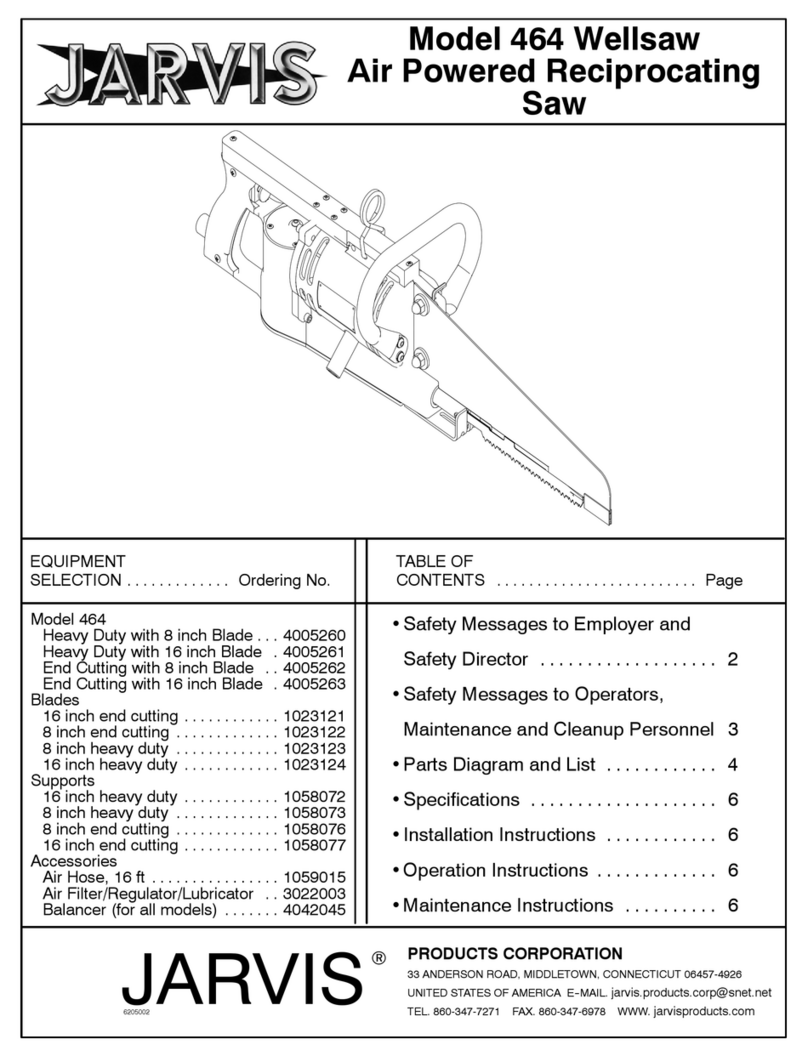

~WeIIsaw

operation instructions

MODEL 400

pg

8

of

12

OPERATION INSTRUCTIONS

Before starting regular operation

of

the JarvisWellsaw,

werecommendthatyou makeafew cuts withafme pitch

blade to acquaint yourself with the operation

of

the tool

before using any

of

the coarser blades.

A. AVERAGE CUTTING AND RIPPING:

1.

Place your work piece on a solid support at a

convenient working height.

2. Adjustthe material so thatthe line

of

cut will be

close to the support. Secure it fmnly.

3. To prevent starting torque

of

the motor from

pullingthe saw away from line

of

cut, theopera-

tor should make a few short strokes until the

bladehas cutintothe material about 1/4inchbe-

fore squeezing trigger switch.

4. Both hands should be on the saw at all times

while cutting. Continue holding the tool with

both hands until the saw blade comes to a com-

plete stop.

S.

The saw should

be

kept at a 90 degree angle to

the work piece while cutting material that is

thicker then 1 inch. For thin materials a

12-

toothbladeanda

30

degreecuttingangleare rec-

ommended.

6. The saw shouldbe pushed firmly into the mate-

rial while cutting.

7.

Do

not allow the saw blade

or

the blade support

to leave the work piece while cutting.

8.

Never allow the saw blade to float into material

while cutting.

9. Never permit any part

of

the saw, except the

blade

or

the blade support, to contact the work

piece during the cut.

B.

LARGE CROSS SECTIONS:

1.

Rocking the saw inthe cutwill speedupthe cut-

ting action.

An

8-tooth

blade is recommended.

C. SINKING

THE

BLADE THROUGH A SUR-

FACE:

1.

Your powerhand saw is notdesignedfor regular

use in starting its own hole by sinking blades

through a surface, commonly called "plunge

cutting".

If

attempted, the operator must:

a. Keep the saw blade as parallel to the work

as possible.

b. Immediately, as the blade makes contact

with the work piece, start to draw the saw

back slowly from the starting point.

c. Repeatthe operationoutlinedin"b",

if

nec-

essary.

d. Have room to draw the saw at least

4-6

in-

ches before cutting through a 1 inch thick-

ness.

e.

Do

not force the saw blade, but keep it

moving slowly on the draw back from the

starting point. After the break through cut

hasbeenmadeandtheend

of

thebladesup-

port extends through the material at least

1-1/2

inches, the saw may be tipped to a

normal cutting angle.

D. NOT FOR

CUITING

METAL:

1.

Due to the blade speed and design, your Jarvis

Wellsaw is not for cutting metal.

E. NOT FOR

CUITING

SMALL RADII:

PRODUCTS CORPORATION

33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457-4926

UNITED STATES OF AMERICA

JARVIS®

FAX 860-347-6978 TEL. 860--347-7271