Austro Engine AE300-Wizard User manual

AE300-Wizard

Document No.: E4.08.09 E4.08.09 : AE_xx_000

Revision: 13 9 : 00

Page: 1 of 89

Copyright © 2019, Austro Engine GmbH

Dept.: Electric/Electronic

Type: User Guide

AE300-Wizard

User Guide

Date: Wiener Neustadt, 2019-09-03

Author: Austro Engine GmbH

Rudolf-Diesel-Straße 11

2700 Wiener Neustadt

AUSTRIA / EUROPE

Revision: 13

These technical data and the information contained therein are the property of Austro

Engine GmbH and may not be reproduced either in full or in part or passed on to a third

party without written consent from Austro Engine GmbH.

This text must be included in any full or partial reproduction of this documentation.

Copyright © Austro Engine GmbH

AE300-Wizard

Document No.: E4.08.09 E4.08.09 : AE_xx_000

Revision: 13 9 : 00

Page: 2 of 89

Copyright © 2019, Austro Engine GmbH

Dept.: Electric/Electronic

Type: User Guide

Table of Contents

1Preface................................................................................................. 10

1.1 Congratulation ............................................................................................10

1.2 Subject.......................................................................................................10

1.3 Objective ....................................................................................................10

1.4 Scope.........................................................................................................10

1.5 Intended Audience ......................................................................................10

1.6 Purchased Parts Package .............................................................................11

1.7 Austro Engine Legal Notices .........................................................................11

1.7.1 Copyright Notice ..................................................................................11

1.7.2 License Restrictions Warranty/Consequential Damages Disclaimer ............11

1.7.3 Warranty Disclaimer .............................................................................11

1.7.4 Hazardous Applications Notice...............................................................11

1.7.5 Trademark Notice ................................................................................12

1.7.6 Third-Party Content, Products, and Services Disclaimer............................12

2Limitations........................................................................................... 13

3Requirements ...................................................................................... 14

3.1 Software..................................................................................................... 14

3.1.1 Operating System ................................................................................14

3.1.2 .NET Environment ................................................................................14

3.1.3 Visual C++ Runtime Library ..................................................................14

3.1.4 Driver for USB/CAN Adapter ..................................................................14

3.1.5 AE300-Wizard......................................................................................14

3.2 Hardware.................................................................................................... 15

3.2.1 Computer System.................................................................................15

3.2.2 USB/CAN Adapter.................................................................................15

3.2.3 USB DataMatrix Scanner .......................................................................15

3.2.4 CAN Extension Cable ............................................................................15

3.3 Aircraft .......................................................................................................16

3.3.1 Ground Power Supply ...........................................................................16

4New Installation.................................................................................. 17

4.1 Pre-Conditions............................................................................................. 17

4.2 Automatic Installation ..................................................................................17

4.3 Manual Installation ......................................................................................17

4.3.1 .NET Environment ................................................................................17

4.3.2 Driver for PCAN-Adapter (USB/CAN) ......................................................18

4.3.3 AE300-Wizard and Visual C++ Runtime Library.......................................18

4.4 Installation for Evaluating Log Files............................................................... 18

5Upgrade Installation ........................................................................... 19

5.1 Download Upgrade Package .........................................................................19

5.2 Remove Previous AE300-Wizard Version........................................................ 19

5.3 Install Upgrade Package...............................................................................19

AE300-Wizard

Document No.: E4.08.09 E4.08.09 : AE_xx_000

Revision: 13 9 : 00

Page: 3 of 89

Copyright © 2019, Austro Engine GmbH

Dept.: Electric/Electronic

Type: User Guide

6Overview and First Steps .................................................................... 20

6.1 CAN Connection ..........................................................................................20

6.2 Starting the AE300-Wizard ...........................................................................20

6.3 Setting up the Aircraft..................................................................................20

6.3.1 Engine Running ...................................................................................20

6.3.2 Engine not Running..............................................................................20

6.3.2.1 Ground Power Supply.....................................................................20

6.3.2.2 Electric Fuel Pumps ........................................................................20

6.3.2.3 Alternator ......................................................................................21

6.3.2.4 Avionics.........................................................................................21

6.3.2.5 Engine Master / Electric Master Switch ............................................21

6.4 Start of Diagnostic Session ...........................................................................22

6.5 Saving of Data during a Diagnostic Session....................................................23

6.6 Saving Screenshots from Data Displays .........................................................24

6.7 End of Diagnostic Session ............................................................................24

7Modes of Operation ............................................................................. 25

7.1 Offline Mode ............................................................................................... 25

7.1.1 Primary Display –Left Page...................................................................25

7.1.1.1 Maintenance Tab ...........................................................................25

7.1.1.2 Engine Logs Tab ............................................................................25

7.1.1.3 Live View Tab ................................................................................26

7.2 Maintenance Mode ......................................................................................27

7.2.1 Primary Display –Left Page...................................................................27

7.2.1.1 Maintenance Tab ...........................................................................27

7.2.1.2 Engine Logs Tab ............................................................................28

7.2.1.3 Live View Tab ................................................................................28

7.2.2 Primary Display –Right Page.................................................................29

7.2.2.1 Engine Data-Tab ............................................................................29

7.2.2.2 Statistics Tab .................................................................................30

7.2.2.3 Fault Details Tab ............................................................................31

7.3 Qualified Maintenance Mode.........................................................................31

7.3.1 Primary Display –Left Page...................................................................32

7.3.1.1 Update SW Tab..............................................................................32

7.3.1.2 IQA Tab ........................................................................................32

8Diagnostic Procedures......................................................................... 34

8.1 Analyzing Operational Data ..........................................................................34

8.1.1 Engine and ECU Operating Hours Counters.............................................34

8.1.2 Operational Statistics............................................................................35

8.1.2.1 Table Format .................................................................................35

8.1.2.2 Bar-Graph Format ..........................................................................36

8.2 Routine Maintenance ...................................................................................38

8.2.1 Engine Log File ....................................................................................39

8.2.2 Event Recorder File ..............................................................................40

8.2.3 Data Logger File (Full Flight Time) .........................................................41

8.2.4 Partial Data Logger File (Fraction of Flight Time).....................................43

AE300-Wizard

Document No.: E4.08.09 E4.08.09 : AE_xx_000

Revision: 13 9 : 00

Page: 4 of 89

Copyright © 2019, Austro Engine GmbH

Dept.: Electric/Electronic

Type: User Guide

8.2.5 Trouble Shooting .................................................................................43

8.2.6 Using the Fault Code Memory (FCM) ......................................................44

8.2.6.1 Overview of the FCM Functionality ..................................................44

8.2.6.2 Displaying Fault Details ..................................................................46

8.2.6.3 Clearing the Fault Code Memory .....................................................48

8.2.7 Offline Analysis Using the Engine Log.....................................................49

8.2.7.1 Displaying Fault Code Memory Entries .............................................49

8.2.7.2 Displaying Engine Operational Statistics...........................................50

8.2.8 Offline Analysis Using the Event Recorder...............................................51

8.2.8.1 The Event Recorder Window...........................................................52

8.2.8.2 Using Filters in the Event Recorder..................................................53

8.2.9 Offline Analysis Using the Data Logger ...................................................54

8.2.9.1 Saving Data Logger Displays as Screenshots....................................55

8.2.9.2 Interpreting the Data Logger Display...............................................55

8.3 Live View....................................................................................................58

8.3.1 Live View –Online Analysis and Recording .............................................58

8.3.1.1 Live View –Standard Mode.............................................................58

8.3.1.2 Live View –Expert Mode ................................................................61

8.3.1.3 Live View –Aux Signal ...................................................................61

8.3.2 Live View –Online Analysis using Pre-Defined Measurements...................61

8.3.3 Live View –Online Analysis Using User-Defined Measurements.................63

8.3.4 Live View –Offline Analysis...................................................................64

8.3.4.1 Live View –Defining and Saving a “LiveView-Config” .......................64

8.3.4.2 Live View –Importing Live View Recordings ....................................65

8.3.4.3 Live View –Analyzing Live View Recordings.....................................66

8.3.5 Live View –Working with Austro Engine Support.....................................67

8.3.5.1 “LiveView-Config” Files ...................................................................67

8.3.5.2 Live View Data saved during Measurements ....................................67

9IQA Codes ............................................................................................ 68

9.1.1 Overview.............................................................................................68

9.1.2 Reading IQA Codes ..............................................................................69

9.1.3 Saving IQA Codes ................................................................................70

9.1.4 Entering IQA Codes..............................................................................71

9.1.5 Scanning Injector IQA Codes.................................................................72

9.1.6 EECU Replacement...............................................................................73

10 EECU Software Update ........................................................................ 76

10.1 Minimum Requirements ...............................................................................76

10.2 Overview of the Software Update Process......................................................76

10.3 Detailed Steps of the Software Update Process ..............................................78

10.4 Software Update Retry................................................................................. 82

10.5 Error Handling during Software Updates........................................................ 83

10.5.1 Pre-Flash Conditions.............................................................................83

10.5.2 Automatic Retries.................................................................................83

10.5.3 Aborts.................................................................................................84

10.5.4 Unsuccessful Completion ......................................................................85

AE300-Wizard

Document No.: E4.08.09 E4.08.09 : AE_xx_000

Revision: 13 9 : 00

Page: 5 of 89

Copyright © 2019, Austro Engine GmbH

Dept.: Electric/Electronic

Type: User Guide

10.5.5 Successful Completion ..........................................................................86

11 Calling for Support .............................................................................. 87

11.1 Saving Failure Information ...........................................................................87

11.1.1 First Step –Engine Log.........................................................................87

11.1.2 Second Step –Event Recorder File.........................................................87

11.1.3 Third Step –Data Logger File................................................................87

11.1.4 Fourth Step (optional) –Live View recordings or Screenshots ...................87

11.1.5 Fifth Step (optional) –IQA Data File ......................................................87

11.2 Sending Maintenance Information................................................................. 87

12 Appendices .......................................................................................... 88

12.1 Error Messages of the AE300-Wizard............................................................. 88

12.2 Details –Freeze Frame ................................................................................88

12.2.1 Combined Engine Status .......................................................................88

12.3 Details –Event Recorder ..............................................................................88

12.3.1 Event Status........................................................................................88

12.4 Details –LiveView .......................................................................................89

12.4.1 Self-Test Timeout Flags (SlfTst_stTOutErr) .............................................89

12.4.2 Self-Test Release Condition Flags (SlfTst_stRls) ......................................89

Index of Tables

Table 1 Abbreviations and Definitions............................................................................9

Table 2 Supported Operating Systems......................................................................... 14

Table 3 Hardware Requirements................................................................................. 15

Table 4 Error Types of FCM Entries ............................................................................. 44

Table 5 Combined Engine Status ................................................................................ 88

Table 6 Event Status.................................................................................................. 88

Table 7 Self-Test Timeout Flags.................................................................................. 89

Table 8 Self-Test Release Condition Flags.................................................................... 89

AE300-Wizard

Document No.: E4.08.09 E4.08.09 : AE_xx_000

Revision: 13 9 : 00

Page: 7 of 89

Copyright © 2019, Austro Engine GmbH

Dept.: Electric/Electronic

Type: User Guide

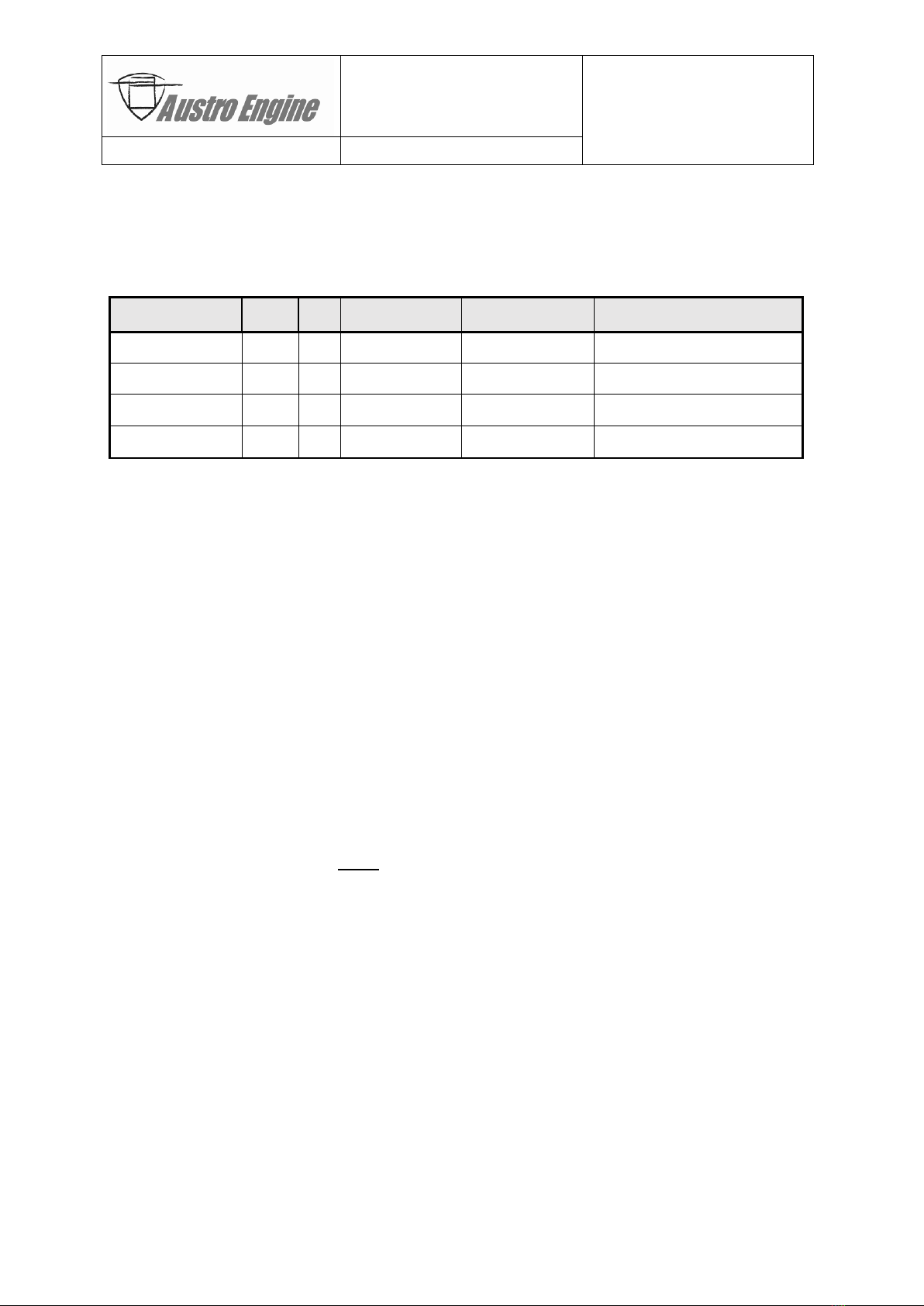

Revision History

Change Description

Author of

Change

Date

Rev.

Initial document, first draft.

Mannsberger

2009-03-19

0

Update to include Wizard V1051 functionality

Mannsberger

2009-04-20

1

Update to include review comments

Mannsberger

2009-04-23

2

Update to include USB/CAN adapter order num-

ber

Mannsberger

2009-05-07

3

Update to include Wizard V1055 new functionali-

ty (6.2.4), update ground usage and alternator

setup (4.2.3.2), update new AR form (Appendix

9.4)

Mannsberger

2009-09-24

4

Update to include Wizard V1100 new functionali-

ty (Live View, Engine-Log offline analysis, GUI)

Mannsberger

2009-12-18

5

Error corrections

Mannsberger

2010-01-15

6

Update to include Wizard V1200 new functionali-

ty (ECU SW update, compressed/encrypted log

files)

Mannsberger

2010-11-09

7

Update to include layout of Self-Test Flags

(Available in Live View) in Appendix

Update to Wizard V1.3.0.xxx

Kucera Walter

2016-05-10

8

Fixed minor bugs in User Guide

Update to AE300-Wizard V1.3.2.xxx

Kucera Walter

2016-11-09

9

Update flash procedure to ECU SW VC33.6.

Kucera Walter

2017-04-10

10

Update new LiveView features (AE300-Wizard

V1.3.4.xxx). Fixed minor bugs.

Kucera Walter

2017-07-25

11

Update new Event Recorder features (AE300-

Wizard V1.3.5.xxx). Fixed minor bugs.

Kucera Walter

2017-11-10

12

Required for Baseline 23 (still compatible with

older versions). Update of LiveView. Minor bugs

fixed.

Dietmüller

2019-09-03

13

AE300-Wizard

Document No.: E4.08.09 E4.08.09 : AE_xx_000

Revision: 13 9 : 00

Page: 8 of 89

Copyright © 2019, Austro Engine GmbH

Dept.: Electric/Electronic

Type: User Guide

Abbreviations

Abbreviation

Designation

act.

active

AE

Austro Engine

.ae3

Extension of AE300-Wizard files (compressed and encrypted)

AE300

Austro Engine 300, marketing name of engine E4

AR

Authorization Request

Atmos.

Atmospheric

bin

binary

BATT

Battery

BPA

Boost Pressure Actuator

CAN

Controller Area Network; CAN bus is a message-based protocol, designed spe-

cifically for automotive applications.

CR

Common Rail

Cyl.

Cylinder

DatRec

Data Logger

d.c.

duty cycle

DTC

Diagnostic Trouble Code

E4

Internal project name (Engine 4)

ECU

Engine Control Unit (in this manual used synonymously to EECU)

EECU

Electronic Engine Control Unit

EECS

Electronic Engine Control System

EEPROM

Electric Erasable Programmable Read Only Memory

E/E

Electric / Electronic System Engineering department (of AE)

Eng.

Engine

EvRec

Event Record

EvtRec

EventRecorder (also Event-Rec)

FCM

Fault Code Memory

FCT

Flash Container (a file containing the ECU-SW)

GND

Ground

GUI

Graphical User Interface

hex

hexadecimal (in the meaning of sedecimal)

HW

Hardware

ICM

Interconnection module

ID

Identification

IE

MS Internet Explorer

IQA

Injector Quantity Adjustment (

German

: IMA, Injektor Mengen Abgleich)

ISO

The International Standardization Organization known as ISO, is an interna-

tional standard-setting body composed of representatives from various national

standards organizations.

Kl

Contact, Terminal

Kl15

Switched battery plus through ignition switch (“engine master” switch)

Kl30

Battery plus (“electric master” switch)

AE300-Wizard

Document No.: E4.08.09 E4.08.09 : AE_xx_000

Revision: 13 9 : 00

Page: 9 of 89

Copyright © 2019, Austro Engine GmbH

Dept.: Electric/Electronic

Type: User Guide

Abbreviation

Designation

Kl31

Engine ground

Kl50

Starter control

KWP2000

Keyword Protocol 2000 (Diagnostic Protocol)

KWPonCAN

KWP2000 on the CAN Bus

MAX

Value above maximum allowed value (overflow)

MIN

Value below minimum allowed value (underrun)

MS

Microsoft (as in MS Windows, MS Internet Explorer)

.NET

.NET Framework is a software framework developed by Microsoft that runs

primarily on Microsoft Windows.

NPL

Value is not plausible

OEM

Original Equipment Manufacturer

pas.

Passive

PCAN

PEAK-System CAN hardware or driver

PCV

Pressure Control Valve

PDF

Portable Document Format. PDF is a file format, which enables presentation

and exchange of documents independent of the original software, hardware or

operating system. Originally developed by Adobe, PDF is now an open stand-

ard of ISO.

Press.

Pressure

RAM

Random Access Memory

RecMng

Record Manager

ROM

Read Only Memory

rpm

revolutions per minute (engine or propeller speed)

RTC

Real Time Clock

SIG

Signal disconnected or broken

SSHD

Solid State Hard Disk

SW

Software

Temp.

Temperature

Trq.

Torque

UBatt

Battery voltage

USB

Universal Serial Bus; USB is an industry standard that defines the cables,

connectors and communications protocols used in a bus for connection, com-

munication, and power supply between computers and electronic devices.

UTC

Universal Time Coordinated (Greenwich Mean Time)

VC++

Visual C++ (from Microsoft)

Vcc

Voltage of the common collector (positive power supply)

XML

eXtensible Markup Language

Table 1 Abbreviations and Definitions

AE300-Wizard

Document No.: E4.08.09 E4.08.09 : AE_xx_000

Revision: 13 9 : 00

Page: 10 of 89

Copyright © 2019, Austro Engine GmbH

Dept.: Electric/Electronic

Type: User Guide

1Preface

1.1 Congratulation

Thank you for buying the AE300-Wizard software including the AE300-ECU-Dongle/Converter

(in the rest of the document called AE300-Dongle). Install the AE300-Wizard software includ-

ing the AE300-Dongle driver. Connect the CAN plug (9-pins) of the AE300-Dongle to the

AE300 EECU and the USB plug to an USB port of your PC (usually a notebook) and you will

be able to measure and log several configurable engine parameters.

1.2 Subject

The AE300-Wizard is a diagnostic tool required to perform both maintenance in the field and

serial production tasks on the Austro Engine (AE) AE300 series engine (E4, E4P) and its elec-

tronic engine control system (EECS).

1.3 Objective

The tool will ease maintenance and will allow AE to provide full “After Sales”support. Pro-

duction activities like necessary coding of variants and serial numbers, configuring software,

writing RTC, etc. will be provided for AE use only.

1.4 Scope

This user guide describes installation and operation of the AE300-Wizard.

Although it provides hints and recommendations on how to employ the Wizard for mainte-

nance and production tasks it does not replace nor supersede the approved maintenance

and build manuals.

Revision 11 of this guide describes the AE300-Wizard starting with version 1.3.4.xxx.

1.5 Intended Audience

This document is intended as a learning aid to be used by maintenance technicians and en-

gineers attending AE300 training classes required as a prerequisite for qualified maintenance

organizations. It provides also additional background information and user guidance for field

maintenance and troubleshooting procedures assisted be functions of the AE300-Wizard.

Engineers performing serial production tasks will find additional descriptions in the approved

build manual.

AE300-Wizard

Document No.: E4.08.09 E4.08.09 : AE_xx_000

Revision: 13 9 : 00

Page: 11 of 89

Copyright © 2019, Austro Engine GmbH

Dept.: Electric/Electronic

Type: User Guide

1.6 Purchased Parts Package

The package contains the following parts.

The CD containing the AE300-Wizard program installer, Visual C++ 2010, .NET

environment version 4.0 and the CAN driver for the AE300-Dongle.

The AE300-Dongle connects the EECU (9-pin CAN connector) to your PC (USB

connector).

The User Manual you are reading as a PDF file.

1.7 Austro Engine Legal Notices

1.7.1 Copyright Notice

Copyright © 2019, Austro Engine Corporation and/or its affiliates. All rights reserved.

1.7.2 License Restrictions Warranty/Consequential Damages Disclaimer

This software and related documentation are provided under a license agreement containing

restrictions on use and disclosure and are protected by intellectual property laws. Except as

expressly permitted in your license agreement or allowed by law, you may not use, copy, re-

produce, translate, broadcast, modify, license, transmit, distribute, exhibit, perform, publish,

or display any part, in any form, or by any means. Reverse engineering, disassembly, or de-

compilation of this software, unless required by law for interoperability, is prohibited.

1.7.3 Warranty Disclaimer

The information contained herein is subject to change without notice and is not warranted to

be error free. If you find any errors, please report them to us in writing.

1.7.4 Hazardous Applications Notice

This software and hardware is developed for usage in aircraft with an AE300 engine in

ground mode. It is not developed or intended for use in any other (e.g. inherently danger-

ous) applications, including applications that may create a risk of personal injury. If you use

this software or hardware in dangerous applications, then you shall be responsible to take all

appropriate fail safe, backup, redundancy, and other measures to ensure its safe use. Austro

Engine Corporation and its affiliates disclaim any liability for any damages caused by use of

this software or hardware in dangerous applications.

AE300-Wizard

Document No.: E4.08.09 E4.08.09 : AE_xx_000

Revision: 13 9 : 00

Page: 12 of 89

Copyright © 2019, Austro Engine GmbH

Dept.: Electric/Electronic

Type: User Guide

1.7.5 Trademark Notice

Austro Engine and AE300-Wizard are trademarks or registered trademarks of Austro Engine

Corporation and/or its affiliates.

All Microsoft trademarks are used under license and are trademarks or registered trademarks

of Microsoft. PCAN is a trademark or registered trademark of the PCAN Corporation.

Other names may be trademarks of their respective owners.

1.7.6 Third-Party Content, Products, and Services Disclaimer

This software or hardware and documentation may provide access to or information about

content, products, and services from third parties. Austro Engine Corporation and its affili-

ates are not responsible for and expressly disclaim all warranties of any kind with respect to

third-party content, products, and services unless otherwise set forth in an applicable

agreement between you and Austro Engine. Austro Engine Corporation and its affiliates will

not be responsible for any loss, costs, or damages incurred due to your access to or use of

third-party content, products, or services, except as set forth in an applicable agreement be-

tween you and Austro Engine.

AE300-Wizard

Document No.: E4.08.09 E4.08.09 : AE_xx_000

Revision: 13 9 : 00

Page: 13 of 89

Copyright © 2019, Austro Engine GmbH

Dept.: Electric/Electronic

Type: User Guide

2Limitations

WARNING

Using the AE300-Wizard for measurements during flight is not permitted!

The AE300-Wizard and its AE300-Dongle have the following limitations:

Use only in conjunction with the Austro Engine AE300 series engine.

Use only with an Austro Engine EECU (part number E4B-92-000-000).

Use no other device parallel to the AE300-Wizard to maintain the EECU firmware.

The AE300-Wizard is only available in English (The AE300-Wizard may be installed

on a system with a different system language, but the GUI will remain in English.

Although all system messages, i.e. file requesters, will be shown in the system lan-

guage.)

AE300-Wizard

Document No.: E4.08.09 E4.08.09 : AE_xx_000

Revision: 13 9 : 00

Page: 14 of 89

Copyright © 2019, Austro Engine GmbH

Dept.: Electric/Electronic

Type: User Guide

3Requirements

3.1 Software

3.1.1 Operating System

Tool

bit

SP

Version

Manufacturer

Remark

MS Windows XP

32

2

5.1.2600.2180

Microsoft

MS Windows XP

32

3

5.1.2600

Microsoft

MS Windows 7

32/64

1

6.1.7601

Microsoft

Only with service pack 1

MS Windows 10

32/64

-

10.0.10240

Microsoft

Table 2 Supported Operating Systems

Note:

Installation requires (local) administrator privileges. Ongoing Wizard operation does

not require administrator privileges.

3.1.2 .NET Environment

The minimum requirement for MS .Net Framework is version 4.0 with Service Pack 2 German

or English language version (dotNetFx40_Full_x86_x64.exe). This version is supplied on the

AE300-Wizard distribution CD.

3.1.3 Visual C++ Runtime Library

MS VC++ 2010 redistributable runtime library. This library is supplied on the AE300-Wizard

distribution CD as part of the AE300-Wizard software.

3.1.4 Driver for USB/CAN Adapter

PEAK System HW driver for the high speed CAN-to-USB adapter. This driver is supplied on

the AE300-Wizard distribution CD.

3.1.5 AE300-Wizard

It is recommended to use the latest version of the AE300-Wizard software. Use at least ver-

sion 1.3.4.xxx. To support Flash Container of SW Version VC33.6 use at least the AE300-

Wizard software version 1.3.3.xxx.

AE300-Wizard

Document No.: E4.08.09 E4.08.09 : AE_xx_000

Revision: 13 9 : 00

Page: 15 of 89

Copyright © 2019, Austro Engine GmbH

Dept.: Electric/Electronic

Type: User Guide

3.2 Hardware

3.2.1 Computer System

The requirements to the PC Hardware are:

Characteristic

Minimum

Recommended

PC System

Standard x86 desktop PC or laptop system

No. of CPU Cores

1

2 or more

Clock Frequency [GHz]

2

at least 2.8

RAM [GByte]

3

8 or more

HD Space (free)

[MByte]

100

for a full Wizard installation (including .NET Framework, VC++ redistrib-

utable library and HW drivers)

Additional HD Space

[MByte]

~100

(will be a good starting point) for log files and aircraft data

Table 3 Hardware Requirements

Note:

3 GByte RAM are required as a minimum space if no other program is concurrently

running! Otherwise more RAM is necessary.

Note 2:

It is recommended to use a Solid State Disk (SSD).

3.2.2 USB/CAN Adapter

A special USB/CAN adapter (provided with the AE300-Wizard) is required to physically con-

nect to the CAN bus of the EECU. It connects to a USB port (at least USB 2.0) of the PC sys-

tem on one end and provides a CAN bus male connector on the other. Additionally this

adapter also acts as a license dongle to enable the AE300-Wizard in one of two operating

modes defined by the license:

-AE-order number “IPEH-002021-M CAN-USB Adapter M” to unlock “Maintenance mode”

-AE-order number “IPEH-002021-QM CAN-USB Adapter QM” to unlock “Qualified mainte-

nance mode”

3.2.3 USB DataMatrix Scanner

A specially programmed DataMatrix scanner is optionally available from Austro Engine to

support scanning of IQA codes from injectors (see chapter “9.1.5 Scanning Injector IQA

Codes”on page 72). This is not a required item, but a recommended one to prevent mis-

reading of IQA codes:

-Part#”TBD” hand held IQA scanner

3.2.4 CAN Extension Cable

It is recommended to use an RS-232 extension cable (female to male connectors) of about

2m (7ft) length for a convenient connection from the USB/CAN adapter of the PC/laptop to

the diagnostic plug in the aircraft cockpit.

AE300-Wizard

Document No.: E4.08.09 E4.08.09 : AE_xx_000

Revision: 13 9 : 00

Page: 16 of 89

Copyright © 2019, Austro Engine GmbH

Dept.: Electric/Electronic

Type: User Guide

3.3 Aircraft

3.3.1 Ground Power Supply

For diagnostic sessions to be performed while the engine is NOT running it is important to

avoid draining the aircraft battery.

Therefore it is recommended to connect external ground power to the aircraft when per-

forming diagnosis for more than 15 minutes.

AE300-Wizard

Document No.: E4.08.09 E4.08.09 : AE_xx_000

Revision: 13 9 : 00

Page: 17 of 89

Copyright © 2019, Austro Engine GmbH

Dept.: Electric/Electronic

Type: User Guide

4New Installation

4.1 Pre-Conditions

Austro Engine provides a distribution CD of the AE300-Wizard for initial installation of the

tool, the required runtime libraries and device drivers. This CD also includes the folder “Doc-

umentation” which contains the AE300-Wizard User Guide (this document) and a Power

Point presentation as well as predefined practical exercises for self-study purposes.

Before starting installation disconnect any USB/CAN adapter!

Note:

Keep in mind, that installation requires (local) administrator privileges!

4.2 Automatic Installation

For automatic installation simply right-click on “setup.bat”and select the menu item “Run

as administrator” (

German:

“Als Administrator ausführen”) to execute the sequence

of required steps.

Note:

If you do not have installed .NET environment the version 4.0 will be installed and the

PC usually reboots after installation.

Note 2:

If you have installed an older version then 4.0, version 4.0 will be installed without

rebooting the PC.

4.3 Manual Installation

If manual installation is required follow the steps outlined below:

4.3.1 .NET Environment

Attention:

Close all applications before installing the .NET environment. Otherwise data loss

can result!

The installation of .NET Framework depends on the language environment and the architec-

ture. Install the version of the .NET Framework mentioned in chapter “3.1.2 .NET Environ-

ment” on page 14. You can find the supported version on the distribution CD:

Data\DotNetFX40\dotNetFx40_Full_x86_x64.exe

Double clicking on the files initiates the installation which will guide the user through the

process.

Note:

After installation of the .NET environment the PC usually reboots!

AE300-Wizard

Document No.: E4.08.09 E4.08.09 : AE_xx_000

Revision: 13 9 : 00

Page: 18 of 89

Copyright © 2019, Austro Engine GmbH

Dept.: Electric/Electronic

Type: User Guide

4.3.2 Driver for PCAN-Adapter (USB/CAN)

Before connecting the USB/CAN adapter to the PC/laptop system for the very first time the

following HW driver has to be installed:

Data\PeakOemDrv.exe

Double clicking on the file initiates the installation which will guide the user through the pro-

cess:

-Accept license agreement

-Select/accept installation folder

-Select “PCAN-USB Driver”

-Click on Next to continue with the installation

After the HW driver installation is complete:

-Connect your USB/CAN adapter to a free USB port on your PC

-The new HW will be recognized by Windows XP and a message box will show up asking

you for instructions on how to continue.

-Select automatic installation of PCAN USB driver

4.3.3 AE300-Wizard and Visual C++ Runtime Library

The AE300-Wizard is provided as an MS-Installer package:

Data\AE_Wizard.msi

Double clicking on the file name initiates the installation which will guide the user through

the process:

-Select a target folder (e.g. "C:\Programs\Austro Engine\AE300-Wizard")

After the installation has finished it is also recommended to

-install a shortcut on your desktop pointing to your personal folder (e.g. "My Docu-

ments\Austro Engine\AE300-Wizard" in standard installations). This allows easy ac-

cess to stored log files and folders created during diagnostic sessions.

4.4 Installation for Evaluating Log Files

If you want to analyze log files only the driver for the PCAN adapter will not be necessary.

You only have to perform the following steps:

Install .NET environment (see chapter “4.3.1 .NET Environment” on page 17), and

Install the AE300-Wizard and the Visual C++ runtime library (see chapter “4.3.3

AE300-Wizard and Visual C++ Runtime Library” on page 18).

AE300-Wizard

Document No.: E4.08.09 E4.08.09 : AE_xx_000

Revision: 13 9 : 00

Page: 19 of 89

Copyright © 2019, Austro Engine GmbH

Dept.: Electric/Electronic

Type: User Guide

5Upgrade Installation

Users with a working installation of an older AE300-Wizard release who wish to perform an

upgrade rather than a new installation can do so, using an MS-Installer (upgrade) package

which is downloadable from the Austro Engine homepage:

Data\AE_Wizard.msi

5.1 Download Upgrade Package

Log in to the customer section of the Austro Engine homepage using your assigned user

name and your password to download the latest AE300-Wizard upgrade package:

Step 1: If you have not done so already, please contact Austro Engine “After Sales”at

(service@austroengine.at) to obtain your login for the customer area.

Step 2: Use your favorite browser to go to http://www.austroengine.at.

Step 3: Type in your username and password to access the customer area.

Step 4: Select “customer area” “Manuals” “AE300-Wizard”.

Step 5: Download “AE300-Wizard Wizard Software version 1.3.4.433”(use always the

latest software version).

Step 6: Download “AE300-Wizard Wizard User Guide”and save it on your PC-system

(e.g. on the “Desktop”) for later use.

5.2 Remove Previous AE300-Wizard Version

To avoid possible incompatibilities between previously installed libraries and new versions in-

cluded in the new AE300-Wizard upgrade package it is highly recommended to manually re-

move the current AE300-Wizard package first –before attempting installation of the upgrade

package. Any aircraft data or log files already stored on your PC-system will remain in “My

Documents”, they will not be removed by the following procedure:

Step 1: “Start” “Control Panel” “Add or Remove Programs”.

Step 2: Look for the entry “AE300-Wizard” and select the “Remove” option.

Step 3: Close “Add or Remove Programs”, close “Control Panel”.

5.3 Install Upgrade Package

Double clicking on the upgrade package downloaded as described in “5.1 Download Upgrade

Package”initiates the upgrade installation which will guide the user through the process:

-Select a target folder (e.g. "C:\Program Files (x86)\Austro Engine\AE300-

Wizard") where the program should be installed.

After the installation has finished it is also recommended to install a shortcut on your desk-

top pointing to your personal folder (in standard installations is this "My Documents\Austro

Engine\AE300-Wizard"). This allows easy access to stored log files and folders created during

diagnostic sessions.

AE300-Wizard

Document No.: E4.08.09 E4.08.09 : AE_xx_000

Revision: 13 9 : 00

Page: 20 of 89

Copyright © 2019, Austro Engine GmbH

Dept.: Electric/Electronic

Type: User Guide

6Overview and First Steps

After successful completion of the installation the following chapter will guide you through

the basic steps required to operate the AE300-Wizard.

6.1 CAN Connection

-Connect the USB/CAN adapter to a USB port of the PC.

-Connect the CAN adapter to the aircraft CAN (Diagnostic) plug using a CAN extension

cord if required.

6.2 Starting the AE300-Wizard

-Double click the AE300-Wizard icon on your desktop.

-The Wizard will start up and depending on the USB-dongle detected one of three oper-

ating modes will be available. For details see chapter “7 Modes of Operation” on page

25.

6.3 Setting up the Aircraft

For safety reasons certain functions of the AE300-Wizard are available only in a safe context

(e.g. aircraft on the ground, engine not running etc.). Below is a summary of those consid-

erations.

6.3.1 Engine Running

If the AE300-Wizard is connected to a running engine only diagnostic functions which do not

interfere with engine control are allowed by the ECU firmware:

-«Engine Data» tab on the right page displays real time engine data and status continu-

ously for BOTH ECUs (

Note:

The Garmin G1000 displays engine data and status for the

ACTIVE ECU only).

-Real time clock and operating hours counters displayed in «Engine Data» tab are not

updated but frozen at the time of Connect ECU button has been pressed.

-Fault Code Memory can be read and cleared on running engine.

-

Note:

Event records and data logs CANNOT be downloaded from a running engine.

6.3.2 Engine not Running

If the engine is not running the primary concerns are in respect to battery exhaustion and to

prevent damage of engine components.

6.3.2.1 Ground Power Supply

Diagnostics session lasting longer than 15-20 minutes (e.g. downloading data logger data)

may drain the aircraft battery.

In twin engine aircraft one engine may be running and supplying power while the other

(stopped) engine can be diagnosed. If both engines are stopped or in single engine aircraft

the use of a ground power supply is highly recommended.

6.3.2.2 Electric Fuel Pumps

Pull circuit breakers of both fuel pumps to prevent overheating, fuel over pressure and pos-

sible damage.

Table of contents