Auger Torque PALLET FORKS User manual

Document No: 99-95 518001 - Rev 1Part No: 51-8901/ 51-8902

PALLET FORKS

INSTRUCTION MANUAL

www.augertorque.com 11

99-95513701 ISSUE 3-1 ENGLISH

Document No: 99-95 518001 - Rev 1Part No: 51-8901/ 51-8902

PALLET FORKS

INSTRUCTION MANUAL

www.augertorque.com 22

SAFETY NOTES

Protect Yourself

Make sure you wear protective clothing and personal safety items.

You May Need

• A Hard Hat

• Safety Goggles

• Hearing Protection

• Foul Weather Clothing

• Reflective Clothing

• Protective Gloves

• Safety Boots

DO NOT wear items of loose clothing, jewellery or other items and tie up any long hair

which could entangle in the controls or other parts of the machine.

Know Your Equipment

Get to know all you how to operate all controls on the machine and the attachments

IF THERE IS SOMETHING IN THE MANUAL WHICH YOU DO NOT UNDERSTAND, CONTACT

THE MACHINE AGENT OR MANUFACTURER AND ASK THEM TO EXPLAIN IT TO YOU.

Danger, Warning And Caution

This symbol below has 3 important meanings when used with the following captions.

DANGER: An IMMINENTLY HAZARDOUS situation that WILL result in DEATH or

VERY SERIOUS INJURY

WARNING: A POTENTIALLY HAZARDOUS situation that COULD result in DEATH

or VERY SERIOUS INJURY

CAUTION: A POTENTIALLY HAZARDOUS situation that MAY result in MINOR

INJURY

Document No: 99-95 518001 - Rev 1Part No: 51-8901/ 51-8902

PALLET FORKS

INSTRUCTION MANUAL

www.augertorque.com 33

Protective And Safety Devices

Keep all protective devices in place and securely fastened. Make sure all guards, sheilds

and safety signs are properly installed and are in good condition.

Check The Equipment

Before you operate the equipment, take time to check your machine and ensure that all

systems are in good operational order.

• Never operate the equipment with worn, damaged or missing parts. Use only genuine

replacement parts.

• Always ensure that the parent machine is secure and stable with its engine switched off

and hydraulic pipes disconnected before carrying out any maintenance work.

• Check for loose, broken, missing or damaged parts. Have everything put into good repair

and make sure all safety devices are in place.

• Perform all maintenance procedures outlined for the equipment.

• Always protect hands. Select appropriate gloves when handling the equipment during

fitting, removing or adjusting

• Always protect feet with safety boots.

Hazard Classification (Only applicable to ANSI Safety Labels)

DANGER: IMMEDIATE HAZARD! - Failure to understand or obey

this information is likely to result in personal injury or death.

WARNING: Failure to follow these instructions may result in

personal injury or death.

CAUTION: Failure to follow these instructions may result in

minor personal injury or damage to the machine or the vehicle.

NOTICE: This is important information for the proper use of this

equipment. Failure to comply may lead to premature equipment

failure.

CLEAN OR REPLACE THE SAFETY LABELS IF THEY CANNOT BE CLEARLY READ OR

UNDERSTOOD

Document No: 99-95 518001 - Rev 1Part No: 51-8901/ 51-8902

PALLET FORKS

INSTRUCTION MANUAL

www.augertorque.com 44

Safety Precautions

NEVER operate or assemble the equipment without fully understanding the operating

instructions of both the equipment unit and the parent machine.

NEVER operate the equipment unless you are in good physical condition and mental

health.

NEVER operate the equipment under the influence of any substance (including drugs &

alcohol) which might impair vision.

NEVER operate the equipment with worn, damaged or missing parts. Use only genuine

replacement parts.

NEVER allow bystanders (including animals) within 6 metres/20 foot of the work area.

NEVER allow minors to operate the equipment.

ALWAYS survey the work area before commencing operations. Check for potential hazards,

eg. Electricity or communication cables etc.

ALWAYS ensure that the parent machine is secure and stable with it’s engine switched off

before carrying out any maintenance work.

ALWAYS ensure the hydraulic oil supply to the attachment is disconnected by uncoupling

the hydraulic hose connectors before fitting, removing or adjusting the equipment

ALWAYS wear head protection and eye protection when working on the unit.

ALWAYS protect hands. Select appropriate when handling the equipment

during fitting, removing or adjusting the unit.

ALWAYS protect feet. Wear approved safety boots.

ALWAYS follow the parent machine instructions regarding noise protection.

STAY ALERT. Should something break, come loose or fail to operate on your equipment,

STOP WORK, lower equipment to the ground, shut off the engine and lock out hydraulic

supply, inspect the machine and have repairs or adjustments made before resuming

operation.

Document No: 99-95 518001 - Rev 1Part No: 51-8901/ 51-8902

PALLET FORKS

INSTRUCTION MANUAL

www.augertorque.com 55

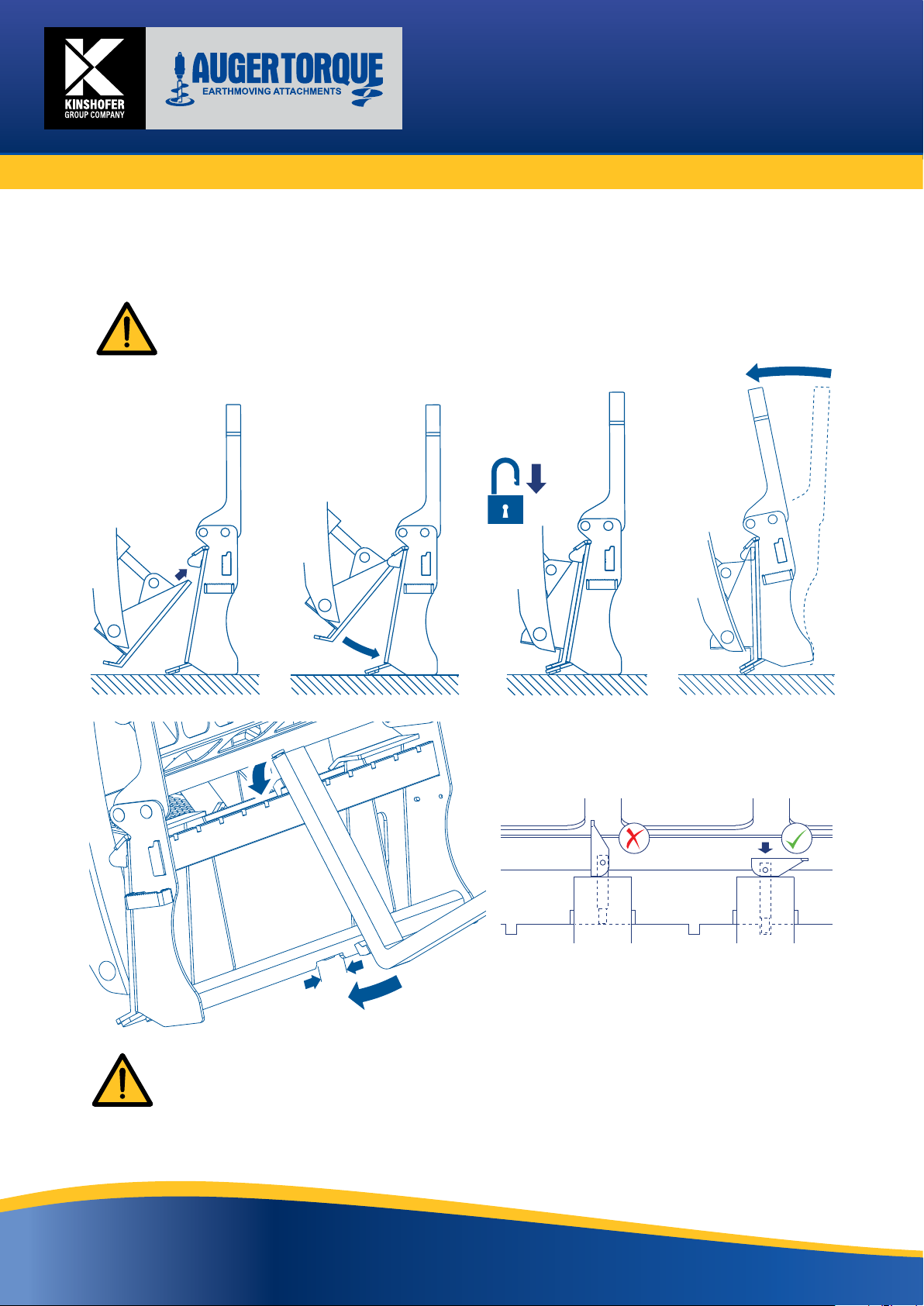

PALLET FORK ASSEMBLY

Remove one bolt from each side (A) lift Brick Guard (B) and repalce bolts, torque to 30Nm /

23 ft-lbs.

30Nm / 23ft-lbs

22Nm / 16ft-lbs

Document No: 99-95 518001 - Rev 1Part No: 51-8901/ 51-8902

PALLET FORKS

INSTRUCTION MANUAL

www.augertorque.com 66

MOUNT AND DISMOUNT THE PALLET FORKS

Mount the Bucket

WARNING: Always position attachments on a solid and level ground when

mounting and dismounting the attachments from the quick hitch assembly.

CAUTION: Avoid injury! Make sure that the forks are mounted securely before

operation or transport.

Always replace immediately any damaged hardware.

Dismount the forks

The forks can be dismounted following the reverse of the mounting procedure.

Document No: 99-95 518001 - Rev 1Part No: 51-8901/ 51-8902

PALLET FORKS

INSTRUCTION MANUAL

www.augertorque.com 77

OPERATION

1. Approach the load in such a fashion that the weight will be centered between the

fork tines. The heaviest side should be closest to the fork frame and not near

the tips of the fork tines.

2. Before lifting, make certain the fork tines are completely under the load and level.

3. Lift the load slightly to make sure the load is stable. If the load appears unstable,

lower and reposition the tines to achieve full stability.

4. Raise the loader to the MINIMUM height required for the terrain.

5. During material handling: keep the fork tines level, stop and start the machine

gradually, slow down before turning and avoid obstacles, bumps or holes.

Check load frequently to ensure stability.

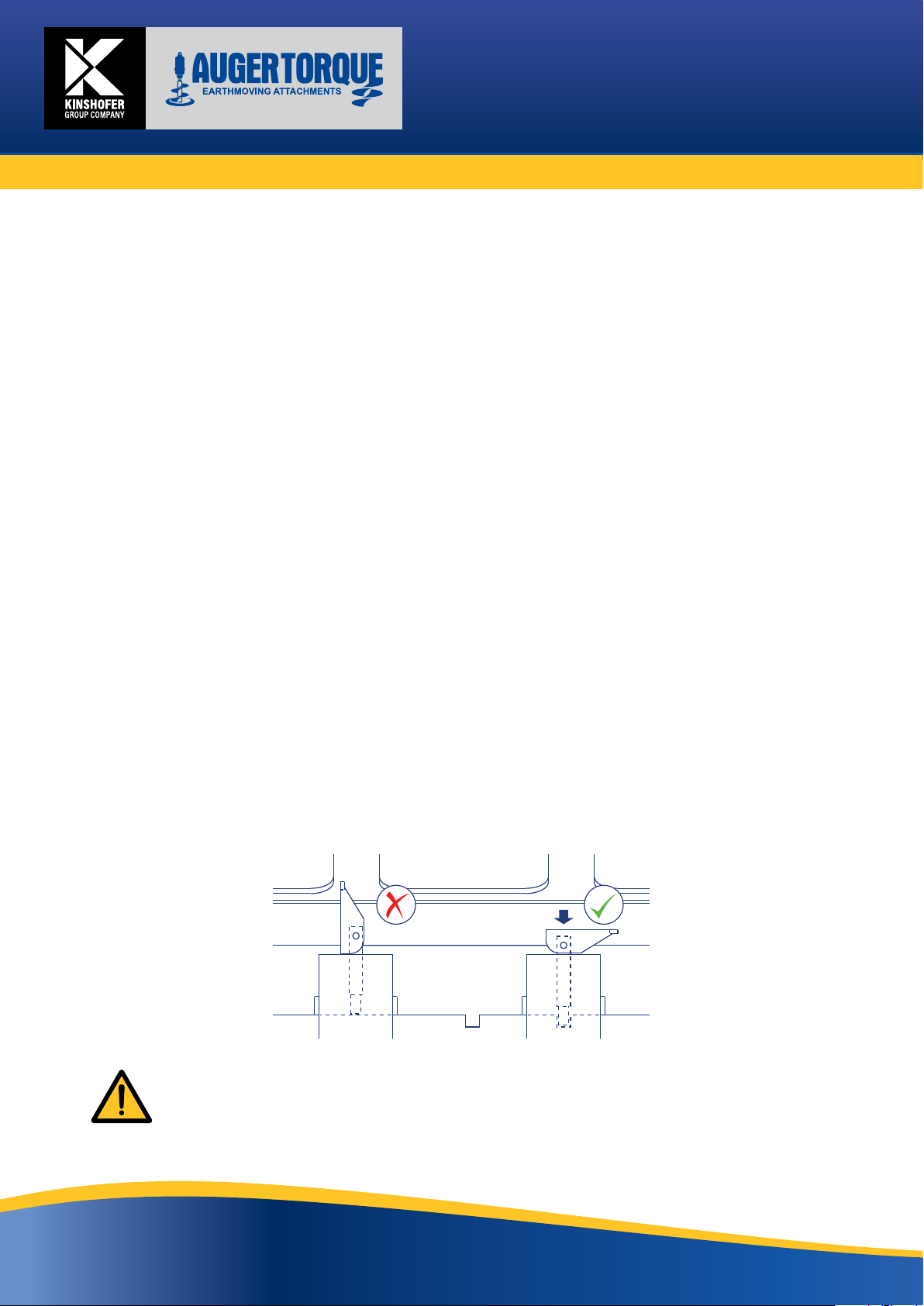

Adjusting The Fork Tines

With the machine arms lowered and completely rolled back, shut down the machine, set

the parking brake and remove the key. (If the tines are still in contact with the ground the

arms may need to be raised just enough to eliminate contact.)

From the right side of your pallet fork, adjust the position of the right fork tine by lifting

the lever to the unlock position and sliding the fork tine to the desired location. Lower the

lever back to lock the fork tine in place. Make sure that the latch has been set into a notch

and therefore securing the tine to the frame.

Move to the left side of the pallet fork frame and repeat the adjustment procedure to the

left fork tine. Make sure that the left tine is the same distance from the center of the frame

as the right tine.

WARNING: Never exceed the recommended lifting capacity of any approved fork

tines or the loader.

Document No: 99-95 518001 - Rev 1Part No: 51-8901/ 51-8902

PALLET FORKS

INSTRUCTION MANUAL

www.augertorque.com 88

WARRANTY STATEMENT

Auger Torque provide a LIFETIME parts replacement warranty on the dislodgement of the Earth Drill shaft and

any failure of the Shock Lock system to prevent loss of teeth under normal operating conditions.

All Auger Torque products are warranted to be free from defects in materials or workmanship for the periods

summarised below:

•Planetary Gearbox Components - 72 Months

•Hydraulic Motors - 36 Months

•All Other Parts / Products - 12 Months

The warranty periods will commence from Date of Sale by an authorised Auger Torque Dealer. Evidence of the

date of sale may be required and for Planetary and Hydraulic Motor warranties to be valid the product must be

registered with Auger Torque within 4 weeks of the date of sale. Extended Warranty (> 12 months) Products can be

registered by returning the Registration Card or completing the form on page 8. This warranty is not transferable

beyond the initial purchaser of the product.

A warranty claim should be reported to the Auger Torque Dealer who supplied the unit. The Dealer, with the

technical backup of Auger Torque, will make an initial assessment.

The customer is responsible for returning the product for warranty inspection to the original supplying dealer’s

facility. Parts should not be delivered without the prior agreement of the dealer or Auger Torque.

During the warranty period Auger Torque, at its option, will repair or replace any parts free of charge determined

as defective by Auger Torque. Such repairs will be undertaken by Auger Torque or its nominated representative

at an Auger Torque facility or a location deemed suitable by Auger Torque. Auger Torque are not liable for any

associated costs relating to a warranty failure.

Parts repaired or replaced by Auger Torque are then covered by this warranty for the remainder of the original

warranty as if such parts were original parts.

Products or parts which, as determined by Auger Torques examination, show wear from normal use, have been

improperly operated, damaged by accident or negligence, altered or modified are not considered defective and

are not covered by this warranty.

This warranty is void if any attempt is made to make field repairs unless these have been pre-approved in writing

by Auger Torque.

This warranty is void if the products are not serviced in-line with the instructions in the Operators Manual.

Particular care should be taken to perform regular oil changes in gearboxes.

This warranty is exclusive and in-lieu of any other expressed warranties. There are no warranties of

merchantability or fitness for a particular purpose. Auger Torque shall not be liable for any consequential,

incidental or punitive damages, losses or expenses, including those resulting from or caused by any defects.

As you would expect from Auger Torque, with our extensive experience and product reliability we’ll always go

the extra mile to keep you working.

TAHITI

BUFFALO

ATLANTA

CHELTENHAM

NINGBO

BRISBANE

MELBOURNE

www.augertorque.com

YOUR DEALER IS

Products and specifications subject to change without prior notice.

Some products may not be available in your country or region.

AUGER TORQUE, SHOCK LOCK™, NDS™ and the AUGER TORQUE LOGO are trademarks of

Auger Torque Europe Ltd © 2021 Auger Torque Europe Ltd. All Rights Reserved.

Auger Torque USALLC

2640 Jason Industrial Parkway

Winston, GA 30187

USA

Tel: (+1) 844 287 6300

Fax: (+1) 770 947 9916

Email: sales@augertorqueusa.com

Auger Torque EuropeLtd

Hazleton

Cheltenham

GL54 4DX

England

Tel: +44 (0) 1451 861652

Fax: +44 (0) 1451 861660

Email: sales@augertorque.com

Auger Torque AustraliaPtyLtd

122 BoundaryRd

Rocklea

Queensland 4106

Australia

Tel: +61 (0) 7 3274 2077

Fax: +61 (0) 7 3274 5077

Email: sales@augertorque.com.au

Table of contents