Installation Manual

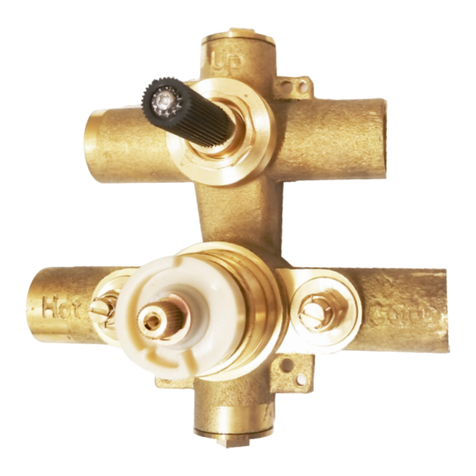

ASR1203-OO *** Valve Rough-In

Dimensions of xtures are approximate and may vary ± 6mm (1/4”). Structure measurements must be veried against the unit to ensure proper t.

Product images and specications are for illustrative purposes only, product design may vary.

5

1

23

1

2

3

Test the Handle/Valve:

Water temperature will decrease when you rotate

clockwise, and water temperature will increase when you

rotate counter clockwise.

CLEANING STOP FILTERS

Removing the stop lters:

Using a wrench, take out both of the Stops (1) by rotating

them counter-clockwise.

Remove Filter (2) and Valve (3) and check for any debris

or build up.

Use clean water to rinse and clean Filter (2).

Installing the stop lters:

Slide Filter (2) on to Valve (3). Then thread it to the valve

body.

Use a wrench to tighten the Stops (1) to the valve.

3A.

4A.

4B.

Thermostatic Valve Cover Plate and Handle Installation

)

Tempature Lock;

must be pushed.

3A.

4A. 4B.

CAUTION!

If you need to adjust temperature more

than 38°C (100°F), then you need to press

the override button and rotate it counter

clockwise. It should not be possible to turn

the stem further counter-clockwise.

Testing Handles and Replacing and Cleaning Stop Filters

CAUTION!

Please check that the marked line on

the thermostatic cartridge points to the

rectangle notch on the plastic parts, if not,

please rotate the brass part. Then install

the handle.

1

2

3

6

9

4

10

511

7

1

2C. 2D.

Thermo Cartridge Calibration Area

D2. D3.

Marked Line & Groove

MUST ALIGN

1

2

TOP VIEW

(1)

(2)

Plastic Body

Boarch

Installing Cover Plate:

Carefully install the Trim Plate (1), make sure to keep the

Trim Plate (1) tight against the wall.

Conguring the Cartridge:

Before installing the handle and the rest of the trim,

ensure the thermo cartridge is positioned correctly. Verify

that the line etched on the top of the Plastic Body (1) of

the cartridge lines up exactly with the black line on the

brass Boarch (2) as you are looking down on it.

(See Figures D2. and D3. on the left)

Installing Volume Control Handle:

Install Plastic Washer (4) on diverter. Install the Volume

Control Handle (1). Use the Allen Key (9) to tighten the

Handle Set Screw (3), then insert Set Screw Cap (3).

Installing Thermostatic Handle:

Install Plastic Washer (5) on the thermostatic mixer.

Install the Thermostatic Mixer Handle (6), so that the

safety stop override button is at the 9:00 position. Use

the Allen Key (9) tighten the Handle Set Screw (8), then

insert Set Screw Cap (7).

2C.

2D.

2E.