Contents

Planning the installation.........................................................................5

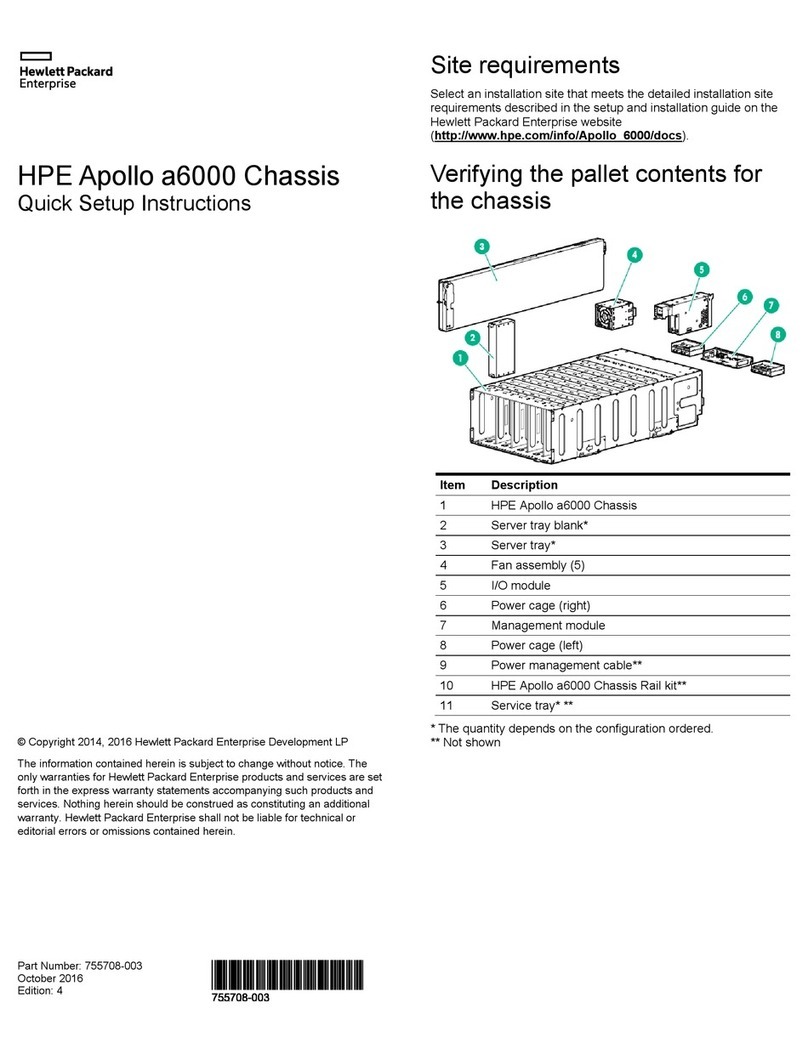

Verifying the pallet contents.......................................................................................................... 5

Warnings and cautions..................................................................................................................6

Space and airflow requirements................................................................................................... 7

Temperature requirements............................................................................................................7

Power requirements......................................................................................................................8

Grounding requirements............................................................................................................... 8

Identifying components and LEDs........................................................ 9

Front panel components............................................................................................................... 9

Storage display LEDs.........................................................................................................9

Server front panel components........................................................................................ 10

Server front panel LEDs and buttons............................................................................... 11

Rear panel components..............................................................................................................12

Power supply LEDs .........................................................................................................12

Management module components...................................................................................13

Management module LEDs..............................................................................................14

I/O module components................................................................................................... 14

I/O module LEDs..............................................................................................................15

PCIe slot definitions (standard I/O module)..................................................................... 15

PCIe slot definitions (I/O module with x16 riser option)................................................... 16

HPE Smart Array P440 Controller port identification....................................................... 18

HPE Smart Array P840 Controller port identification....................................................... 18

HPE H240 Smart Host Bus Adapter port identification.................................................... 19

I/O module power connector identification....................................................................... 19

LFF drive bay numbering............................................................................................................ 20

LFF drive LED definitions............................................................................................................20

Optional 8LFF drive cage bay numbering...................................................................................22

Installing the chassis............................................................................23

Setting up and installing the chassis...........................................................................................23

Disassembling the chassis..........................................................................................................23

Installing the chassis into the rack.............................................................................................. 27

Installing the system components into the chassis..................................................................... 30

Installing a server............................................................................................................. 30

Installing a hot-plug drive................................................................................................. 31

Installing a flex slot power supply.....................................................................................32

Installing the system fan...................................................................................................33

Installing a management module..................................................................................... 34

Installing the expansion board......................................................................................... 34

Installing an I/O module................................................................................................... 36

Installing the HPE Smart Storage Battery option............................................................. 37

Cabling and powering up the chassis.................................................39

Cabling the chassis.....................................................................................................................39

Installing the cable management arm.............................................................................. 39

3