Aura Cebilon Platinum Manual

REVERSE OSMOSIS SYSTEM

Cebilon Platinum with pump

Operating and maintenance instructions

Before installing and using the system, please read these instructions carefully.

EN

a

1

We thank you for choosing our reverse osmosis system.

Our Cebilon Platinum reverse osmosis system is available in 2 versions.

· Cebilon Platinum reverse osmosis system

· Cebilon Platinum reverse osmosis system with pump

We recommend that you have the installation carried out by qualied personnel.

Tap water

Water without solid particles

Water without solid particles and chlorine

Clean water

Waste water

2

Water leakage system

1

Regulator

3

Low pressure switch*

4 5 -μm sediment lter

5 Pressure pump*

6 Activated carbon granulate lter

7 1-μm sediment lter

8

4-way shut -o valve

9

Membrane

10

Downstream activated carbon lter

11 High pressure switch*

12 Flow rate restrictor

13

Clean water tank valve

14

Clean water tank

15 Tap

16 Pressure pump adapter (24 VDC)*

* Available for the model with

pressure pump

Fig. 2: Diagram of the reverse osmosis system

THE SYSTEM COMPONENTS

15

11

12

10

9

16

8

5

13

14 7 6

2

1

3

4

Mains water inlet

(Tap water)

Waste water

2

D

ischarge outlet

Outer layer

Waste water

I

nlet

Clean water

Tube

Welded area

The 5-μm sediment lter removes the materials and particles oating in

the water. The activated carbon granulate lter (GAC) lters out organic

materials and unwanted odors. The 1-μm sediment lter removes the rest

of the particles to ensure the correct functioning of the membrane.

The membrane is where the phenomenon of reverse osmosis occurs.

This component consists of a partially permeable material which is wound

in a spiral around the clean water (permeate) collecting pipe. Water that

cannot penetrate the partially permeable membrane is discharged

through the waste water pipe.

Fig. 3: Membrane structure

COMPONENT FUNCTIONS

3

APPLICATION

In order to generate a suitable outlet pressure for the clean water and to

store it under ideal disinfection conditions, the clean water tank has an

inner surface which is covered with a plastic material suitable for

foodstus. With the clean water tank valve you can open and close the

water inlet to the clean water tank.

The downstream activated carbon filter enriches the clean water by

adding minerals. Thereby, the lter regulates pH value of the water before

its consumption.

The flow rate restrictor generates the pressure on the membrane required

for the operation of the system. It is located in the waste water tube.

The mineral-enriched clean water with a regulated pH value can be taken

from the tap.

The l ow pressure switch* stops the pressure pump when the water

supply is turned o or the pressure is less than 0.2 bar (3 psi).

The pressure pump* increases the pressure on the water owing through

the 5-µm sediment lter to the value required for reverse osmosis.

The 4-way shut-off valve regulates the water ow. It interrupts the water

ow as soon as the pressure in the clean water tank reaches the inlet

pressure of the membrane.

The high pressure switch* stops the pressure pump as soon as the

pressure in the clean water tank reaches 2.6 bar (38 psi).

The pressure pump adapter* provides the power supply for the

pressure pump. Here the power supply voltage is converted to 24 VDC.

* Available for the model with pressure pump

This system is used to obtain drinking and cooking water from tap water

by subjecting water that has already passed through the municipal waste

water treatment plant to the process of reverse osmosis.

This water must be microbiologically safe with regard to the required

disinfection.

4

Clean water tank capacity 2.2 gallons (approx. 8 liters)

Clean water tank air pressure

0.40 - 0.48 bar (40 - 40 kPa, 6 - 7 psi)

Daily production 34.03 gpd (128.6 l/d)

Inlet of total dissolved solids

(TDS)

Max. 1250 ppm

Waste water rate 85 - 98 %

Pressure pump ow rate*

0.8 - 1.2 l/m

Pump pressure 0.8 - 1.10 bar (551 - 758 kPa,

80 - 110 psi)

Pump power supply* Input: 220 - 240 VAC / 50/60 Hz;

output: 24 VDC / 0.8 (nom.) max.

1.2 A

System dimensions (mm) 270 x 400 x 385

Total weight With pump: 12.5 kg /

without pump: 9.5 kg

* Available for the model with pressure pump

Do not use water for this system that is microbiologically unsafe, that has

not been suciently disinfected before or after operation or that is of

unknown quality.

Cebilon Platinum reverse osmosis system contains components

that need to be replaced regularly in order to eciently lter the dissolved

solids (TDS) from the water. To check the eciency of the system, check

the water in the system regularly.

Therefore, please also replace regularly the components that need to be

replaced. To ensure continuous eciency and performance of the

system, only use components that meet the dened specications for

replacement.

TECHNICAL SPECIFICATIONS

5

INSTALLATION

The rst lter in the system is the 5 µm sediment lter, in which solid

particles are retained. The water then passes through the activated carbon

granulate lter (GAC). This lter retains organic substances and especially

free chlorine. Furthermore, odors are eliminated. The 1-µm sediment lter

is the last lter before the membrane. This also protects the membrane,

which increases its service life.

The water ltered through the three pre-lters then ows through the

membrane, which forms the basis of the water treatment in the reverse

osmosis system. A large number of small particles are retained here,

which are then discharged through the waste water tube.

The water that has been able to penetrate the membrane rst passes

through the downstream activated carbon lter, which has the function of

a pH regulator, and then to the clean water tank.

To ensure reliable functioning and a long service life of the membrane, the

amount of waste water must always be bigger than the amount of clean

water. The treated clean water in the tank increases the water supply. The

storage capacity of your system is 2.2 gallons, which is approximately

8 liters.

The system is very easy to use and the water pipe system can be easily

installed anywhere. The installation should only be carried out by a

qualied technician.

Cebilon Platinum reverse osmosis system contains components that need

to be replaced regularly to eciently lter the dissolved solids (TDS) from

the water.

Free chlorine can negatively aect the polymer structure of the membrane

within the system.

Please read the operating instructions and pay particular attention to the

chapters about installation, operation, maintenance and warranty conditions.

The operating sequence of the system is shown in Figure 4.

OPERATING PRINCIPLE

6

1- Make sure that the installation is protected against possible freezing.

2- Do not intervene in the waste water system.

3- However, if muddy water (clay etc.) comes out of the pipe, close the

water inlet valve of the system.

4- If you wish to use a water supply system other than the local water

supply system, it must be subjected to a drinking water analysis by the

responsible institutions.

5- If the water used is not tap water, make sure that the water is properly

disinfected.

The ters are considered accessories and are not covered by the warranty.

Clean water

Waste water

Fig. 4: Installation of the reverse osmosis system

WARNING!

Tap water

1- Cebilon reverse osmosis system

2- Water inlet valve

3- Water inlet

4- Waste water outlet

5- Clean water outlet

6- Waste water clamp

7- Tap

7

6

2

1

5

4

3

3

7

d

e

b

Close the water inlet valve.

After the remaining water in the tubes has been drained at the appropriate

points, connect the 3-way adapter to the water inlet. Make sure that there

are no leaks.

First, install the 1/4 " ball valve on the adapter by wrapping it with Teon

tape in a position that allows easy opening and closing of the ball valve

(Fig. 5 a).

Then, connect the water supply hose to the ball valve (Fig. 5 b).

Make sure that the ball valve is closed (Fig. 5 c).

Open the water inlet valve and check the installation for possible leaks

(Fig. 5 d).

Place the system in a suitable place under the sink in an upright position.

Fig. 5: Water connection ttings

WATER CONNECTION

d

8

Install the tap with regard to use and aesthetics.

When drilling through the kitchen worktop or sink, before drilling, make sure

that the dimensions are suitable for installing the washers, nuts and joints

under the kitchen worktop or sink (Fig. 6). Otherwise, there is a risk that you

will carry out the drilling incorrectly.

The tube should be carefully installed between the tap and the clean water

outlet of the system.

Water connection fittings

1 Tap tube

2 Upper tap body

3 Tap handle (open/close)

4 Hub cover

5 Tap body

6 Housing sleeve

7 O-ring of the housing sleeve

8 Mounting piece

9 Plastic mounting piece

10 Plastic mounting washer

11 Washer

12 Compression nut

13 Thread bar

14 1/4" hose

Fig. 6: Tap

INSTALLATION OF THE TAP

9

To install the waste water outlet, drill into the 8 mm diameter hole of the

clamp in the same tube (Fig. 7 b). Connect one end of the 3/8-inch tap to

this clamp and the other end to the 3/8-inch outlet.

Fig. 7: Waste water connection

Fig. 8: Water inlet valve

• Insert the plug of the pressure pump adapter into the 24 VDC power

supply input of the system. Then, connect the adapter to the power

supply.*

• Open the tap for the clean water.

• Close the clean water tank valve.

• By opening the 1/4" ball valve, the tap water is supplied to the

system (Fig. 8). The pump starts working.

• When the water ows, close the tap.

• As soon as pump operation has stopped, check each individual

connection for possible leaks and open the clean water tank valve.

• Since the tank is being lled for the rst time, drain the clean water

at least once.

* Available for the model with pressure pump

CHECKS BEFORE THE START -UP

CONNECTION OF THE WASTE WATE

R

OUTLET

10

MAINTENANCE

This system has been developed for private use in households.

Components such as the clean water tank, the waste water tube and the

water tap are not intended for outdoor installation.

Before using the system, carry out the necessary measures to disinfect

microbiologically unsafe water.

Install the system with its own power supply unit.*

If there is no one in the house, we recommend that you close the water inlet

valve for safety reasons (Fig. 8).

Repairs have to be carried out by qualied personnel.

The maintenance of your system should only be carried out by an authorized

technician.

The service life of the lters used in Cebilon Platinum reverse osmosis

systems changes with the amount of water treated, depending on several

factors. These main factors are: the quality of the incoming water, the

amount of chlorine, the amount of dry residue, etc. The lters are

considered accessories and are not covered by the warranty.

IMPORTANT NOTES

11

To use your system eciently and for a long time, carry out the

maintenance regularly and on time. The following replacement intervals

apply to lters that are used under normal conditions in the water system.

The operating conditions of the lters can change depending on the

quality of the inowing water and the amount of chlorine and sediments.

Only authorized technicians should perform the periodic

maintenance required to keep your system operating eciently

every six months.

Filter name Replacement

interval Notes

5-µm sediment

lter

6 months

Sediments are ltered by retaining the coarse particles

in the water. Thus , the water is ltered down to the

micrometer level. Its service life depends on the quality

of the inowing water.

Activated carbon

granulate lter

(GAC)

6-12 months

This lter removes the chlorine from the water. Excess

chlorine reduces the service life of the upstream

activated carbon granulate lter (GAC). Timely

replacement protects against chlorine damage and

extends the service life of the membrane.

1-µm sediment

filter 6-12 months This 1 -µm sediment lter retains carbon dust to

prevent membrane clogging.

Activated carbon

lter 6-12 months This lter regulates the pH value by adding minerals

to the water.

Membrane

2 - 5 years

The membrane is where the phenomenon of reverse

osmosis occurs.

The service life of the membrane changes depending

on the ion concentration in the tap water, the amount

of clean water produced and sucient maintenance.

For spare parts, please contact your local distributor.

RECOMMENDED INTERVALS FOR FILTER REPLACEMENT

12

SPECIFICATIONS FOR USE

The Cebilon Platinum reverse osmosis system meets the NSF/ANSI Standard 58

(US standard for point of use (POU) reverse osmosis systems (RO)) for

performance standards veried with conrmed test data.

Do not use water for this system that is microbiologically unsafe, that has

not been suciently disinfected before or after operation or that is of

unknown quality.

Cebilon Platinum reverse osmosis system contains components that need

to be replaced regularly to eciently lter the dissolved solids (TDS) from

the water. To check the eciency of the system, check the water in the

system regularly.

Please also replace the lters according to the specied replacement

intervals.

• Water inlet pressure for systems without pressure pump (min/max):

3 - 5 bar

• Water inlet pressure for systems with pressure pump (min/max):

1 - 3 bar

• Clean water production of the reverse osmosis membrane:

75 gpd (283,4 l/d)

• Clean water tank capacity: 2.2 gallons (approx. 8 liters)

• Inlet of total dissolved solids (TDS): max. 1250 ppm

• Average salt ltration: 97 - 98 %

• Water inlet temperature (min/max): 5 - 45 ºC

• Power supply (system with pressure pump): Input: 220 - 240 VAC

/ 50/60Hz; Output: 24 VDC / 0.8 (nom) max. 1.2 A

TECHNICAL DATA SHEET

13

TROUBLESHOOTING AND SOLUTIONS

Errors Possible causes Recommended solution

There are air

bubbles in the water

or the water is

colored white.

There is air in the system.

Air in the system shortly after the rst installation is normal.

Sometimes, there may be air from the water supply.

After a certain operating time, however, this will

decrease. The use of this water is not harmful.

The system produces

little clean water.

The pressure pump is not working and there

is no suitable pressure available*.

Check if the pressure pump adapter is plugged in.

If the adapter is plugged in, please contact a technician.

The pre -lters are clogged. Please contact a technician.

The membrane does not work. Please contact a technician.

The temperature of the incoming water has

dropped.

This is not a malfunction. It is normal that the amount of

fresh water in winter decreases by a certain amount.

The check valve is defective. Please contact a technician.

Although the clean

water tank is full, no

water runs out of the

tap.

The air pressure in the tank is insucient. There is not enough air left in the tank.

Please contact a technician.

The system

generates excessive

noise.

A water ow noise can be generated in the

waste water tube.

Correctly align the clamp attached to the siphon and

to the outlet pipe.

This may be due to an obstruction or a bent

tube.

Remove the obstruction in the waste water tube or align

the benttube.

The pump works

constantly.*

The pressure switch is defective. Close the water inlet valve and contact a technician.

The low pressure switch is defective.

Close the water inlet valve and contact a technician.

The check valve is defective. Please contact our technical support.

The shut -o valve is defective. Please contact our technical support.

The pump is defective. Please contact our technical support.

* Available for the model with pressure pump

The warranty period of our workshops is 2 years.

The warranty does not cover consumables such as filters and the reverse osmosis

membrane. In order to apply for the guarantee,itis essential to present the purchase

invoice.

The warranty is void if the system has been modified or if the user has not followed the

instructions in the manual.

If the system is not working properly, close the water inlet valve. Disconnect the system

from the power supply and contactour technical support.

Any use not specified in this manual will invalidate the warranty.

Table of contents

Popular Water System manuals by other brands

Alliance Laundry Systems

Alliance Laundry Systems F232122R3 Supplement

Sanela

Sanela SLUN 43 Instructions for use

Graco

Graco ProMix Easy Installation

Clear Flo

Clear Flo Clear Flo Installation & owner's manual

evenes

evenes EV-ZUP-T 15 PLUS Installation and operating instructions

Reliable

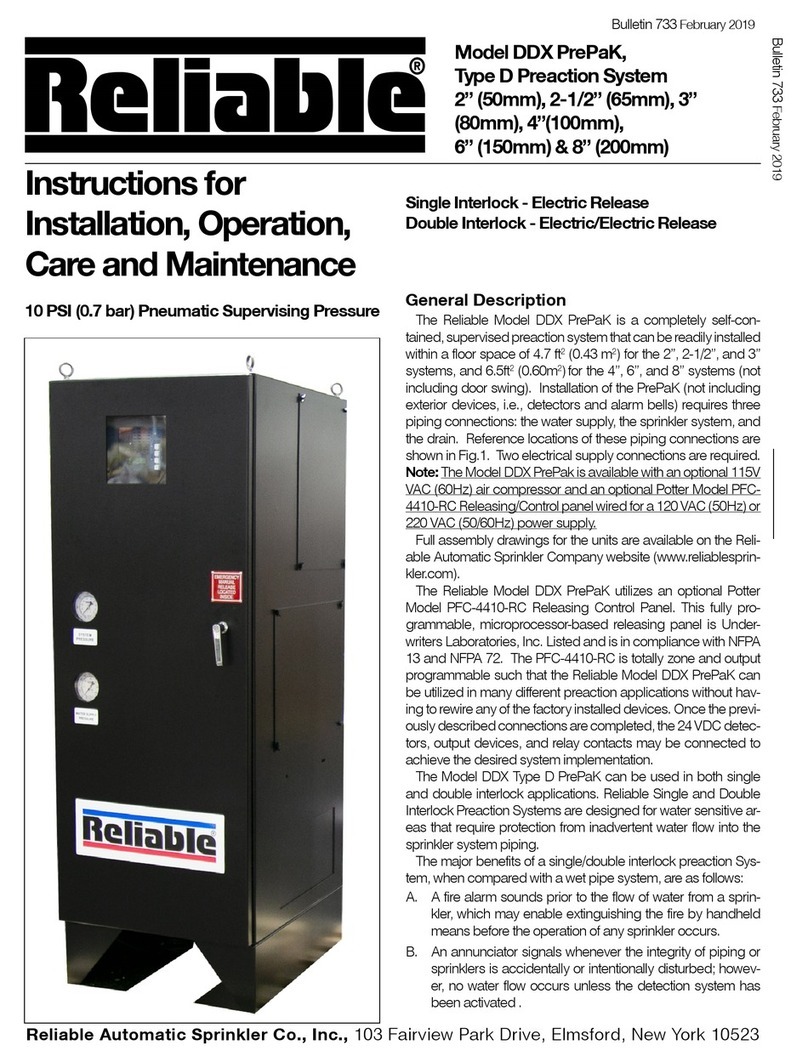

Reliable DDX PrePaK Instructions for installation, operation care and maintenance

Ecolab

Ecolab Connexx red & blue operating instructions

Eljen

Eljen Mantis M5 Series Design & Installation Manual

Taco Comfort Solutions

Taco Comfort Solutions 0015-MSF-IFC instruction sheet

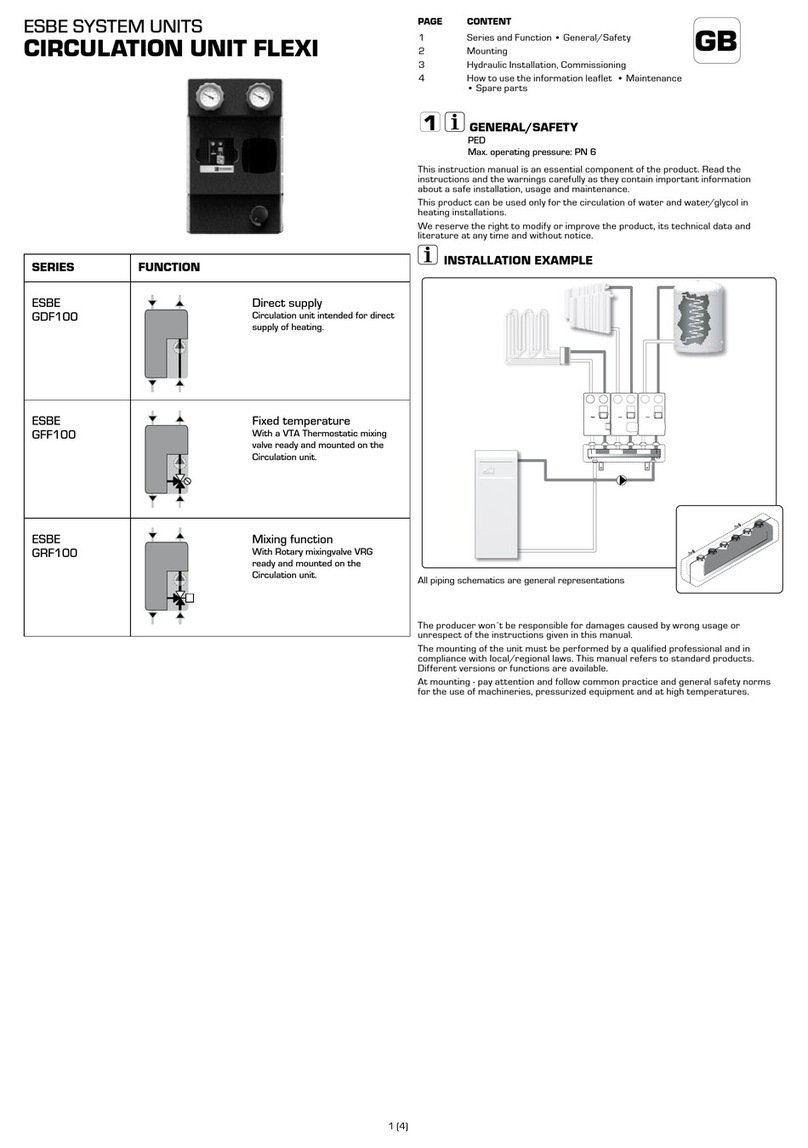

ESBE

ESBE GRF100 quick guide

Zip

Zip HydroTap G4 Install instructions

Elkay

Elkay EZH2O LZWS-LRPBM28K installation instructions