Aura LM-270 User manual

Manual

Metal Cutting Band Saw

Model LM-270

F o r y o u r s a f e t y , p l e a s e r e a d t h i s m a n u a l b e f o r e operationcarefully

Motor Power 400V,3~,50Hz,1500/1100W, 4/8pole

Gear rate 25:1

Fly wheel diameter 380 mm

Blade size 3160x27x0.9mm

Blade speed 68 or 34 m/min

O

Saw arm swivel 45 L, , 1 , 0

Coolant pump 400V~, 45W

Packing Size 1770x765x1120 mm

Weight

O O O O O O O

30 L 5 L ,15 R,30 R,45 R,60 R

CONTENT

Specifications 1 Clamping the work piece 8

Safety 2 Adjust cutting angle 9

Safety Instructions For Power Tools 2 Operation cycle 9

Additional Safety Instructions For The Adjusting 11

Metal-cutting Bandsaw 2 Blade tension adjusting 11

Site Considerations 3 Adjusting the blade guide 11

Getting to Know your Metal Cutting Blade guide block 11

BandSaw 4 Changing the blade 11

Unpacking 6 Adjusting the blade to the flywheel 12

Assembly 7 Maintenance 13

Assembling the machine stand 7 Blade choice 14

Assembling the loosen parts and Electrical system 16

accessories 7 Troubleshooting 17

Operation 8 Parts list & diagram 22

Vice adjustment 8

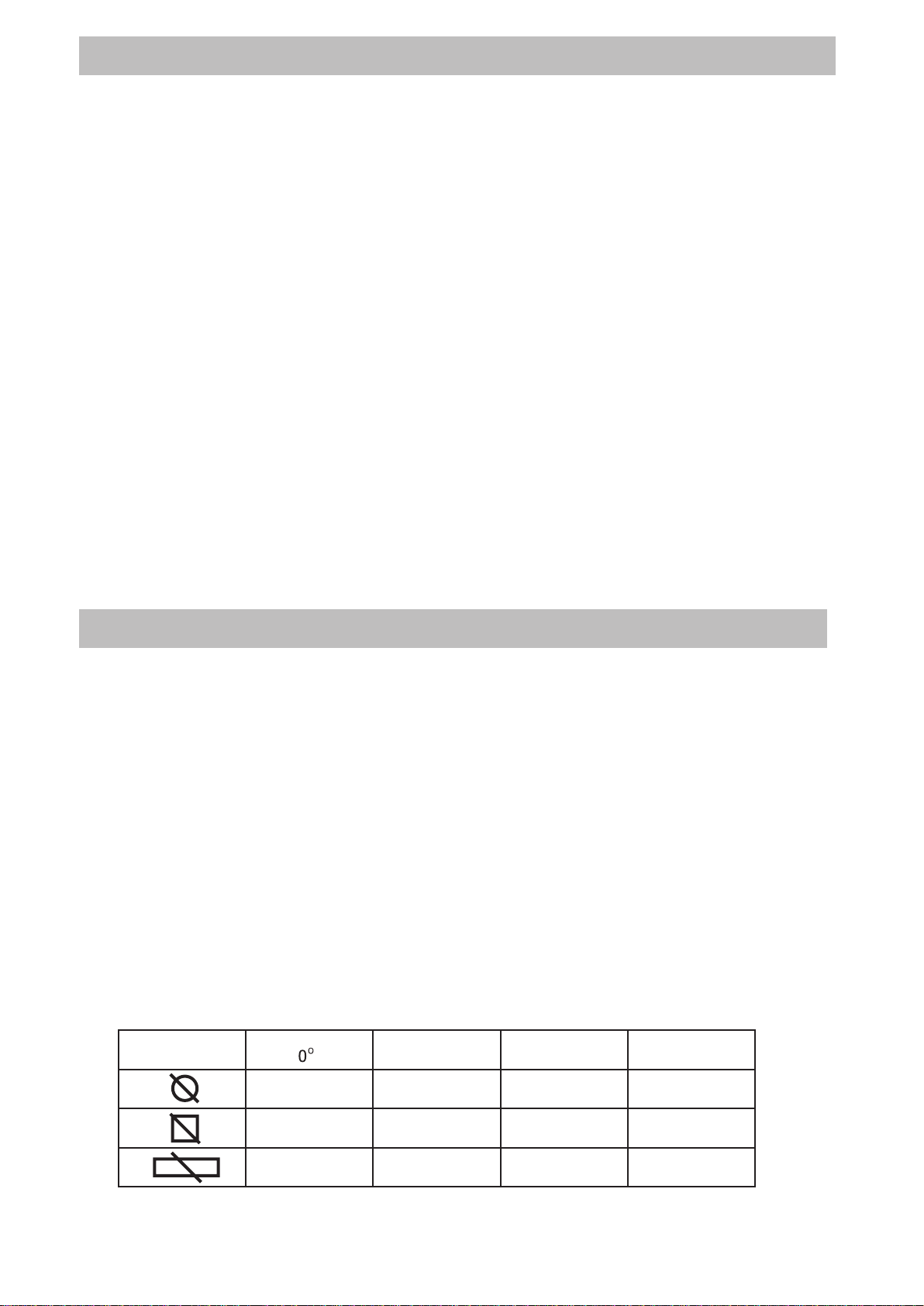

SPECIFICATIONS

1

Max cutting capacity

mm O

45 L

O

45 R O

60 R

270

260

370x220

240

220

240x160

160

150

210

180

180x180

420/490 kg

13. DON’T OVERREACH. Keep proper footing and balance at

SAFETY all times.

14. MAINTAIN TOOLS WITH CARE. Keep tools sharp and

For Your Own Safety Read Instruction clean for best and safest performance. Follow instructions

Manual Before Operating This Equipment for lubricating and changing accessories.

15. DISCONNECT TOOLS before servicing and changing

The purpose of safety symbols is to attract your attention to accessories, such as blades, bits, cutters, and the like.

possible hazardous conditions. This manual uses a series of

symbols and signal words which are intended to convey the 16. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make

level of importance of the safety messages. The progression sure switch is in off position before plugging in.

of symbols is described below. Remember

that safety messages by themselves do not eliminate danger 17. USE RECOMMENDED ACCESSORIES. Consult the owner’s

and are not a substitute for proper accident prevention manual for recommended accessories. The use of improper

measures.accessories may cause risk of injury.

18. CHECK DAMAGED PARTS. Before further use of the tool,

Indicates an imminently hazardous a guard or other part that is damaged should be carefully

situation which, if not avoided, WILL result in checked to determine that it will operate properly and

death or serious injury.perform its intended function.Check for alignment of

moving parts, binding of moving parts, breakage of parts,

Indicates a potentially hazardous situation mounting, and any other conditions that may affect its

which, if not avoided, COULD result in death or operation. A guard or other part that is damaged should

serious injury.be properly repaired or replaced.

Indicates a potentially hazardous situation 19. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

which, if not avoided, MAY result in minor or POWER OFF. Don’t leave tool until it comes to a

moderate injury. It may also be used to alert complete stop.

against unsafe practices.

This symbol is used to alert the user to

useful information about proper operation of the Additional Safety Instructions For The

equipment.Metal-Cutting Bandsaw

1. Do not operate your bandsaw with dull or badly worn

Safety Instructions For Power Tools

blades. Dull blades require more effort to use and are

difficult to control. Inspect blades before each use.

1. KEEP GUARDS IN PLACE and in working order.

2. Make sure the blade has been properly tensioned and is

2. REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of tracking on the center of the wheels

checking to see that keys and adjusting wrenches are

removed from tool before turning on.3. Always support stock in the vise and make certain it is

firmly secured. Never attempt to hold material by hand

3. KEEP WORK AREA CLEAN. Cluttered areas and benches while sawing.

invite accidents.

4. Keep belt guard and bandsaw wheel covers in place when

4. DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use operating the machine.

power tools in damp or wet locations, or where any

flammable or noxious fumes may exist. Keep work area 5. Never force the saw through the cut. Allow the feed

well lighted.cylinder to control the rate of cutting. If the saw blade

binds or stalls turn the power off immediately.

5. KEEP CHILDREN AND VISITORS AWAY. All children and

visitors should be kept a safe distance from work area.6. Never position fingers or thumbs in line with the cut.

Serious injury could occur.

6. MAKE WORK SHOP CHILD PROOF with padlocks, master

switches, or by removing starter keys.7. Periodically check the horizontal stop screw and the

automatic shutoff limit switch to make sure they are

7. DON’T FORCE TOOL. It will do the job better and safer properly adjusted.

at the rate for which it was designed.

8. Exercise great caution when replacing blades. Wear

8. USE RIGHT TOOL. Don’t force tool or attachment to do a protective gloves and safety glasses when handling the

job for which it was not designed.blade.

9. USE PROPER EXTENSION CORD. Make sure your extension 9. Support long or heavy workpieces which extend from the

cord is in good condition.machine bed with a roller stand or other support device.

10. WEAR PROPER APPAREL. Do not wear loose clothing, 10. Habits-good and bad-are hard to break. Develop good

gloves, neckties, rings,bracelets, or other jewelry which habits in your shop and safety will become second-nature

may get caught in moving parts. Non-slip footwear is to you.

recommended. Wear protective hair covering to contain

long hair.

11. ALWAYS USE SAFETY GLASSES. Also use face or dust

mask if cutting operation is dusty. Everyday eyeglasses Operating this equipment has the potential to propel debris

only have impact resistant lenses, they are NOT safety into the air which can cause eye injury. Always wear

glasses.safety glasses or goggles when operating equipment.

Everyday glasses or reading glasses only have impact

12. SECURE WORK. Use clamps or a vise to hold work when resistant lenses, they are not safety glasses.

practical. It’s safer than using your hand and frees both

hands to operate tool.

2

Like all power tools, there is danger associated with this

Metal Bandsaw. Accidents are frequently caused by lack of

familiarity or failure to pay attention. Use this tool with

respect and caution to lessen the possibility of operator

injury. If normal safety precautions are overlooked or

ignored, serious personal injury may occur.

No list of safety guidelines can be complete. Every shop

environment is different. Always consider safety first, as it

applies to your individual working conditions. Use this and

other machinery with caution and respect. Failure to do so

could result in serious personal injury, damage to

equipment or poor work results.

Site Considerations

Lighting and Outlets

Lighting should be bright enough to eliminate shadow

and prevent eye strain. Electrical circuits should be

dedicated or large enough to handle combined motor

amp loads. Outlets should be located near each machine

so power or extension cords are not obstructing high-

traffic areas. Be sure to observe local electrical codes for

proper installation of new lighting, outlets, or circuits.

Read the manual before assembly and operation.

Become familiar with the machine and its operation

before beginning any work. Serious personal injury may

result if safety or operational information is not

understood or followed.

General Condition

1. Electrical connection: Steady state voltage: 0.9-1.1 of

nominal voltage.

Frequency: 0.99-1.01 of nominal frequency continuously;

0.98-1.02 short time

The mains connection must have maximum16A fuse.

Electrical supply which has protection devices of under-

voltage, over-voltage, over-current as well as a residual

current device (RCD) which maximum residual current rated

at 0.03A.

2. Altitude are not exceeding 1000m.

O

Maximum ambient air temperature is +40 C, minimum

O

ambient air temperature is not less than +5 C.

O

Storage and transportation temperature range is -25 C~

O

+55 C.

The relative humidity does not exceed 50% at a maximum

O

temperature of +40 C, higher relative humidity may be

O

permitted at lower temperature (e.g. 90%@ 20 C).

Floor Load

This machine represents a moderately large weight load in a

small footprint. Most commercial shop floors will be adequate

for the weight of the machine. Some floors may require

additional support. Contact an architect or structural engineer if

you have any question about the ability of your floor to handle

the weight.

To ensure sufficient upright stability of the machine it should be

bolted to floor. For this purpose 4 slots are provided in the

machine's bracket of work stand.

Working Clearances

Working clearances can be thought of as the distances between

machines and obstacles that allow safe operation of every

machine without limitation. Consider existing and anticipated

machine needs, size of material to be processed through each

machine, and space for auxiliary stands and/or work tables. Also

consider the relative position of each machine to one another

for efficient material handling. Be sure to allow yourself

sufficient room to safely run your machines in any foreseeable

operation.

3

A Saw arm lock lever J Contorl panel----Contains On/Off buttons, Power-

B Vise hand -wheel On indicator light, and the Feed Rate valve.

C Vise quick lock lever K Main motor

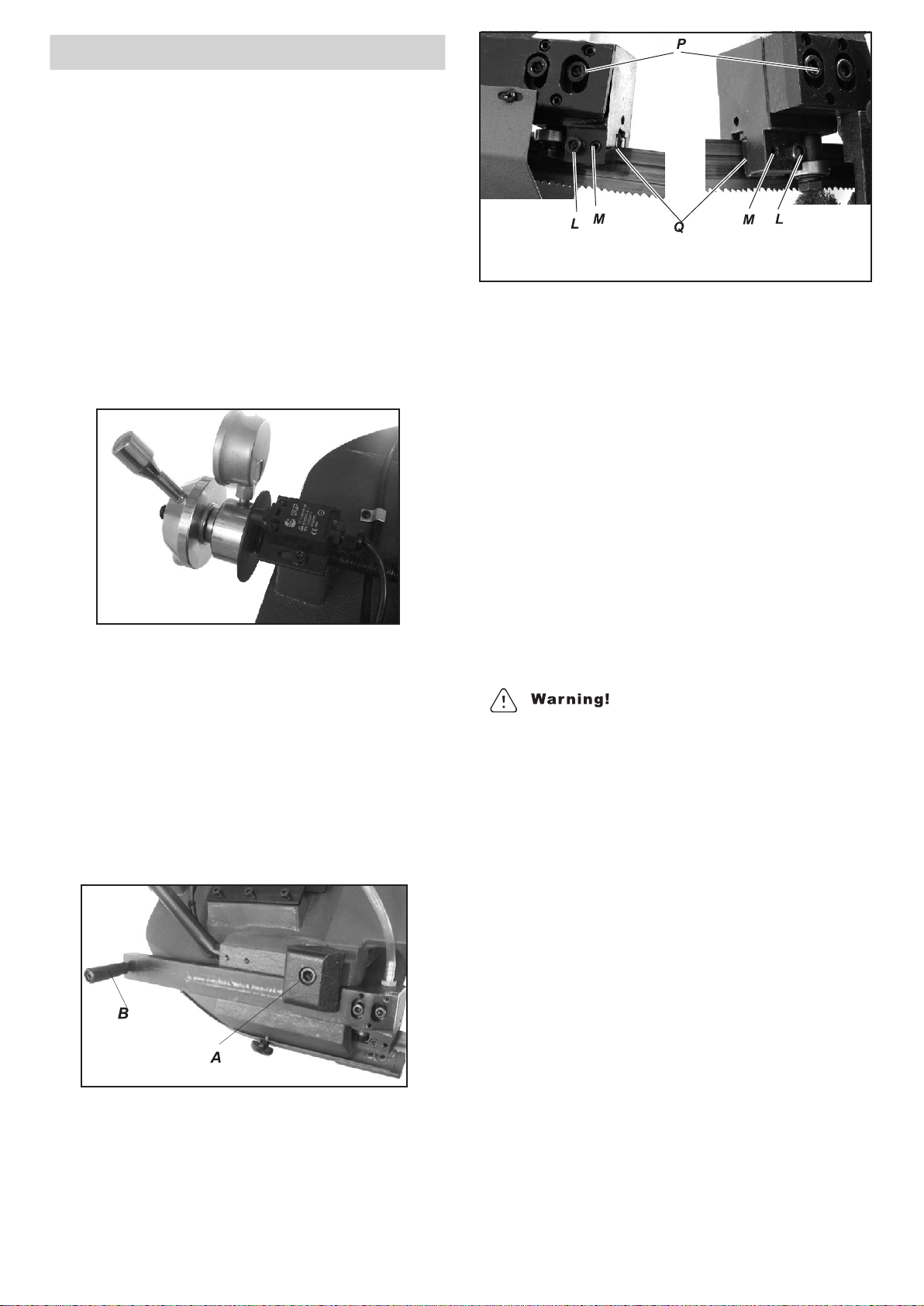

D Jaw, vise L Sling plate

E Hydraulic cylinder M Coolant and chip tray

F Saw arm N Bar stop/ work stop

G Blade tension adjusting hand-wheel P Machine stand/ Cabinet stand

H Trigger/ handgrip

GETTING TO KNOW YOUR METAL CUTTING BAND SAW

4

Q Gear box

R Fork, Auto/manual changing

S Saw arm return spring

T Hydraulic flow control valve

W

X

Hydraulic flow regulation valve

Stroke lower position limit switch

Q

R

T

W

X

5

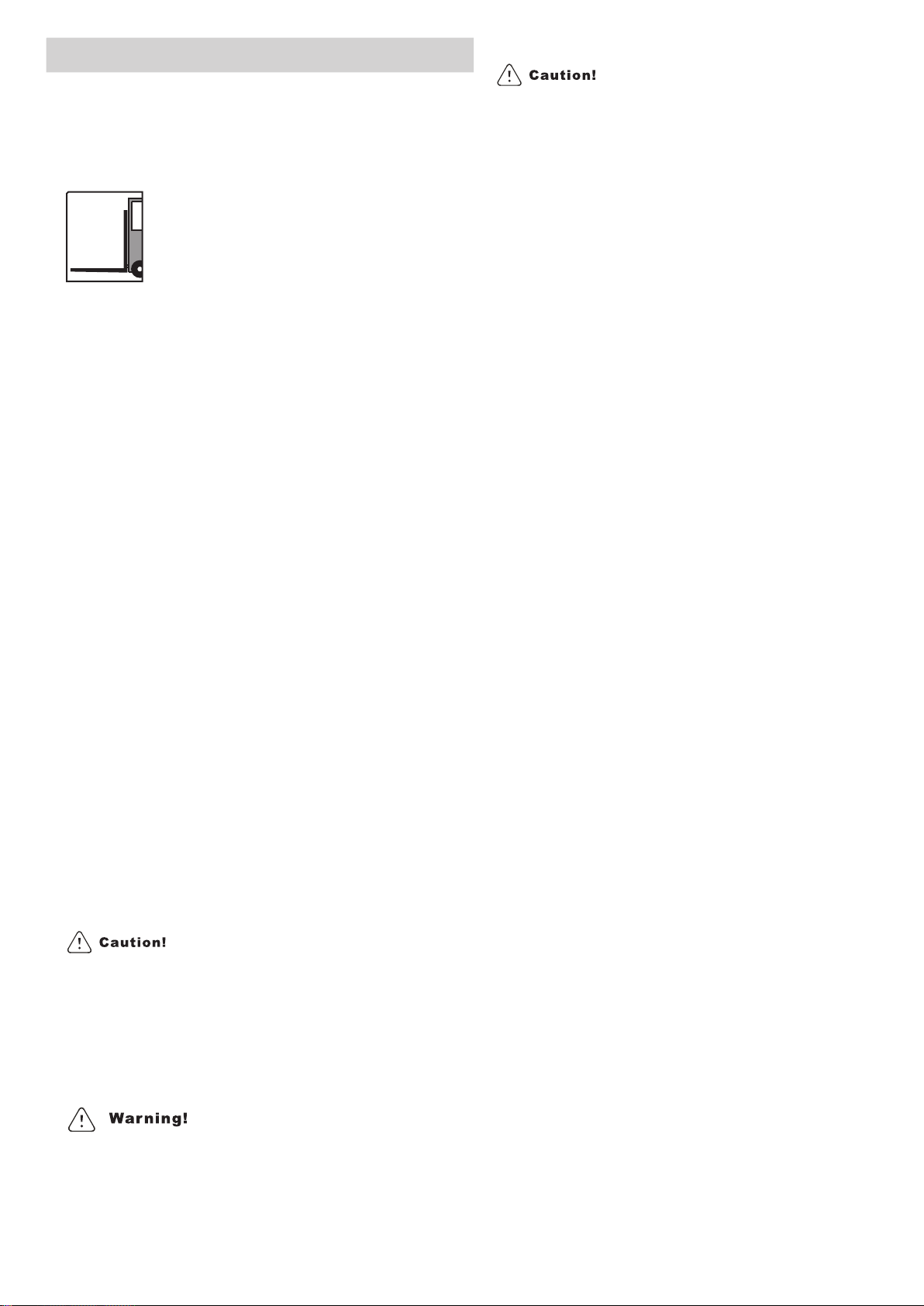

The metal bandsaw is shipped from the factory in a

carefully packed crate. If you find the machine to be All die-cut metal parts have a sharp edge (called “flashing”

damaged, save the containers and all packing materials, ) on them after they are formed. This is generally removed

call your agent.at the factory. Sometimes a bit of flashing might escape

inspection, and the sharp edge may cause cuts or

lacerations when handled, please examine the edges of all

This metal bandsaw is a very heavy machine die-cut metal parts and file or sand the edge to remove the

(400 kgs. shipping weight). DO NOT over-

flashing before handling.

exert yourself while unpacking or moving

your machine--get assistance. In the event

that your machine must be moved up or

down a flight of stairs, be sure that the

stairs are capable of supporting the

combined weight of people and the machine.

Serious personal injury may occur.

When you are completely satisfied with the condition

of your shipment, you should inventory its parts.

Piece inventory

Main saw unit

6- Hex head screw M10x20

6- Washer 10mm

Bar stop/work stop

2.5,3,4,6,10 mm allen wrench(5)

10-13 duo-open wrench

17-19 duo-open wrench

Machine stand parts

Right part

Left part

Bottom plate

Door frame w/door

Shelf( V & H)

16-Hex head screw M8x16

20-Washer 8mm

4-Hex nut M8

5-Hex head screw M6x12

5-Hex nut M6

10-Washer 6mm

Clean Up

The unpainted surfaces are coated with a waxy oil to

protect them from corrosion during shipment. Remove this

protective coating with a solvent cleaner or citrus-based

degreaser. Avoid chlorine--based solvents as they may

damage painted surfaces should they come in contact.

Always follow the usage instructions on the product you

choose for clean up.

Many of the solvents commonly used to clean machinery

can be highly flammable, and toxic when inhaled or

ingested. Always work in well--ventilated areas far from

potential ignition sources when dealing with solvents. Use

care when disposing of waste rags and towels to be sure

they do not create fire or environmental hazards. Keep

children and animals safely away when cleaning and

assembling this machine.

Do not use gasoline or other petroleum-based solvents to

remove this protective coating. These products generally

have low flash points which makes them extremely

flammable. A risk of explosion and burning exists if these

products are used. Serious personal injury may occur.

UNPACKING

6

ASSEMBLY

This metal cutting bandsaw is completely assembled, just

needs to assemble the machine stand.

Assembling the machine stand

Join the left part, right part to bottom plate with 6-hex

head screws M8x16 w/6- 8mm washers.

Attach the H-shelf to assembled parts with 4--hex head

screws M8x16 w/4- 8mm washers.

Attach the V-shelf to assembled parts with 5--hex head

screws M6x12 w/10- 6mm washers, 5-hex nuts M6.

Attach the door frame w/door and fasten it with 4-hex

head screws M8x16 w/8-8mm washer, 4-hex nuts M8.

Mount the Coolant system assembly to bottom plate

with 2-Hex head screws M8x16 w/2-8mm washer.

Assemble the loose parts and accessories

Fit the components supplied:

Mount bar stop rod.

Mount and align the roll-supporting arm as per the

counter-vice table.

Dis activation of machine

Carefully lift the saw head onto base, and fasten the If the machine is to be out of use for a long period, it is

machine head by 6-Hex head screw M10x20, and washer advisable to proceed as follows:

10mm.

Detach the plug from the electric supply panel,

Loosen blade,

Release the saw arm return spring,

Lowing the saw arm as possible,

Empty the coolant tank,

Carefully clean and grease the machine,

If necessary, cover the machine.

lCheck the condition and suitability of the equipment

available.

lDo not touch the suspended loads and remain at a

safe distance from them.

Before starting to lift the machine make sure that all

movable parts have been securely fastened.

Ensure that the crane's lifting capacity is suitable for the

machine. Lift the machine carefully and move it slowly,

avoiding bumps or sudden movements.

lThe lifting and transporting operations can be

extremely dangerous if not carried out with maximum

caution.

lMove all unqualified personnel away from the area.

Clean, clear and close off the installation area.

Fig 1

7

Fig 2

OPERATION

The machine has been designed to cut metal building

materials, with different shapes and profiles, used in

workshops, turner’s shops and general mechanical

structural work.

Only one operator is needed to use the machine, that

must stand on the front of machine as shown in the

picture.

Before starting each cutting operation, ensure that

the part is firmly clamped in the vice and that end is

suitably supported.

Do not use blades of a different size from those stated

in machine specifications.

If the blade gets stuck in the cut, release the running

button immediately, switch off the machine, open the

vice slowly, remove the part and check that the blade

or its teeth are not broken. If they are broken, change

the tool.

Clamping the work piece

Place work piece between the jaws.

Use the hand wheel to approach the vice jaw to the

work piece, leaving 3-4mm of space. Lock down work

piece by lowering the quick lock lever(4).

When the cutting cycle is finished, release vice by

raising the quick lock lever (4). Upon releasing the

quick lock lever (4), the vice jaw will open to the same

distance that was set initially. This allows for rapid

loading of same size material.

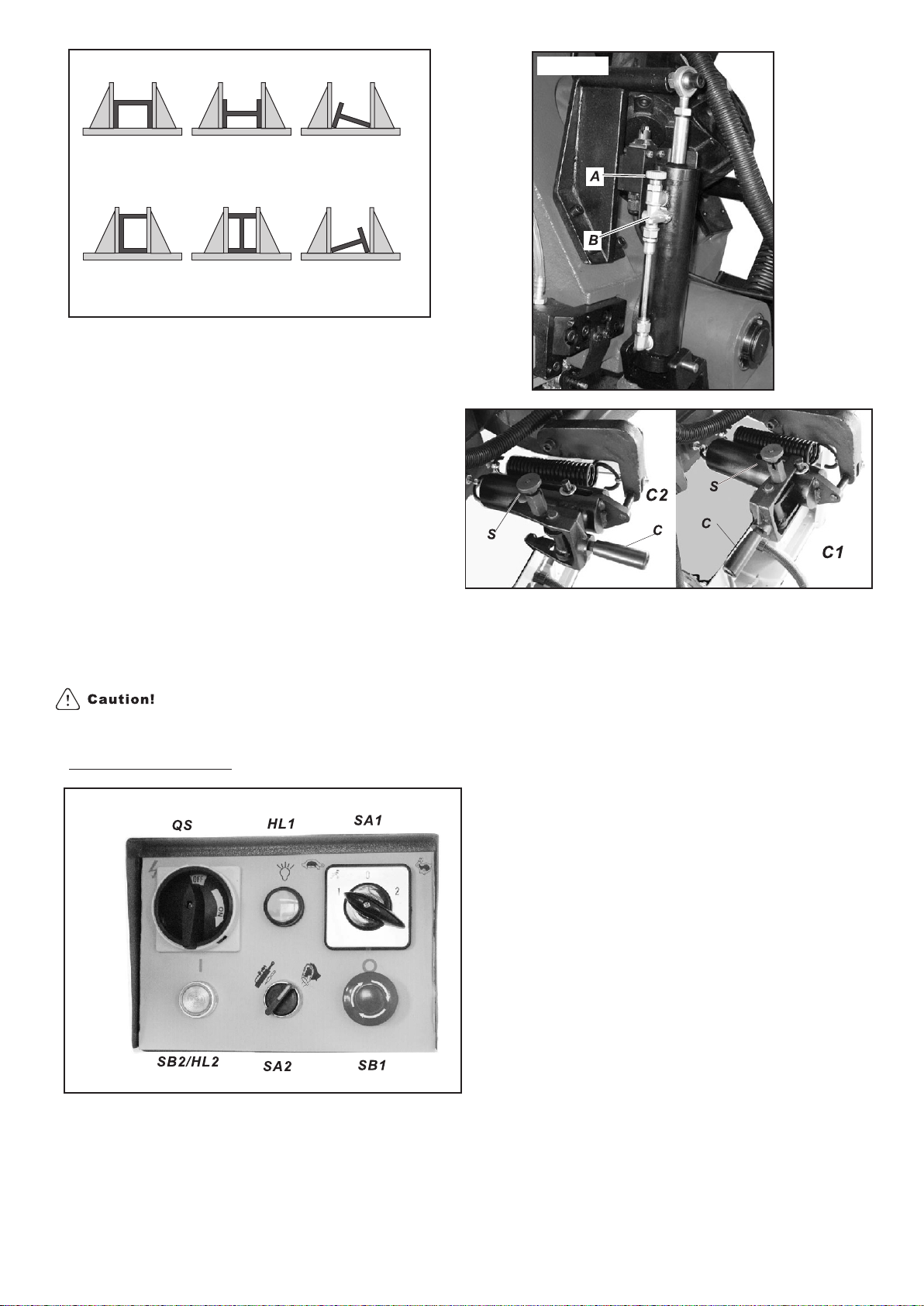

These figures below examples of suitable clamping of

different section bars, bearing in mind the cutting

capacities of the machine in order to achieve a good

efficiency and blade durability.

Once in position, move the lever(2) to the right to

lock it into position. If the lever (2) is not between the

vise/bed mounts and facing the user, then the vise will

not be able to lock. If the vise lever(2) has gone

beyond or is obstructed by a vise/bed mount, then use

the following procedures.

Adjust the lever(2) by grasping at the pivot point(P)

and lowering it, which may assist in the adjustment.

The lever can now be freely rotated into a more

convenient position. Some movement of the vise

Vice adjustment jaw may be required. Raise the lever (2) then move to

the right to lock.

The device does not require any particular adjustment;

in case of excess play of the sliding guide, tighten Lock the track support(1) by turning handle clockwise.

slide screw more.

To move the vise in either direction, the vise jaw must

be unlocked at two points.

Release the track support by turning the handle(1)

counter-clockwise.

Release the vise by moving the lever(2) to the left.

The vise (5) may now be moved to right position (7) or

left position (6)by pushing it with one hand on the vise

and the other hand on the track handle(1).

Fig 3

8

Fig 4

Fig 5

Fig 6

Adjust cutting angle

Operation cycle

Before operation, all the main organs of machine must

be set in optimum conditions.

Auto cutting operation

Using the right side, angles can be cut up to 60

degrees. This requires that vise jaw to be set on

the left side(6, fig6). Use the procedures for Vise

Adjustment, to place it in left side position.

Using the left side, angles can be cut up to 45

degrees. This requires the vise jaw to be set on the

right side(7,fig6). Use the procedures for Vise

Adjustment, to place it in right side position.

Unlock lever (3,fig4) and use the handle under the

control box to rotate the saw frame arm until you

reach mechanical stop and check if the index

corresponds to desired degrees; if not , operate on

Move the handle to the auto position (C2,fig10).Lift

the set screws to make measures meet.

the spring knob (S) and secure its pin into its slot.

Use manual/auto selector(SA2 fig8) to select auto.

Select c u tting speed by turning speed

selector(SA1 fig8).Turtle is low speed, rabbit is high

speed, and ‘O’ is neutral.

Turn main connect switch (QS fig8) to the ON

position.

Check that the indicator light (HL1) is on.

Load work piece and clamp it properly.

Press start/reset button(SB2) to start machine.

Check that the blade is running in the correct

direction.

Slightly pull the saw arm down to get rid of air

bubbles from the hydraulic cylinder.

Adjust hydraulic flow control valve(A) by slightly

turning the valve counter-clockwise to let saw arm

descend and start cutting.

Press the emergency push button ( K fig 11 or SB1

fig8) down to shut off all functions. To release the

emergency shut off rotate emergency push button (K

or SB1) clock-wise. The button will pop up and then

the cutting cycle can be restarted.

Close the hydraulic flow control valve(A) by turning

the valve clockwise all the way to the end.In general, start cuts by slightly turning hydraulic

flow control valve(A) counter-clockwise from 2 to 3

Raise the saw arm. to control the saw arm descent rate. If the arm

descends too quickly, turn hydraulic flow regulation

Lift the spring knob (S) to release the pin from its slot. valve (B) counter-clockwise all the way back to stop

This will free the fork handle( C). its descent.

9

Fig 7

Fig 8

Fig 9

Fig 10

Fully open the hydraulic flow control valve(A) by

turning the valve counter-clockwise all the way to the

end.

Press trigger switch(J) to start operation.

If cutting pipe with thin walls, reduce the saw arm

descent rate by adjusting the flow control valve(A).

Press the emergency push button(K fig11,or SB1 fig8)

down to shut off all functions.

To release the emergency push button(K fig11, SB1

fig8) rotate the mushroom shaped button clock-wise.

The button will pop up and then the cutting cycle can

be restarted.

A saw arm dropping too quickly can cause the blade

to stall on the work pieces and the machine will shut

off. Push down the emergency push button (K or SB1)

to immediately stop all machine functions.

Lift the spring knob (S) to release the pin from its slot.

This will free the fork handle(C).Move the handle to

the manual position (C1,fig10). Lift the spring

knob(S) and secure its pin into its slot.

Use manual/auto selector(SA2) to select handle

icon.

Select cutting speed by turning speed selector(SA1).

Turtle is low speed, rabbit is high speed, and ‘O’ is

neutral.

Turn main connect switch(QS) to the ON position.

Check that the indicator light(HL1) is on.

Load work piece and clamp it properly.

Fully open the hydraulic flow regulation valve(B) by

turning the valve clockwise all the way to the end.

Trigger switch (manual cutting) operation

Full close the hydraulic flow control valve(A) by

turning the valve clockwise all the way to the end.

Raise the saw arm as possible.

Fig 11

Fig 12

J

10

ADJUSTING

In case the blade needs to be replaced, make sure to

always install 0.9mm thick blades for which the the

blades guide pads have been adjusted.

In the case of toothed blade with different thickness

adjustment should be carried out as follows:

Loosen allen screw (L), adjusting the set screw (M),

the movable teeth (Q) will far away or close to the

blade.

Make sure that between blade and two side teeth

there is 0.05mm of play.

Then re-tighten allen screw (L).

Make sure that between blade and upper teeth of the

pad this is at least 0.2~0.3 mm of play; if necessary,

loosen the allen screws(P) that fasten the block and

adjust accordingly.

Changing the blade

Before performing the following operations , the

electric power supply and the power cable must be

completely dis-connected.

Lift the saw arm.

Loosen the blade with the hand-wheel, slide the

mobile blade guide to far away as possible, remove

the blade guard lock knob, remove the blade guard

and remove the old blade, from the flywheel and the

blade guide block.

Assemble a new blade by placing it first between the

pads and then on the race of flywheels, paying

particular attention to the cutting direction of the

teeth.

Tension the blade and make sure it perfectly fits

inside the seat of the flywheels.

Assemble the blade guard, and fasten it with relative

knobs.

Check the safety microswitch is activated othewise

when electric connection will be restored the machine

will not start.

Blade guide block

The blade is guided by means of adjustable pads set

place during inspection as per the thickness of the

blade with minimum play as shown in the figure.

Blade tension adjusting

The ideal tension of the blade is achieved rotating the

hand wheel until it touches the micro switch, that

actuates the operation of the machine is actuated.

The position of this switch is factory set during

inspection, after having tightened the blade on

the lengthening values indicated by its

manufacturer as per specific dimensions set with

the help of a special instrument. When replacing

the blade, if the thickness and the width differ, it

will be necessary to correct the projection of the

switch. For this purpose we suggest to strictly select

blades having the same features as mounted

originally.

Proper blade tension is 12 to14 MPa as measured on

a blade tension gauge.

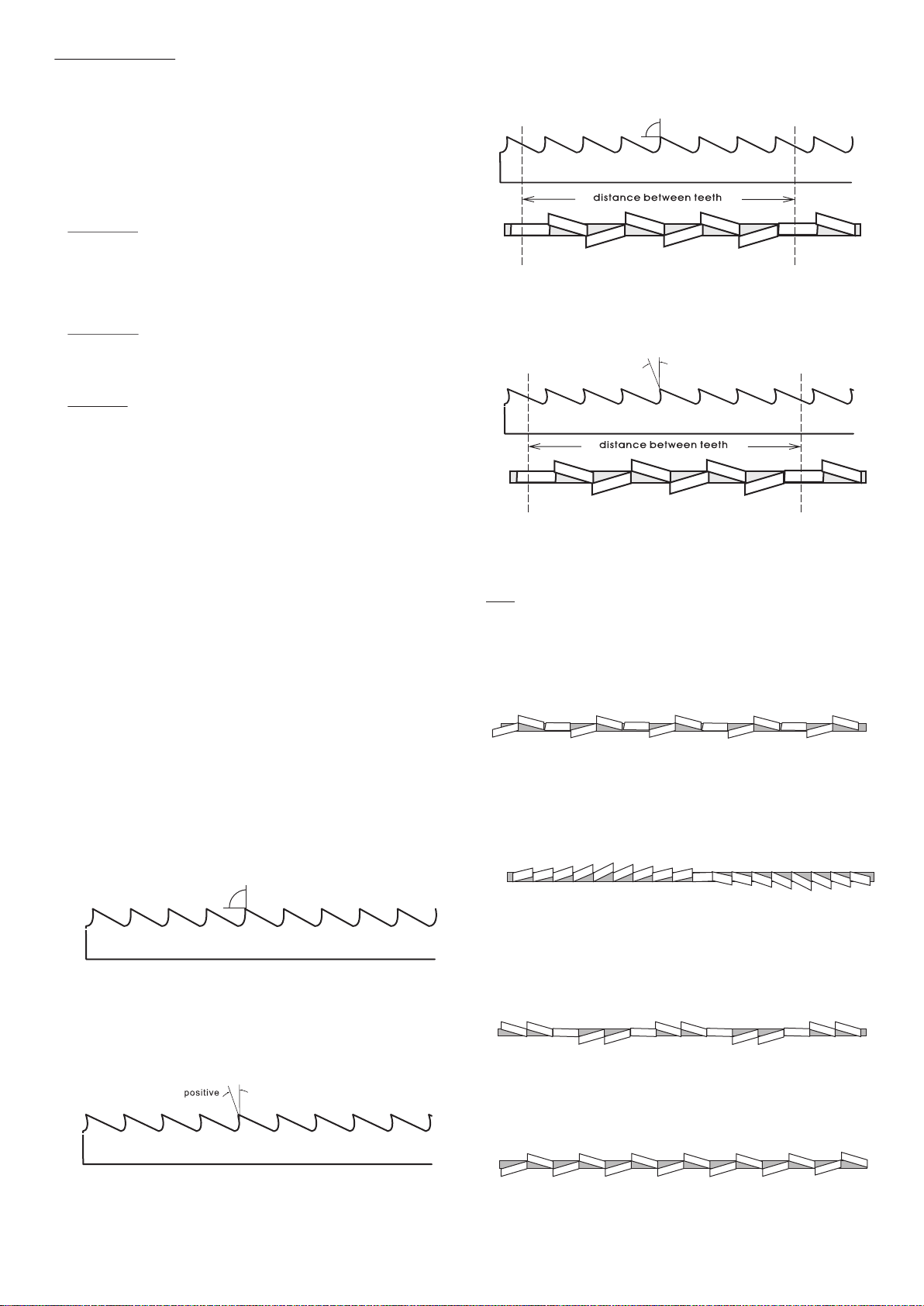

Adjusting the blade guide

Disconnect the machine from the power source.

Use a Allen wrench to loosen allen screw (A) on the

square lock plate.

Hold the handle(B) and slide blade guide block as

close as possible to the material without interfering

with the cut.

Tighten the allen screw(A).

Reconnect the machine to power source.

Fig 13

Fig 14

Fig 15

11

12

Always assemble blades having dimensions

specified in this manual and for which the blade

guide heads have been set.

This metal cutting bandsaw can not accept thick

than 0.9mm blade.

Adjusting the blade to the flywheel

Loosen the hex screws (Q1,Q2,Q3).

Use an allen wrench on set screw ( R) to adjust the tilt

of the flywheel.

Turning the set screw clockwise will tilt flywheel so

that the blade will ride closer to the flange.

Turning the set screw counter-clockwise will tilt

flywheel so that the blade will ride away from the

flange.

After the adjustment is finished fasten the hex

screw in this order: Q3, Q2, Q1.

Checking the adjustment of the blade

Use a strip of scrap paper and slide it between the

blade and the flywheel while it is running.

if the paper is cut then the blade is riding too close to

the flange. Re-adjust.

if you notice that the blade is riding away from the

flange.Then re-adjust.

Always assemble blades having dimensions

specified in this manual and for which the blade

guide heads have been set.

Fig 18

Fig 16

Fig 17

Fig 19

The gear box

MAINTENANCE

The maintenance jobs are listed below, divided into

Daily, Weekly, Monthly and 6-monthly intervals. If the

following operations are englected, the result will be

premature wear of the machine and poor performance.

Daily maintenance

General cleaning of the machine to remove

accumulated shavings.

Clean the lubricating coolant drain hole to avoid excess

fluid.

Top off the level of lubricating coolant.

Check blade for wear.

Rise of saw frame to top position and partial slacking of

the blade to avoid useless yield stress.

Check functionality of the shields and emergency

stops.

Weekly maintenance

Thorough cleaning of the machine to remove shavings,

especially from the lubricant fluid tank.

Removal of pump from its housing, cleaning of the

suction filter and suction zone.

Use compressed air to clean the blade guides (guide

bearing and drain hole of lubricating cooling).

Cleaning flywheel housing and blade sliding surface on

flywheels.

Monthly maintenance

Check the tightening of the motor flywheels screws.

Check that the blade guide bearings on the heads are

perfect running condition.

Special maintenance

Check the tightening of screws of the gear motor, pump,

Special maintenance must be conducted by skilled

and accident protection guarding.

personal. We Advise contacting your nearest dealer

and/or importer. Also the reset of protective and safety

6-monthly maintenance

equipment and devices ( of the reducer), the motor, the

motor pump, and other electrical components requires

Continuity test of the equipotential protection circuit.

special maintenance.

Maintenance of other machine parts

The worm drive gearbox mounted on the machine is

maintenance-free guaranteed by its manufacture.

Oils for lubricating coolant

Considering the vast range of products on the market,

the user can choose the one most suited to their own

requirements, using as reference the type SHELL

LUTEM OIL ECO. THE MINIMUM PERCENTAGE OF

OIL DILUTED IN WATER IS 8-10%.

The gear box requires periodic changing of oil. The oil

must be changed by the first 6 months of a new

machine and every year thereafter.

To change the gear box oil

Disconnect the machine from the power source.

Raise the saw arm to vertical position.

B

Replace the screw after oil completely flows off.

Place the saw arm back to horizontal position.

Fill Gear box with approximately 0.6 liter of gear oil

through the hole of the vent screw ( ).

For reference, use SHELL type gear oil or Mobile

gear oil #90.

13

Fig 20

B

Draw off gear oil by loosening the allen head screw ( A )

A

14

BLADE CHOICE

Structure” is for reference only.)

4. In the applicable row, read across to the right and find

the box where the row and column intersect. Listed in

Selecting the right blade for the job depends on a variety the box is the minimum TPI recommended for the

of factors, such as the type of material being cut, variable tooth pitch blades.

hardness of the material, material shape machine

capability, and operator technique. 5. The "Cutting Speed Rate Recommendation" section of

the charts offers guidelines for various metals, given in

The chart below is a basic starting point for choosing feet per minute (speed FPM) and meters per minute in

blade type based on teeth per inch (TPI) for variable parenthesis. Choose the speed closest to the number

tooth pitch blades and for standard raker type bi-metal shown in the chart.

blades/HSS blades. However, for exact specifications of

bandsaw blades, contact the blade manufacturer. (The next page”Blade

To select the correct blade TPI:

1. Measure the material thickness. This measurement is

the length of cut taken from where the tooth enters the

workpiece, sweeps through, and exits the workpiece.

2. Refer to the "Material Width/Diameter" row of the

blade selection chart and read across to find your

workpiece thickness you need to cut.

3. Refer to the "Material Shapes" row and find the shape

and material to be cut.

196~354

(60) (108)

196~354

(60) (108)

180~220

(54) (67)

180~220

(54) (67)

220~534

(67) (163)

229~482

(70) (147)

150~203

(46) (62)

108~225

(33) (75)

65~85

(20) (26)

321

(98)

220

(67)

203-413

(62) (65)

95-213

(29) (65)

75-118

(25) (36)

203

(62)

229~482

(70) (147)

220~534

(67) (163)

180~220

(54) (67)

180~220

(54) (67)

203

(62)

15

Blade Structure COMBO TOOTH

Pitch varies between teeth and consequently varying teeth

size and varying gullet depths. Pitch varies between teeth,

Bi-metal blade are the most commonly used. They consist of which ensures a smoother, quieter cut and longer blade life

silicon-steel blade backing by a laser welded high speed steel owing to the lack of vibration.

(HSS) cutting edge. The type of stock are classified in M2, M42,

M51 and differ from each other because their major hardness

due to increasing percentage of Cobalt (Cc) and molybdenum

(Mo) contained in metal alloy.

There are several key factors to consider in choosing a blade:

Tooth Pitch---The number of teeth per inch (TPI) on the

blade, also known as tooth pitch. Select a pitch

which will assure that at least three teeth are

contacting the workpiece while cutting. This helps to Another advantage offered in the use of this type of blade in

distribute the cutting forces and avoids tooth the fact that with an only blade it is possible to cut a wide

breakage.range of different material in size and type.

Tooth Form---There are four common forms of teeth on the COMBO TOOTH

blade: buttress, claw-tooth, precision and tungsten O O

9 -10 positive rake

carbide. Precision is the most common and is the

type supplied with this saw.

Tooth Set---Set is the degree to which the teeth are bent

away from the blade. Typical tooth set styles are

raker, wave and straight set.

Always select and use good-quality saw blades and choose

the right blade for the job. Discuss your cutting

requirements with your saw blade dealer to make sure you

are getting the type of blade which best suits your need.

Poor quality blades and improper use are often the cause This type of blade is the most suitable for the cutting of

of premature blade failure.section bars and large and thick pipes as well as for the

cutting of solid bars at maximum machine capacity. Available

Many conditions can lead to breakage. Blade breakage is, in pitches: 3-4/4-6.

some cases, unavoidable, since it is the natural result of the

peculiar stresses that bandsaw blades are subjected to. Sets

Blade breakage is also due to avoidable causes.

Saw teeth bent out the plane of saw body, resulting in a wide

Avoidable breakage is most often the result of poor care cut in the work-piece.

or judgement on the part of the operator when mounting or

adjusting the blade or support guides. The most common Regular or Raker Set

causes of blade breakage are:Cutting teeth right and left, alternated by a straight

tooth.

(1) faulty alignment and adjustment of the guides;

(2) insufficient number of teeth contacting the cut;

(3) feeding too fast;

(4) tooth dullness or absence of sufficient set;

Of great use for materials with dimensions superior to 5mm.

(5) excessive tension;

Used for cutting of steel, castings and hard nonferrous

(6) using a blade with a lumpy or improperly finished

materials.

weld;and

(7) continuously running the bandsaw when not in use.

Wavy Set

REGULAR TOOTH Set in smooth waves.

O

0 rake and constant pitch

This set is associated with very fine teeth and it is mainly

used for cutting of pipes and thin section bars (from 1-3mm).

Most common form for transversal or inclined of solid small and Alternate Set (in groups)

average cross-sections or pipes, in laminated mild steel and Groups of cutting teeth right and left, alternated by a

gray iron or general metal. straight tooth.

POSITIVE RAKE TOOTH

O O

9 -10 positive rake and constant pitch This set is associated with very fine teeth and it is used for

extremely thin materials (less than 1mm).

Alternate Set( individual teeth)

Cutting teeth right and left.

Particular use for crosswise or inclined cuts in solid sections or

large pipes, but above all harder materials (highly alloyed and This set is used for the cutting of nonferrous soft materials,

stainless steels, special bronze and forge pig iron). plastics and wood.

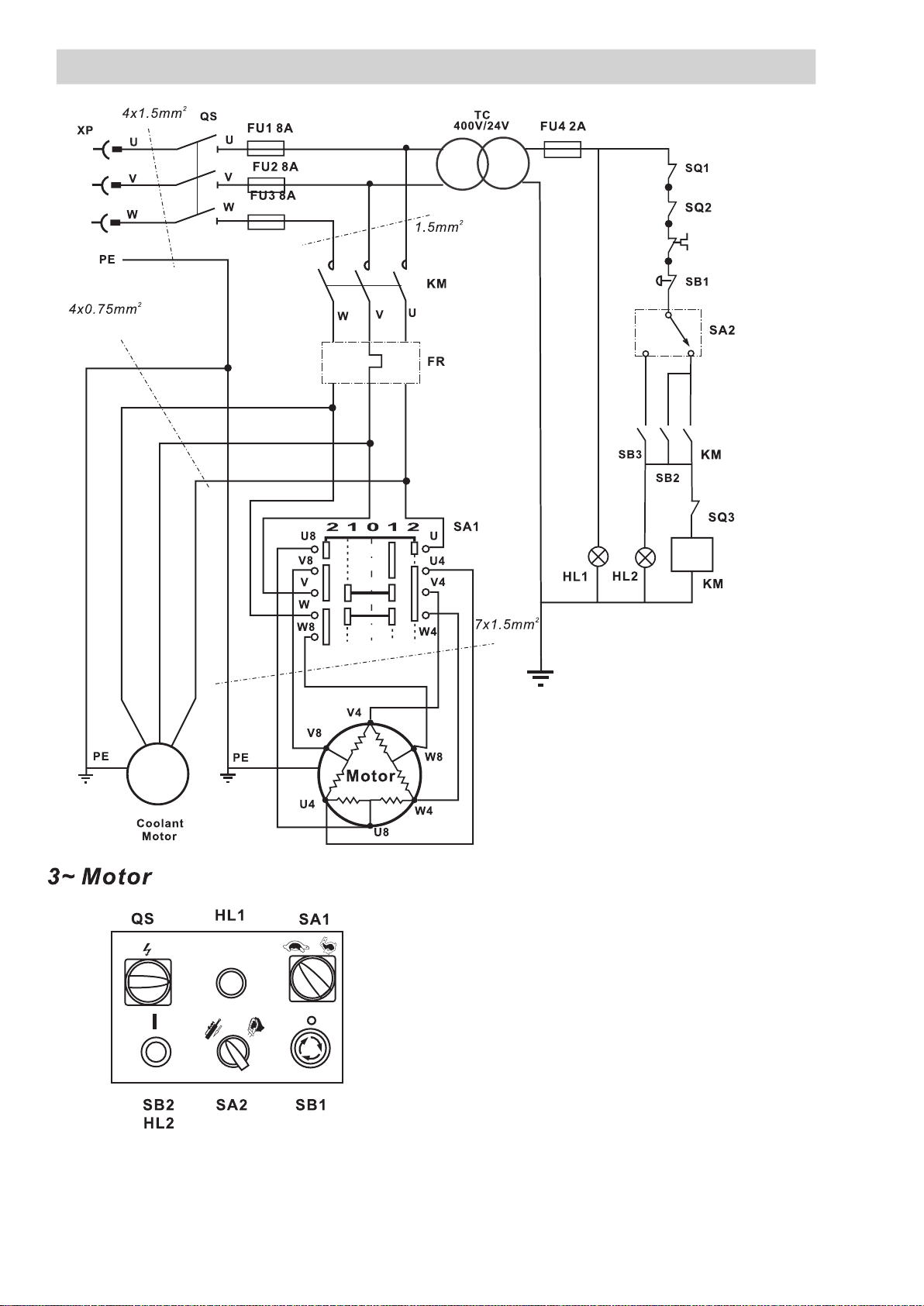

ELECTRICAL SYSTEM

QS:Main Switch

SA1: Hi/Low Speed Control

SA2: Mode Switch

KM:Contactor

FR: Thermal protector

TC: Transformer

FU1-3: Fuse 8A

FU4:Transformer Fuse 2A

HL1:Power Light

HL2:Run Light

SB1: Emergency Stop Button

SB2: ON Button

SB3:Button on Grip-hand

SQ1-3: Limit Switch

16

TROUBLESHOOTING

This chapter lists the probable faults and malfunctions that could occur while the machine is being used and suggests possible

remedies for solving them.

The first paragraph provides diagnosis for TOOL and CUTS, the second for ELECTRICAL COMPONENTS.

FAULT

Tooth Breakage

PROBABLE CAUSE

Too fast advance

Wrong cutting speed

Wrong tooth pitch

Chips sticking onto teeth and in the

gullets or material that gums

Defects on the material or material too

hard

Ineffective gripping of the part in the vise

The blade gets stuck in the material

Starting cut on sharp or irregular section

bars

Poor quality blades

Previously broken tooth left in cut

Cutting resumed on a groove made

previously

Vibrations

Wrong tooth pitch or shapes

insufficient lubricating, refrigerant, or

wrong emulsion

REMEDY

Decrease advance exerting less cutting pressure.

Adjust the braking device.

Change speed and /or type of blade .See chapter

on “Material classification and blade selection”, in

the section Blade selection table according to

cutting and feed speed.

Choose a suitable blade. See Chapter “Material

classification and blade selection”.

Check for clogging of coolant drain holes on the

blade-guide blocks and that flow is plentiful in

order to facilitate the removal of chips from the

blade.

Material surface can be oxidized or covered with

impurities making them, at the beginning of the

cut , harder that the bade itself , or have harder

areas or inclusions inside the section due

productive agents used as casting sand, welding

wastes, etc. Avoid cutting these materials or in

a situation a cut has to be made use extreme care,

cleaning and remove any such impurities as

quickly as possible.

Check the gripping of the part.

Reduce feed and exert less cutting pressure.

Pay more attention when you start cutting.

Use a superior quality blade.

Accurately remove all the parts left in.

Make the cut elsewhere, turning the part.

Check gripping of the part.

Replace blade with a more suitable one. See

“Material classification and blade selection” in

the Blade Types selection. Adjust bade guide

pads.

Check level of liquid in the tank. Increase the flow

of lubricating refrigerant, checking that the hole

and the liquid outlet pipe are not blocked .Check

the emulsion percentage.

17

FAULT

Premature Blade Wear

Blade Breakage

PROBABLE CAUSE

Faulty running-in of blade

Teeth positioned in the direction opposite

the cutting direction

Poor quality blade

Too fast advance

Wrong cutting speed

Defects on the material or material too

hard

insufficient lubricating refrigerant or

wrong emulsion

Faulty welding of blade

Too fast advance

wrong cutting speed

Wrong tooth pitch

Ineffective gripping of the part in the vice

Blade touching material at beginning of

cut

Remedy

REMEDY

See “Material classification and blade selection”

in the Blade running –in section.

Turn teeth in correct direction.

Use a superior quality blade.

Decrease advance, exerting less cutting pressure.

Adjust the braking device.

Change speed and /or type of blade. See chapter

on “Material classification and blade selection”,

in the section Blade selection table according to

cutting and feed speed.

Material surface can be oxidized or covered with

impurities making them, at the beginning of the

cut, harder the blade itself , or have hardened

area or inclusion inside the section due to

productive agents used such as casting sand,

welding wastes, etc. Avoid cutting these

materials or perform cutting with extreme care,

cleaning and remove such impurities as quickly

as possible.

Check level of liquid in the tank. Increase the flow

of lubricating coolant, checking that the coolant

nozzle and pipe are not blocked. Check the

emulsion percentage.

The welding of blade is of utmost importance. The

meeting surfaces must perfectly match and once

they are welded they must have no inclusion or

bubbles; the welded part must be perfectly

smooth and even. They must evenly thick and

have no bulges that can cause dents or instant

breakage when sliding between the blade guide

pads.

Decrease advance, exerting less cutting pressure.

Adjust the breaking device.

Change speed and /or type of blade.

See chapter on “Material classification and blade

selection”, in the section Blade selection table

according to cutting and feed speed.

Choose a suitable blade .See Chapter “Material

classification and blade selection”.

Check the gripping of the part.

At the beginning of the cutting process, never

lower the saw arm before starting the blade

motor.

18

FAULT

Steaked or etched bands

Cuts off the straight

PROBABLE CAUSE

Blade guide pads not regulated or dirty

because of lack of maintenance.

Blade guide block too far from material to

be cut.

Improper position of blade on flywheels.

Insufficient lubricating coolant or wrong

emulsion.

Damaged or chipped blade guide pads.

Tight or slackened blade guide bearings.

Blade not parallel as to the counter

service.

Blade not perpendicular due to the

excessive play between the guide pads

and maladjustment of the blocks.

Too fast advance.

Worm out blade

Wrong tooth pitch

REMEDY

Check distance between pads ( see “Machine

adjustments” in the Blade Guide Blocks

section): extremely accurate guiding may cause

cracks and breakage of the tooth. Use extreme

care when cleaning.

Approach head as near as possible to material to be

cut so that only the blade section employed in the

cut is free, this will prevent deflections that would

excessively stress the blade.

The back of blade rubs against the support due to

deformed or poorly welded bands (tapered),

causing cracks and swelling of the back contour.

Check level of liquid in the tank. Increase the flow

of lubricating refrigerant, checking that the hoe

and the liquid outlet pipe are not blocked. Check

the emulsion percentage.

Replace them.

Adjust them ( see Chapter “Machine

Adjustments” in Blade guide section).

Check fastenings of the blade guide blocks as to

the counter-vice so that they are not too loose

and adjust blocks vertically; bring into line the

position of the degrees and if necessary adjust

the stop screws of the degree cuts.

Check and vertically re-adjust the blade guide

blocks; reset proper side guide play (see

Chapter “Machine adjustments” in Blade guide

section) .

Degree advance, exerting less cutting pressure .

Adjust the braking device.

Approach it as near as possible to material to be

cut so that only the blade section employed in the

cut is free, this will prevent deflection that would

excessively stress the blade.

Replace it. Blade with major density of teeth is

being used, try using one with less teeth (see

Chapter “Material classification and blade

selection” in the Blade Types section) .

19

Table of contents