2.1A-88002-C06

Subject to change without notice

Page 5 of 15

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

User Manual

MagneticPumpPMA-2

Start-up

Connection of the tube lines and filling of the pump

* connect the pressure line(s) and the filling line to the

corresponding connections on the pump.

Take care that no dirt or other foreign

particles enter the pump housing.

* Clean the tube lines before connecting them.

* Avoid contamination of the environment.

* Fill the reservoir with clean oil.

* Open the shut-off valve in the oil supply line to the pump.

Venting

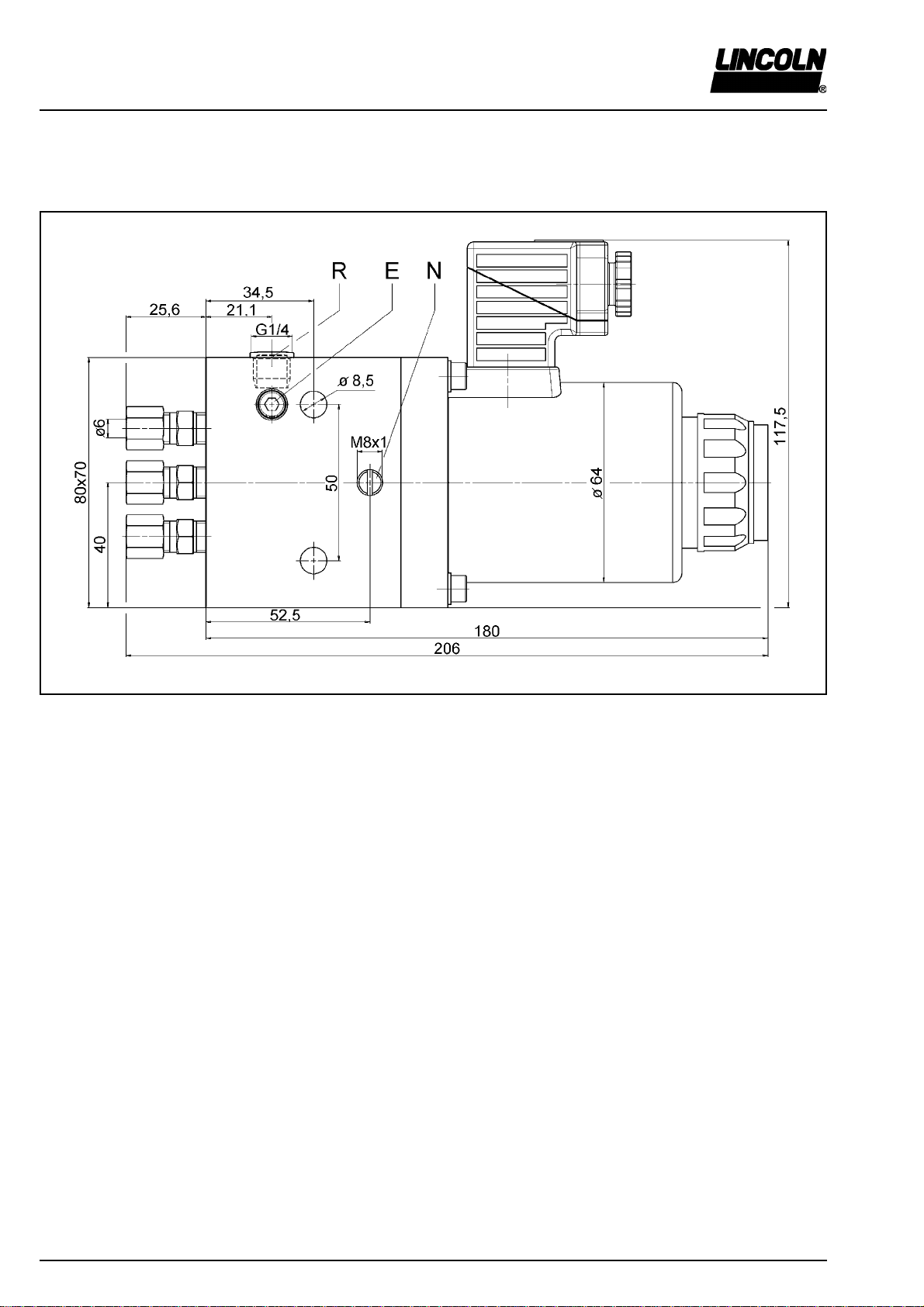

* Unscrew the venting screw (E, Fig. 11) until oil emerges.

Then re-tighten the venting screw.

* Let the pump run until all connected nozzles operate

properly.

Operation

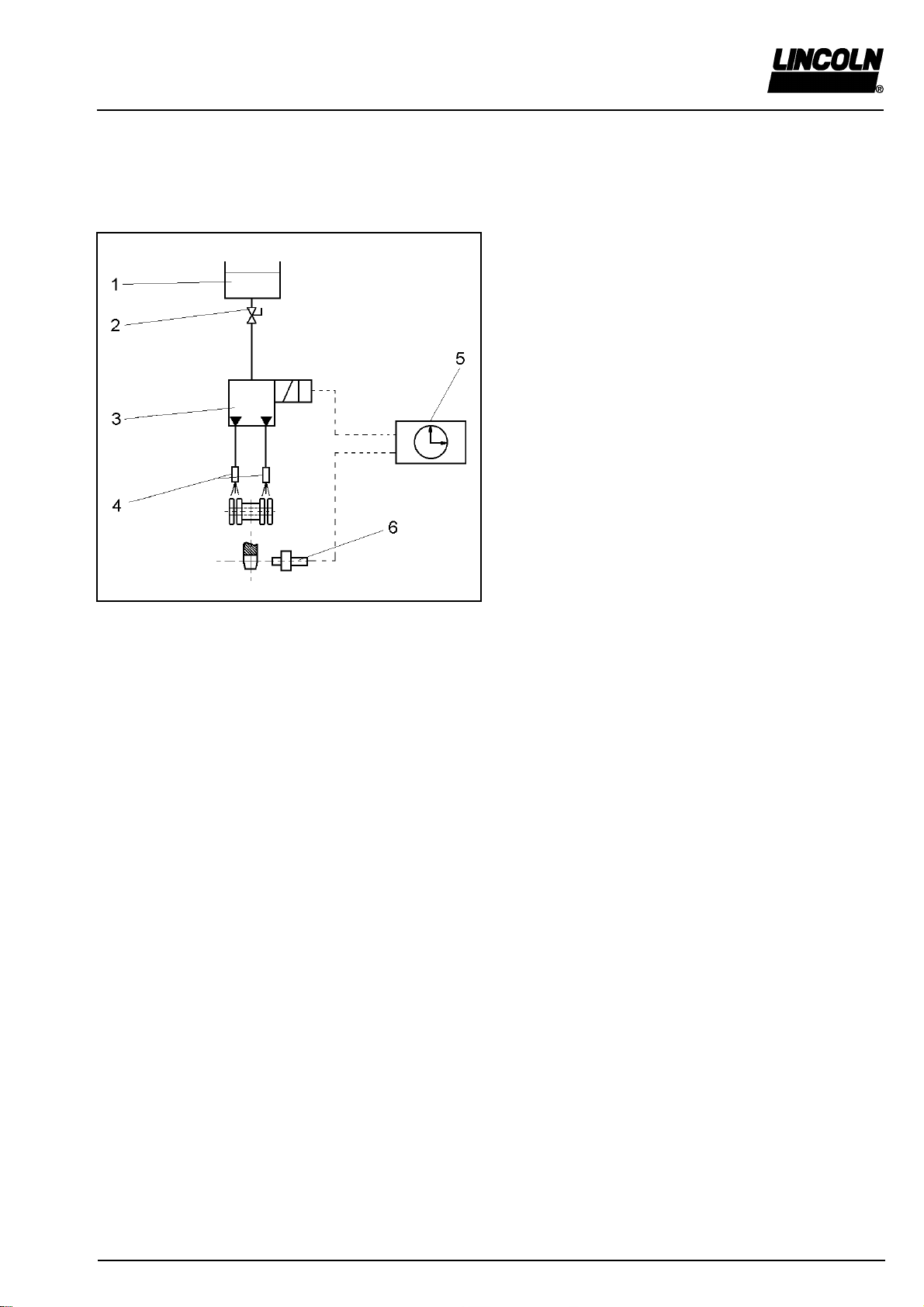

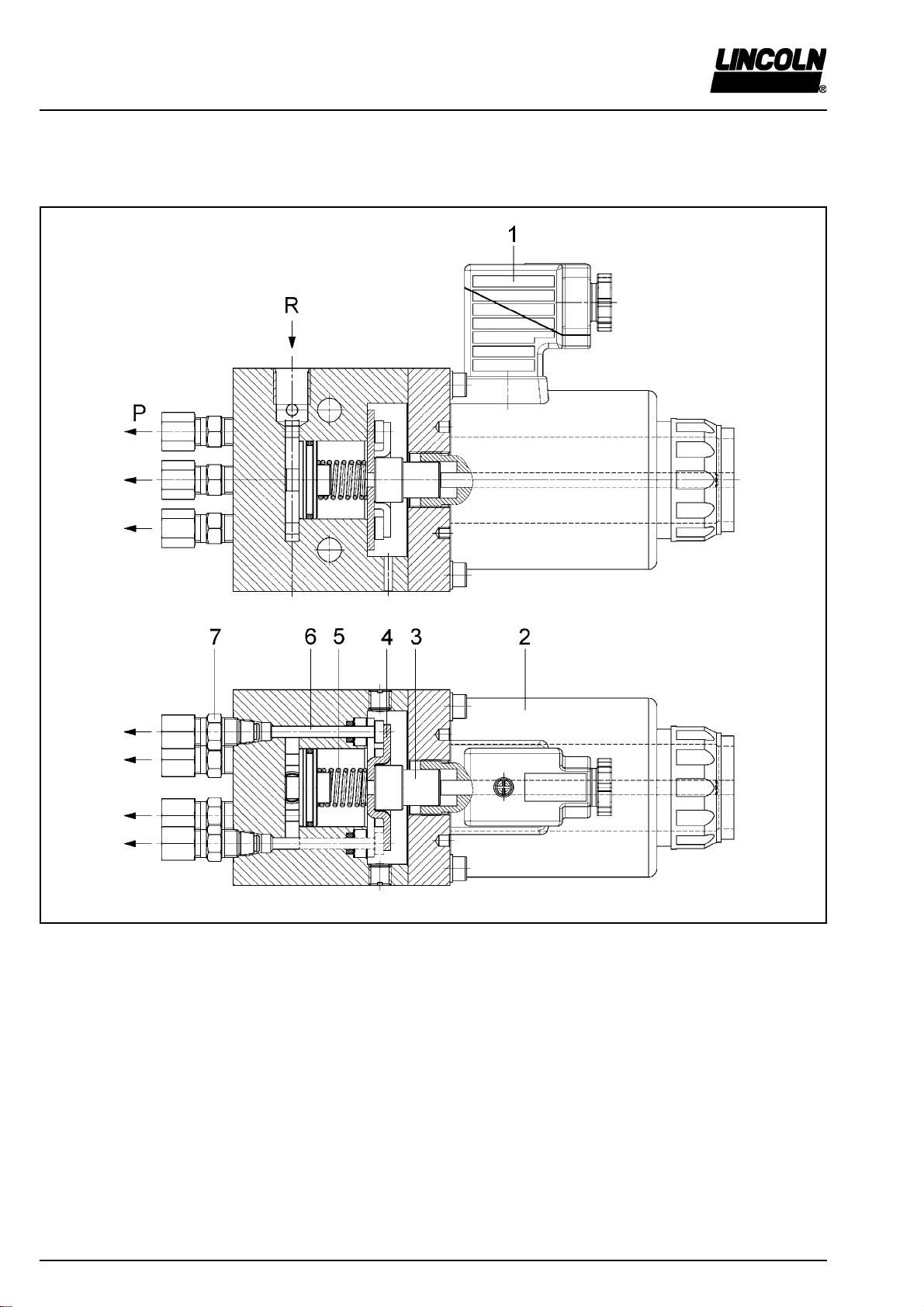

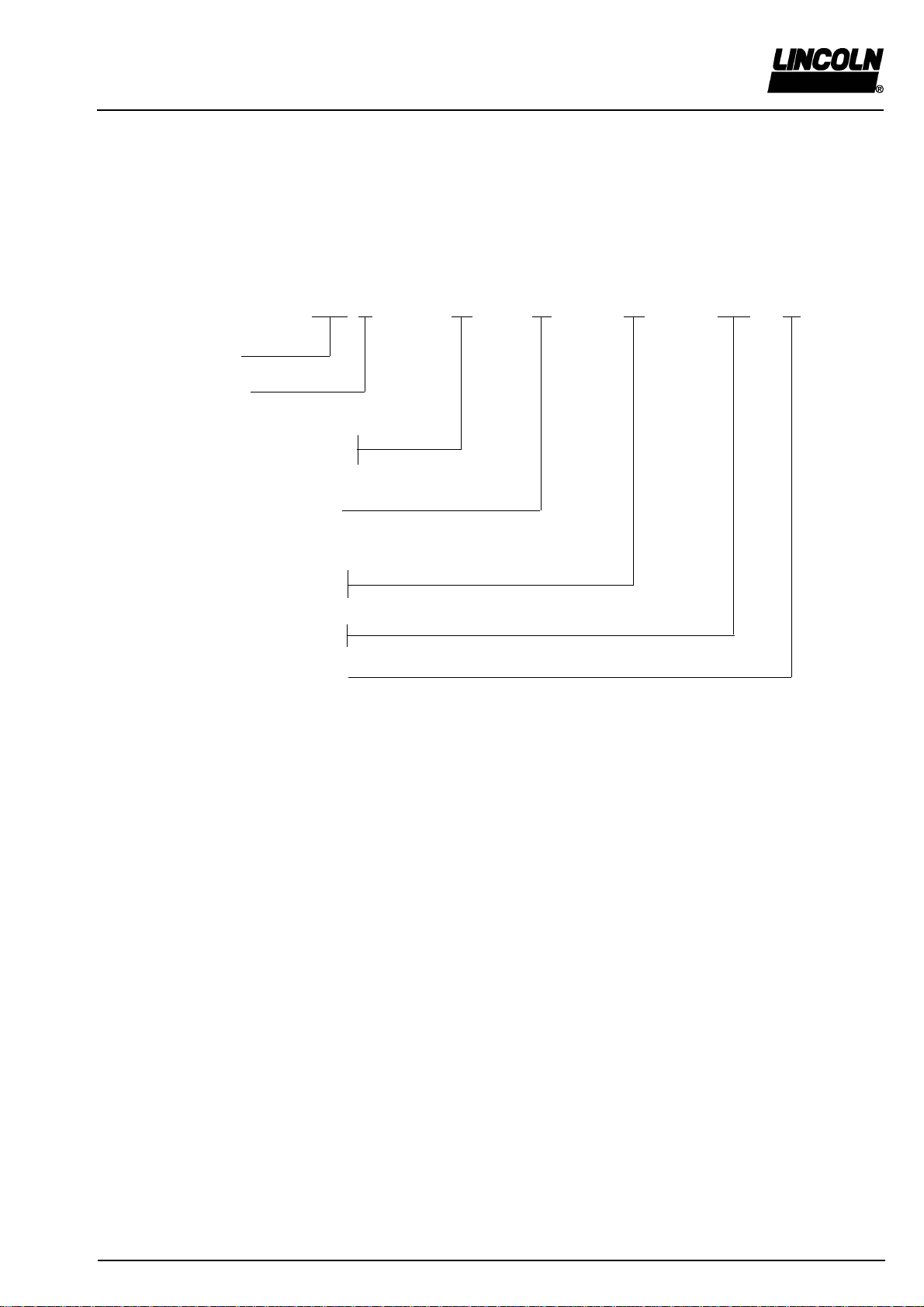

• The armature of the electric solenoid (2, Fig. 2) receives

an electrical pulse (energizing) from the proximity switch

(6, Fig. 1). It contacts the piston support (4, Fig. 2) via a

tappet (3). The piston support causes the pistons (6) to

move.

ErectionandInstallation

• even, solid and vibration-free installation surface

• protected from dust and dirt

• safe from atmospheric influences

• Installation position: horizontal, venting screw

to the left or to the right

• Oil supply: free oil supply from the

reservoir

Tightening torque of the faste-

ning screws 15 Nm 10%

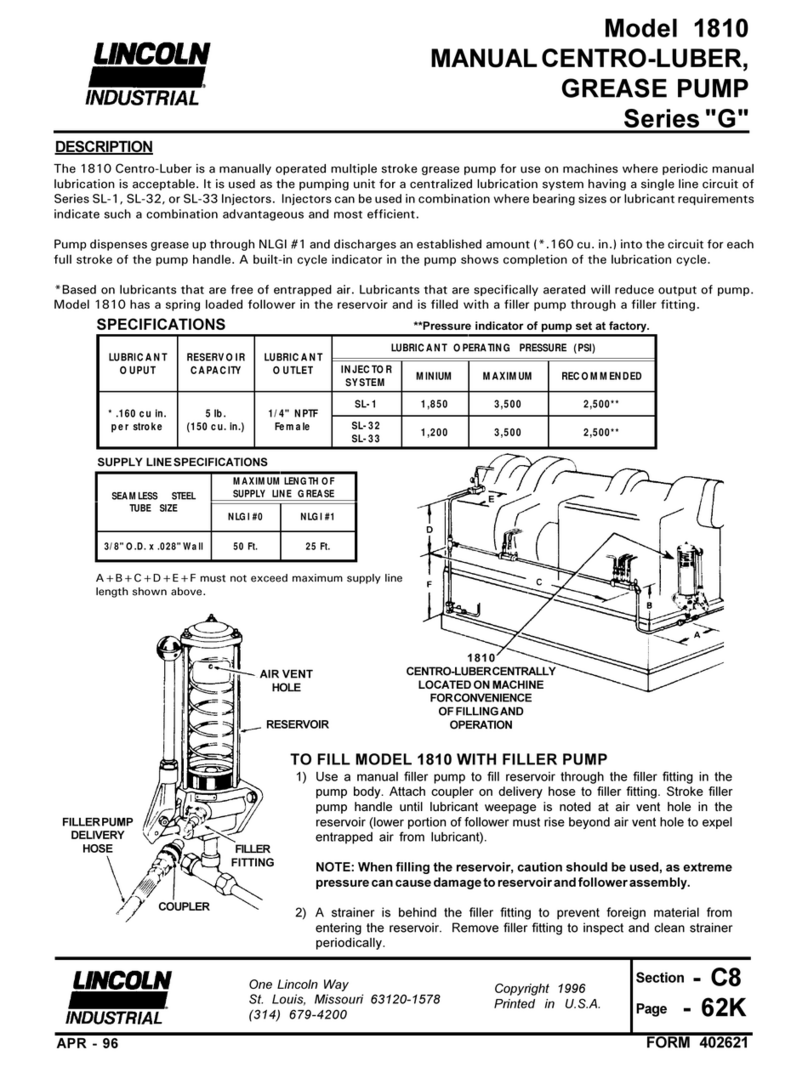

Max. length of tube line

to the nozzles:

Output 60 mm³: steel tube 6 m

plastic tube 3 m

Output 30 mm³: steel tube 3 m

plastic tube 1.5 m

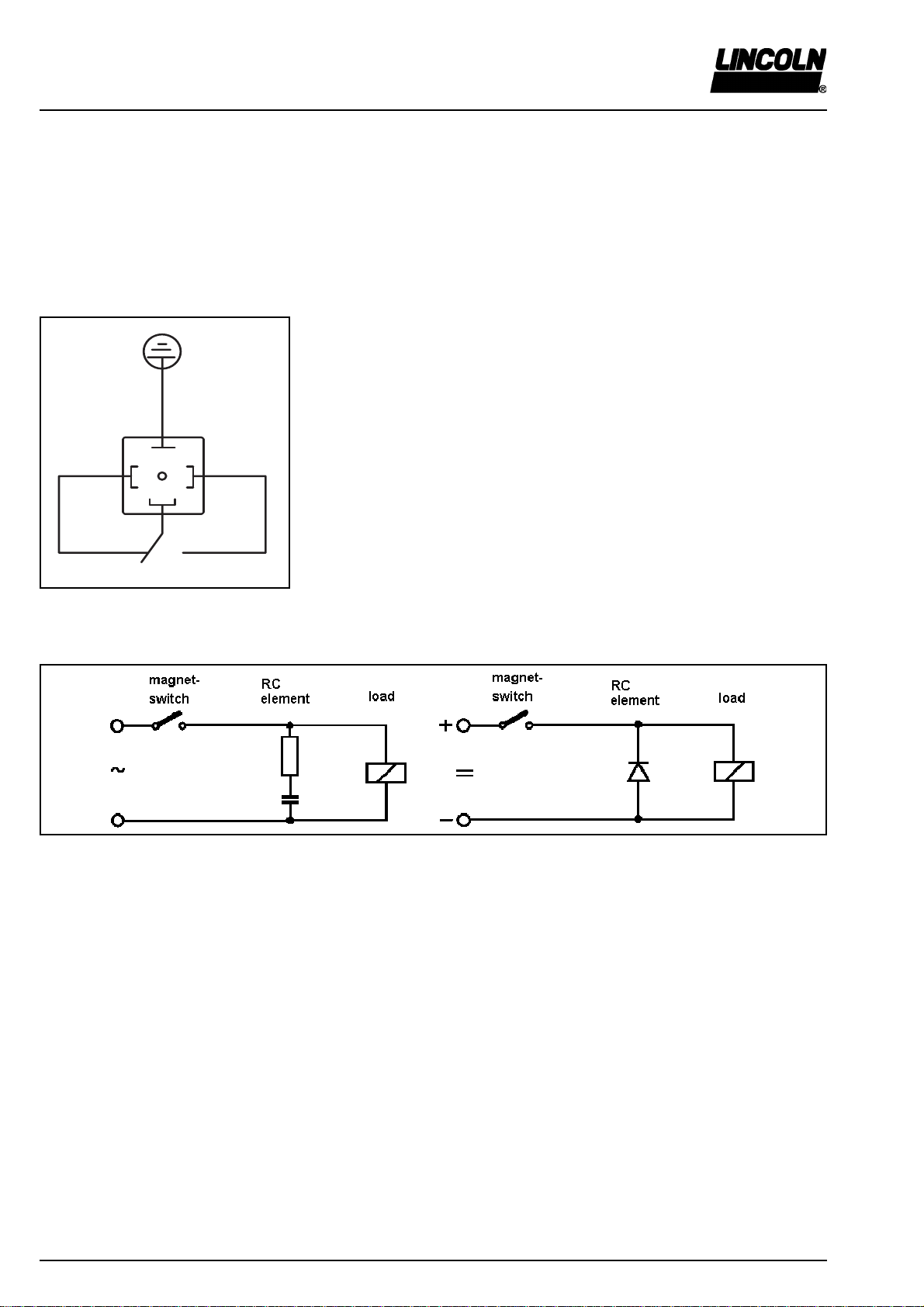

Specifications of the installation site Electrical connection

Before connecting the device,

disconnect the system from the

power supply.

The installation and connection of electric devices must

be carried out only by qualified electrician personnel!

Observe the relevant rules of technology and the respec-

tive work protection legislation (directives, standards).

Electric connection of the electrical solenoid

• in accordance with the electrical wiring diagram and the

switching diagram

Electric connection of the proximity switch

• in accordance with the electrical wiring diagram and the

switching diagram

OperatingInstructions

Maintenance and Repair

Before undertaking any repair on the

pump:

*Disconnect the system from the

power supply and make sure that it

cannot be restarted inadvertently

* Close the shut-off valve in the oil

supply line

* Reduce the pump and system

pressure to zero. Danger due to

splashing oil.

•Repair work may be carried out only by qualified

personnel using original Lincoln spare parts.

• Provided that the pump dispenses only clean oil, it does

not need any particular maintenance.

• The piston of each pump element lies directly in the oil

being dispensed and is therefore lubricated automatical-

ly.

• The pistons eject a dosed quantity of oil to the pressure

connection (P). The return stroke of the pump pistons

and that of the armature are spring activated. During the

return stroke the pistons suck fresh oil from the storage

chamber. The pump is ready for the next lubrication

pulse.

• A proximity switch (optional version) monitors the operati-

on of the pump.