August Penkert Hero Operating instructions

HERO / HERO BASIC

Guide-Information for use

HERO / HERO BASIC

August Penkert GmbH

Xantener Str. 12, D-45479 Mülheim an der Ruhr

Hand protecting -

the safe way!“

HERO

HERO BASIC

HERO /HERO BASIC

Special cut protection gloves for technical

Emergencyand rescue services according to EN 388:2016

Cut protective glove accordingtoEN 388:2016

3434E

The marking on the protective glove shows the essential

protective features and the contact to the responsible

manufacturer.

August Penkert GmbH

Xantener Str.12

45479 Mülheim an der Ruhr

Phone: 0208-41969-0

fax: 0208-41969-22

Description

The HERO model offers ideal characteristics for everyneed

in emergencyand rescue service. Safe working at the

highest level of cut-resistance, excellent heat insulation by

using heat-resistant materials. The HERO BASIC model is

the low-priced alternative with the same mechanical strength

for the underhand. However, this model does without heat-

resistant materials for the upper hand (Spantex instead of

Nomex®) and the cuff (neoprene instead of Nomex®).

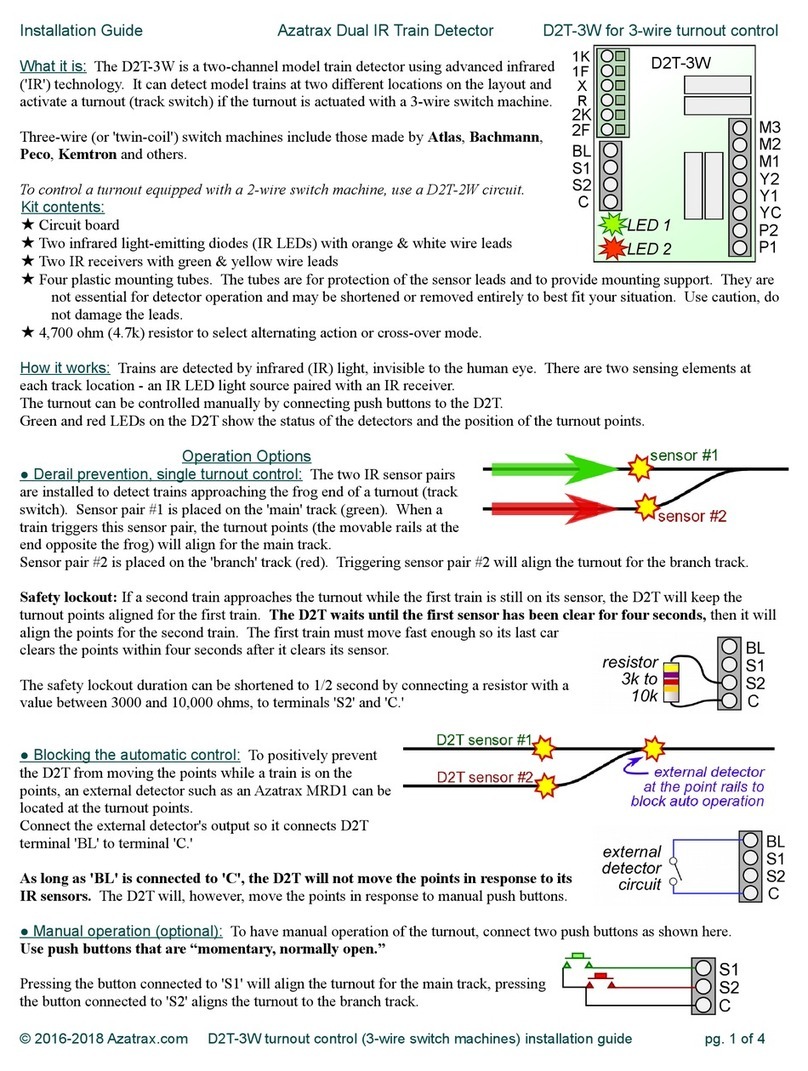

Conformitywith EN 388:2016

performance levels: (innersurface)

abrasion resistance

cut resistance

tear strength

puncture resistance

TDM:section

1= lowest power levels; 4 (5) = highest power level (A= weakest and F=

highest power level linear cutting resistance); 0 = indicates that the

glove falls below the minimum power level for the given single hazard. X

= indicates that the glove has not been tested, or

that the test procedure does not appear suitable / applicable.

Note: If blunting occurs during the Coupe Cutting Strength Test, the

results of the Coupe Test are for guidance only, whereas the TDM

Cutting Strength Test provides reference performance results.

Information on the performance level of the TDM test is binding for

higher blunting of the cutting blade in the coupe test. In this case a

Too high power level determined by blade truncation.

Even a high power level when determining the puncture resistance

should not lead to the assumption of protection against puncture of a

thin cannula.

The protective gloves meet the requirements of the European PPE Regu-

lation (EU) 2016/425 and protect against mechanical and thermal risks

(heat) covered bythe standards on which the certification is based.

The applied standards are EN 388:2016 and EN 420:2003+A1:2009.

Certification body/testing institute

MIRTAKONTROL d.o.o

Gradiska 3

HR-10040 Zagreb Durava

Croatia

(NB): 2474

The declaration of conformity can be

viewed at www.penkert.com

3

4

3

4

E

HERO:

>> palm: made of heat-resistant cowgrain leather

(approximately1.0/1.1 mm thick)

>> Handrücken: made of 100%Nomex III®orange-

coloured and impregnated with fluorocarbon

>> Nomex®Comfort knitted loop approximately8 cm long

>> large leather loop as a convenient pull-on strap and

for fastening on the belt

>> total length approximately28 cm (size 10)

HERO BASIC:

>> palm: made of heat-resistant cowgrain leather

(approximately1.0/1.1 mm thick)

>> back of the hand: made of Spantex orange-coloured

(instead of Nomex®)

>> Neoprene cuff approximately7 cm long with a Velcro strip

(instead of Nomex®knitted loop)

EN 388:2016

FACTS

Cut protective glove according to EN 388:2016

MODELL HERO /HERO BASIC

Size 5- 13

If you wash the gloves, please use a pH-neutral

detergent.

Es gibt derzeit kein Standard-Prüfverfahren für die Durchlässigkeit

der UV-Strahlung von Handschuhmaterialien, aber die

Schweißerhandschuhe sind so hergestellt, dass sie normalerweise

Use

There is currently no standard test method for the transmittance of

UV radiation from glove materials, but the

Welding gloves are manufactured in such a way that they should

normally not allow UV radiation to pass through, gloves type B are

recommended if high skill is required, e.g. in TIG welding. Type A

gloves are recommended for the other welding processes, choose a

pair of gloves according to your hand size. Observe the following

points when wearing gloves: The glove does not protect against

chemical and bacteriological hazards.

- In cases where there is a risk of moving machine parts getting

caught, this protective glove must not be worn.

- Oil, grease and moisture reduce the cut resistance and increase

the flammability of all gloves and should be avoided.

- The protective gloves are designed for work in a dry environment.

The expiration date (month and year) is indicated on the protective

glove. (Example: 12.2026) It is not known that the performance

levels according to EN388:2016 and EN 420:2003+A1:2009 change

after up to 8 years of proper storage. Note: The production date is

the printed expiration date minus 8 years..

Care and Repair

Protective gloves of the HERO glove series must not be chemically

cleaned, washed or treated with bleaching agents, gloves which

are so severely damaged and no longer provide protection must

not be moved and the protective gloves used must be disposed of

at an appropriate time depending on their use.

Storage

These gloves should be stored in their original packaging in a dry,

clean place. Avoid exposing them to moisture or high

temperatures.

Warning

The degree of protection required for a particular task depends

on the risks involved. You are ultimately responsible for selecting,

using and operating the protective equipment that is appropriate

to the risks at your workplace. Note that the protective

performance may be adversely affected by application-related

wear.

- according to washing report

Lars Reuter (Textile Cleaner Master, Hamburg)

This manual suits for next models

1