Audipack DWS-120 E User manual

Other Audipack Lifting System manuals

Audipack

Audipack FWS-7075V User manual

Audipack

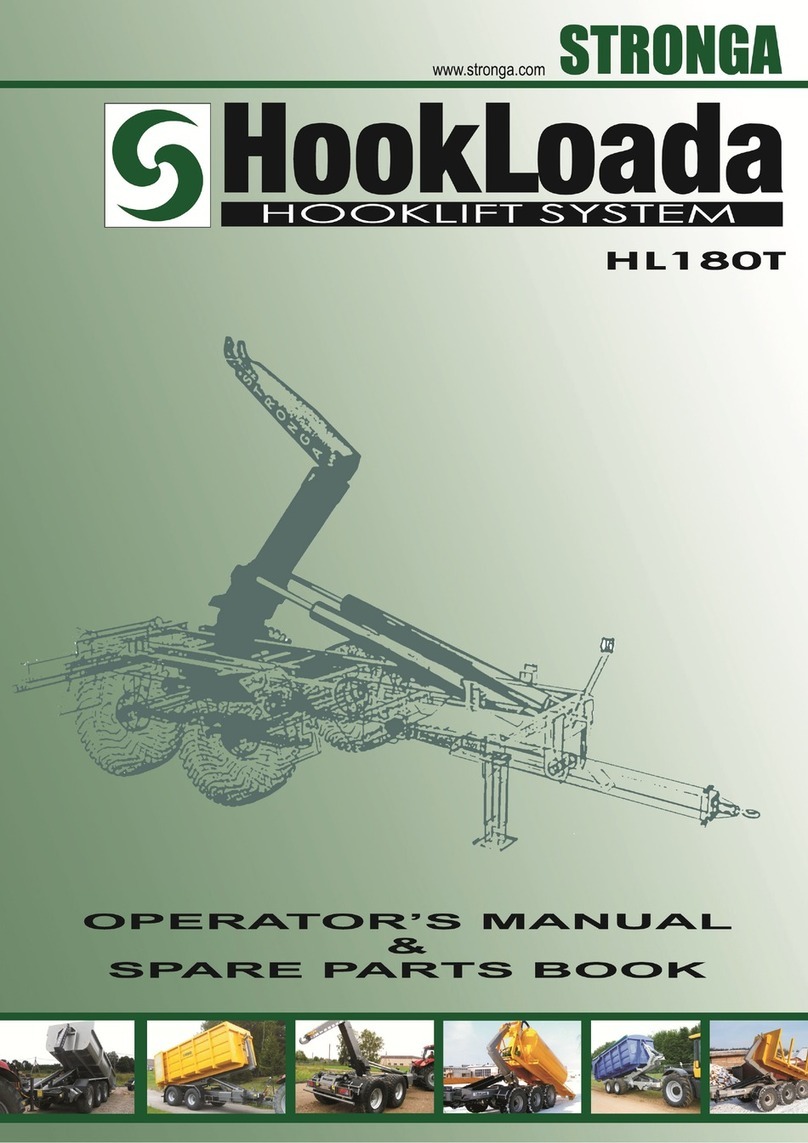

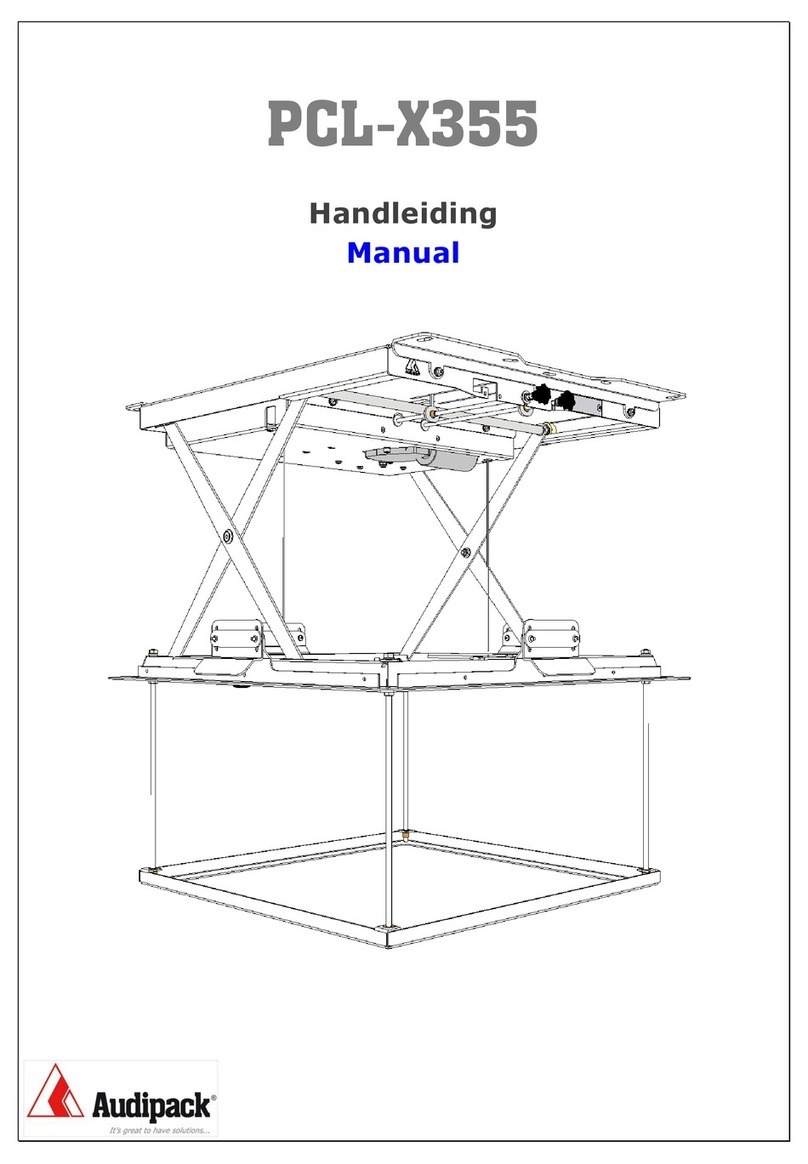

Audipack PCL-X355 User manual

Audipack

Audipack DWS-Smart User manual

Audipack

Audipack FFCL-8590 User manual

Audipack

Audipack ML-350 Series User manual

Audipack

Audipack PCL-M350 User manual

Audipack

Audipack FPL-90E User manual

Audipack

Audipack PCL-5050-10 User manual

Audipack

Audipack FFCL-90100 User manual

Audipack

Audipack VCCL Series User manual

Popular Lifting System manuals by other brands

MoJack

MoJack PRO Instructions for assembly and operation

Bend-Pak

Bend-Pak HD-7ZM Installation and operation manual

Bend-Pak

Bend-Pak XPR-10AS-168-LP Service manual

PRO LIFTS

PRO LIFTS VMB TE-064 Operating instructions & user manual

Bend-Pak

Bend-Pak XPR-10XLS-LP-181 Service manual

Bend-Pak

Bend-Pak GP-9XLT Package Service manual

PROPOINT

PROPOINT 8817793 user manual

Bend-Pak

Bend-Pak HDS-14 Installation and operation manual

ARJO HUNTLEIGH

ARJO HUNTLEIGH Alenti Instructions for use

ARJO HUNTLEIGH

ARJO HUNTLEIGH EASYTRACK FS Assembly instructions

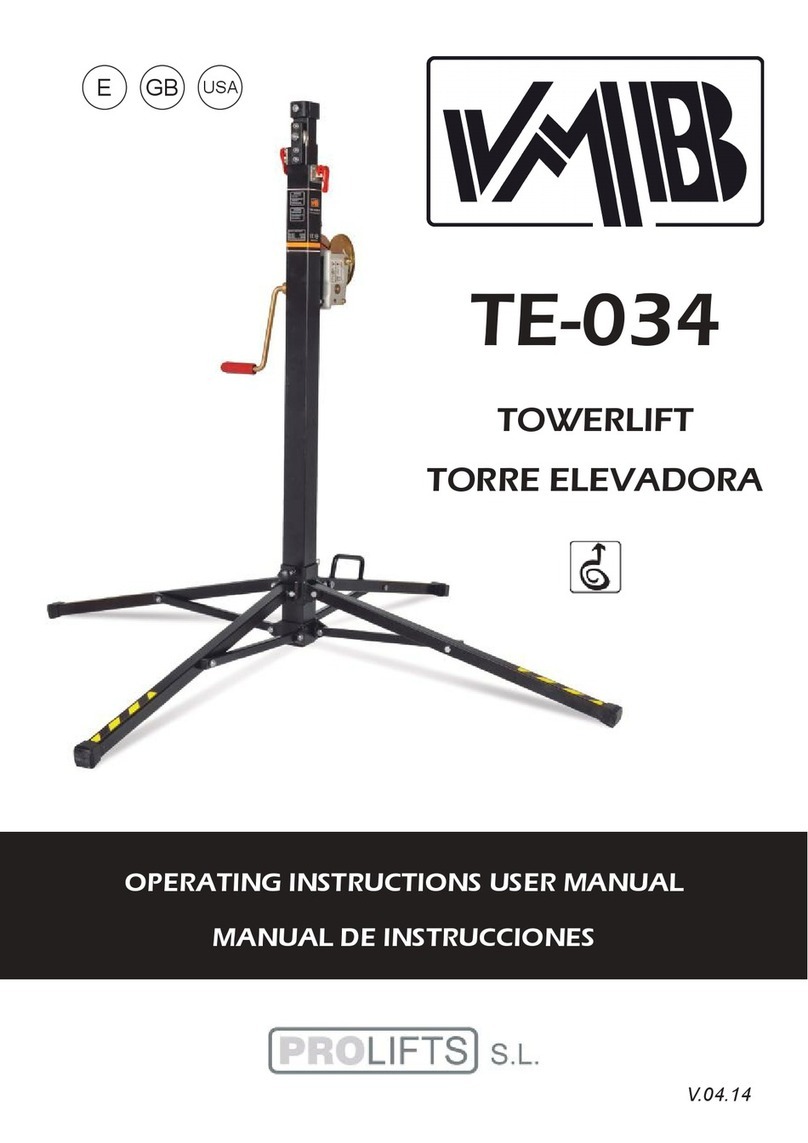

PRO LIFTS

PRO LIFTS VMB TE-034 Operating instructions & user manual

Bend-Pak

Bend-Pak XPR-10AS-168 Service manual