AUTOFLAME MM Series User manual

Combustion Management Systems

MM APPLICATION

POSSIBILITIES

Technical Manual 18.12.2019

AUTOFLAME ENGINEERING LTD

Unit 1-2, Concorde Business Centre

Airport Industrial Estate

Wireless Road, Biggin Hill

Kent TN16 3YN

United Kingdom

Combustion Management Systems

+44 (0)1959 578 820

Tel:

technicalsupport@autoflame.com

Email:

www.autoflame.com

Website:

Technical Manual

MM Application Possibilities

18 December 2019

This manual and all the information contained herein is copyright of Autoflame Engineering Ltd. It may

not be copied in the whole or part without the consent of the Managing Director.

Autoflame Engineering Ltd’s policy is one of continuous improvement in both design and

manufacture. We therefore reserve the right to amend specifications and/or data without prior notice.

All details contained in this manual are correct at the time of going to print.

Important Notes

A knowledge of combustion related procedures and commissioning is essential before embarking

work on any of the MM./EGA systems. This is for safety reasons and effective use of the MM/EGA

system. Hands on training is required. For details on schedules and fees relating to group training

courses and individual instruction, please contact the Autoflame Engineering Ltd. offices at the

address listed on the front.

Short Form - General Terms and Conditions

A full statement of our business terms and conditions are printed on the reverse of all invoices. A copy

of these can be issued upon application, if requested in writing.

The System equipment and control concepts referred to in this Manual MUST be installed,

commissioned and applied by personnel skilled in the various technical disciplines that are inherent to

the Autoflame product range, i.e. combustion, electrical and control.

The sale of Autoflame’s systems and equipment referred to in this Manual assume that the dealer,

purchaser and installer has the necessary skills at his disposal. i.e. A high degree of combustion

engineering experience, and a thorough understanding of the local electrical codes of practice

concerning boilers, burners and their ancillary systems and equipment.

Autoflame’s warranty from point of sale

•Two years on all electronic systems and components.

•One year on all mechanical systems, components and sensors.

The warranty assumes that all equipment supplied will be used for the purpose that it was intended

and in strict compliance with our technical recommendations.

Autoflame’s warranty and guarantee is limited strictly to product build quality, and design. Excluded

absolutely are any claims arising from misapplication, incorrect installation and/or incorrect

commissioning.

Contents

1SENSORS....................................................................................................................................... 1

1.1 Gas Pressure Sensor .......................................................................................................... 1

1.1.1 Mk8 MM Valve Proving Schematics.................................................................................... 4

1.1.2 Mini Mk8 MM Valve Proving Schematics ............................................................................ 9

1.1.3 Calculating Proving Time and Pressure Change ..............................................................15

1.2 Oil Pressure Sensor .............................................................................................................. 18

1.3 Air Pressure Sensor .............................................................................................................. 20

1.3.1 Air Pressure Proving ......................................................................................................... 23

1.3.2 Air Pressure Tapped Fitting .............................................................................................. 24

1.4 Steam Pressure Sensor ........................................................................................................ 25

1.5 Water Temperature Sensor................................................................................................... 27

1.6 Outside Temperature Sensor................................................................................................ 29

1.6.1 Night Setback .................................................................................................................... 34

2FLAME SAFEGUARD .................................................................................................................. 35

2.1 Burner Control Sequence Diagrams ..................................................................................... 35

2.1.1 Interrupted Pilot – Gas ...................................................................................................... 36

2.1.2 Interrupted Pilot – Oil ........................................................................................................ 37

2.1.3 Intermittent Pilot – Gas with Post VPS.............................................................................. 38

2.2 Flame Scanner Types ........................................................................................................... 39

2.2.1 IR End View Scanner ........................................................................................................ 39

2.2.2 Self-Check End View UV Scanner – High Sensitivity ....................................................... 41

2.2.3 Self-Check Side View UV Scanner – High Sensitivity ......................................................43

2.2.4 Mk8 Series Side View UV Scanner................................................................................... 45

2.2.4 Standard European Side Viewing UV Scanner................................................................. 46

2.2.6 Standard North American UV Scanner – End Viewing ..................................................... 48

2.2.7 Standard North American UV Scanner – End Viewing High Sensitivity ...........................50

2.2.8 Swivel Mount Assembly .................................................................................................... 51

2.3 Selection Of UV Scanner Types ........................................................................................... 52

2.3.1 UV Installation ................................................................................................................... 53

2.3.2 UV Self Adaptive Pulse Width Modulation ........................................................................ 54

2.3.3 Dual Flame Scanner Operation......................................................................................... 55

2.4 Mk8 MM Flame Detection Using An External Flame Switch ................................................56

2.5 Mini Mk8 MM Flame Detection Using Ionisation................................................................... 56

2.6 No Pre-Purge ........................................................................................................................ 57

2.7 Continuous Pilot .................................................................................................................... 58

2.7.1 Continuous Pilot with Interrupted Pilot Sequence............................................................. 59

2.7.2 Continuous Pilot with Intermittent Pilot Sequence ............................................................60

2.8 Mini Mk8 MM Single Servomotor .......................................................................................... 61

2.8.1 Single Servomotor with VSD............................................................................................. 61

2.8.2 Digital Fan Adapter............................................................................................................ 63

2.8.3 No Air Servomotor............................................................................................................. 64

2.9 Mk8 MM External 4-20mA Servomotor................................................................................. 65

2.9.1 Overview ........................................................................................................................... 65

2.9.2 External 4-20mA Servomotor Requirements .................................................................... 65

2.9.3 Wiring ................................................................................................................................ 66

2.9.4 Settings ............................................................................................................................. 67

2.9.5 Commissioning.................................................................................................................. 67

3HAND, LOW FLAME HOLD AND AUTO..................................................................................... 68

3.1Hand Operation ..................................................................................................................... 68

3.2 Low Flame Hold .................................................................................................................... 68

3.3 Auto Operation ...................................................................................................................... 68

4PID CONTROL.............................................................................................................................. 69

4.1 Proportional Band ................................................................................................................. 69

4.2 Integral Control...................................................................................................................... 70

4.3 Derivative Control.................................................................................................................. 71

5INTELLIGENT BOILER SEQUENCING....................................................................................... 72

5.1 Sequencing Schematics........................................................................................................ 73

5.1.1 Sequencing Connection Diagram ..................................................................................... 73

5.1.2 DTI Connection Diagram................................................................................................... 74

5.1.3 Hot Water Example ........................................................................................................... 75

5.1.4 Single/ Multi-Burner Examples.......................................................................................... 76

5.1.5 IBS Communications......................................................................................................... 77

5.2 Sequencing Options and Parameters ................................................................................... 78

5.3 Hot Water Sequencing .......................................................................................................... 79

5.3.1 Implementing Hot Water Sequencing ............................................................................... 79

5.3.2 Two Port Valve Operation ................................................................................................. 80

5.4 Steam Sequencing................................................................................................................ 81

5.4.1 Warming Steam Boilers .................................................................................................... 81

5.4.2 Implementing Steam Sequencing ..................................................................................... 81

5.4.3 Low Pressure Steam Sequencing..................................................................................... 82

5.5 Troubleshooting – Sequencing ............................................................................................. 83

6MULTI-BURNER OPERATION – MK8 MM .................................................................................84

6.1 Multi-Burner Overview........................................................................................................... 84

6.2 Configuring Multi-Burner Operation ...................................................................................... 85

6.2.1 Wiring ................................................................................................................................ 85

6.2.2 Options and Parameters ................................................................................................... 86

6.2.3Commissioning in Multi-Burner Operation ........................................................................ 86

6.2.4 Fuel Flow Metering in Multi-Burner Operation .................................................................. 86

6.2.5 Single Point Change in Multi-Burner Operation ................................................................ 86

6.3 Multi-Burner Operation.......................................................................................................... 87

6.3.1 Fully Linked Operation ...................................................................................................... 87

6.3.2 Independent on Fault ........................................................................................................ 88

6.3 Multi-Burner with Water Level Control .................................................................................. 89

6.4 Multi-Burner with EGA........................................................................................................... 89

6.4.1 Multi-Burner with Single EGA............................................................................................ 89

6.4.2 Multi-Burner with individual EGAs..................................................................................... 90

6.5 Multi-Burner External Modulation.......................................................................................... 91

6.5.1 Permanent External Modulation........................................................................................ 91

6.5.2 Switched External Modulation........................................................................................... 91

1Sensors

Page | 1

MM Application Possibilities

1 SENSORS

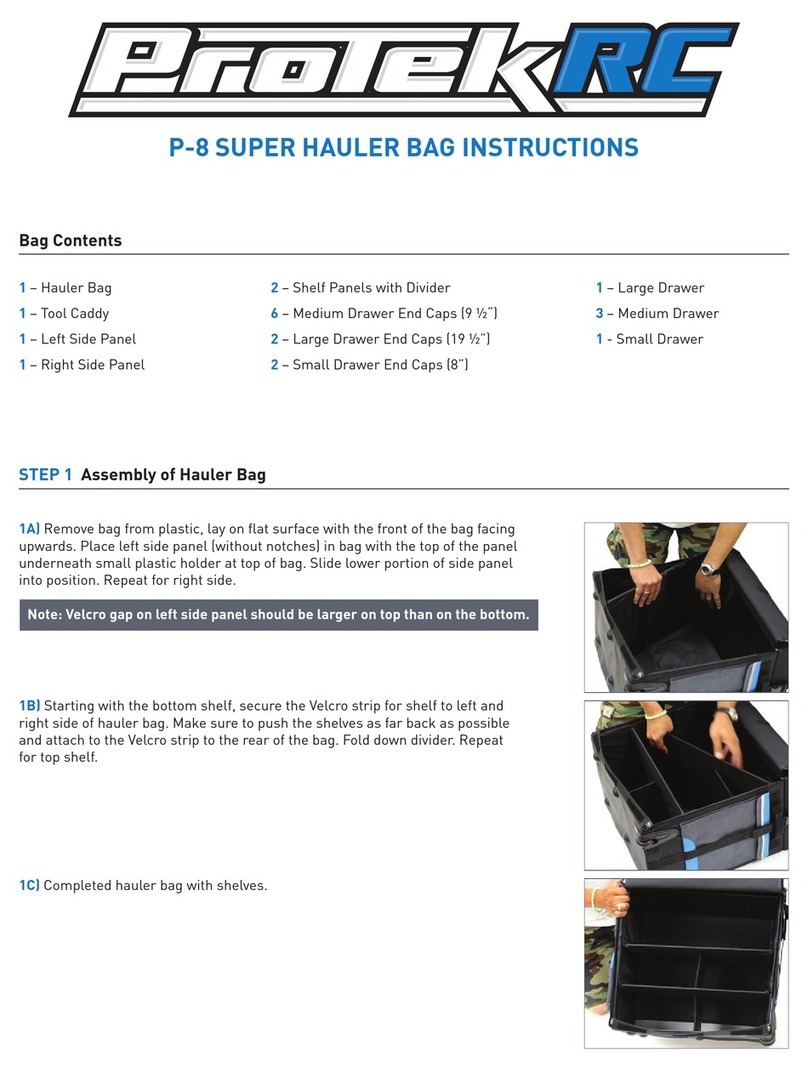

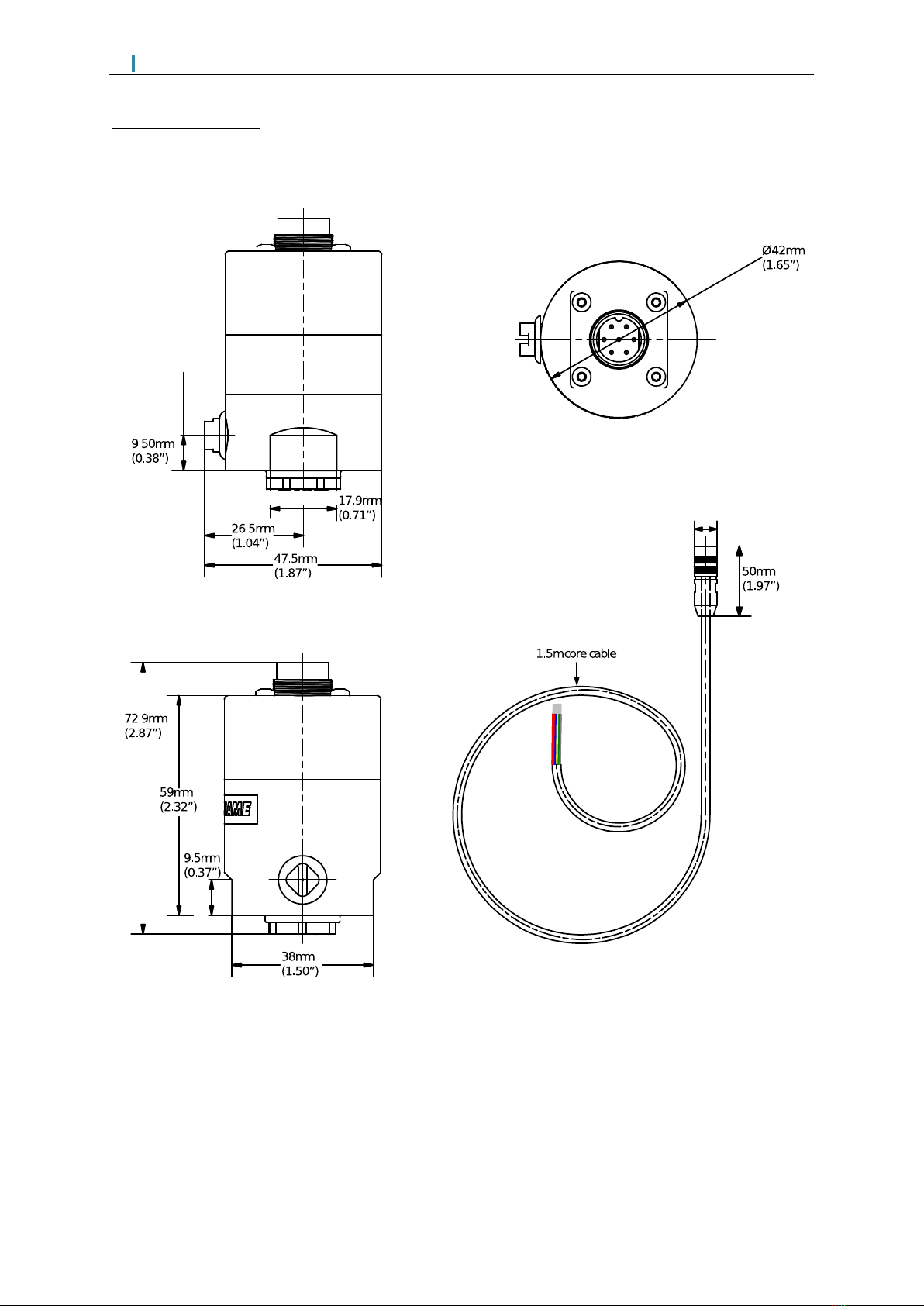

1.1 Gas Pressure Sensor

IP

65

NEMA

4

Housing & Lid

Aluminium

Power Consumption

0.1 Watts

Mounting

Breather hole to be piped or used as differential pressure for IP65/NEMA 4

Installation

Sensor should be installed vertically

Operating Temp.

-25OC to 85OC (-13OF to 185OF)

Part No.

Min. Pressure

Max. Pressure

Zero Range

mbar

“wg

PSI

mbar

“wg

PSI

mbar

“wg

PSI

MM80006

Digital

-68

-27

-1

68

27

1

-1.36 to 1.36

-0.54 to 0.54

-0.02 to 0.02

Analogue

12.5

5

0.18

65

25

1

-2.5 to 1.25

-1.0 to 0.5

-0.04 to 0.02

MM80008

Digital

-344

-138

-5

344

138

5

-6.88 to 6.88

-2.76 to 2.76

-0.1 to 0.1

Analogue

52

25

0.75

340

135

5

-12.5 to 6.25

-5.0 to 2.5

-0.2 to 0.1

MM80011

Digital

-1034

-415

-15

1034

415

15

-20.68 to 20.68

-8.3 to 8.3

-0.3 to 0.3

Analogue

115

50

1.8

750

300

11

-30.0 to 15.0

-12.0 to 6.0

-0.44 to 0.22

MM80012

Digital

-2068

-831

-30

2068

831

30

-41.36 to 41.36

-16.62 to 16.62

-0.6 to 0.6

Analogue

207

83

3

1380

550

20

-55.0 to 27.6

-22.0 to 11.0

-0.8 to 0.4

MM80014

Digital

-6894

-2770

-100

6894

2770

100

-137.88 to 137.88

-55.4 to 55.4

-2 to 2

Analogue

400

162

6

4000

1620

60

-166.0 to 82.0

-67.0 to 32.0

-2.4 to 1.2

Digital - when used with Mk8 MM, Mini Mk8 MM and Mk8 DTI

Analogue - when used with Mk7 MM

Gas Sensor

Mk8 MM

Mini Mk8 MM

Brown

T31

T29

Purple

T32

T30

Blue

T33

T48

Red

T34

T49

Connect screen at one end only

Drawing No. 9004

Socket

Plug

Circuit board

Pressure

switching unit

Sealing O-rings

1/8” NSP Nylon

plug with

breather hole

Quick connection

screened flying

lead (1.5m)

Plug

¼” Tapered male

nipple

1Sensors

Page | 2

MM Application Possibilities

Gas Pressure Sensor

1Sensors

Page | 3

MM Application Possibilities

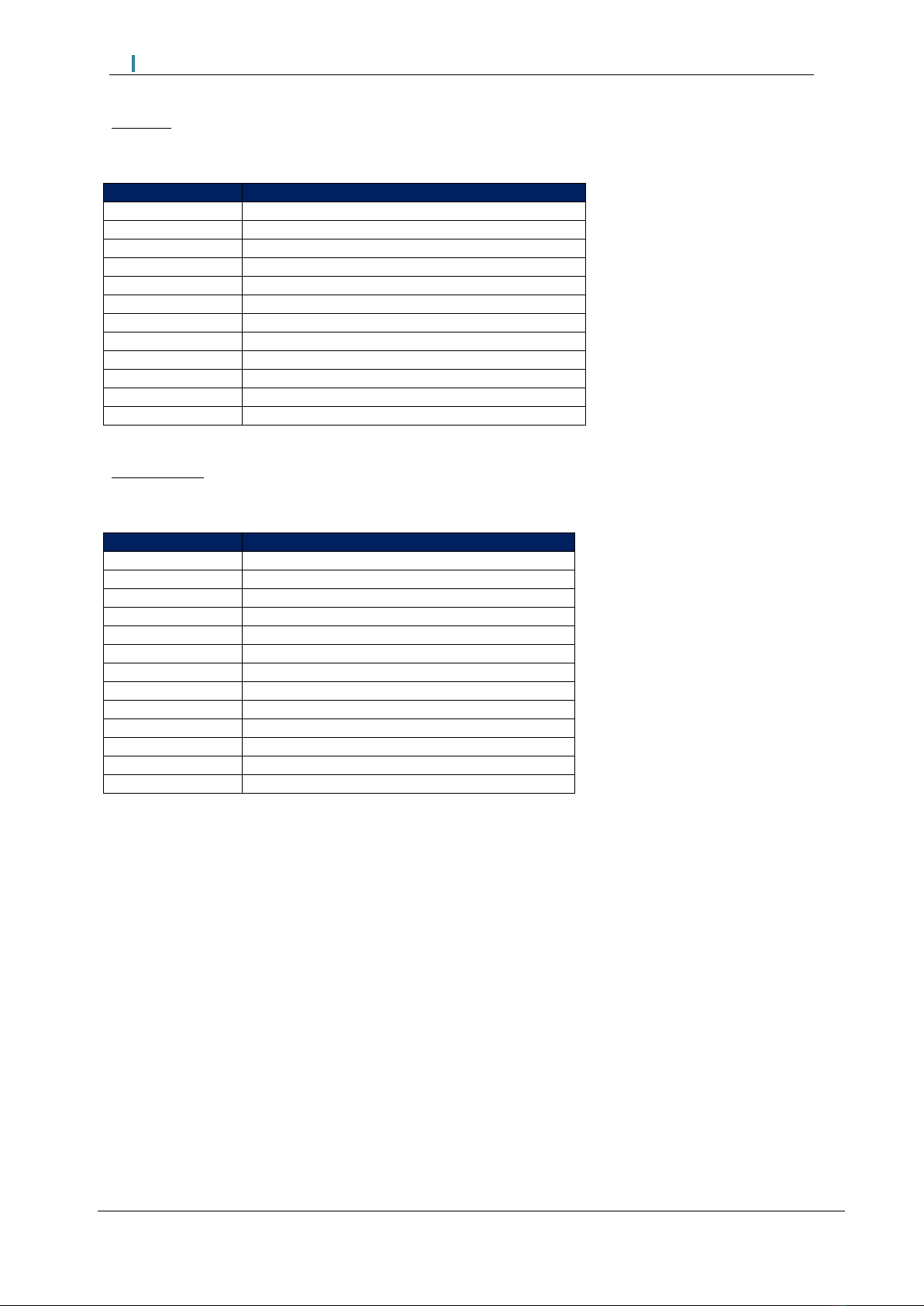

Mk8 MM

If the Valve Proving System (VPS) facility is to be used then specific options/parameters must be set.

Option/Parameter

Mk8 MM

125

Fuel pressure sensor mode – fuel 1

126

Fuel pressure sensor mode – fuel 2

127

Fuel pressure sensor mode – fuel 3

128

Fuel pressure sensor mode – fuel 4

129

VPS operation

130

Gas valve configuration

132

Gas valve proving time

133

Maximum pressure change allowed during VPS

134

VPS valve opening time

136

Gas pressure switch – offset lower limit

137

Gas pressure switch – offset upper limit

Parameter 41

Gas pressure units

Mini Mk8 MM

If the Valve Proving System (VPS) facility is to be used then specific options/parameters must be set.

Option/Parameter

Mini Mk8 MM

125

Fuel pressure sensor mode – fuel 1

126

Fuel pressure sensor mode – fuel 2

128

VPS sensor type

129

VPS operation

130

Gas valve configuration

131

Gas pressure units

132

Gas valve proving time

133

Maximum change allowed during proving time

134

VPS valve opening time

136

Gas pressure switch – offset lower limit

137

Gas pressure switch – offset upper limit

138

Gas static line pressure lower limit offset

156

Terminal T82 function

IT IS THE RESPONSIBILITY OF THE COMMISSIONING ENGINEERS TO ENSURE THAT

THE RELEVANT VALVE PROVING SYSTEM STANDARDS ARE ADHERED TO.

1Sensors

Page | 4

MM Application Possibilities

1.1.1 Mk8 MM Valve Proving Schematics

VPS and High/low Pressure Limits using Autoflame Gas Pressure Sensor (3 valves)

Option/ parameter 125 (126, 127, or 128 if fuel 2, 3 or 4) to 1

Option/ parameter 130 to 1 or 2

High/low Pressure Limits using Autoflame Gas Pressure Sensor (3 valves)

Option/ parameter 125 (126, 127, or 128 if fuel 2, 3 or 4) to 2

Option/ parameter 130 to 1 or 2

Note: Please refer to page 3 for full list of VPS options/parameters.

1Sensors

Page | 5

MM Application Possibilities

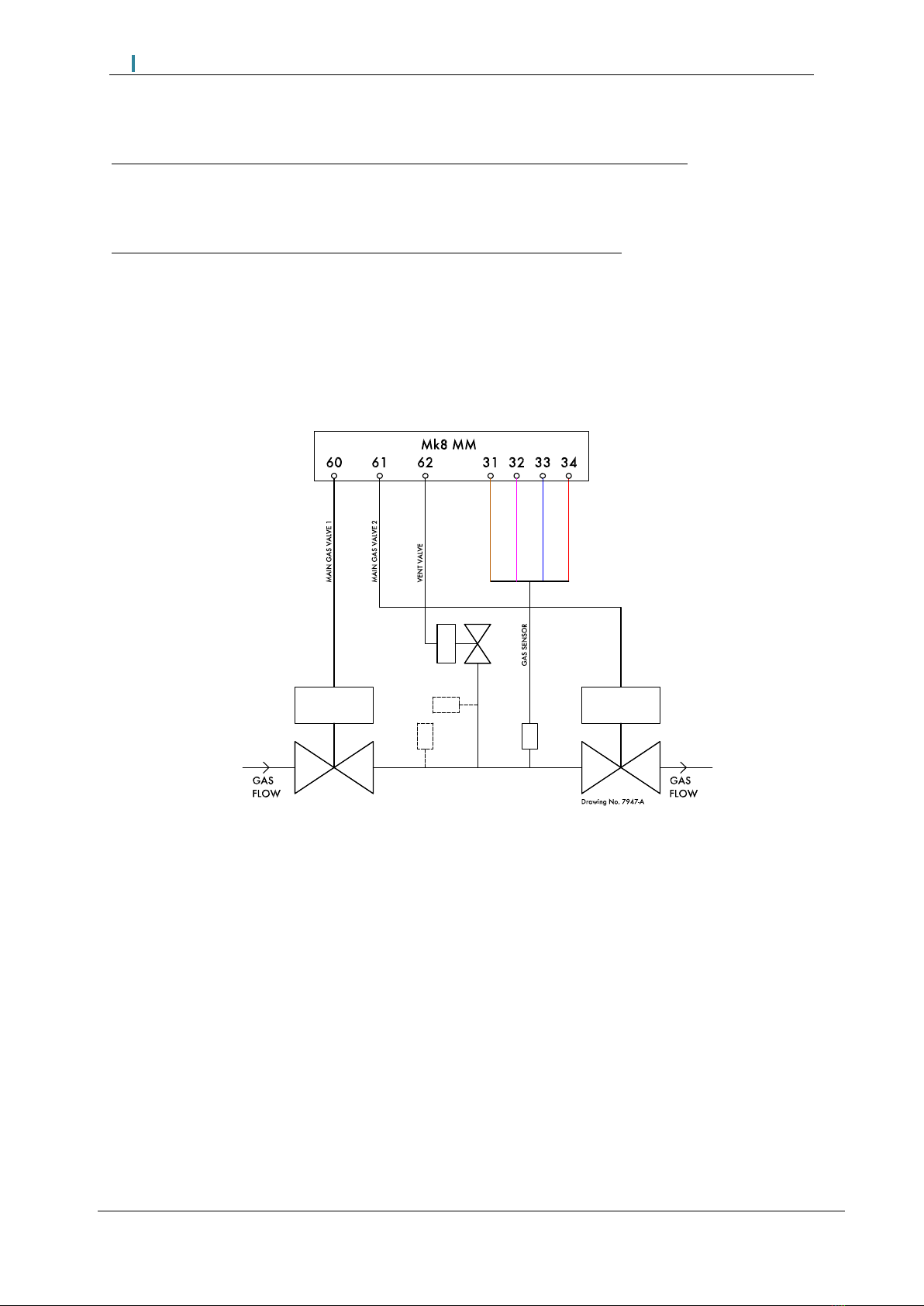

VPS and High/Low Pressure Limits using Autoflame Gas Pressure Sensor (2 valves)

Option/ parameter 125 (126, 127, or 128 if fuel 2, 3 or 4) to 1

Option/ parameter 130 to 0

High/Low Pressure Limits using Autoflame Gas Pressure Sensor (2 valves)

Option/ parameter 125 (126, 127, or 128 if fuel 2, 3 or 4) to 2

Option/ parameter 130 to 0

Note: Please refer to page 3 for full list of VPS options/parameters.

1Sensors

Page | 6

MM Application Possibilities

VPS and High/Low Pressure Limits using Autoflame Gas Pressure Sensor (3 valves, single valve

pilot)

Option/ parameter 125 (126, 127, or 128 if fuel 2, 3 or 4) to 1

Option/ parameter 130 to 4 or 5

High/Low Pressure Limits using Autoflame Gas Pressure Sensor (3 valves, single valve pilot)

Option/ parameter 125 (126, 127, or 128 if fuel 2, 3 or 4) to 2

Option/ parameter 130 to 4 or 5

Note: Please refer to page 3 for full list of VPS options/parameters.

1Sensors

Page | 7

MM Application Possibilities

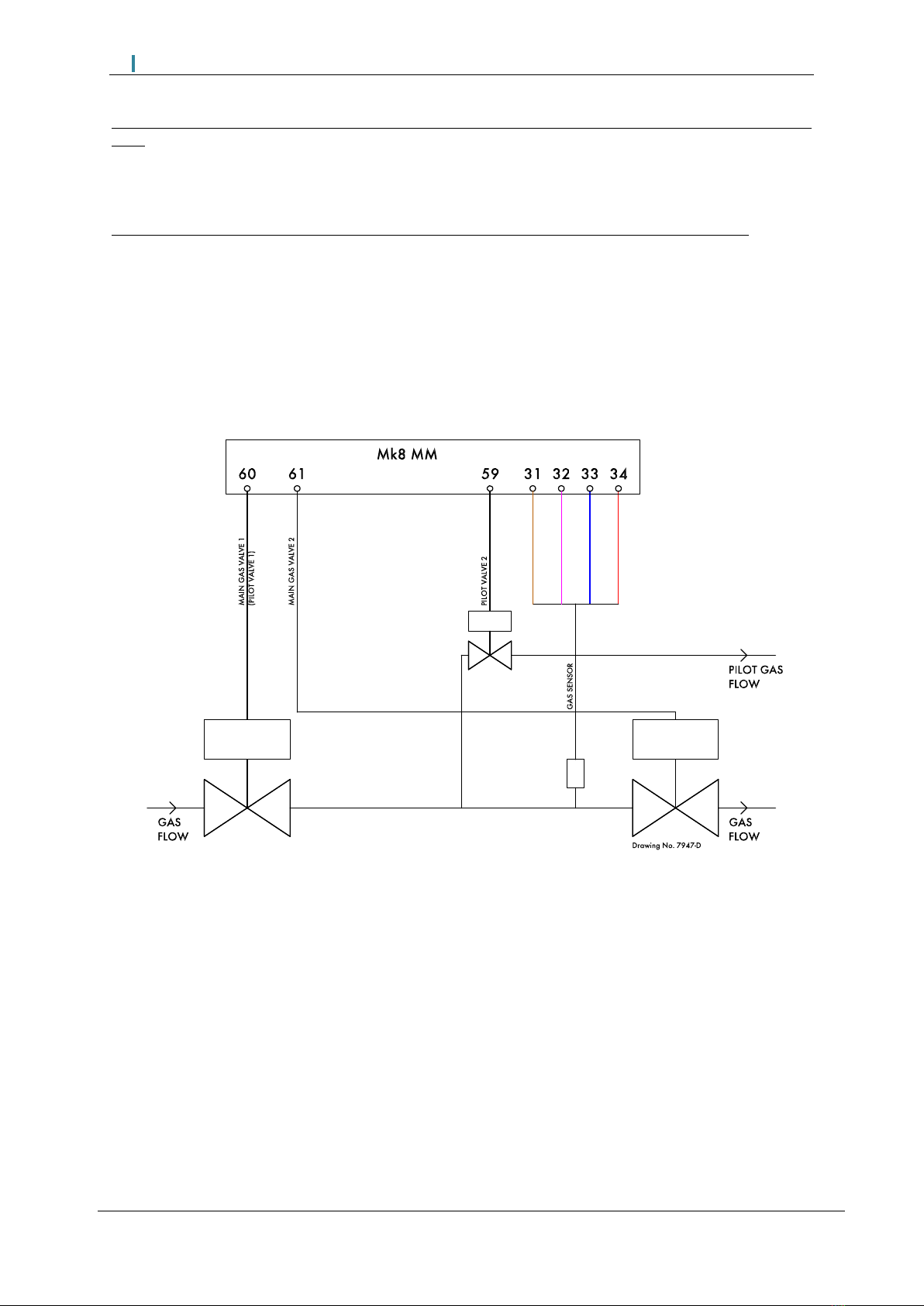

VPS and High/Low Pressure Limits using Autoflame Gas Pressure Sensor (2 valves, single valve

pilot)

Option/ parameter 125 (126, 127, or 128 if fuel 2, 3 or 4) to 1

Option/ parameter 130 to 3

High/Low Pressure Limits using Autoflame Gas Pressure Sensor (2 valves, single valve pilot)

Option/ parameter 125 (126, 127, or 128 if fuel 2, 3 or 4) to 2

Option/ parameter 130 to 3

Note: Please refer to page 3 for full list of VPS options/parameters.

1Sensors

Page | 8

MM Application Possibilities

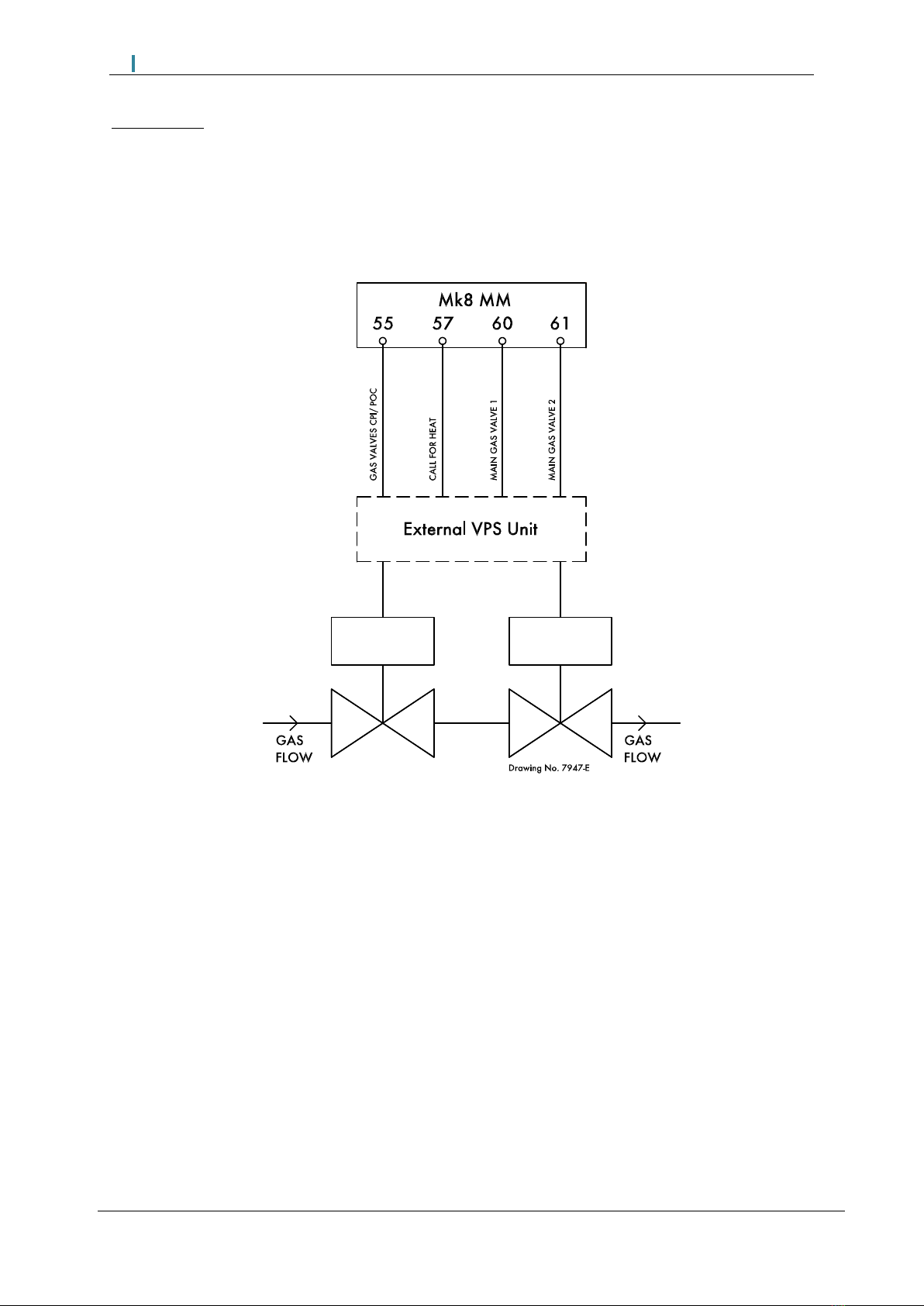

External VPS

Option / parameter 125 (126, 127, or 128 if fuel 2, 3 or 4) to 3

Note: Please refer to page 3 for full list of VPS options/parameters.

1Sensors

Page | 9

MM Application Possibilities

1.1.2 Mini Mk8 MM Valve Proving Schematics

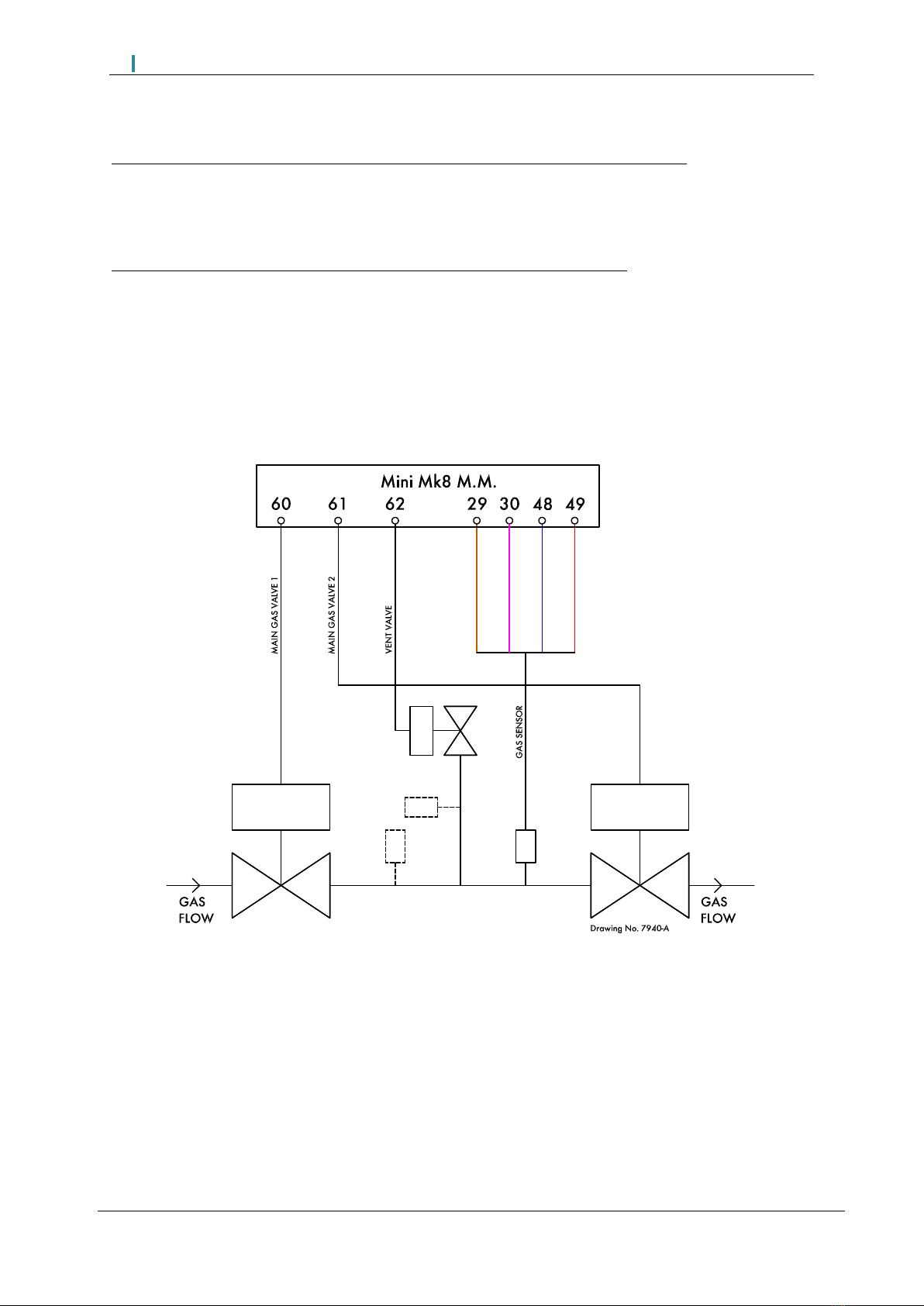

VPS and High/Low Pressure limits using Autoflame Gas Pressure Sensor (3 valves)

Option/ parameter 125 (126 if fuel 2) to 1

Option/ parameter 128 to 1

Option/ parameter 130 to 1 or 2

High/Low Pressure Limits using Autoflame Gas Pressure Sensor (3 valves)

Option/ parameter 125 (126 if fuel 2) to 2

Option/ parameter 128 to 1

Option/ parameter 130 to 1 or 2

Note: Please refer to page 3 for full list of VPS options/parameters.

1Sensors

Page | 10

MM Application Possibilities

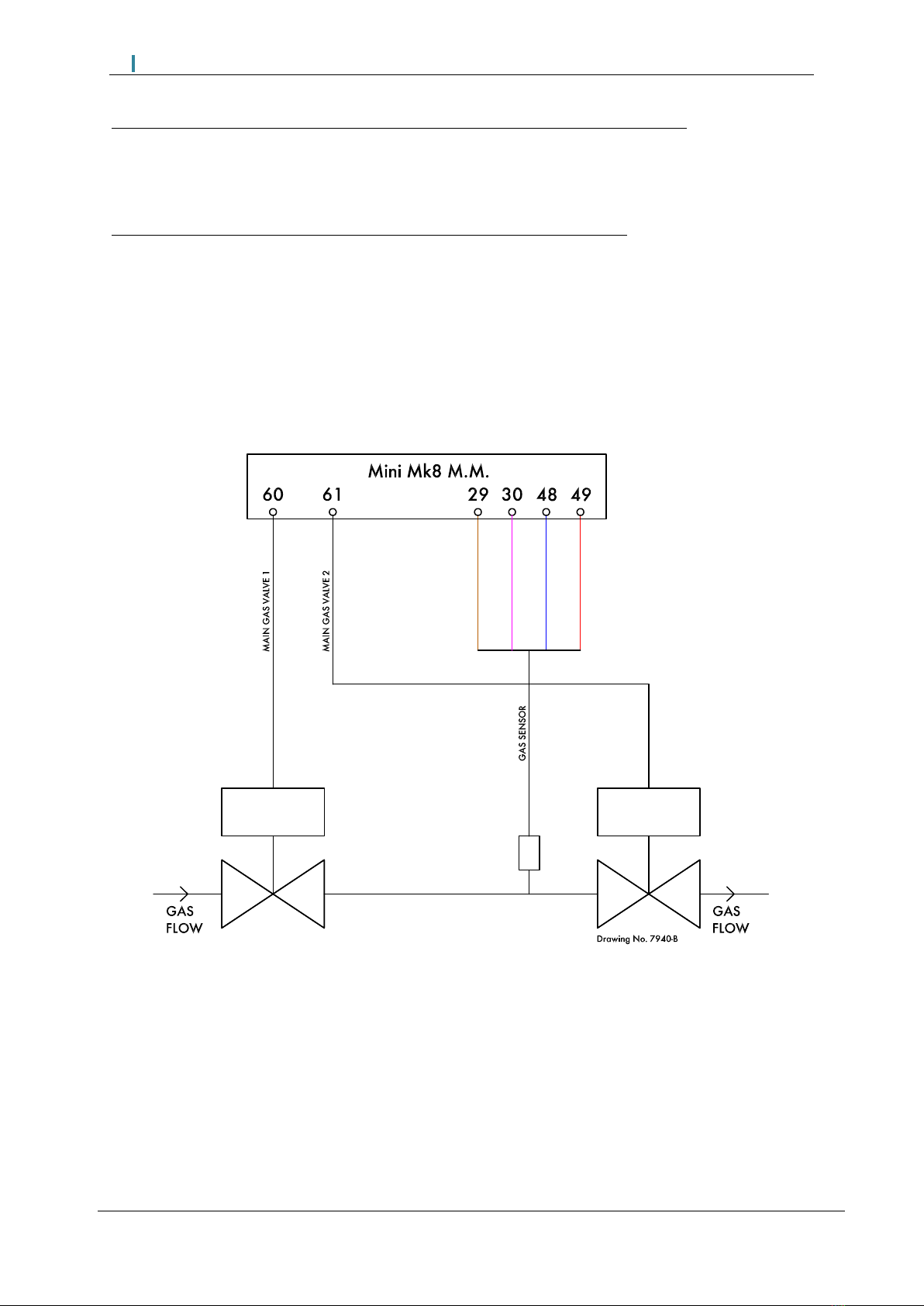

VPS and High/Low Pressure limits using Autoflame Gas Pressure Sensor (2 valves)

Option/ parameter 125 (126 if fuel 2) to 1

Option/ parameter 128 to 1

Option/ parameter 130 to 0

High/Low Pressure Limits using Autoflame Gas Pressure Sensor (2 valves)

Option/ parameter 125 (126 if fuel 2) to 2

Option/ parameter 128 to 1

Option/ parameter 130 to 0

Note: Please refer to page 3 for full list of VPS options/parameters.

1Sensors

Page | 11

MM Application Possibilities

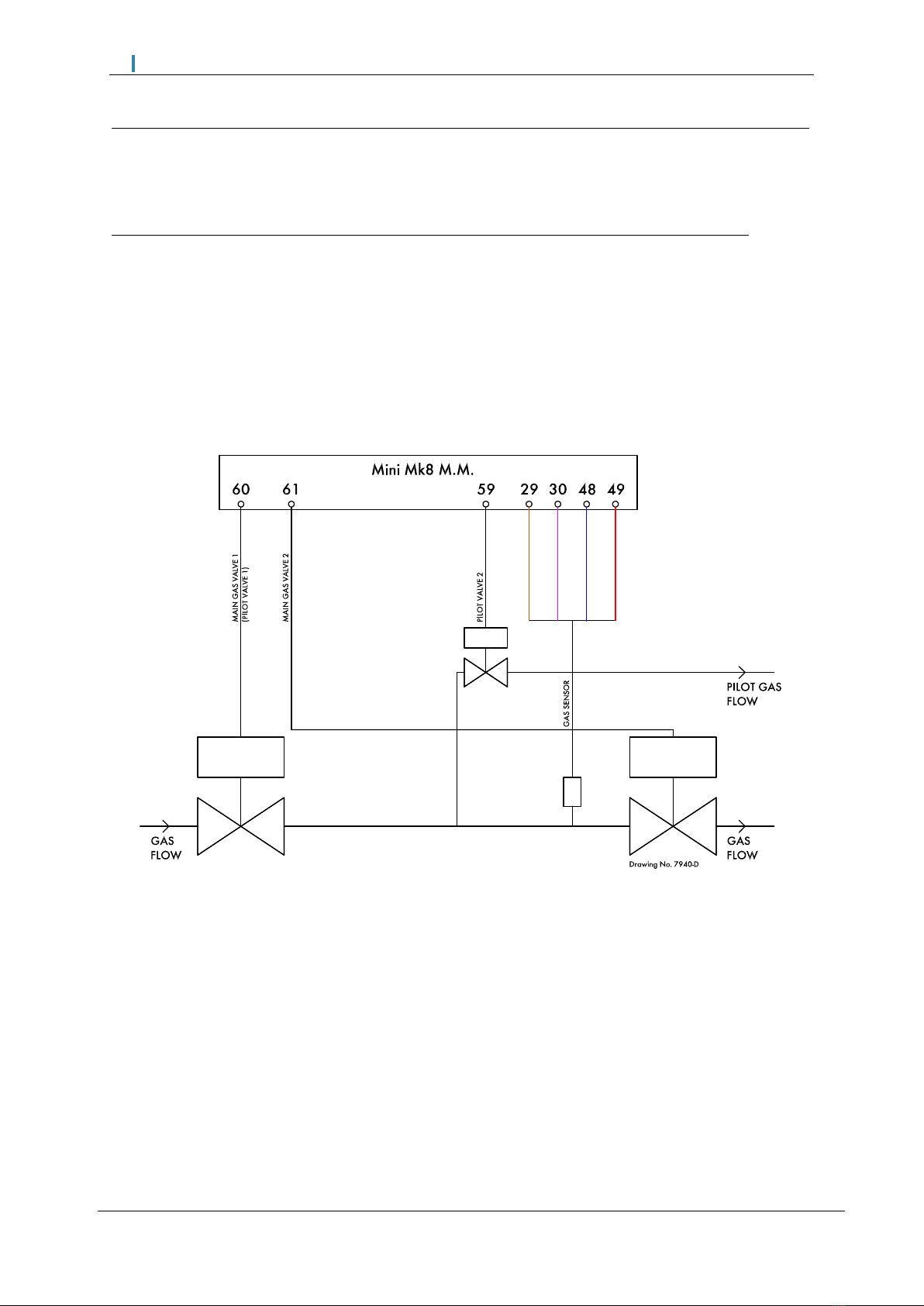

VPS and High/Low Pressure limits using Autoflame Gas Pressure Sensor (3 valves, single valve pilot)

Option/ parameter 125 (126 if fuel 2) to 1

Option/ parameter 128 to 1

Option/ parameter 130 to 4 or 5

High/Low Pressure Limits using Autoflame Gas Pressure Sensor (3 valves, single valve pilot)

Option/ parameter 125 (126 if fuel 2) to 2

Option/ parameter 128 to 1

Option/ parameter 130 to 4 or 5

Note: Please refer to page 3 for full list of VPS options/parameters.

1Sensors

Page | 12

MM Application Possibilities

VPS and High/Low Pressure limits using Autoflame Gas Pressure Sensor (2 valves, single valve pilot)

Option/ parameter 125 (126 if fuel 2) to 1

Option/ parameter 128 to 1

Option/ parameter 130 to 3

High/Low Pressure Limits using Autoflame Gas Pressure Sensor (2 valves, single valve pilot)

Option/ parameter 125 (126 if fuel 2) to 2

Option/ parameter 128 to 1

Option/ parameter 130 to 3

Note: Please refer to page 3 for full list of VPS options/parameters.

Note: Void to boiler phase is done via the pilot valve.

1Sensors

Page | 13

MM Application Possibilities

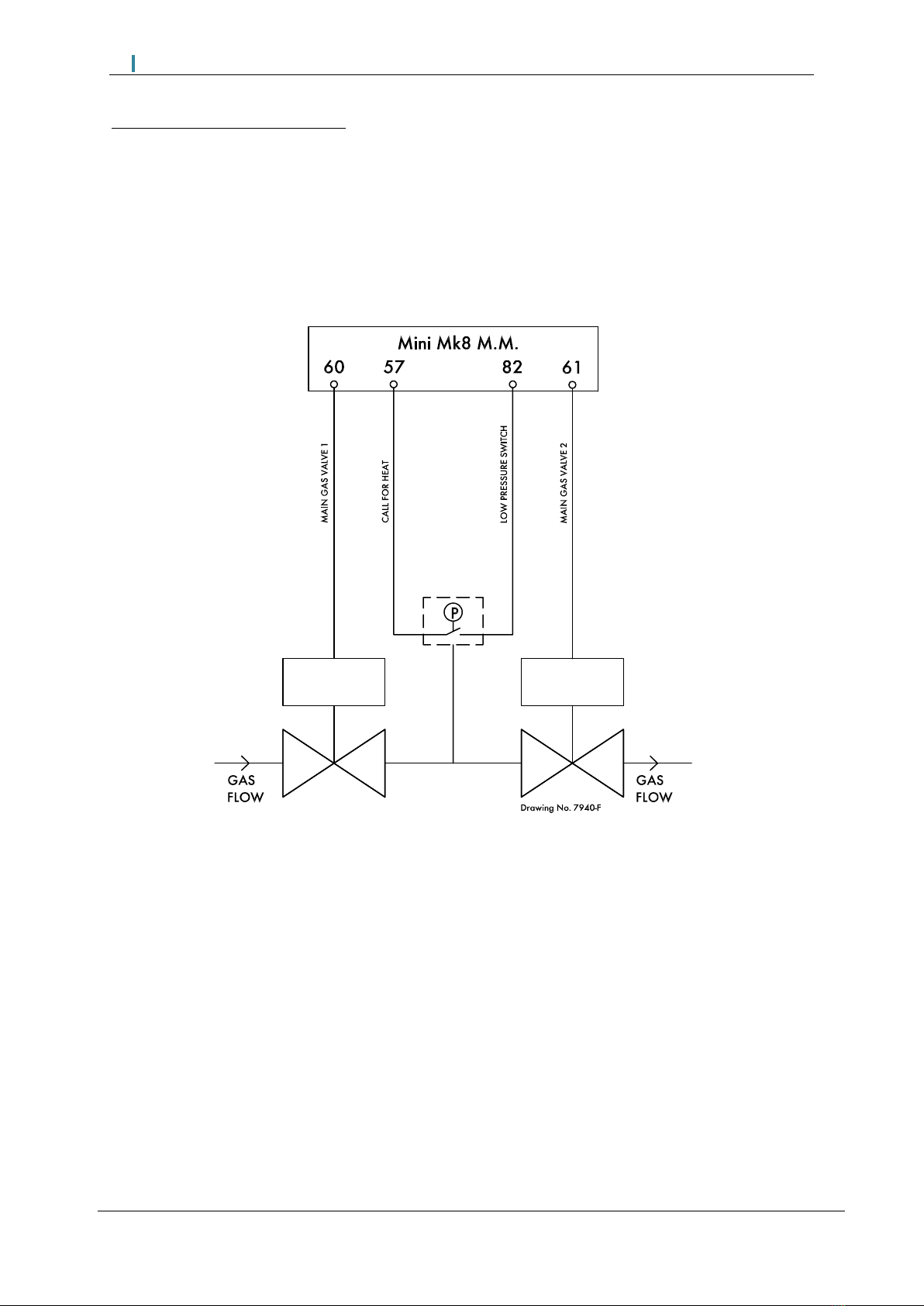

VPS using a Low Pressure Switch

Option/ parameter 125 (126 if fuel 2) to 1

Option/ parameter 128 to 0

Option/ parameter 156 to 1

Note: Please refer to page 3 for full list of VPS options/parameters.

Note: During VPS, the input on terminal 82 should be on during the VPS air proving and gas proving

phases, and at all other VPS phases, the input to terminal 82 should be off. The pressure detected is

the static line pressure, so the pressure switch should be set at a value just below this line pressure.

When the burner is firing, terminal 82 is not checked.

1Sensors

Page | 14

MM Application Possibilities

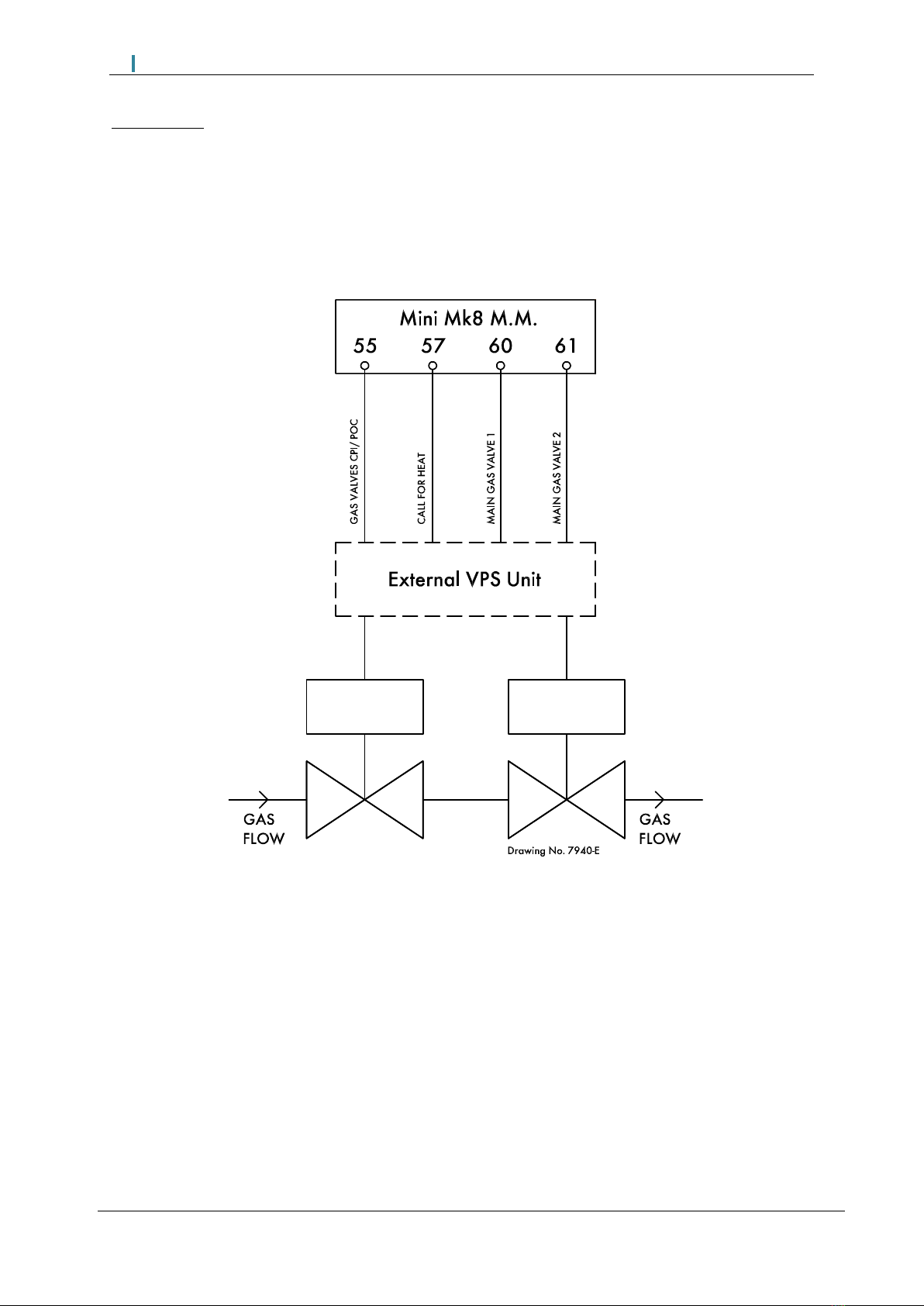

External VPS

Option/ parameter 125 (126 if fuel 2) to 3

Note: Please refer to page 3 for full list of VPS options/parameters.

This manual suits for next models

7

Other AUTOFLAME Accessories manuals

Popular Accessories manuals by other brands

C.P. Electronics

C.P. Electronics SPIR-F/C-IP installation guide

Silvercrest

Silvercrest SPB 5200 A1 Operating instructions and safety instructions

Concept2

Concept2 DV7420 instruction manual

Fire-Lite

Fire-Lite CHG-120 series instruction sheet

MD SPORTS

MD SPORTS SOC054_017E Assembly instructions

Remo+

Remo+ REMOBELL quick start guide

1 BY ONE

1 BY ONE O00QH-050 instruction manual

Pegasus Astro

Pegasus Astro FocusCube operating manual

Kieback&Peter

Kieback&Peter DU0/5 manual

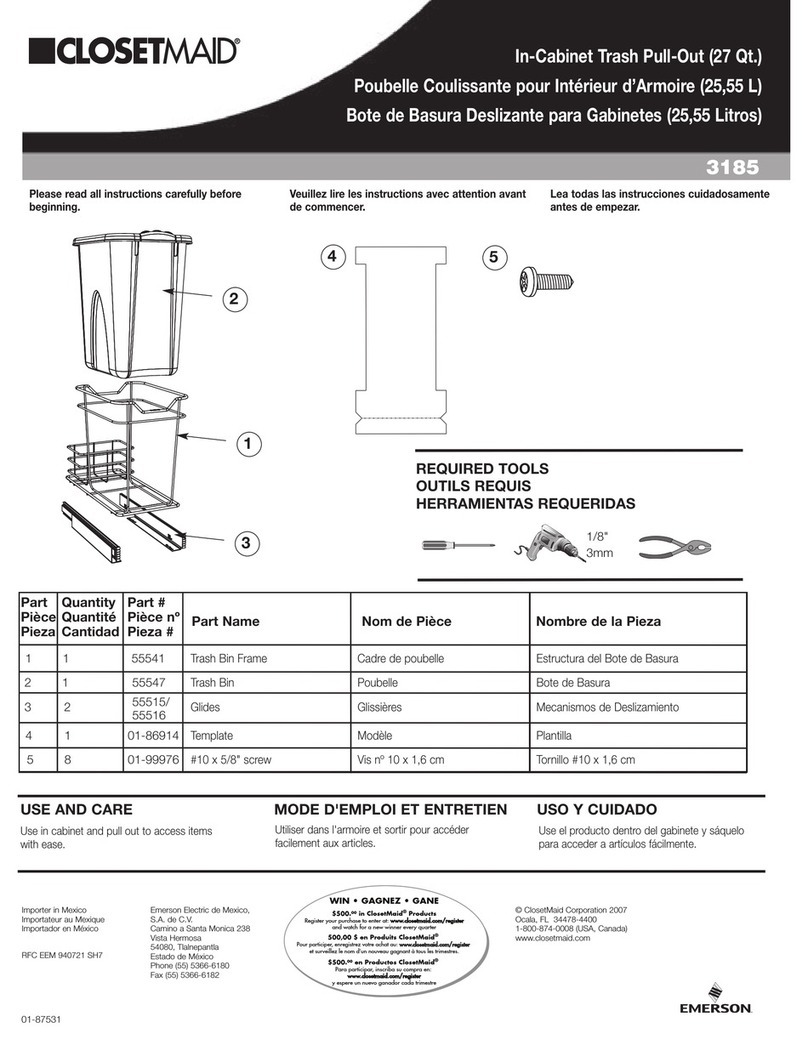

Closet Maid

Closet Maid In-Cabinet Trash Pull-Out 3185 Use and care guide

Metalcraft

Metalcraft GR-4100 Mounting and user instructions

New Air

New Air AB1200BC1 owner's manual