ATS Diesel Performance Aurora Plus - 5000 User manual

Installation Manual v1.2:

Aurora Plus - 5000 Turbo Kit

(2003-2007) 5.9L Dodge

Please read all instructions before installation.

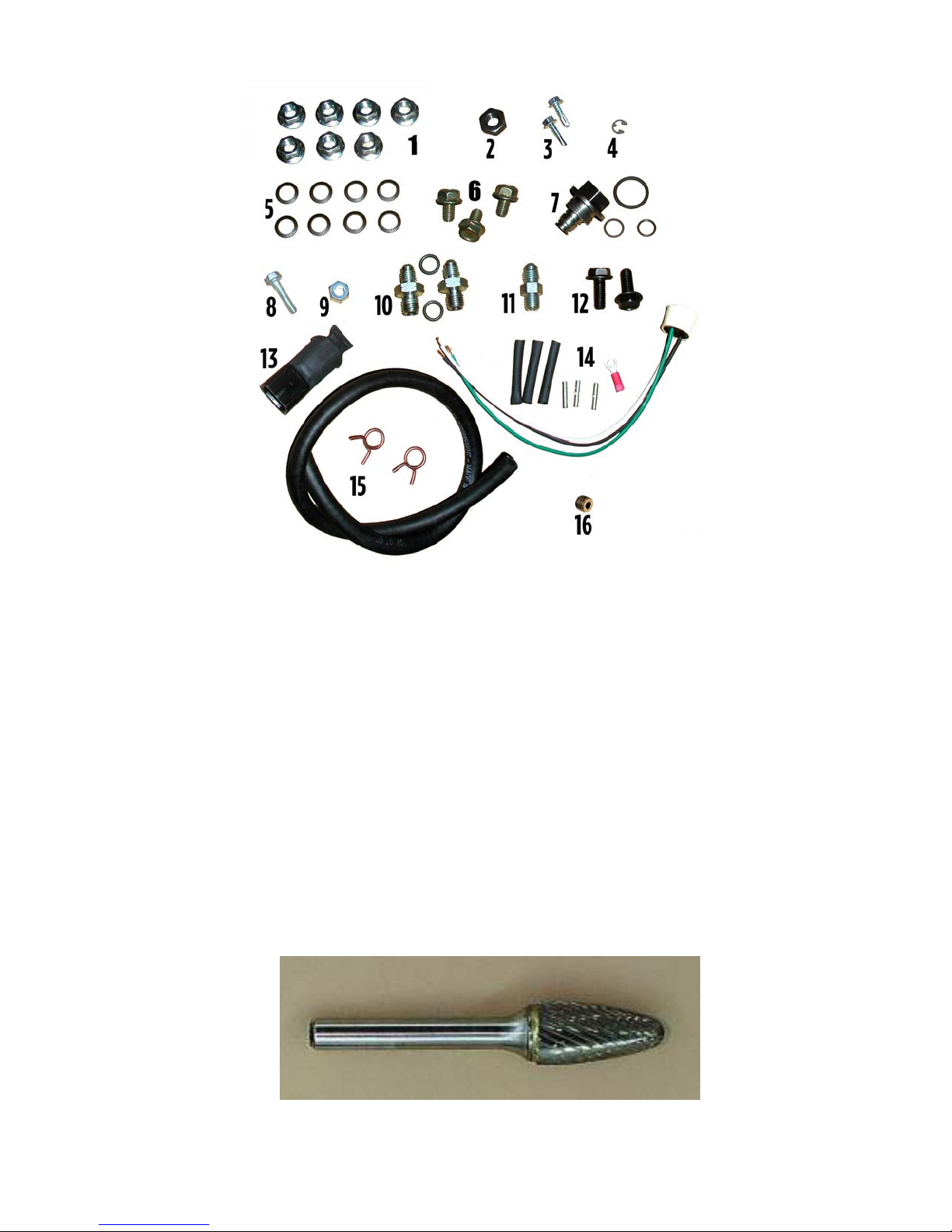

Figure 1: Aurora Plus - 5000 Kit Contents

Figure 2: Aurora Plus Hardware Kit

Please make sure all of the components are in the Aurora Plus – 5000 Turbo kit

before beginning installation. A complete corresponding list of parts and part

numbers can be found on pages 17-19.

Tools Required:

1. Large set of I.D. snap-ring

pliers

2. 7/16” drill bit

3. 3/32” drill bit

4. Electric drill

5. 17mm wrench

6. 15mm wrench

7. 13mm wrench

8. 11mm deep socket

9. 10mm deep socket

10. 13mm deep socket

11. 11/16” wrench

12. Vise-grip pliers

13. Needle nose pliers

14. Square nose pliers

15. 8mm nut driver

16. Dikes or side cutters

17. Die Grinder w/ Round Tip

Carbide Burr (shown below)

Preparing the vehicle:

1. Set parking brake and block the wheels.

2. Disconnect batteries by removing both negative (-) terminals. Secure the

negative (-) terminals away from batteries.

3. Remove the passenger side inner fender to make it easier to access the

side of the engine (driver side shown).

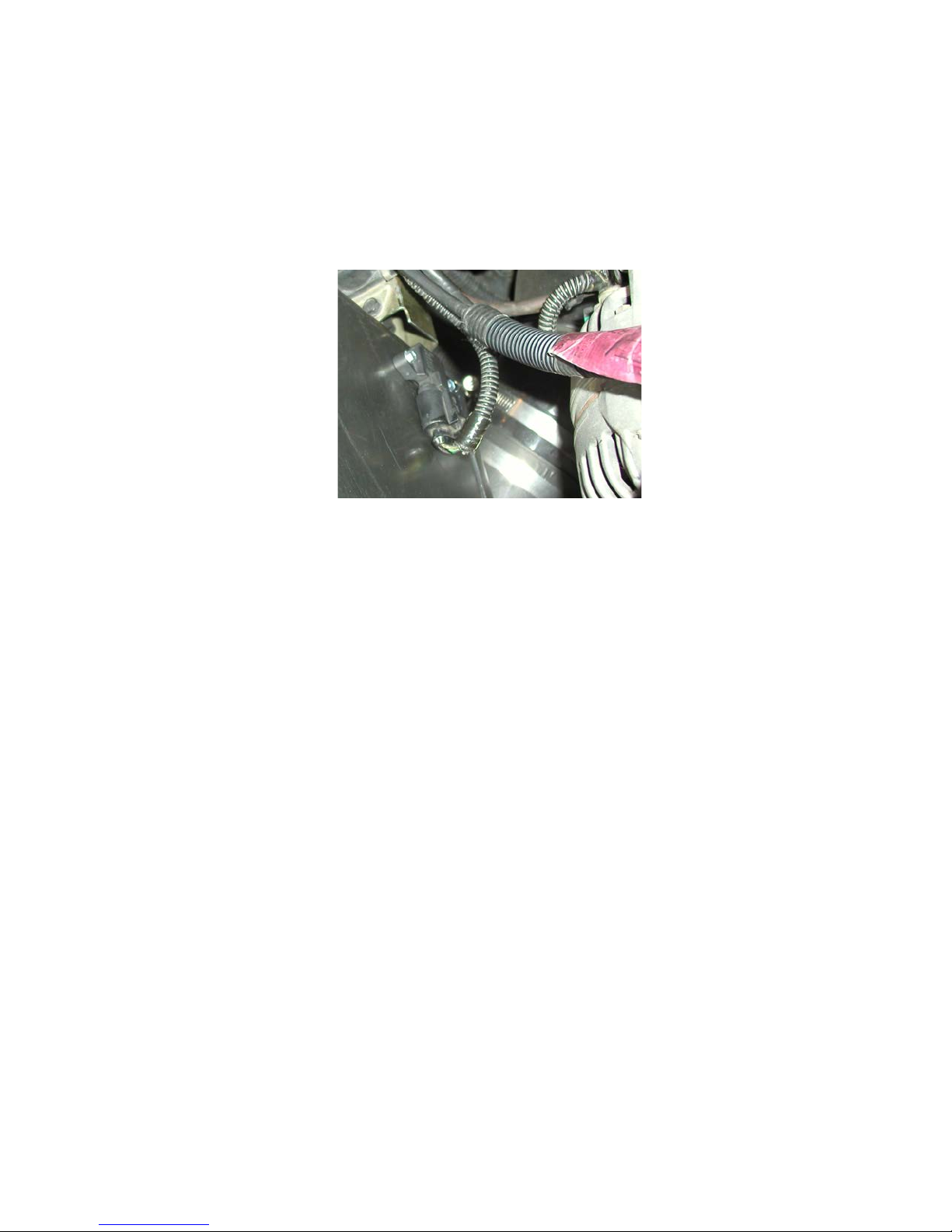

4. Disconnect the IAT (Intake Air Temperature) sensor and remove it from

the intake tube. Remove the air filter housing and intake tube.

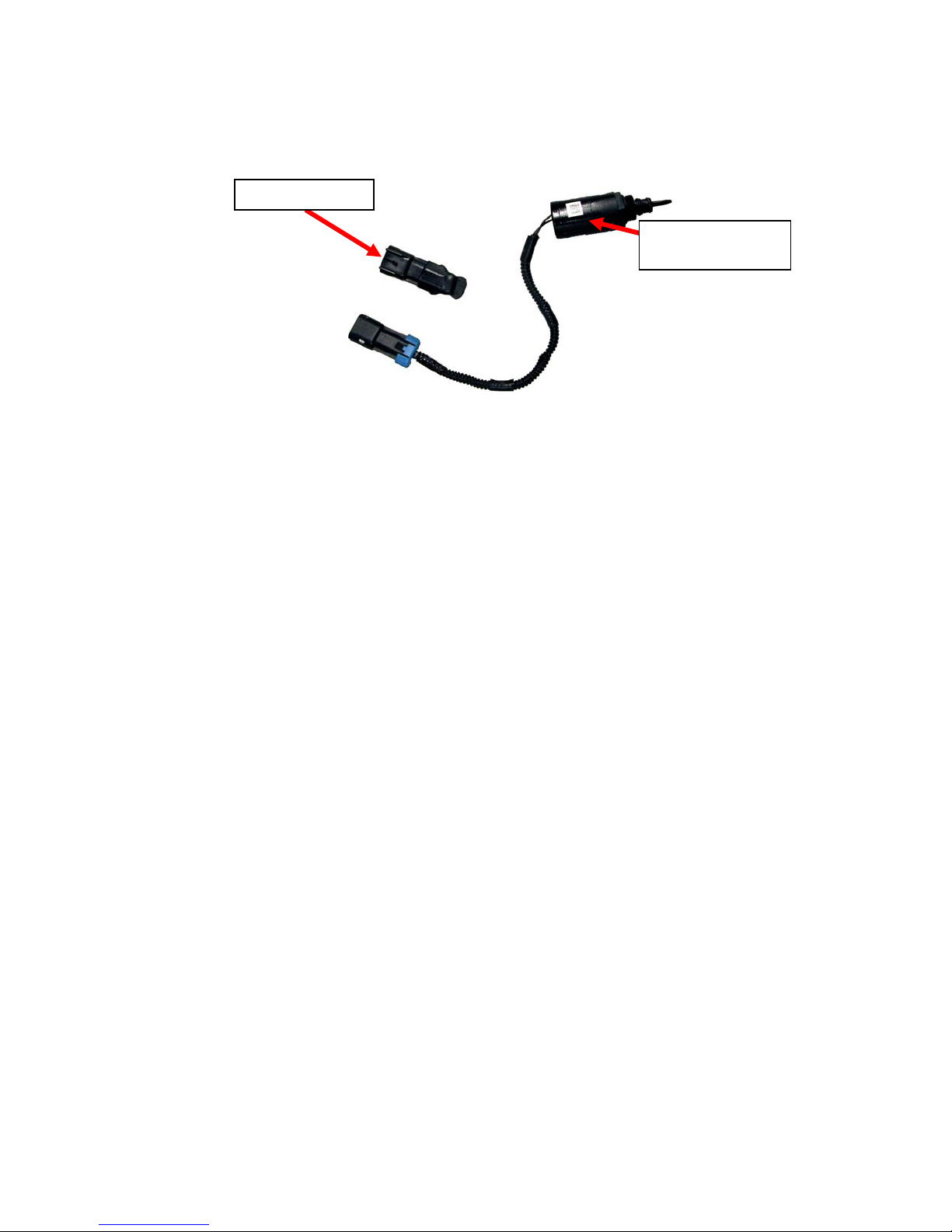

5. (04.5-07 Trucks only) On the front of the stock turbo is a round, black

colored component, which is connected to the engine harness. This

component is the Wastegate control solenoid. Disconnect the Wastegate

control solenoid from the engine harness and remove it from the stock

turbo. Install the harness jumper provided (Figure 2, #13) in the kit to

prevent the computer from setting the check engine light.

6. Remove the rubber grommet from the factory front air box and install it

into the ATS air box mounting bracket. If the grommet cannot be found, a

large flat washer will work.

7. Remove the factory turbo-to-intercooler charge pipe.

8. Remove the rubber hump boot on the intercooler inlet.

9. Disconnect the factory oil feed line from the top of the factory turbo and

disconnect the oil drain from the bottom of the factory turbo. Retain the

bolts.

10.Disconnect the exhaust by removing the v-band clamp that holds the

exhaust elbow to the turbine housing. There are two locating pins that will

either be stuck in the exhaust elbow or turbo outlet flange; remove and

discard both pins.

11.Remove the four nuts securing the heat shield to the manifold.

12.Cut and remove the bracket securing heater hose to the manifold stud.

Be sure not to cut the heater hose.

13.Using a pair of side cutters, remove the safety straps from the back four

manifold bolts.

14.With the factory turbo still in place, remove the 12 manifold bolts to

remove the stock turbo and manifold as one piece. Place the assembly

on a workbench or equivalent sturdy work surface.

15.With the turbo/manifold assembly on the workbench, remove the four nuts

securing manifold to turbo flange and separate the turbo and manifold.

The four nuts can be very difficult to loosen. Use penetrating oil on stud

threads before attempting to loosen nuts.

Harness Jumper

Wastegate Control

Solenoid

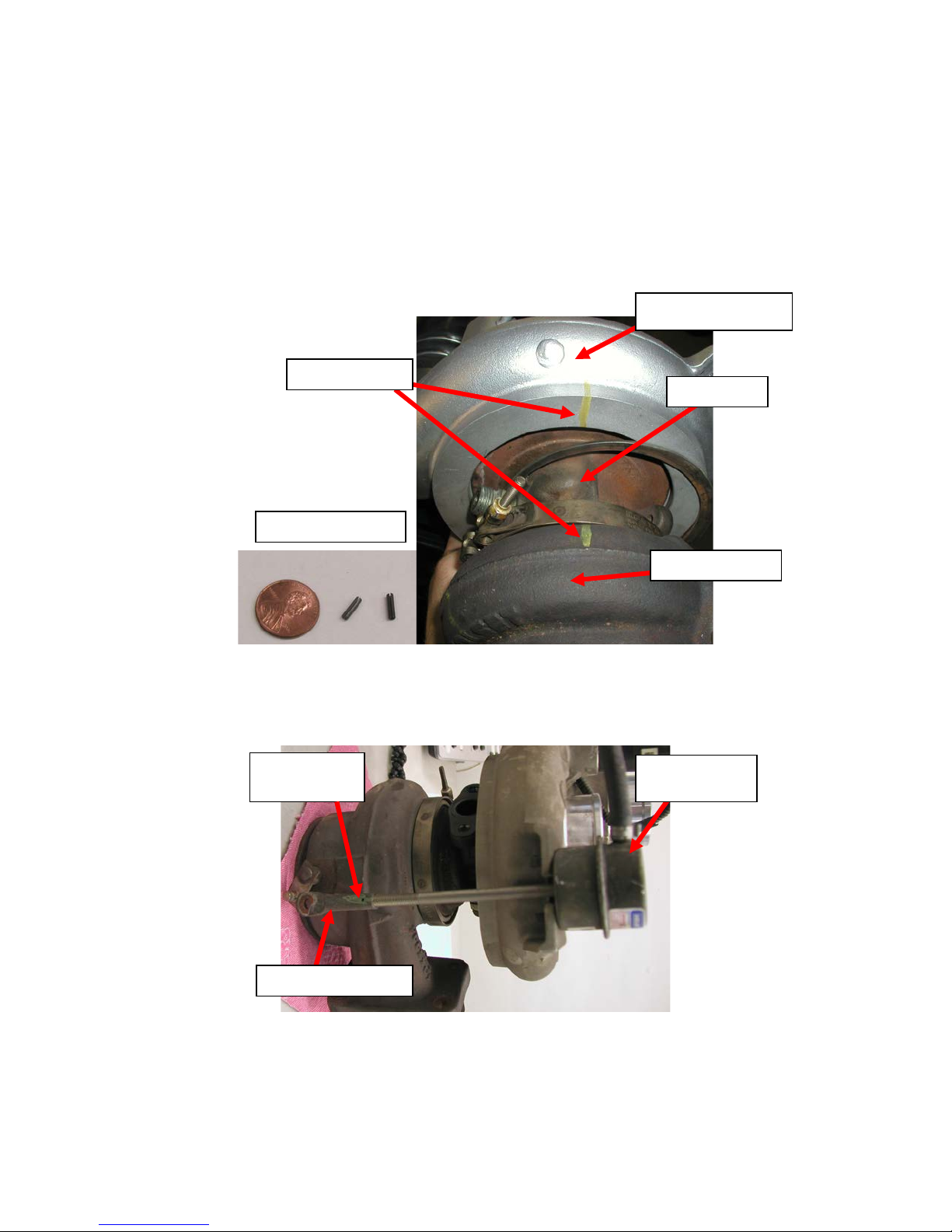

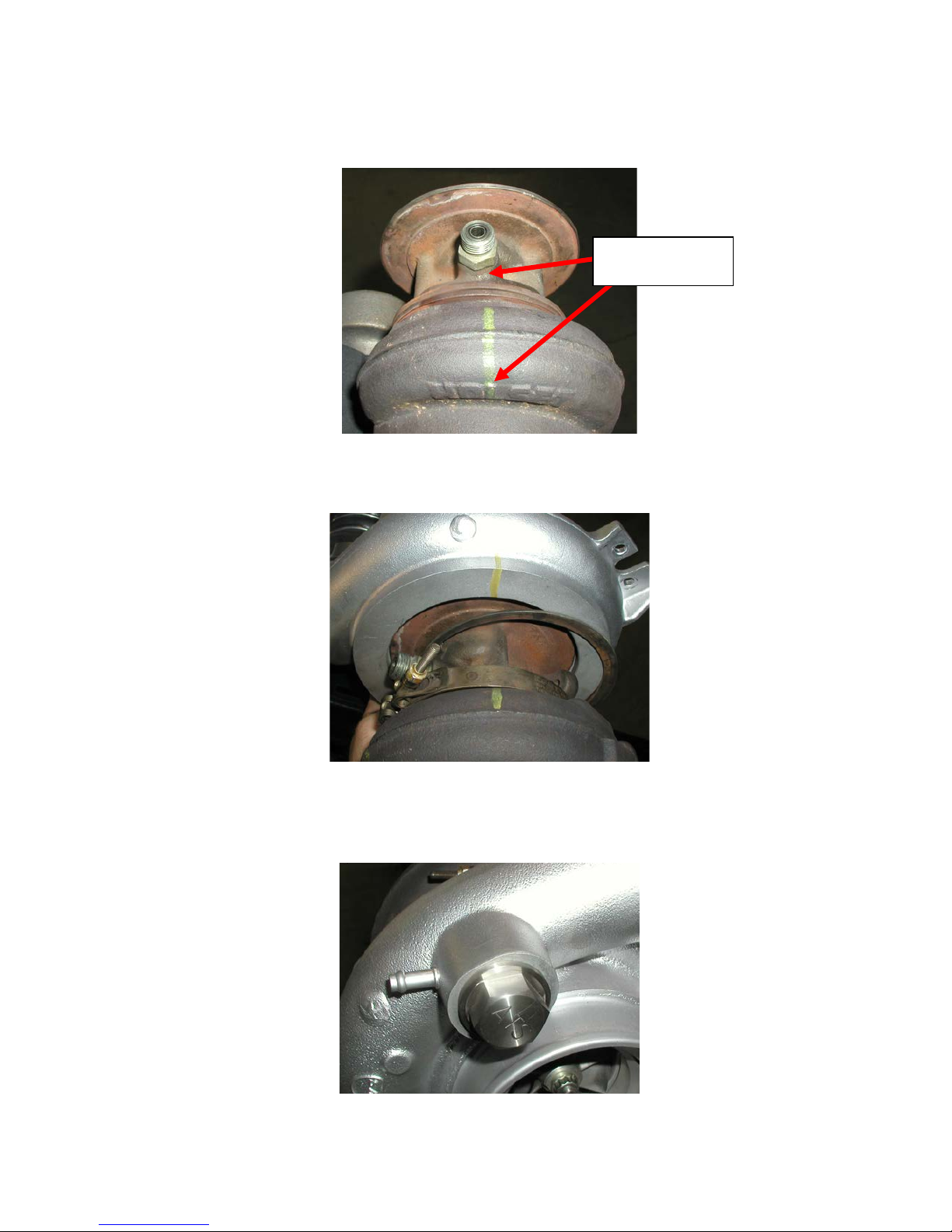

Modifying the Factory Turbo:

1. The factory turbo cartridge must be clocked (rotated) in order to correctly

mount the assembly in the new location. The oil drain must be at the

bottom of the cartridge when the turbo is installed on the ATS manifold.

To do this, the alignment pins inside on the cartridge flanges must be

removed. To access the pins, the turbine and compressor housings must

be removed from the turbo cartridge. Before disassembling the stock

turbo, make two indexing marks on the turbine housing and the

compressor housing so they can be realigned.

2. Remove the wastegate valve actuator by removing the e-clip that retains

the rod on the lever and the two nuts that hold the actuator on the

compressor housing. Disconnect and discard the rubber hose.

3. The factory preload on the Wastegate adjustment rod is set to 1/16” on

03-04 trucks and .1/4” on 04.5-07 trucks. The Aurora Plus – 5000 system

operates best when preload is set to .312” (5/16”). To allow for

adjustment of the preload, drill out the small notch on the wastegate clevis

Thread Lock

Punch

Compressor Housing

Cartridge

Turbine Housing

Indexing Marks

Wastegate

Actuator

Alignment Pins

Wastegate Clevis

to remove the thread lock punch. Do not use a drill bit larger than .125”.

Drill deep enough to allow the clevis to break the lock on the threaded rod.

Do not drill completely through the rod.

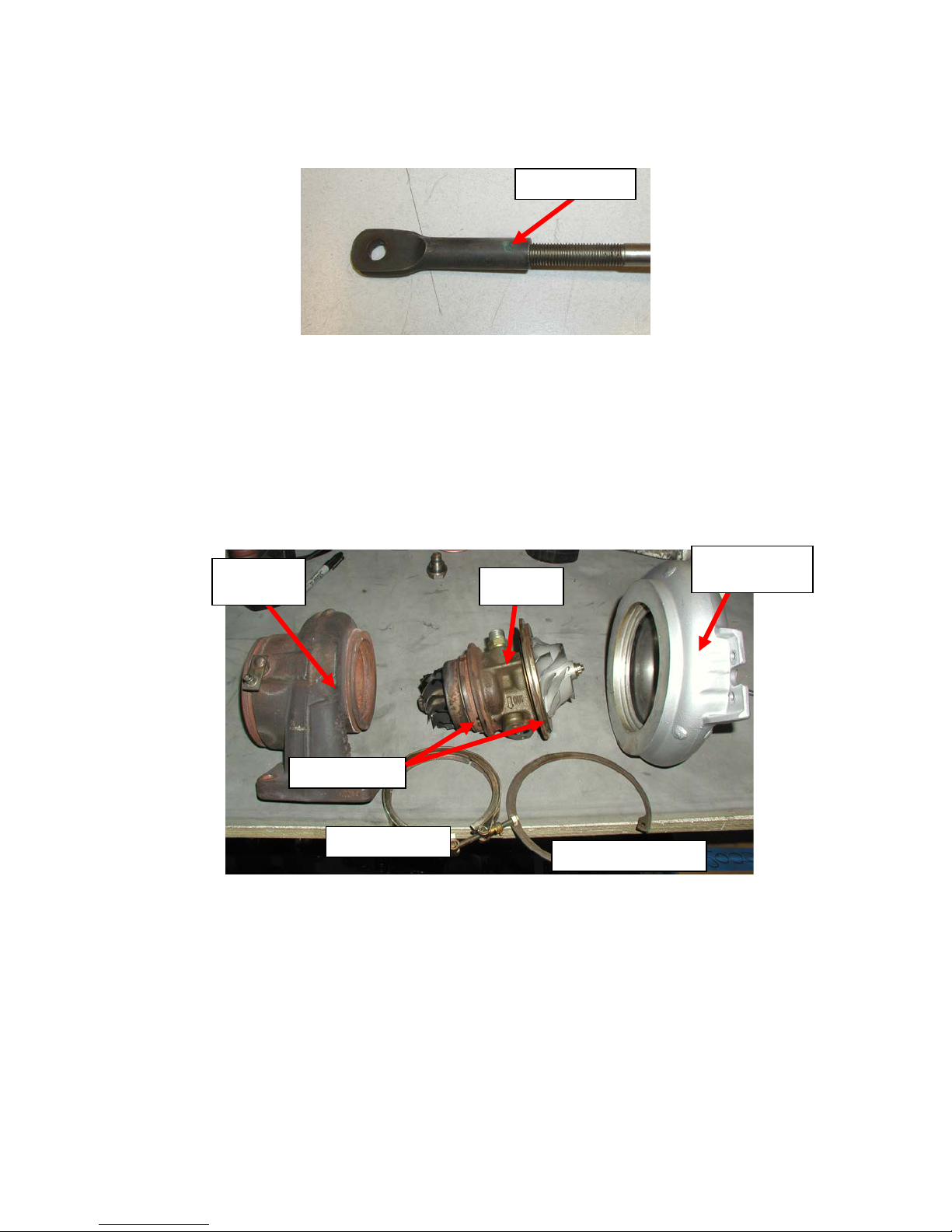

4. After the thread lock punch is drilled out. Remove the clevis and thread

on the 5/16-24 lock nut supplied with the kit. Thread on the clevis, but

leave the lock nut loose to allow for adjustment later.

5. Remove the turbine housing by loosening the v-band clamp on the

cartridge. While wearing safety glasses, remove the compressor housing

using a large set of snap-ring pliers to release the internal snap-ring in the

housing rim. Adequate snap-ring pliers are available through ATS.

6. Remove the alignment pins from both sides of the cartridge. Discard the

alignment pins.

Drill Here

Cartridge

Compressor

Housing

Turbine

Housing

Internal Snap Ring

V-Band Clamp

Locating Pins

7. Remove the two 10mm studs using a set of vise-grip pliers.

8. Drill out the two threaded holes using a 7/16” drill bit. Remove all burrs

after drilling.

9. The factory Wastegate hole measures .710” on the HX35 (03-04 trucks)

turbine housing and .840” on the HY35 (04.5-07 Trucks). To maintain

safe drive pressures (exhaust manifold pressure) this hole must be bored

out to 1”. Use a die grinder with the carbide burr to enlarge this hole.

Keep the hole as round and centered as possible. Drilling or milling the

hole will provide the best finish, but a die grinder will work.

10.Reinstall the turbine housing and locate the oil feed fitting as shown in the

picture below. Align the oil feed fitting with the letter “L” in the “Holset”

name on the turbine housing.

11.Reinstall the compressor housing. Use the indexing marks applied in step

1 to correctly align the compressor housing with the turbine housing.

12.(04.5-07 Trucks only) Install the Wastegate solenoid plug-cap (Figure 2,

#7) into the compressor housing. Make sure there are three o-rings on

the plug.

Oil Feed Fitting

Alignment

13.(03-04 Trucks only) Remove the brass 90°fitting and rubber hose from the

front of the compressor housing. Install the 1/8NPT plug (Figure 2, #16)

supplied in the kit.

14.Remove the oil feed fitting located on the top of the cartridge. Install the

provided 12mm to JIC-4 fitting with one 12mm o-ring (Figure 2, #10).

15.For optimal performance, set the Wastegate preload to .312” (5/16”);

exactly 7.5 turns of the clevis. Thread the clevis out until it slides on the

pin easily, then turn the clevis back 7.5 turns to set the preload. Too

much preload will cause high EGT’s and too little will cause slow throttle

response. Once the preload is correctly set pull the clevis onto the lever

pin. Tighten the lock nut. Secure the clevis on the lever using the original

e-clip.

5/16” Gap (7.5 turns)

Lock Nut

16.Make sure the Wastegate control rod is aligned correctly as shown. The

picture below shows the factory turbo ready to be used on the Aurora Plus

system.

Installing the Aurora Plus – 5000 Compound System

1. Remove the plug from the auxiliary oil drain port located on the side of the

engine block just above the oil pan on the passenger side. Use a hammer

and a flat tip punch to turn the plug by tapping it on one side. Do not hit

the plug in the center. Once turned, grab the exposed plug edge with a

set of vise-grip pliers and remove it from the engine block.

2. Once the factory turbo and ATS manifold are installed, there is not

enough room to get the Aurora 5000 installed in the proper location

without removing the battery. To avoid having to remove the battery, set

the Aurora 5000 charger into the passenger side of the engine

compartment. Rest the turbo on the frame in a secure position.

3. Place the ATS 3-piece manifold onto a work bench. Install the factory

turbo on the ATS manifold using the provided turbo flange gasket (Figure

1, #27). The factory turbo does not provide much clearance for the inner-

rear nut. A standard nut (Figure 2, #2) with a serrated washer provides

Aux. Oil Drain Port

the best clearance for a wrench in this location. Install this nut first by

holding the turbo just off and while turning the nut lower the turbo onto the

studs. Install the three serrated flange hex nuts and use three more

serrated washers. Tighten all four in a crisscross pattern.

4. Modify the factory exhaust-manifold-heat-shield by trimming off the

section behind the first two sets of manifold bolts so that it can be

reinstalled with the ATS exhaust manifold.

5. Install the ATS manifold and factory turbo assembly onto the engine block

using the six gaskets provided (Figure 1, #28) in the kit and the trimmed

heat-shield.

6. Install the compound exhaust elbow (Figure 1, #12) onto the factory turbo.

Align the pins on the exhaust elbow with the holes on the factory turbo.

Use the supplied 4” v-band clamp (Figure 1, #19) to secure the exhaust

elbow in place.

7. Once the exhaust elbow is in place, use (4) flange hex nuts, (4) serrated

washers, and the gasket supplied (Figure 1, #28) in the kit to connect the

Aurora 5000 turbo to the exhaust elbow. Use a small amount of heavy

grease to hold the gasket in place while lifting the Aurora 5000 up to the

exhaust elbow.

8. Use the three supplied 8mm hex flange bolts to attach the supplied heat

shield (Figure 1, #8) to the rear of the exhaust elbow.

Inner-Rear HoleAlignment Pin Holes

Alignment Pins

Installed

Inner-Rear Nut

9. Connect the factory oil drain tube to the Aurora 5000 using the gasket

provided in the kit (Figure 1, #25) and the two 8mm x 20 bolts (Figure 2,

#12).

10.Route the supplied long drain tube (Figure 1, #17) from the front oil drain

port up to the factory turbo charger. Try to route the drain tube as close to

the engine block as possible to make room for the intake tube.

11.Install the intake tube (Figure 1, #13) using one 5.5” and one 4.5” clamp

provided. Use the 4” coupler (Figure 1, #7) provided to connect the

compact 90°boot (Figure 1, #6) and the 4” intake tube (Figure 1, #13).

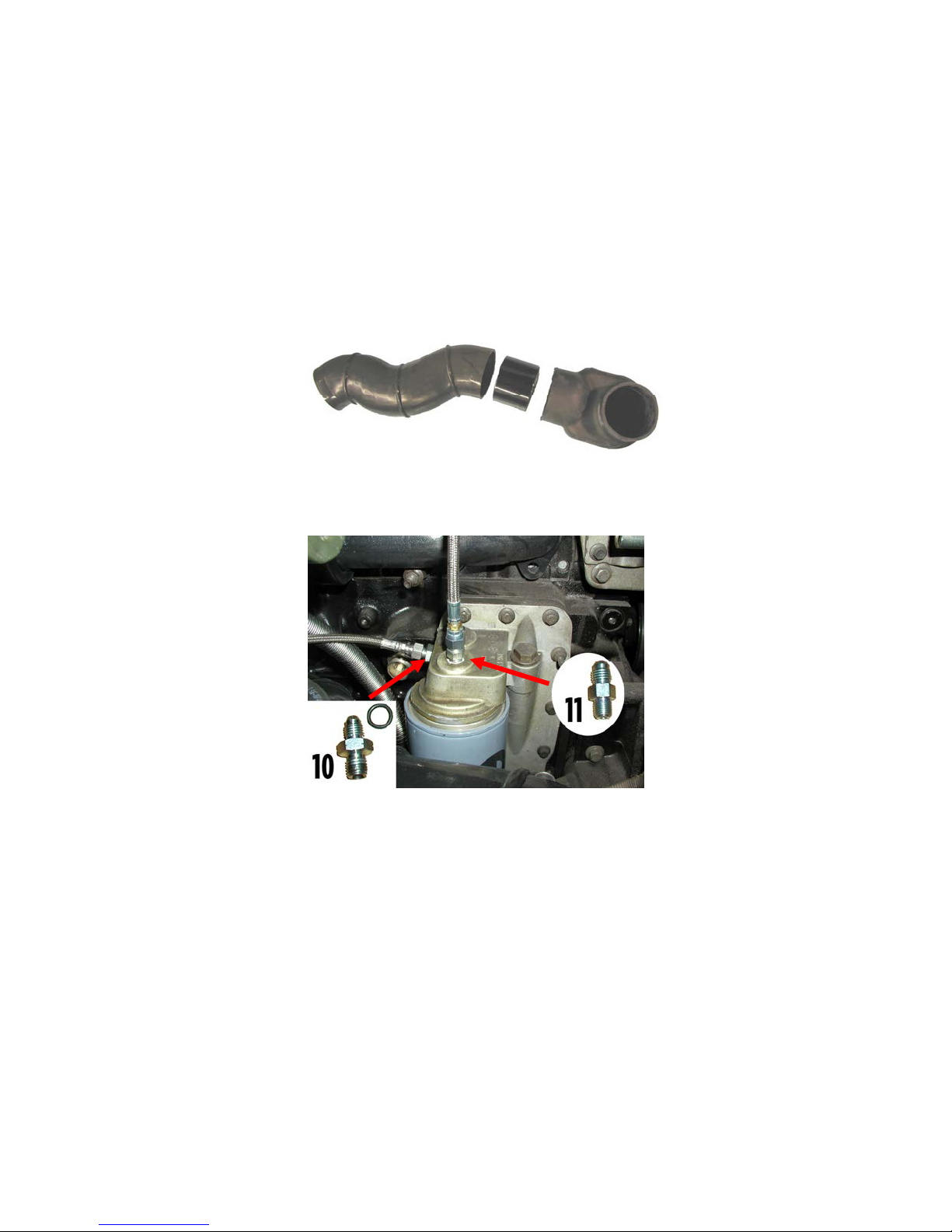

12.Remove the factory oil feed fitting from the side of the oil filter housing

and remove one of the plugs from the top of the oil filter housing.

13.Install the supplied 14mm to -4 JIC (Figure 2, #10) oil feed fitting into the

side of the filter housing and the 1/8NPT to -4 JIC (Figure 2, #11) oil feed

fitting into the top of the filter housing.

14.Install the supplied 14” oil feed line (Figure 1, #16) from the filter housing

to the oil feed fitting on the Aurora 5000. Route the oil feed line away

from the exhaust manifold. Connect the 45°fitting to the Aurora 5000.

15.Install the supplied 17” oil feed line (Figure 1, #15) from the fitting on top

of the filter housing to the oil feed fitting on the factory turbo. Route the oil

feed line away from the exhaust manifold and turbine housing. Connect

the 90°fitting to the factory turbo.

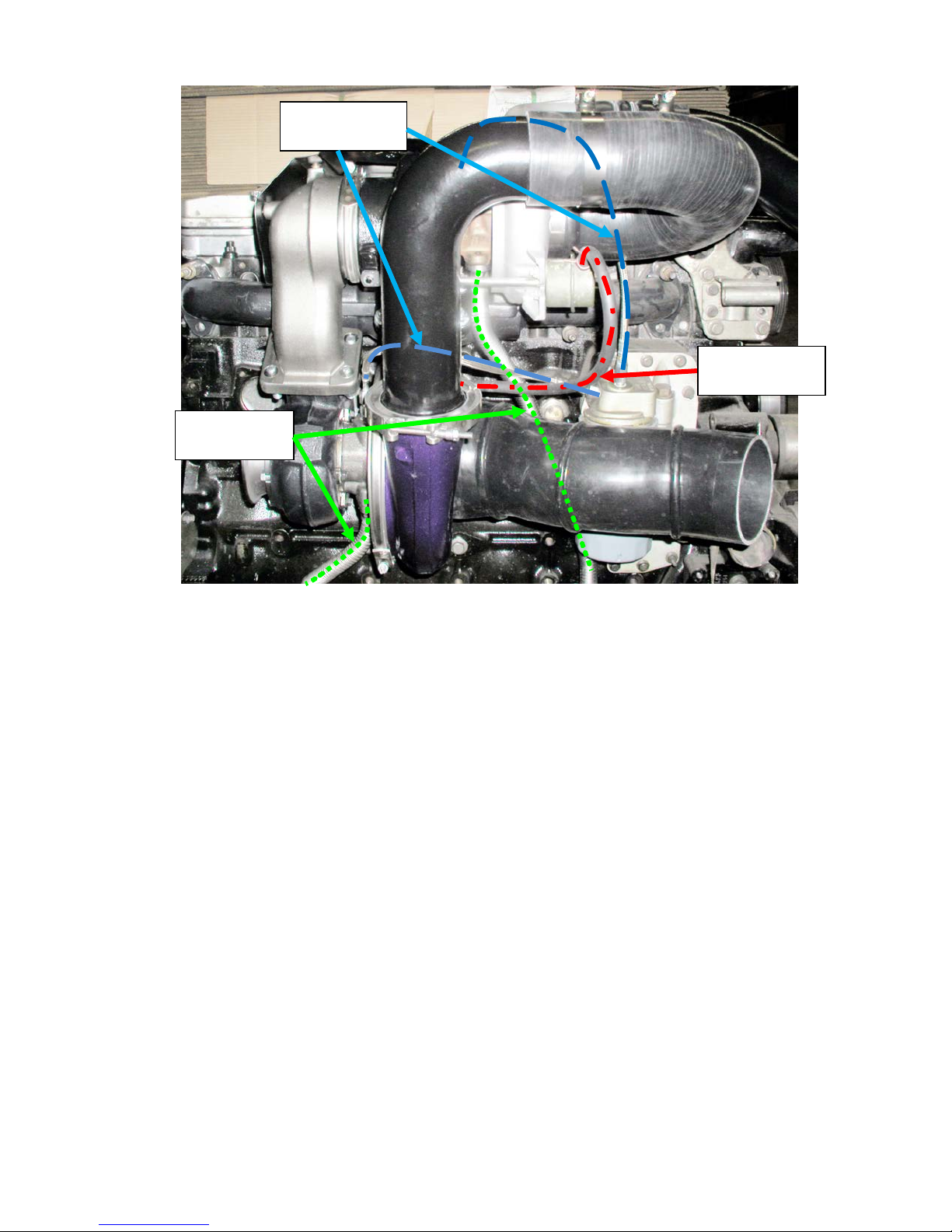

Figure 3: Line and Drain Tube Routing

16.Connect the Wastegate actuator to the port on the Aurora 5000

compressor housing using the ¼” rubber line and two hose clamps (Figure

2, #15) supplied in the kit. The red dashed line in Figure 3 shows the

correct routing.

17.Install the 90°intermediate pipe (Figure 1, #11) onto the compressor

housing of the Aurora 5000 using the o-ring and smaller v-band clamp

(Figure 1, # 26 and # 20). The o-ring goes between the flange on the

Aurora 5000 and the flange on the 90°pipe.

18.Push the 180°silicone hose onto the 90°pipe and align it with the inlet of

the factory charger. Use a 3.5” T-bolt clamp (Figure 1, #22) and a 4.5” T-

bolt clamp (Figure 1, #21) to secure the hose in place.

Note: Make sure both clamps are tight and seated behind the ribs on the

pip and factory charger inlet. If the clamp is tightened on top of the inlet

or pipe rib, the 180°hose may blow off during driving.

19.Install the 2.75” to 3” reducer hose (Figure 1, #9) on to the outlet of the

factory charger using the original 3.25” T-bolt clamp.

20.(2007 Trucks only) The engine lift mount located on the engine block

behind the alternator will have to be replaced with bracket (Figure 1, #18)

Drain Tubes

(green)

Oil Feed Lines

(blue)

Wastegate Line

(red)

provided in the kit to make room for the turbo-to-intercooler charge pipe.

Install the bracket by removing the alternator and bolts that secure it to the

block.

21.Install the 2-bend silicone (Figure 1, #10) elbow onto the intercooler inlet.

The A/C line that is connected to the A/C compressor and the condenser

must be routed on the driver’s side of the 2-bend silicone elbow.

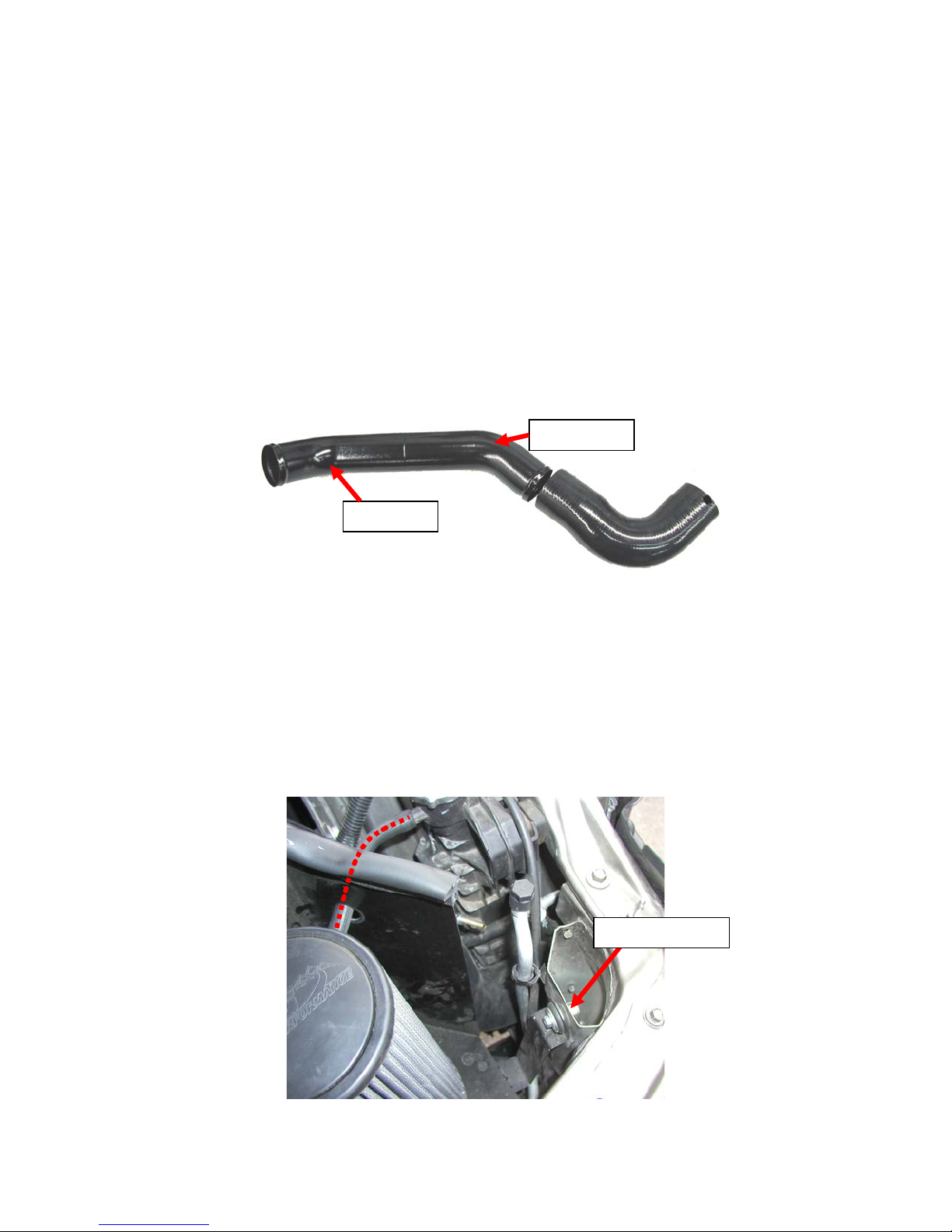

22.Install the charge tube (Figure 1, #14) with the 41°bend connected to the

2-bend elbow and the 50°bend connected to the reducer boot on the

factory charger.

Note: The 2-bend elbow supplied with this kit will fit intercoolers with 3”

inlets only. If the truck is equipped with an after-market intercooler that

has 3.5” inlets please order P/N 2272-202-026 from ATS Diesel.

23.Install the ATS air box (Figure 1, #1) by setting the enclosure into the

rubber mounts on the battery tray. To connect the 90°compact boot,

reach through the opening in the base of the enclosure and pull the

compact 90°boot up and onto the air box enclosure. Tighten the 4” hose

clamp to secure it in place.

24.Use the 6mm x 25mm (Figure 2, #8) bolt supplied in kit to secure the air

box mount to the fender support through the grommet removed from the

factory air box.

Air Box Mount

41°Bend

50°Bend

25.Route the radiator overflow line through the air box grommet and

reconnect it to the radiator fill spout.

26.Install the air filter (Figure 1, #5) provided in the kit and secure it using a

4” clamp.

27.Install the IAT sensor into the side of the ATS air box using the 10-¾”

sheet metal screws provided.

28.Connect the exhaust system to the Aurora 5000 turbine housing using the

factory components.

29.Install the Map Sensor Voltage Cap (Boost Fooler) (Figure 2, #14) by

following the instructions included in the hardware kit for the 03-07 Dodge.

The MAP sensor is located on the driver side of the engine head, on top

of the intake plenum cover.

30.Double check all T-bolt clamping points to make sure the clamps are

secure and properly seated. Reconnect the batteries.

Bill of Materials

1. Air Box Enclosure 206-030-2272

2. Silicone 180°Hose 202-040-2164

3. 2.75” to 3.00” Reducer Boot 202-017-2272

4. 3-Piece 24V Manifold 204-930-2218

a. (1) 1.625” x M10-1.5 stud installed

b. (3) 2” x M10-1.5 stud installed

5. ATS Air Filter w/ 4” Clamp 206-410-1000

6. 4” 90°Compact Rubber Boot 90CB40

7. 4” Intake Tube Connector (4in OD X .065 X 4”) 206-005-1000

8. Heat Shield, Exhaust Elbow 202-043-2272

9. Aurora 5000 Turbo Assembly 202-501-1000

10. 3” 2-Bend Elbow 202-025-2272

a. (not included unless specified with original order, use with 3.5”

intercoolers) 3” to 3.5” 2-Bend Elbow 202-026-2272

11. 90°5000 Intermediate Pipe 202-005-2272

12. Plus Compound Exhaust Elbow 202-042-2272

a. (2) alignment pins 98296A122

b. (4) 2” x M10-1.5 stud installed

13. 5” to 4” Reinforced Silicone Intake Tube 202-070-2272

14. CR Charge Pipe (turbo to intercooler) 202-006-2272

15. 17” Oil Feed Line 202-028-2164

16. 14” Oil Feed Line 202-046-2272

17. 22” Flexible Drain Tube 3934084

18. (2007+ Only) Engine Lift Bracket 5086831AA

19. 4.4” V-band Clamp 3535399

a. ¼-28 Lock Nut

20. 4.2” V-band Clamp 134348

a. ¼-28 Lock Nut

21. 4.5” T-Bolt Clamp 94100-0450

22. (3) 3.5” T-Bolt Clamp 94100-0350

23. (1) 5.5” Worm Drive Hose Clamp SS-88

24. (3) 4.5” Worm Drive Hose Clamp ET-72

25. (2) Gasket, Oil Drain Flange 3937706

26. 3.52” O-ring AS568-235

27. (2) Gasket, Exhaust Flange (open) 3919369 or 196570

28. (6) Gasket, Exhaust Manifold Flange 3946275

Aurora Plus Hardware Kit

1. (7) M10-1.5 Serrated Flange Hex Nut

2. (1) M10-1.5 Standard Hex Nut

3. (2) #10 x 3/4” Sheet Metal Screws 90054A245

4. Extra 7/32” e-clip 98407A122

5. (8) 10mm Serrated Belleville Washer 93501A031

6. (3) M8-1.25 x 12 Flange Bolts

7. Wastegate Solenoid Plug-Cap 202-003-2272

a. 10mm O-ring 9263K143

b. 11mm O-ring 9263K623

c. 20mm O-ring 9263K305

8. 6mm-1.0 x 25mm Hex Head Flange Bolt 98093A445

9. 5/16-24 Hex Nut

10. (2) Oil Feed Fitting (12mm to JIC-4) 30J041215R

a. (2) O-ring 9262K671

11. Oil Feed Fitting (1/8NPT to JIC-4) 4FTX-S

12. (2) M8-1.25 x 20 Flange Bolts

13. Wastegate Solenoid Harness Jumper 202-010-2272

14. Map Sensor Voltage Cap (Boost Fooler)

a. (3) section of heat shrink

b. (3) non-insulated butt connector

c. ring terminal

15. 16” Section of 1/4” rubber line

a. (2) spring clamp for ½” OD hose 5324K12

16. 1/8NPT Pipe Plug 50785K918

Not Pictured:

1. Optional: Internal Snap Ring Pliers 5449A98

2. Instruction Manual: 202-952-2272-INST

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction