AUTOFLAME Mini Mk8 M.M. User manual

1

2

Mini Mk8 M.M.

Installation and Commissioning Guide

MK8微型控制模块安装和调试指南

Issued by:

AUTOFLAME ENGINEERING LTD

AUTOFLAME工程有限公司

Unit 1-2, Concorde Business Centre

Airport Industrial Estate, Wireless Road

Biggin Hill, Kent TN16 3YN

Tel: +44 (0)845 872 2000

Fax: +44 (0)845 872 2010

Email: salesinfo@autoflame.com

Website: http://www.autoflame.com/

Registered Holder 注册持有人 : _____________________________________

Company 公司: ___________________________________________________

Department 部门: _________________________________________________

This manual and all the information contained herein is copyright of Autoflame Engineering Ltd. It

may not be copied in the whole or part without the consent of the Managing Director.

Autoflame工程有限公司拥有本手册的所有版权。在未经Autoflame公司常务董事同意的情况下,

本手册内容不得被整体或部分引用。

Autoflame Engineering Ltd’s policy is one of continuous improvement in both design and

manufacture. We therefore reserve the right to amend ecifications and/or data without prior

notice. All details contained in this manual are correct at the time of going to print.

Autoflame工程有限公司致力于不断提升Autoflame产品的设计和制造,我们保留修订本手册规

范/数据的权利,恕不另行通知。本手册内容于付印时准确无误。

3

Important Notes

重要提示

A knowledge of combustion related procedures and commissioning is essential before embarking

work on any of the M.M./E.G.A. systems. This is for safety reasons and effective use of the M.M./

E.G.A. system. Hands on training is required. For details on schedules and fees relating to group

training courses and individual instruction, please contact the Autoflame Engineering Ltd. offices

at the address listed on the front.

为了安全有效地使用控制模块/EGA系统,控制模块/EGA系统的操作人员必须具有与燃烧相关的

流程和调试知识。我们要求使用者参加实践培训,请使用首页上Autoflame办公室通讯方式来

详细了解团体培训和个别教学事宜。

Short Form - General Terms and Conditions

一般条款

A full statement of our business terms and conditions are printed on the reverse of all

invoices. A copy of these can be issued upon application, if requested in writing.

在所有发票背面都印有我们的商业条款全文。客户可书面申请获得我公司商业条款文件。

The System equipment and control concepts referred to in this Manual MUST be installed,

commissioned and applied by personnel skilled in the various technical disciplines that are

inherent to the Autoflame product range, i.e. combustion, electrical and control.

只有专员人员才能安装,调试和使用本手册所提及的系统设备和控制概念。他们必须精通

Autoflame产品所涉及的各个技术学科,即:- 燃烧,电气和控制。

The sale of Autoflame’s systems and equipment referred to in this Manual assume that the dealer,

purchaser and installer has the necessary skills at his disposal. i.e. A high degree of combustion

engineering experience, and a thorough understanding of the local electrical codes of practice

concerning boilers, burners and their ancillary systems and equipment.

经销,购买或者安装本手册提及的Autoflame系统和设备的人员都要具有必要的专业知识,即:-

与锅炉,燃烧器和辅助系统/设备相关的丰富燃烧工程从业经验和全面电气行业规范知识。

Autoflame’s warranty from point of sale is two years on all electronic systems and components.

One year on all mechanical systems, components and sensors.

Autoflame保修条款:- 对所有电子系统和部件实行两年售后保修;

对所有机械系统和部件和感应器实行一年售后保修。

The warranty assumes that all equipment supplied will be used for the purpose that it was

intended and in strict compliance with our technical recommendations. Autoflame’s warranty and

guarantee is limited strictly to product build quality, and design. Excluded absolutely are any

claims arising from misapplication, incorrect installation and/or incorrect commissioning.

保修前提: 所有设备必需被用于预期使用目的并且严格符合我们的技术建议。Autoflame产品保

修条款只适用于产品制造质量问题和设计问题。根据保修条款,Autoflame不接受由于错误操

作,错误安装和/或调试导致的索赔请求。

4

Contents

目录

1 DIMENSIONS AND WIRING尺寸和接线............................................................................. 6

1.1 Mini Mk8 M.M Mk8微型控制模块. ...................................................................................... 6

1.1.1 Fixing Holes and Dimensions 固定孔和尺寸.................................................................... 7

1.2 Wiring Schematic 配线线路图............................................................................................. 8

1.3 Electrical Specifications 电气规格........................................................................................9

1.3.1 Classifications 等级........................................................................................................... 9

1.3.2 Inputs and Outputs 输入和输出....................................................................................... 9

1.3.3 Cable Specifications 电缆规范..........................................................................................11

1.3.4 Terminals Description 接线端子描述.............................................................................. 12

1.4 Connection Between Mini Mk8 M.M. and Mk8 E.G.A

Mk8微型控制模块与Mk8 E.G.A.的连接. ............................................................................15

1.5 Connection Between Mini Mk8 M.M. and Mk7 D.T.I

Mk8微型控制模块与Mk7 D.T.I.的连接…………………………………........................................... 16

1.6 Sequencing Connection Diagram

多台Mk8微型控制模块排序连接图................................................................................... 17

2 OPTIONS AND PARAMETERS 选项和参数........................................................................ 18

2.1 Options选项……… ................................................................................................................ 18

2.2 Parameters 参数……............................................................................................................ 40

3 COMMISSIONING PROCEDURE 调试流程......................................................................... 48

3.1 Introduction to Commissioning 调试简介........................................................................... 48

3.1.1 Commissioning Procedure 调试流程................................................................................ 49

3.2 Installation Checks 安装检查 ............................................................................................. 49

3.2.1 Commissioning Checks 调试检查...................................................................................... 49

3.2.2 Operational Checks 运行检查 ......................................................................................... 49

3.2.3 Installation Precautions 安装注意事项............................................................................. 50

3.2.4 Maintenance and Servicing 维护和保养........................................................................... 50

3.3 Servomotors 伺服马达......................................................................................................... 50

3.3.1 Adjusting the Servomotor Potentiometer 调节伺服马达电位计..................................... 51

3.3.2 Servomotor Feedback Voltage 伺服马达反馈电压。....................................................... 52

3.3.3 Servomotors –Direction Change伺服马达 –改变马达转动方向................................... 53

3.3.4 Servomotors with Autoflame Valves带有Autoflame阀门的伺服马达............................... 54

3.4 Commissioning Fuel and Air Positions调试燃油和空气位置.................................................55

3.4.1 Starting Commissioning 开始调试….................................................................................. 56

3.4.2 Enter CLOSE Position 输入关闭位置................................................................................. 57

3.4.3 Enter OPEN Position 输入开启位置.................................................................................. 58

3.4.4 Enter START Position 输入启动位置 ............................................................................... 59

3.4.5 Phase Hold 阶段保持......................................................................................................... 60

3.4.6 Add Trim Data During Commissioning在调试阶段添加EGA调节数据.............................. 62

3.4.7 Commissioning VSD 调试变速驱动................................................................................... 64

3.4.8 Set GOLDEN START Position 设置黄金启动位.................................................................. 65

3.4.9 Set FGR START Position设置烟气再循环启动位................................................................ 66

3.4.10 Set HIGH Position 设置高火位置..................................................................................... 68

3.4.11 Set INTER Position 设置中间位置.................................................................................... 69

5

3.4.12 Set INTER or START Position 设置中间或启动位置......................................................... 70

3.4.13 Save Commission 保存调试............................................................................................. 71

3.5 Fuel Flow Commissioning 燃料流量调试............................................................................. 73

3.5.1 Calorific Fuel Data 燃料数据.............................................................................................. 77

3.5.2 Conversion Factor for Imperial Gas Flow Meters

英制燃气流量表的换算因子............................................................................................... 78

3.5.3 Correction Factor for Burners Significantly Above Sea Level

较高海拔处燃烧器运行的校正系数................................................................................... 78

3.5.4 Gas Volume Conversion Factors 燃气体积换算因数......................................................... 79

3.6 Gas/ Air Pressure Commission 燃气/空气压力调试............................................................. 81

3.7 Single Point Change 单点更改............................................................................................... 82

3.8 Online Changes 线上更改...................................................................................................... 87

3.9 General Operation 一般操作................................................................................................. 89

3.9.1 Calibrating the Actual Value 校正实际数值....................................................................... 89

3.9.2 External Modulation 外部控制........................................................................................... 90

3.9.3 Additional Functions 额外功能........................................................................................... 90

4 REMOTE CONTROL 远程控制。........................................................................................... 92

4.1 Modbus Settings Modbus设置................................................................................................. 92

4.2 Modbus Addresses Modbus地址............................................................................................. 93

5 ERRORS AND LOCKOUTS 错误和锁定................................................................................. 100

5.1 M.M. Errors 控制模块错误.................................................................................................... 100

5.2 Burner Lockouts 燃烧器锁定................................................................................................. 106

5.3 Troubleshooting and Further Information 故障检修和进一步信息..................................... 113

5.3.1 UV Shutter Faults 紫外线快门故障。................................................................................ 113

5.3.2 UV Problems 紫外线问题................................................................................................... 113

5.3.3 Snubbers 缓冲器................................................................................................................. 114

5.3.4 Channel Positioning Error 频道定位错误........................................................................... 115

5.3.5 Input Fault 输入故障…........................................................................................................ 115

5.3.6 Setting Conflicts 设置冲突.................................................................................................. 116

5.3.7 Forced Commission 强迫性调试......................................................................................... 119

6 STANDARDS 标准............................................................................................................... 121

1 DIMENSIONS AND WIRING

6

尺寸和接线

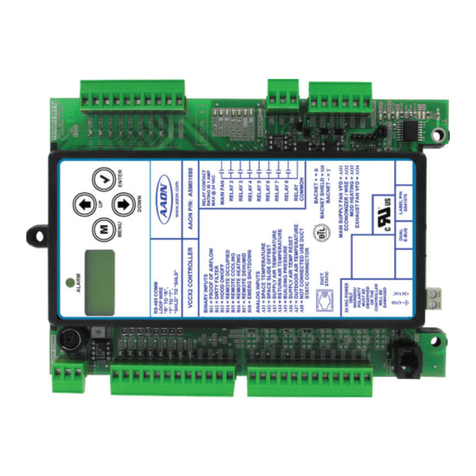

1.1 Mini Mk8 M.M.

MK8微型控制模块

1.1.1 Fixing Holes and Dimensions

固定孔和尺寸

7

1.2 Wiring Schematic

配线线路图

8

9

1.3 Electrical Specifications

电气规格

1.3.1 Classifications

等级

Classification according to EN298

根据EN298的分级

Mains Supply: 230V, +10%/-15%} 47-63 Hz, unit max. consumption 140W

电源: 230V, +10%/-15%} 47-63 Hz, 单位最大用电量 140W

120V, +10%/-15%}

120V, +10%/-15%}

Climate: Min. Temperature 0C (32OF)

气候:最低温度 0C (32OF)

Recommended Temperature Less than 40C (104OF)

建议温度 低于40C (104OF)

Max. Temperature 60C (140OF)

最高温度 60C (140OF)

Humidity 0 to 90% non-condensing

湿度 0 to 90% 不冷凝

Storage: Temperature -20 to 85C (-4 to 185OF)

储藏: 温度 -20 to 85C (-4 to 185OF)

Protection Rating: The unit is designed to be panel mounted in any orientation and the front facia

is IP65, NEMA4. The back of the unit is IP20, NEMA1.

防护等级:控制模块的设计安装朝向是任意方向。控制模块的前部仪表板的防护等级是IP65,

NEMA4;控制模块背部的防护等级是IP20, NEMA1。

1.3.2 Inputs and Outputs

输入和输出

Inputs and Outputs

输入和输出

230V Unit:

230V设备

Outputs Terminal 57 250mA Must be connected through contactor Max Load 5A

输出 端口 57 250mA 必须通过接触器连接,最大荷载5A

58 250mA Must be connected through contactor

58 250mA 必须通过接触器连接

59 1A 0.6 power factor

59 1A 0.6 功率因数

60 1A 0.6 power factor

60 1A 0.6功率因数

61 1A 0.6 power factor

61 1A 0.6功率因数

62 1A 0.6 power factor

62 1A 0.6功率因数

63 1A 0.6 power factor

63 1A 0.6 功率因数

78 100mA To drive relay only –switched neutral

78 100mA 仅用于驱动继电器 –切换至中性

79 100mA To drive relay/lamp only –switched neutral

10

79 100mA 仅用于驱动继电器/灯–切换至中性

120V Unit:

120V设备

Outputs Terminal 57 250mA Must be connected through contactor Max Load 5A

输出 端口 57 250mA 必须通过接触器连接,最大荷载5A

58 250mA Must be connected through contactor

58 250mA 必须通过接触器连接

59 2A 0.6 power factor

59 2A 0.6 功率因数

60 2A 0.6 power factor

60 2A 0.6 功率因数

61 2A 0.6 power factor

61 2A 0.6 功率因数

62 2A 0.6 power factor

62 2A 0.6 功率因数

63 2A 0.6 power factor

63 2A 0.6 功率因数

78 100mA To drive relay only –switched neutral

78 100mA 仅用于驱动继电器 –切换至中性

79 100mA To drive relay/lamp only –switched neutral

79 100mA 仅用于驱动继电器/灯–切换至中性

Note:

注意:

1. The high and low voltage connections are not safe to touch. Protection against electric shock is

provided by correct installation. CAUTION –ELECTRIC SHOCK HAZARD.

用手触摸高压和低压连接是危险行为。正确安装电气设备可以防止触电事故。警告:触电危

险。

2. Control voltage cabling should be maximum 10m, screened (if not screened then less than 1m,

however servomotors can be unscreened up to 10m)

控制电压电缆的最大长度应为10m,经屏蔽(若未屏蔽应短至1米);伺服马达的未屏蔽电缆

最大长度可为10m。

3. Any cabling over 10m must have additional surge protection.

所有超过10m的电缆必须配备电涌保护。

4. Low voltage cables should be screened cable as specified in section 1.3.3.

低压电缆应符合章节1.3.3规定的经屏蔽电缆。

5. The burner ‘High Limit Stat’ must be a manual reset type.

燃烧器的“上限启停控制器”必须为手动复位型。

Note: There is a lid (back plate) fitted onto the back of the Mini Mk8 M.M. with a Warning label to

prevent any unauthorised fuse replacements.

注意:在MK8微型控制模块背部装有一个盖板。盖板上的标识明确指出更换保险丝操作前必需

获得授权。

11

1.3.3 Cable Specifications

电缆规范

High/ Control Voltage

高/控制电压

Screened cable should not exceed 10m and unscreened cable should not exceed 1m. The ionisation/

flame rod cable must be shielded to prevent interference with other cables, as it is a high voltage

and high frequency signal.

经屏蔽的电缆长度不应超过10m,未经屏蔽的电缆长度不应超过1m。为防止干扰,由于离子/

火焰感应棒电缆将产生高压和高频信号,离子/火焰感应棒电缆必须经过屏蔽。

Low Voltage

低压

The screened cable used from the M.M. to the servomotors and detectors must conform to the

following The screened cable used for low voltage wiring from the M.M. to the servomotors,

detectors and variable speed drive must conform to the following specification:

控制模块,伺服马达,检测器和各种速度传动装置的已屏蔽低压电缆要符合以下规范:

16/0.2mm PVC insulated overall braid, screened, PVC sheathed.

16/0.2mm PVC 绝缘编织层,屏蔽电缆,PVC电缆护皮。

每芯16线

0.2mm

芯内电线直径0.2mm

额定交流电压440V rms 1600Hz

-12 current rating per core 2.5A

DEF 61-12每芯额定电流2.5A

最高工作温度70C (158F)

core

公称导体面积 –每芯0.5平方米

每芯公称绝缘层径向厚度 –0.45mm

每芯公称导体直径0.93mm

20C时电缆公称电阻值 –40.1Ω/1000m

Nominal overall diameter per core 1.83mm

每芯公称总直径 –1.83mm

编织层填充因子 0.7

等效英制导体尺寸 14/0.0076

Use the number of cores suitable for the application. A universal part numbering system appears to

have been adopted for this type of cable as follows:

根据实际使用需要来选用合适的电缆。以下是通用的电缆编号方法:

12

16-2-2C 2 Core

16-2-2C 2芯

16-2-3C 3 Core

16-2-3C 3芯

16-2-4C 4 Core

16-2-4C 4芯

16-2-6C 6 Core

16-2-6C 6芯

(5 Core not readily available)

(无现成的5芯电缆)

Note: If using 4 Core cable and interference is detected, use 2 sets of 2 Core.

注意:如果使用4芯电缆时检测到相互干扰,就应使用两套2芯电缆。

Data Cable

数据电缆

Data cable must be used for connections between M.M.s for sequencing applications and between

M.M.s and E.G.A.s and for connection between M.M.s and D.T.I.

数据电缆用于控制模块的排序连接,控制模块与EGA的连接,以及控制模块与DTI的连接。

Types of data cable that can be used:

可选用的数据电缆类型:

1 Beldon 9501 for 2-core shielded cable (1 twisted pair)

Beldon 9501 用于2芯屏蔽电缆(一对双绞线)

2 Beldon 9502 for 4-core shielded cable (2 twisted pairs)

Beldon 9502 用于4芯屏蔽电缆(两对双绞线)

3 STC OS1P24

STC OS1P24

Samples are available upon request. Low voltage and data cable can be ordered directly from

Autoflame Engineering, please contact Autoflame Sales.

客户可询问和获得样品。客户可直接向Autoflame工程有限公司采购低压电缆和数据电缆。请联

系Autoflame公司销售部。

1.3.4 Terminals Description

接线端子描述

S All terminals marked S are internally connected. They are provided for connections to

the various screened cables.

所有标记为S的接线端子都已内部连接。这些端子将和各屏蔽电缆相连接。

1 Current Input, 0-20mA/ 4-20mA. For channel 4 only. Can be connected to the current

output of a VSD or tachometer system or 4-20mA servomotor feedback

电流输入,0-20mA/ 4-20mA。仅用于4频道,该端子可与变速驱动或者转速计系统

的电流输出信号连接,或者和4-20mA伺服马达的反馈信号连接。

2 Voltage Input, 0-10V. For channel 4 only. Can be connected to the voltage output of a

VSD or tachometer system or 4-20mA servomotor feedback

电压输入,0-10V。仅用于4频道,该端子可与变速驱动或者转速计系统的电压输出

信号连接,或者和4-20mA伺服马达的反馈信号连接。

3 Common for Terminals 1 or 2

13

与端子1和端子2通用。

10 Current Output, 0-20mA/ 4-20mA. For channel 4 only. Can be connected to the

current input of a VSD or 4-20mA servomotor feedback

电流输出,0-20mA/ 4-20mA。仅用于4频道,该端子可与变速驱动的电流输入信号

口连接,或者和4-20mA伺服马达的反馈信号口连接。

11 Voltage Output, 0-10V. For channel 4 only. Can be connected to the voltage input of a

VSD or 4-20mA servomotor feedback

电压输出,0-10V。仅用于4频道,该端子可与变速驱动的电压输入信号口连接,或

者和4-20mA伺服马达的反馈信号口连接。

12 Common for Terminals 10 or 11

与端子10或者端子11通用

21, 22 Connections to an Autoflame self-check UV sensor

与Autoflame自检紫外线传感器连接

25, 26 Communications port connections to an Exhaust Gas Analyser (E.G.A.)

与尾气分析仪(E.G.A.)相连的通讯接口

27, 28 Communications port connections for D.T.I. and/or IBS, or Modbus

与D.T.I. 和/或IBS, 或者Modbus相连的通讯接口

29, 30 Digital communications connections to an Autoflame IR scanner (MM70017),

Autoflame air pressure sensor and/or Autoflame gas pressure sensor

与Autoflame红外线扫描仪(MM70017),Autoflame 空气压力感应器和/或Autoflame

燃气压力感应器相连的数字通讯接口。

37, 38 (39) Connections to an Autoflame boiler temperature detector (pressure)

与Autoflame锅炉温度(压力)检测器相连的接口

40 0V supply to channel 1 and channel 2 servomotors

与频道1和频道2伺服马达相连的0v电源

41 +12V supply to channel 1 and channel 2 servomotors

与频道1和频道2伺服马达相连的+12V电源

42 Signal from channel 1 servomotor, indicating position

频道1伺服马达的信号,表示位置

43 Signal from channel 2 servomotor, indicating position

频道2伺服马达的信号,表示位置

44 Signal from channel 3 servomotor, indicating position

频道3伺服马达的信号,表示位置

46 0V Supply to channel 3 servomotor

与频道3伺服马达相连的0V电源

47 +12V Supply to channel 3 servomotor

与频道3伺服马达相连的+12V电源

48, 49 +15V connections to an Autoflame IR scanner (MM70017), Autoflame air pressure

sensor and/or Autoflame gas pressure sensor

与Autoflame 红外线扫描仪 (MM70017), Autoflame 空气压力感应器和/或

Autoflame 燃气压力感应器相连的+15V电压接口

50, 51 Connections to an Autoflame UV sensor

与Autoflame紫外线感应器相连的接口

64 Connections to a flame rod

与火焰感应棒相连的接口

53 Mains voltage input –burner on/off signal, running interlock circuit

输电干线电压输入 –燃烧器启闭信号,运行连锁电路

54 Mains voltage input –safety circuits, e.g. air proving

输电干线电压输入 –安全电路,例如空气校验

55 Mains voltage input - proving circuits, e.g. gas valve proof of closure

14

输电干线电压输入 –检验用电路,例如燃气阀门关闭检验

57 Mains voltage output –call for heat

输电干线电压输出 –要求热量

58 Mains voltage output –burner motor

输电干线电压输出 –燃烧器马达

59 Mains voltage output –start/pilot valve

输电干线电压输出 –启动阀/导阀

60 Mains voltage output –main fuel valve 1

输电干线电压输出 –主燃料阀1

61 Mains voltage output –main fuel valve 2

输电干线电压输出 –主燃料阀2

62 Mains voltage output –vent valve

输电干线电压输出 –排气阀

63 Mains voltage output –ignition transformer

输电干线电压输出 –点火变压器

66 Mains supply –earth

干线供电 –接地

67 Main supply –neutral

干线供电 –中性

68 Mains supply –live/hot

干线供电 –火线

69 Mains voltage output, power to servomotors and/or servomotor stepdown transformer

干线电压输出,向伺服马达和/或伺服马达变压器供电

70 Switched neutral –drives channel 1 servomotor clockwise

处于中性位 –驱动频道1伺服马达顺时针转动

71 Switched neutral –drives channel 1 servomotor counter clockwise

处于中性位 –驱动频道1伺服马达反时针转动

72 Switched neutral –drives channel 2 servomotor clockwise

处于中性位 –驱动频道2伺服马达顺时针转动

73 Switched neutral –drives channel 2 servomotor counter clockwise

处于中性位 –驱动频道2伺服马达反时针转动

74 Switched neutral –drives channel 3 servomotor clockwise

处于中性位 –驱动频道3伺服马达顺时针转动

75 Switched neutral –drives channel 3 servomotor counter clockwise

处于中性位 –驱动频道3伺服马达反时针转动

78 Switched neutral –2-port valve for IBS operation

处于中性位 –2端口阀门,用于IBS运行(智能锅炉排序)

79 Switched neutral –alarm output for M.M. lockout/M.M. error/E.G.A. error.

处于中性位 –控制模块锁定/模块错误/EGA错误的警报输出

80 Start position interlock/ night setback input/ reduced setpoint input

初始位置连锁/夜间调低值输入/降低设定点值输入

81 Purge interlock/ low flame hold input

吹扫连锁/低火焰保持信号输入

82 Warming stat/ valve proving mains input

加温控制点/阀门校验干线输入

89 Mains voltage input –selects fuel 1 curve

干线电压输入 –选择燃料1曲线

90 Mains voltage input –selects fuel 2 curve

干线电压输入 –选择燃料2曲线

15

1.4 Connection Between Mini Mk8 M.M. and Mk8 E.G.A.

Mk8微型控制模块与Mk8 E.G.A.的连接

16

1.5 Connection Between Mini Mk8 M.M. and Mk7 D.T.I.

Mk8微型控制模块与Mk7 D.T.I.的连接

17

1.6 Sequencing Connection Diagram

多台Mk8微型控制模块排序连接图

18

2 OPTIONS AND PARAMETERS

选项和参数

2.1 Options

选项

Note: The Options and Parameters must only be changed by factory trained and certified

technicians who have a thorough appreciation of the Autoflame combustion systems and the

combustion process in general. Any person changing these set-ups who does not have the correct

factory training and understanding of these settings/adjustments may place themselves and

others in a potentially dangerous situation.

注意:只有接受过工厂培训的持证人员才能更改选项和参数设置,他们应该整体充分理解

Autoflame的燃烧系统和燃烧过程。未接受过培训和不理解这些设置项的人员所做的任何选项

和参数更改会给自身和他人带来潜在危险。

CH1, CH2, CH3 and CH4, refer to the rows of buttons respectively starting with CH1

at the top.

CH1, CH2, CH3和CH4分别指的是各行按钮 ,CH1按钮在最顶行。

The options and parameters are all viewable while the M.M. is in run mode and the burner is firing; a

number of options and parameters can be adjusted through Online Changes. All Burner Control (BC)

options/parameters can only be changed in Commissioning mode.

在控制模块运行和燃烧器燃烧期间,操作者可以在屏幕上读取所有选项和参数值或者在线更改

一些选项和参数值。但是所有燃烧器控制(BC)选项/参数的更改只能在调试模式下进行。

Through Commissioning Mode, all the options and parameters can be adjusted according to the

application.

在调试模式下,操作者可以根据使用情况来调节所有的选项和参数。

Power up the unit. If the M.M. has already been commissioned, press when the

system starts up. If the system is not already commissioned, the M.M. will go to commissioning

mode automatically.

向控制模块通电。如果控制模块已被调试过,在系统启动时应按下 按钮;如果控

制模块未被调试过,控制模块将自动进入调试模式。

19

Figure 2.1.i Enter Password

输入密码

“Enter Commissioning Password” is displayed. Use the keypad to enter the password, then press

. Press on or to change the value of an incorrect entry.

屏幕出现“输入调试密码”界面。用小键盘输入密码,然后按下 按钮。在输错密

码时可按下 按钮或者 按钮来进行更改。

Note: The commissioning password should not be distributed to anyone who is not a factory trained

and a certified engineer.

注意:不得向未经过培训的人员或者非持证人员泄漏调试密码。

20

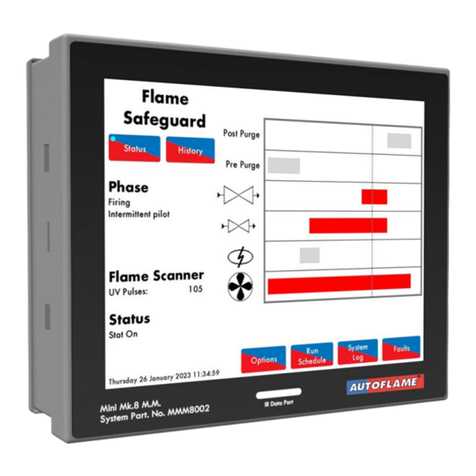

Figure 2.1.ii Commission Mode

调试模式

The “Commission Mode” screen gives information on which fuel is selected, how many times the

unit has been commissioned, serial number, bootloader, and BC, MM and Display software.

操作者在“调试模式”界面上可以读取燃料信息,设备调试次数,序列号,引导装载程序和燃

烧器控制信息,控制模块和显示软件信息,等等。

In the Commission Mode screen, all the options/ parameters can be adjusted, the gas pressure

sensor can be commissioned, the commissioned IR data can be uploaded and the fault logs can also

be viewed.

操作者在“调试模式”界面上可进行选项/参数值的更改,燃气压力感应器的调试,红外线扫描

仪数据的上传,和故障记录查询。

Note: The Times Commissioned is for the total system and will increment with every fuel

commission, single point change and commission upload.

注意:设备调试次数是对整个系统而言。设备调试次数包括了每一次燃料调试,单点变更,和

调试数据上传。

Other manuals for Mini Mk8 M.M.

2

Table of contents

Other AUTOFLAME Controllers manuals