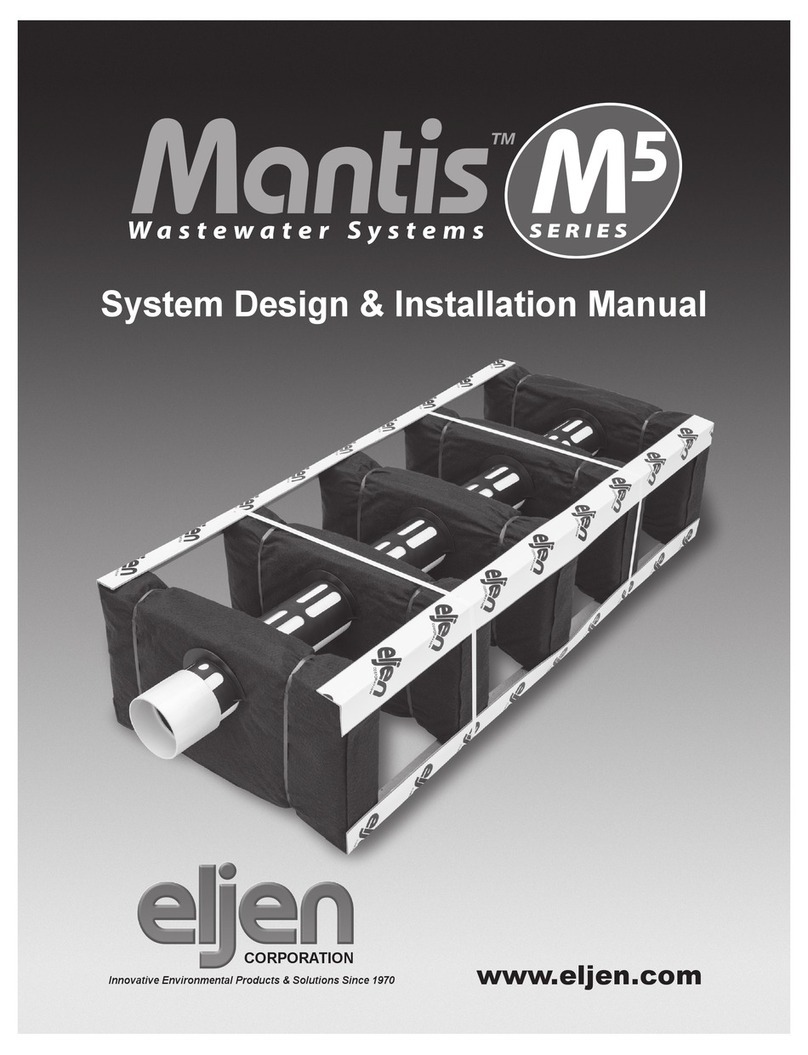

GMP #116–Appendix A

2013 Virginia Mantis M5Design & Installation Manual Page 17 www.eljen.com

Appendix A contains two versions of the Warranty, Notice of Substitution

and Waiver. The rst is to be used when VDH has issued a permit for a

gravel-type draineld system and the Owner elects to install a Substituted

System. The second is to be used when an AOSE or a PE has specied a

Substituted System as part of a design package for a construction permit.

WARRANTY,

NOTICE OF SUBSTITUTION

AND

WAIVER OF LIABILITY

County/City of ____________________________________________________________

Sewage Disposal System Construction Permit ID # ______________________________

Tax Map # ____________________ or property description:_______________________

Owner:__________________________________________________________________

Date: ___________________________________________________________________

LIMITED FIVE YEAR WARRANTY

(a) [Insert Manufacturer] (the “Company”) warrants that the [insert product] manufactured

by the Company (collectively, the “Units”), when installed and operated in accordance

with the manufacturer’s instructions and the current Virginia Department of Health GMP

116, Use of Gravelless Systems at Manufacturer’s Specications, and pursuant to all

necessary building permits, are warranted for a period of ve (5) years from the date of

installation (i) to be free from defective materials and workmanship; and (ii) to perform in

accordance with the state performance requirements in effect on the date of installation.

This warranty extends only to the property owner. For purposes of this warranty, the [insert

product] System must be installed in accordance with all site conditions specied in the

Local Health Department Construction Permit and sized according to the Company’s

specications.

(b) System failures determined to be due to improper siting, excessive water usage,

improper grease disposal, improper installation, improper operation, or improper

maintenance are not part of this warranty.

Upon notication of a system failure, the Company may, at its option, perform or have

performed certain tests to determine the cause of failure. A registered soil scientist or

professional engineer may be used to evaluate the soil conditions and compare those

conditions with any original evaluation, which may appear on the permit.

In order to exercise these warranty rights, the property owner must notify the Company

in writing at its corporate headquarters within 15 days of discovery of the alleged defect.

The notice shall be accompanied by (i) a copy of the warranty which is signed and dated

by the installer and the property owner as set forth below; (ii) a copy of the appropriate

permit for the septic system; and (iii) proof to the Company’s satisfaction that the septic

tank has been maintained in accordance with the Company’s operating instructions. In the

event of a breach of warranty due to a failure of the trench, the Company will provide and

install [insert product] units as necessary to extend the size of the trench to provide a fully

functional wastewater system. The Company will not be responsible for pumps and any

other necessary mechanical devices needed to extend the trench.

(c) THE WARRANTY IN SUBPARAGRAPH (a) AND THE REMEDIES IN SUBPARAGRAPH

(b) ARE EXCLUSIVE. THERE ARE NO OTHER WARRANTIES. ANY IMPLIED

WARRANTIES OF MERCHANTABILITY AND OF FITNESS FOR A PARTICULAR

PURPOSE SHALL NOT EXTEND BEYOND THE PERIOD IN SUBPARAGRAPH (a). THE

WARRANTY DOES NOT EXTEND TO INCIDENTAL, CONSEQUENTIAL, SPECIAL,

OR INDIRECT DAMAGES. THE COMPANY SHALL NOT BE LIABLE FOR PENALTIES

OR LIQUIDATED DAMAGES, LOSS OF PRODUCTION AND PROFITS, LABOR AND

MATERIALS, OVERHEAD COSTS, OR OTHER LOSS OR EXPENSE. SPECIFICALLY

EXCLUDED ARE DAMAGE DUE TO ORDINARY WEAR AND TEAR, ALTERATION,

ACCIDENT, MISUSE, ABUSE, OR NEGLECT; THE UNITS BEING SUBJECTED TO

STRESSES OR VEHICLE TRAFFIC GREATER THAN THOSE PRESCRIBED IN THE

INSTALLATION INSTRUCTIONS OR OPERATION INSTRUCTIONS; FAILURE TO

MAINTAIN THE MINIMUM GROUND COVERS SET FORTH IN THE OPERATION

INSTRUCTIONS; THE PLACEMENT OF IMPROPER MATERIALS INTO THE SYSTEM;

OR ANY OTHER EVENT NOT CAUSED BY THE COMPANY. THIS WARRANTY SHALL

BE VOID IF THE PROPERTY OWNER FAILS TO COMPLY WITH ALL OF THE TERMS

SET FORTH IN SUBPARAGRAPH (b).

FURTHERMORE, IN NO EVENT SHALL THE COMPANY BE RESPONSIBLE FOR ANY

LOSS OR DAMAGE TO THE PROPERTY OWNER, THE UNITS, OR ANY THIRD PARTY

RESULTING FROM THE INSTALLATION OR SHIPMENT OF THE UNITS, OR FROM

ANY PRODUCT LIABILITY CLAIMS OF THE ORIGINAL PROPERTY OWNER OR ANY

THIRD PARTY. THE COMPANY SHALL NOT BE RESPONSIBLE FOR ENSURING

THAT INSTALLATION OF THE SYSTEM IS COMPLETED IN ACCORDANCE WITH ALL

APPLICABLE LAWS, CODES, RULES, AND REGULATIONS.

(d) No representative of the Company has the authority to change this warranty in any

manner whatsoever, or to extend this warranty. No warranty applies to any party other

than to the property owner.

NOTICE OF SUBSTITUTION

This is to notify the Virginia Department of Health (“VDH”) that a ___ _(insert manufacturer’s

name and model # or description)_ ___ (“Substituted System”) will be substituted for the

gravel-type draineld system specied on the above-referenced sewage disposal system

construction permit.

I understand that the Substituted System is not the system designed by the

______________ County/City Health Department. The Substituted System, however,

is authorized for use in the Commonwealth of Virginia pursuant to VDH’s Guidance

Memoranda and Policy (GMP) #116. I further understand that the Substituted System

is covered by a manufacturer’s warranty and that such a warranty is not available for the

system prescribed by the County/City Health Department in the above-referenced permit.

I understand that, regardless of whether the Substituted System or the gravel-type

draineld system is installed, the Commonwealth of Virginia requires that the owner

maintain and preserve the entire approved absorption area (including reserve area where

applicable) that was required by the permit. This condition is intended to assure that any

absorption area that is not used will be available in the future should it become necessary

to repair or replace the System. I hereby agree that I will maintain and preserve the entire

absorption area as required.

WAIVER

As OWNER of the property described above and subject to the exception described

below, I hereby release and agree to hold harmless the Virginia Department of Health and

the Commonwealth of Virginia, including, without limitation, any and all of its agencies,

boards, and commissions, their insurer(s), ofcers, directors, employees, representatives,

and agents [hereafter referred to as the “COMMONWEALTH OF VIRGINIA”], from any

and all claims, complaints, demands, actions, causes of action, liabilities and obligations,

of whatever source or nature, whether administrative, legal or equitable, whether known

or unknown, which the OWNER now has or has in the future relating to or arising out of

the installation of the Substituted System including, without limitation, any and all claims

due to the failure of any person to comply with federal, state, or local laws or regulations,

claims under the Virginia Tort Claims Act, the Virginia Constitution, the United States

Constitution and amendments thereto, or under common law.

I understand that the COMMONWEALTH OF VIRGINIA does not warrant in any way

the performance of any System and that the manufacturer’s warranty is the sole remedy

available to me with respect to any performance deciency associated with a Substituted

System. Furthermore, I agree to rst seek and exhaust any and all remedies under the

manufacturer’s warranty before applying for indemnication under the Onsite Sewage

Indemnication Fund.

EXCEPTION—Onsite Sewage Indemnication Fund: I do not release the

COMMONWEALTH OF VIRGINIA from any liabilities, claims, or causes of action provided

under § 32.1-164.1:01 of the Code of Virginia (Onsite Sewage Indemnication Fund). I

acknowledge and afrm that the Onsite Sewage Indemnication Fund shall be the sole

remedy for failure of the Substituted System where such failure results from negligence

on the part of VDH. I also acknowledge and afrm that the Virginia Department of Health’s

authorization of the Substituted System pursuant to GMP #116 shall not constitute an act

of negligence pursuant to § 32.1-164.1:01 of the Code of Virginia.

This agreement shall be binding upon all subsequent owners of this property including any

and all HEIRS, SUCCESSORS, and ASSIGNS.

ACKNOWLEDGEMENT

I acknowledge that I have read this WARRANTY, NOTICE OF SUBSTITUTION, and

WAIVER and that I understand their terms. I also understand that there is no warranty if

I do not comply with all of the above steps or if the system is not installed or maintained

properly. I acknowledge to the Company that this warranty is part of my original agreement

to purchase the septic system and that the warranty and its limitations were provided to

me at the time of purchase.

Address of Installation Name (print) and Address of Property Owner:

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

Signature Date ___________________________________________________________

I acknowledge to the Company and the homeowner that the septic system and the [insert

product] units have been installed in accordance with GMP 116, the installation instructions

of the Company and in accordance with all state trench requirements and other applicable

laws.

________________________________________________________________________

Business Name of Installer Name (print)_______________________________________

Signature Date ___________________________________________________________

Notice of Substitution to be used when an AOSE or PE has specied a

Substituted System as part of a permit application.