10

PSP3090357 Rev. Q

DISASSEMBLY INSTRUCTIONS

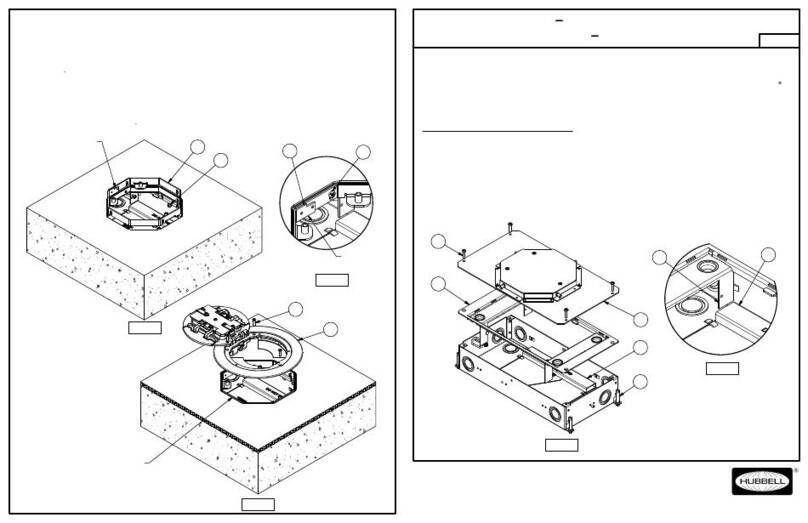

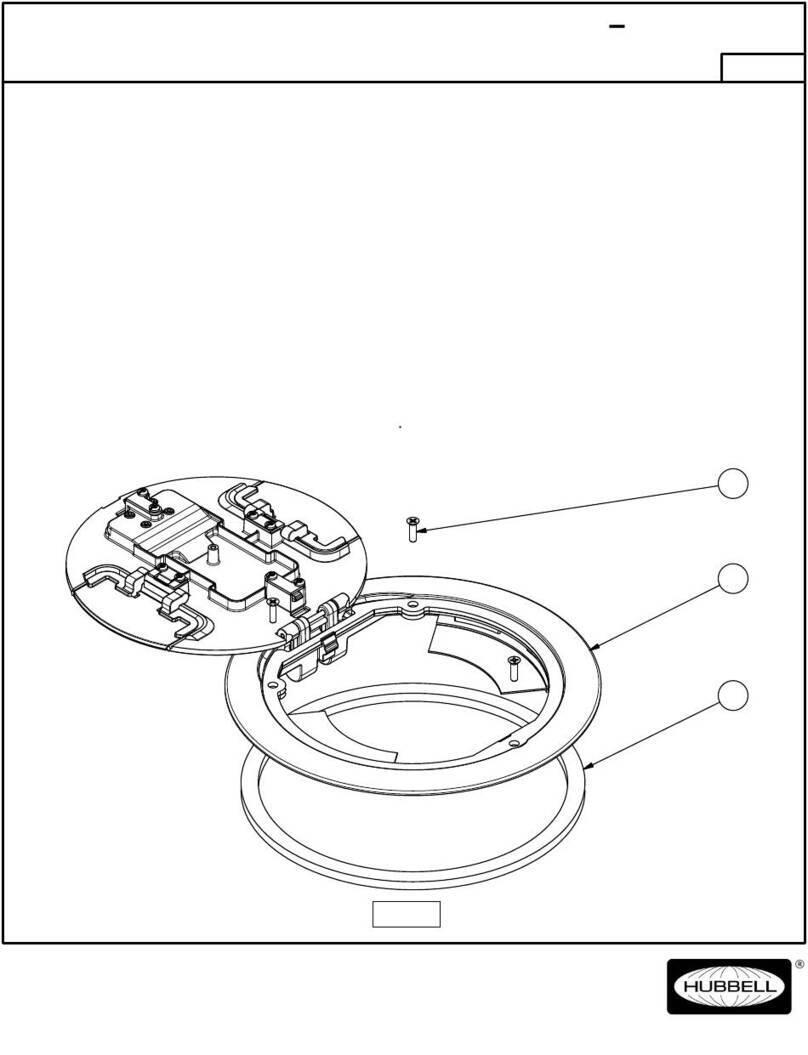

In order to best visualize these instructions, study and refer to the exploded view of the hoist and parts list.

1. Remove snap ring from shaft.

2. Push "Release Key" located in the indented area of the handle in the direction marked "Release" to

disengage the working pawl from the unloader plate and lift handle o the shaft. This will expose the

mechanism.

3. The working pawl, in the handle, may be removed by first removing the screw and washer from the post

supporting the pawl. The torsion spring may be removed after the pawl has been removed.

4. When reassembling working pawl and spring, place the short leg of the spring against the pin on the pawl,

and the long leg of the spring against the handle housing. This should move the pawl towards the center of

the housing.

5. If necessary to replace the pawl post or release key, remove nut, press the pawl post out of housing with

a careful and steady force. When replacing the new pawl post, be certain it is pressed in straight, using an

even pressure, and that the release key is in position before pressing post into housing. Install nut, tighten

securely.

6. The holding pawl on the main body can be removed by unhooking the two extension springs from the

unloader plate and from screw in the housing. Remove snap ring and slide unloader plate o shaft after

which pawl can be lifted o post.

7. When replacing the holding pawl, make sure the pin which is permanently secured to the pawl is faced to

the outside, so that it projects through the hole in the unloader plate.

8. To remove ratchet shaft, remove hand wheel roll pin, hand wheel and snap ring. Then remove two web

anchor screws, web clamp and nylon web assembly. Next, remove the spool by driving out pin. Shaft will

now slide out of the housing.

9. If the top hook or safety latch is damaged, the hook/housing must be replaced as a unit. The new housing

has all required bearings installed.

10. The Up & down lever (shift key) is removed by removing the roll pin holding the reversing rod to the shift

key.

11. The oilite bearings can be replaced in the accepted practice of pressing them out and pressing the new

ones in, using appropriately sized bushing drivers.

! WARNING

• Do not attempt to clean the strap. If the strap is dirty or contaminated, it must be replaced.

• Always wear safety glasses and other appropriate protective equipment during the following

procedures. Use the correct tools for the operations being performed.