PRODUCT DESCRIPTION

1. Product Description

The MP3 chassis is a 3RU design that comes in both a passive and active conguration. Both congurations include options

for dual cable management bars and a large cable management tray as well as user congurable horizontal and vertical

cable management systems. The MP3 active chassis also include a ber management tray that can be congured into two

positions.

The passive and active chassis’ can accommodate up to 24 single-width passive modules (DC Logic A/B RF Switch; 2,

4, 8, dual 4-way and triple 2-way splitters\combiners; DC & triple DCs) or up to 12 dual-width modules (16-way splitter\

combiners).

The active chassis can accommodate all the modules that a passive chassis can, but also up to 12 dual-width active modules

(amplier, power supply, optical receiver\transmitter, RF Switch).

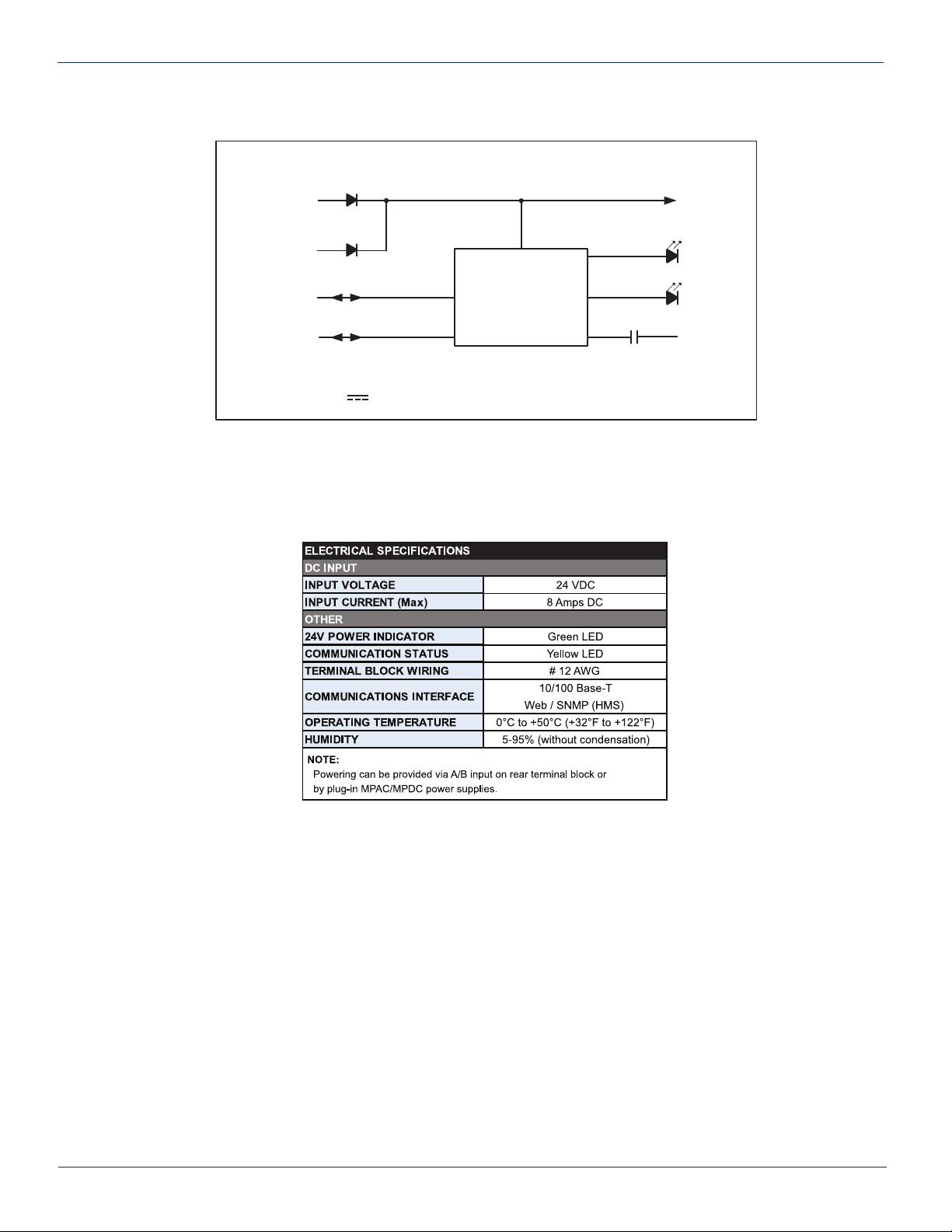

The active chassis comes with a +24 VDC power interface backplane/rail and a removable communications module that

draws power from the rail. This communications module can be removed without affecting the operation of the modules in the

chassis by removing the two Phillips screws on either side that fasten it to the chassis. All active modules are hot-swappable.

Power is supplied to the backplane by installing an MPAC or MPDC power supply into one of the chassis slots or by remotely

powering the chassis from an external 24 VDC supply. The MP3 active chassis is equipped with an HMS compliant SNMP

management system. An RJ-45 port is used for both set-up and status monitoring. No custom software is required.

Please refer to the web page for up-to-date specications – www.atxnetworks.com

__________________________________________________

1Provided that the chassis is not being solely powered via the terminal block on the comm module, there would simply be no alarms and no remote

adjustment of parameters. The modules would continue to run with the last set values.

2It is not recommended to hot swap a power supply module into a full chassis if there is no other power supply present. The current surge to supply a

full rack of active modules would be stressful on the electrical contacts during mating and may reduce the lifespan of the chassis and power supply. It

is recommended that you install the power supply rst, then apply AC or DC input to the power supply connector.

MAXNET®II – MP3 Active / Passive Chassis – Installation & Operation Manual 1-1

CHAPTER 1: PRODUCT DESCRIPTION

Table #1: Ordering Information

(See http://www.atxnetworks.com/pdf/ANW0614_MNII_ChassisCableOptns.pdf

for photos of various options)

MP1 1RU Passive Chassis with Cable Management Bar

MP3B 3RU Passive Chassis with Dual Cable Management Cable Bars

MP3H 3RU Passive Chassis with Configurable Horizontal Channel Cable Management

MP3V 3RU Passive Chassis with Configurable Vertical Channel Cable Management

MP3T 3RU Passive Chassis with Large Cable Management Tray

MP3R 3RU Passive Reverse Chassis

MP3BA 3RU Active Chassis with Dual Cable Management Cable Bars

MP3RA 3RU Active Reverse Chassis

MP3HA 3RU Active Chassis with Configurable Horizontal Channel Cable Management

MP3VA 3RU Active Chassis with Configurable Vertical Channel Cable Management

MP3TA 3RU Active Chassis with Large Cable Management Tray

MPRB Round Cable Management Steel Bar

MPBAR Flat Cable Management Steel Bar

MPFT Fiber Management Tray (includes 12 push fit plastic fiber guides) for 3RU Chassis

MPLT Large Cable Management Tray (includes clips)

MP3FA 3RU Active Chassis for F Connector Optics Platform (includes rear rails for patch

panels & front fiber tray)

MP3FA-COM Replacement Communication Module for MP3FA

MP3FA-T Replacement Fiber Management Tray for MP3FA

MPHKIT Configurable Horizontal Channel Cable Management Kit