARDS..................................................................................................................................... 16

2.5. FALLING HAZARDS..................................................................................................................................................... 17

2.6. OTHER HAZARDS ........................................................................................................................................................ 17

2.7. OPERATION LIMITS..................................................................................................................................................... 17

2.8. TOWING, LIFTING, TRANSPORT............................................................................................................................... 18

2.9. MAINTENANCE ............................................................................................................................................................ 18

Section 3. PREPARATION AND INSPECTION................................................................................................................. 20

3.1 INSPECTION BEFORE START-UP............................................................................................................................... 20

3.2 INSPECTION TOUR ....................................................................................................................................................... 20

3.3 OPERATING CHECKS ................................................................................................................................................... 23

Section 4. OPERATION......................................................................................................................................................... 25

4.1. CONTROLS AND INDICATORS.................................................................................................................................. 25

4.2. DIESEL ENGINE OPERATION .................................................................................................................................... 33

4.3. DRIVE - STEERING....................................................................................................................................................... 35

4.4. LIFTING STRUCTURE.................................................................................................................................................. 36

4.5. PARKING - STORAGE.................................................................................................................................................. 38

4.6. HANDLING - STOWAGE FOR TRANSPORT............................................................................................................. 40

Section 5. SAFETY DEVICES............................................................................................................................................... 42

5.1. TILT SENSOR ................................................................................................................................................................ 42

5.2. LOAD CONTROL........................................................................................................................................................... 43

5.3. CALIBRATION OF THE OVERLOAD PLATFORM SYSTEM.................................................................................. 43

5.4. SYSTEM FAULT............................................................................................................................................................ 44

5.5. MOVEMENT ALARMS................................................................................................................................................. 44

5.6. ANTICRUSHING SYSTEM (OPTION)......................................................................................................................... 45

Section 6. EMERGENCY PROCEDURES .......................................................................................................................... 46

6.1. EMERGENCY CONTROLS........................................................................................................................................... 46

6.2. EMERGENCY TOWING................................................................................................................................................ 47

6.3. AFTER AN INCIDENT .................................................................................................................................................. 48

Section 7. MAINTENANCE FOR THE OPERATOR ........................................................................................................ 49

7.1. DIESEL ENGINE............................................................................................................................................................ 49

7.2. LUBRICATION .............................................................................................................................................................. 50

7.3. WHEELS ......................................................................................................................................................................... 51

7.4. BATTERY....................................................................................................................................................................... 52

Section 8. CONTROL MODULE.......................................................................................................................................... 54

8.1. WELCOME SCREEN..................................................................................................................................................... 54

8.2. MENUS ........................................................................................................................................................................... 55

8.3. SETTINGS - LOGS......................................................................................................................................................... 67

8.4. FACTORY SETTINGS................................................................................................................................................... 71

Section 9. DIAGRAMS........................................................................................................................................................... 73

9.1. WIRING DIAGRAM....................................................................................................................................................... 73

9.2. HYDRAULIC DIAGRAM.............................................................................................................................................. 77