OA-1

SECTION OA

GENERAL INFORMATION

CONTENTS

SUBJECT PAGE

Service Parts Identification L ab e l..........................................................................................................................................OA- 1

Vehicle Identification Plate........................................................................................................................................................OA- 1

Certification Label........................................................................................................................................................................ OA- 1

Engine Identification Num ber...................................................................................................................................................OA- 2

Model Reference...........................................................................................................................................................................OA- 2

Metric Fasteners...........................................................................................................................................................................OA- 2

Fastener Strength Identification.............................................................................................................................................. OA- 3

Six Lobed Socket Head Fasteners..........................................................................................................................................OA- 4

Prevailing Torque Fasteners......................................................................................................................................................OA- 4

Conversion Table...........................................................................................................................................................................0A-10

Decimal and Metric Equivalents...............................................................................................................................................OA-11

2

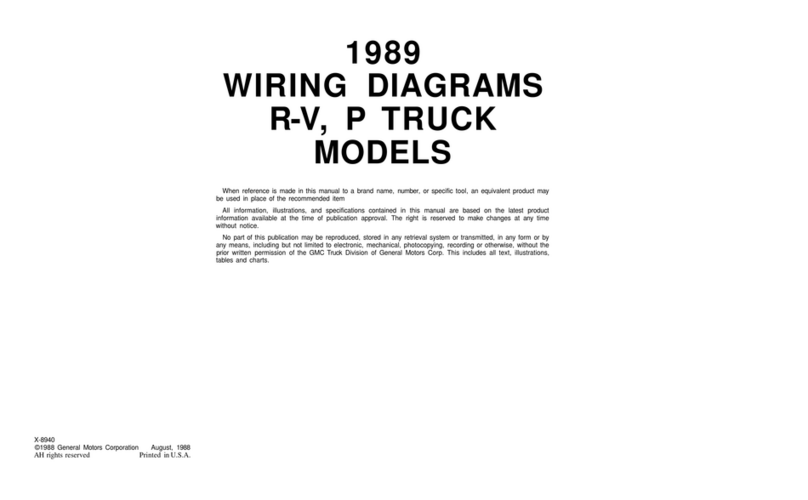

Service Parts Identification DO NOT REMOVE

1. VIN 6

2. Wheel Base 5. RPO/SEO Codes

3. Model Number 6. Exterior Color WA Numbers

4. Order Num ber 7. Paint System F-05402

Figure 1—Service Parts Identification Label

SERVICE PARTS

IDENTIFICATION LABEL

The Truck Service Parts Identification Label is provided

on all models (figure 1). It is located on the inside of the

glove box door (or on an inner body panel for Forward

Control models). The Label lists the VIN (Vehicle

Identification Number) wheelbase paint information and

all Production options or Special Equipment on the

vehicle when it was shipped from the factory. ALWAYS

REFER TO THIS INFORMATION WHEN ORDERING

PARTS.

VEHICLE IDENTIFICATION

NUMBER

The VIN is the legal identifier of the vehicle. On all

models except Forward Control it is located on a plate

which is attached to the left top of the instrument panel

and can be seen through the windshield from the outside

of the vehicle (figure 2). On Forward Control models the

plate is on the dash and toe panel. To find out the

F-00687

Figure 2—VIN Location

manufacturer model and chassis type engine type GVW

range model year plant code and sequential number

refer to figure 3.

CERTIFICATION LABEL

The Certification Label shows the GVWR and the front

and rear GAWRs and the Payload Rating for your vehicle

(figure 4).

Gross Vehicle Weight (GVW) is the weight of the

orginally equipped vehicle and all items added to it after it

has left the factory. This would include bodies winches

booms etc.; the driver and all occupants; and the load the

vehicle is carrying. The GVW must not exceed the

GVWR. Also the front and rear gross axle weights must

not exceed the front and rear GAWRs.

The Payload Rating shown on the label is the maximum

allowable cargo load (including the weight of the driver

and all occupants) that the vehicle can carry based on all