5

Contents

1 Introduction ................................................................................ 6

2 Safety Instructions .................................................................... 6

3 Product........................................................................................ 7

3.1 General Description ............................................................ 7

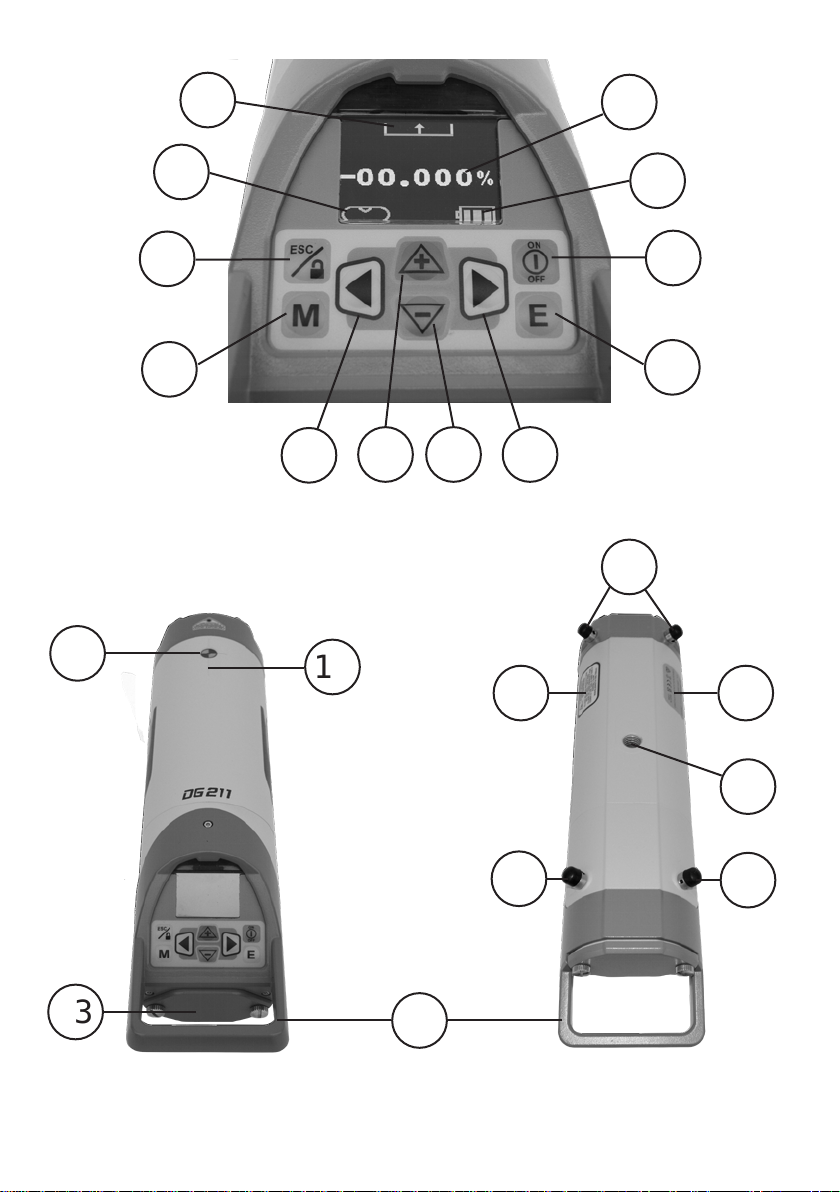

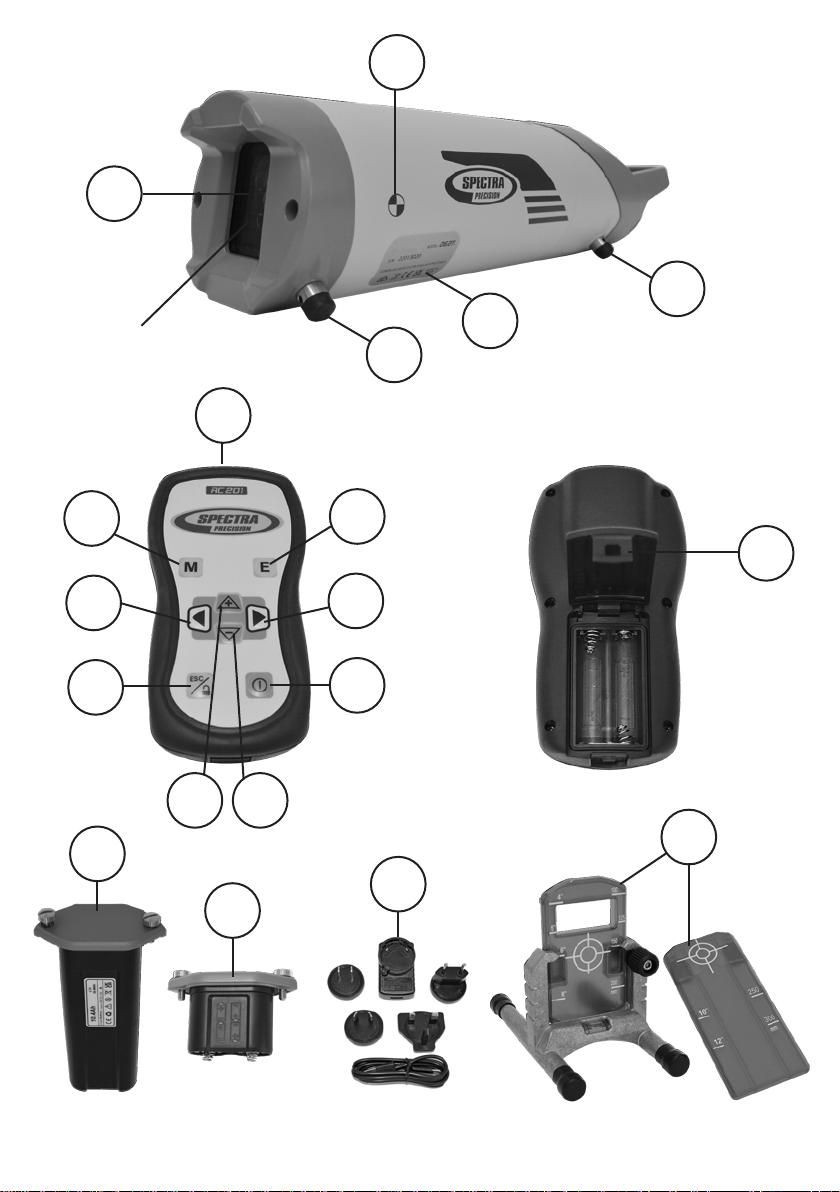

3.2 Product Components .......................................................... 8

3.3 Installing The Batteries ...................................................... 9

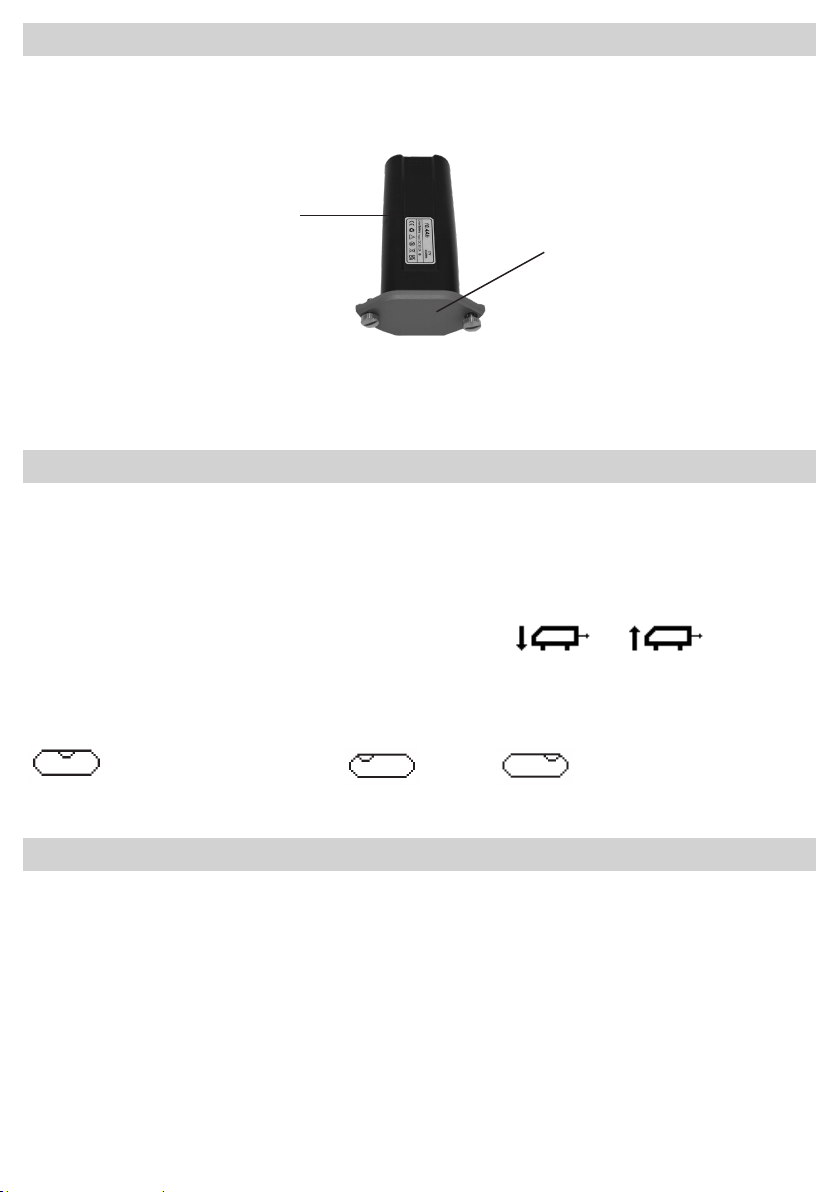

3.4 Battery Status Indication................................................... 9

3.5 Recharging The Batteries................................................... 19

3.6 Battery Door ........................................................................ 10

3.7 Laser Setup .......................................................................... 10

3.8 Turn On/O The Laser ........................................................ 10

3.9 Grade Entry With Digit Select Mode ................................. 11

3.10 Grade Entry With Step & Go Mode .................................... 11

3.11 Laser Alignment................................................................... 12

3.12 Center Laser......................................................................... 12

3.13 Manual Mode........................................................................ 12

3.14 Lock Keypad ......................................................................... 13

3.15 Roll Alert............................................................................... 13

3.16 Standby Mode...................................................................... 13

4 Check Calibration....................................................................... 14

4.1 Check Level Accuracy ......................................................... 14

4.2 Check Grade Accuracy........................................................ 15

5 Cleaning And Maintenance ....................................................... 16

6 Protecting The Environment..................................................... 16

7 Warranty...................................................................................... 17

8 Technical Specication.............................................................. 18

8.1 Technical Specication Laser DG211................................. 18

8.2 Technical Specication Remote Control RC201 .............. 18

9 CE Declaration Of Conformity .................................................. 19

10 UKCA Declaration Of Conformity............................................. 19

11 Service And Customer Advice .................................................. 19