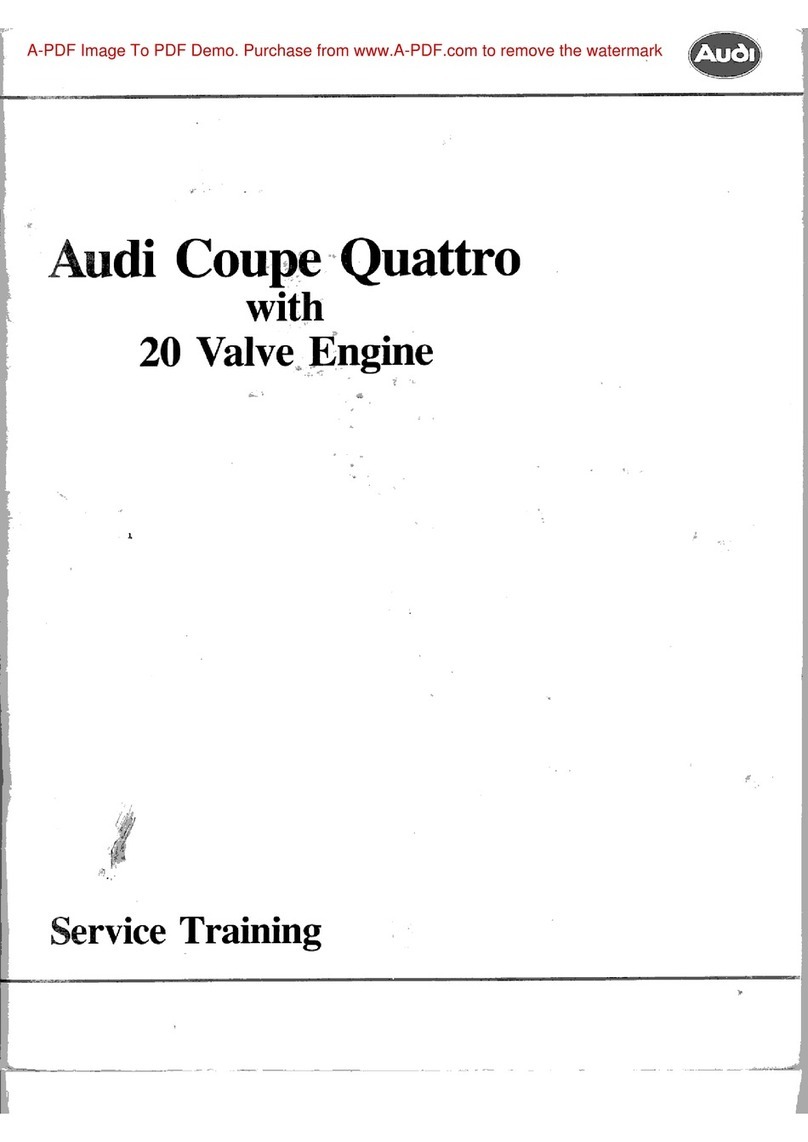

10

The degree of damping of the vibration

damper has no significant influence on the

value of the natural frequency of the

bodywork. It influences only how quickly the

vibrations cease (damping coefficient). For

further information, see chapter “Vibration

damping”.

Matching of the natural frequency of the

bodywork

The axle loads (sprung masses) of a vehicle

vary, at times considerably, depending on the

engine and equipment installed.

To ensure that the bodywork height

(appearance) and the natural frequency of the

bodywork (which determines the driving

dynamics) remains practically identical for all

vehicle versions, different spring and shock

absorber combinations are fitted to the front

and rear axles in accordance with the axle

load.

For instance, the natural frequency of the

bodywork of the Audi A6 is matched to 1.13Hz

on the front axle and 1.33Hz on the rear axle

(design position).

The spring rate of the springs therefore

determines the value of the natural frequency

of the bodywork.

The springs are colour-coded to differentiate

between the different spring rates (see table).

Principles

For standard running gear without self-

levelling, the rear axle is always

matched to a higher natural frequency

of the bodywork because when the

vehicle is loaded, it is principally the

load to the rear axle which increases,

thus reducing the natural frequency of

the bodywork.

242_073

Vehicle heightNatural frequency of the bodywork

Component tolerance band

Natural frequency tolerance band

Usable load range

of a spring

Height tolerance

Axle load800 kg 850 kg 900 kg 950 kg

1.13 Hz

c

F1

= 33.3 N/mm

c

F2

= 35.2 N/mm

c

F3

= 37.2 N/mm

c

F4

= 39.3 N/mm

c

F5

= 41.5 N/mm

c

F6

= 43.7 N/mm

Spring rate levels of the front axle for the A6