AUTOFLAME Mk8 MM User manual

Mk8 MM

End User Guide

Mk8 MM

End User Guide

Issued by:

AUTOFLAME ENGINEERING LTD

Unit 1-2, Concorde Business Centre

Airport Industrial Estate, Wireless Road

Biggin Hill, Kent TN16 3YN

Tel: +44 (0)845 872 2000

Fax: +44 (0)845 872 2010

Email: [email protected]

Website: http://www.autoflame.com/

Registered Holder:

Company:

Department:

This manual and all the information contained herein is copyright of

Autoflame Engineering Ltd. It may not be copied in the whole or part without

the consent of the Managing Director.

Autoflame Engineering Ltd’s policy is one of continuous improvement in both

design and manufacture. We therefore reserve the right to amend

specifications and/or data without prior notice. All details contained in this

manual are correct at the time of going to print.

Important Notes

A knowledge of combustion related procedures and commissioning is essential before

embarking work on any of the M.M./E.G.A. systems. This is for safety reasons and

effective use of the M.M./ E.G.A. system. Hands on training is required. For details on

schedules and fees relating to group training courses and individual instruction, please

contact the Autoflame Engineering Ltd. offices at the address listed on the front.

Short Form - General Terms and Conditions

A full statement of our business terms and conditions are printed on the reverse of all

invoices. A copy of these can be issued upon application, if requested in writing.

The System equipment and control concepts referred to in this Manual MUST be installed,

commissioned and applied by personnel skilled in the various technical disciplines that

are inherent to the Autoflame product range, i.e. combustion, electrical and control.

The sale of Autoflame’s systems and equipment referred to in this Manual assume that

the dealer, purchaser and installer has the necessary skills at his disposal. i.e. A high

degree of combustion engineering experience, and a thorough understanding of the

local electrical codes of practice concerning boilers, burners and their ancillary systems

and equipment.

Autoflame’s warranty from point of sale is two years on all electronic systems and

components.

One year on all mechanical systems, components and sensors.

The warranty assumes that all equipment supplied will be used for the purpose that

it was intended and in strict compliance with our technical recommendations. Auto-

flame’s warranty and guarantee is limited strictly to product build quality, and design.

Excluded absolutely are any claims arising from misapplication, incorrect installation

and/or incorrect commissioning.

Contents

1 OVERVIEW AND BENEFITS……………………………………………………………………………… 1

1.1 Features and Benefits……………………………………………………………………………………………1

1.2 System Example…………………………………………………………………………………………………… 4

1.3 Micro-Modulation (MM)……………………………………………………………………………………….5

2 ELECTRICAL SPECIFICATIONS………………………………………………………………………….. 6

2.1 Classifications………………………………………………………………………………………………………. 6

2.2 Inputs and Outputs………………………………………………………………………………………………. 6

2.3 Cable Specifications……………………………………………………………………………………………… 8

3 END USER OPERATION…………………………………………………………………………………… 9

3.1 Home Screen…………………………………………………………………………………………………… 9

3.1.1 Home Screen Components………………………………………………………………………10

3.1.2 Faults………………………………………………………………………………………………………12

3.2 Status Screen………………………………………………………………………………………………….13

3.2.1 Status………………………………………………………………………………………………………13

3.2.2 Status –History……………………………………………………………………………………….14

3.2.3 Status –Burner Enable/Disable……………………………………………………………… 15

3.2.4 Status –Low Flame Hold………………………………………………………………………… 16

3.2.5 Status –Hand Mode………………………………………………………………………………..17

3.3 Fuel-Air Screen……………………………………………………………………………………………… 18

3.3.1 Fuel-Air –Curve……………………………………………………………………………………… 18

3.3.2 Fuel-Air –Map……………………………………………………………………………………….. 19

3.3.3 Fuel-Air –History…………………………………………………………………………………….20

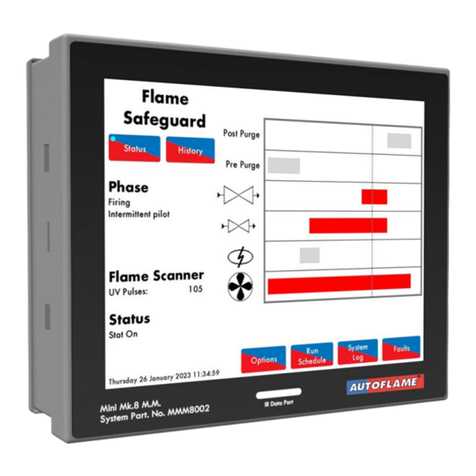

3.4 Flame Safeguard Screen………………………………………………………………………………….21

3.4.1 Flame Safeguard……………………………………………………………………………………..21

3.4.2 Flame Safeguard –History……………………………………………………………………… 22

3.5 Channels Screen……………………………………………………………………………………………..23

3.5.1 Servomotor…………………………………………………………………………………………… 23

3.5.2 VSD Channel…………………………………………………………………………………………. 24

3.6 Gas Pressure Sensor Screen 35 3.6.1 Gas Pressure…………………………………………. 25

3.6.2 Gas Sensor –History………………………………………………………………………………. 26

3.7 Air Pressure Sensor Screen……………………………………………………………………………. 27

3.7.1 Air Pressure……………………………………………………………………………………………. 27

3.7.2 Air Sensor –History…………………………………………………………………………………28

3.8 First Outs………………………………………………………………………………………………………..29

3.9 System Configuration Screen…………………………………………………………………………. 30

3.9.1 Language Selection………………………………………………………………………………….31

3.9.2 Options……………………………………………………………………………………………………32

3.9.3 Parameters…………………………………………………………………………………………… 33

3.9.4 Expansion Options…………………………………………………………………………………..34

3.9.5 Set Clock………………………………………………………………………………………………….35

3.9.6 Manual……………………………………………………………………………………………………36

3.9.7 Commission Data…………………………………………………………………………………….37

3.9.8 Diagnostics ……………………………………………………………………………………………. 38

3.9.9 System Log………………………………………………………………………………………………39

4 ERRORS AND LOCKOUTS……………………………………………………………………………… 40

4.1 Errors…………………………………………………………………………………………………………………. 40

4.2 Lockouts………………………………………………………………………………………………………………44

4.3 Alarms and Warnings…………………………………………………………………………………………. 49

4.4 Settings Conflicts…………………………………………………………………………………………………57

4.5 Forced Commission Reasons………………………………………………………………………………. 62

4.6 Troubleshooting and Further Information……………………………………………………………64

4.6.1 UV Shutter Faults………………………………………………………………………………………… 64

4.6.2 UV Problems………………………………………………………………………………………………..64

4.6.3 Snubbers…………………………………………………………………………………………………….. 64

4.6.4 Channel Positioning Error……………………………………………………………………………. 65

4.6.5 Input Fault……………………………………………………………………………………………………65

6 STANDARDS…………………………………………………………………………………………………. 66

1 Overview and Benefits

22.05.2017 Mk8 MM End User Guide Page 1

1 OVERVIEW AND BENEFITS

1.1 Features and Benefits

Micro-Modulation (MM) / Flame Safeguard

Fuel/ air ratio control

Full colour touch screen

120V or 230V standard operation 50/60Hz

Controls up to 5 servomotors and 2 variable speed drives (VSD/ VFD)

4 independent fuel programmes

Fully adjustable PID load control for temperature or pressure

Internal flame safeguard – full flame supervision with self-check UV or IR

Dual flame scanner operation (IR and UV scanners)

Gas valve train leak supervision and high/low gas pressure monitoring

Air pressure proving and monitoring

128 lockouts, errors, alarms and warnings stored with date, time, phase and reset

1000 entry system log stored with date, time and status

Online diagnostics showing system electronics information

Single point change for adding, removing and adjusting fuel/air positions on fuel-air curve

Golden start position for optimum ignition position

Flue gas recirculation start position

Variable servomotor travel speed

Burner control safety times user selectable

External voltage/current load control and setpoint adjustment

Outside temperature compensation of boiler setpoint

Second setpoint and run times scheduling

Hand/auto/low flame hold firing modes

Various boiler load detectors available

Fuel flow metering capability – instantaneous and totalised

Fuel flow feedback

Multi-burner capability with synchronised firing rate up to 10 MMs

4-20mA (0-20mA) / 0-10V (2-10V) input for external modulation

4-20mA (0-20mA) / 0-10V (2-10V) output confirming firing rate

Fully metered combustion control for commissioning based on equivalence ratio and excess air

Draft control to maintain stack pressure

Password protection of all safety related functions

Infra-red port for upload/download of commission data

1 Overview and Benefits

Page 2 Mk8 MM End User Guide 22.05.2017

15 First out annunciation inputs

4 fuel commission curves possible

24 hour history graphical information on MM when powered on

Custom boiler display configuration

Water Level Control

Fully modulating feed water control with servomotor and VSD as well pump on/off

Capacitance probes for patented wave signature level detection

Water level alarms 2nd low, 1st low, high water and optional pre 1st low and pre-high water

Conductivity probe for auxiliary 2nd low alarm

Automatic bottom blowdown with time reduction for blowdown savings

Continuous modulating top blowdown control to maintain TDS in water

Steam/ hot water flow metering to calculate flow rates based on temperature sensor

Exhaust Gas Analyser (EGA)

3 Parameter trim of O2, CO2and CO

Analysis of O2, CO, CO2, NO, exhaust gas temperature, efficiency and delta temperature

Optional analysis of NO2and SO2

Local display for re-calibration, changing cells, user configuration and standalone operation

Upper/lower offset and absolute limits for O2, CO, CO2, NO and exhaust gas temperature

Six 4-20mA output signal for interface with other controls/chart recorders

Intelligent Boiler Sequencing

System will sequence hot water boilers or steam boilers via lead/lag distribution

Fully adjustable user options within the system to tailor sequencing operation to the application

System control for isolation of valves or pumps (2 port valve operation)

Standby setpoint and warming for lag boilers via a standby pressure and timing sequence

Lead boiler and lag boiler warming modes selection

Remote Control and Data Transfer Interface (DTI)

Direct Modbus communications from MM including remote setpoint and firing rate adjustment,

burner enable/disable (without DTI or intelligent boiler sequencing)

DTI will collect operational data for up to 10 MM modules, 10 EGA modules and 10 universal

I/O modules in one communications loop

Information transmitted via RS422 or Ethernet link to local PC/network for running Autoflame

CEMS Audit software

1 Overview and Benefits

22.05.2017 Mk8 MM End User Guide Page 3

PC Compatible

Download all commissioning data and controller settings from MM module to a PC

Upload commission data and controller settings from PC to MM module

Universal Digital and Analogue Input/ Output Module

Detailed logging inputs and outputs when coupled with Mk7 DTI

16 Line voltage inputs (110V/ 230V)

6 Analogue inputs and 6 analogue outputs

8 Volt free contacts

Configurable alarms through Mk7 DTTI

1 Overview and Benefits

Page 4 Mk8 MM End User Guide 22.05.2017

1.2 System Example

1 Overview and Benefits

22.05.2017 Mk8 MM End User Guide Page 5

1.3 Micro-Modulation (MM)

To ensure maximum efficiency and reliability of the boiler plant operation, two requirements are of

paramount importance, the air to fuel ratio and the target temperature or pressure:

The air to fuel ratio must be kept to the minimum to ensure complete combustion within the

limitations of the combustion head design. A very high air to fuel ratio will be an indication of

high excess air, which decreases the overall efficiency of the boiler. The fuel valve and air

damper positions set for this minimum air to fuel ratio along the whole commission curve must

be infinitely repeatable to an incredibly high degree of accuracy.

The target temperature or pressure of the boiler should be monitored by the combustion system

and at all times, with exactly the right amount of fuel and air fired to achieve this target value.

Irrespective of load changes, the burner/boiler system should be able to meet the target

temperature or pressure.

The burner’s fuel to air ratio was traditionally governed by mechanical systems which involved multiple

cams, shafts and linkages controlled by one motor. The inherent hysteresis that occurred from the

system design allowing components to be loose, which made the level of accuracy required impossible.

With this poor accuracy, the response of the fuel input to the monitored temperature/ pressure of the

boiler meant that the set target value at most times would overshoot or fall short.

The Micro-Modulation module is the basic building block of the Autoflame System. The Autoflame MM

module provides an easily programmable and flexible means of optimising combustion quality

throughout the load requirement range of the burner/boiler unit whilst ensuring the temperature is

accurate to within 1°C (°F) and pressure to within 1 PSI (0.1Bar). Using direct drive motors to

individually control the air damper and fuel valve(s), gives the optimum combustion of the burner at

every point along the firing range. The allowed error in angular degrees of rotation between the two

servomotors at any position in the load range is 0.1°.

This automated system of burner control can achieve ‘locked on’ near stoichiometric air to fuel mixing

throughout the fuel input range of the boiler while maintaining exact temperature or pressure target

values. The load control incorporates user-variable Proportional Integral Derivative control. The PID

control is infinitely adjustable to match any boiler room requirements.

2 Electrical Specifications

2 ELECTRICAL SPECIFICATIONS

2.1 Classifications

Classification according to BS EN298:2012

Mains

Supply:

Single phase 230V, +10%/-15%} 47-63 Hz, unit max. consumption 140W

Single phase 120V, +10%/-15%}

Climate: Min. Temperature 0OC (32OF)

Recommended Temperature Less than 40OC (104OF)

Max. Temperature 60OC (140OF)

Humidity 0 to 90% non-condensing

Storage: Temperature -20 to 85OC (-4 to 185OF)

Protection

Rating:

The unit is designed to be panel mounted in any orientation and the front facia is IP65,

NEMA4. The back of the unit is IP20, NEMA1.

2.2 Inputs and Outputs

MM Inputs and Outputs

230V Unit:

Outputs Terminal 57 250mA Must be connected through contactor

Max Load 6A

58 250mA Must be connected through contactor

59 1A 0.6 power factor

60 1A 0.6 power factor

61 1A 0.6 power factor

62 1A 0.6 power factor

63 1A 0.6 power factor

78 100mA To drive relay only – switched neutral

79 100mA To drive relay/lamp only – switched neutral

120V Unit:

Outputs Terminal 57 250mA Must be connected through contactor

Max Load 6A

58 250mA Must be connected through contactor

59 2A 0.6 power factor

60 2A 0.6 power factor

61 2A 0.6 power factor

62 2A 0.6 power factor

63 2A 0.6 power factor

78 100mA To drive relay only – switched neutral

79 100mA To drive relay/lamp only – switched neutral

22.05.2017 Mk8 MM End User Guide Page 6

2 Electrical Specifications

Expansion Board Inputs and Outputs

Outputs: 120/230 V All outputs with the exception of PF are switched neutrals

BFW 250mA Must be connected through contactor

BB 250mA Must be connected through contactor

HWV 100mA (alarm indicator)

2LA 100mA (alarm indicator)

2LV 100mA (alarm indicator)

H1A 100mA (alarm indicator)

1LV 100mA (alarm indicator)

79 100mA (alarm indicator on MM board)

TB 250mA Solenoid only, must be connected through contactor

PF Maximum 2A (load currents for above terminals)

Note: Max number of alarm indicators on at any time is 3 (1LV, 2LA, 2LV)

Main Voltage Signal Inputs:

At 120V current loading is approximately maximum 0.7mA per input.

At 230V current loading is approximately maximum 1.5mA per input.

Note:

1. The high and low voltage connections are not safe to touch. Protection against electric shock is

provided by correct installation. CAUTION – ELECTRIC SHOCK HAZARD.

2. Control voltage cabling should be maximum 10m, screened (if not screened then less than 1m,

however servomotors can be unscreened up to 10m)

3. Any cabling over 10m must have additional surge protection.

4. Low voltage cables should be screened cable as specified in section 2.3.

5. The burner ‘High Limit Stat’ must be a manual reset type.

Note: There is a lid (back plate) fitted onto the back of the Mk8 MM with a Warning label to prevent

any unauthorised fuse replacements.

Page 7Mk8 MM End User Guide 22.05.2017

2 Electrical Specifications

2.3 Cable Specifications

Low Voltage

The screened cable used for low voltage wiring from the MM to the servomotors, detectors and

variable speed drive must conform to the following specification:

U.V. cable length should not exceed 25m, all other screened cable should not exceed 50m.

16/0.2mm PVC insulated overall braid, screened, PVC sheathed.

Sixteen wires per core

Diameter of wires in each core 0.2mm

Rated at 440V AC rms at 1600Hz

DEF 61-12 current rating per core 2.5A

Maximum operating temperature 70oC (158oF)

Nominal conductor area 0.5sq mm per core

Nominal insulation radial thickness on core 0.45mm

Nominal conductor diameter per core 0.93mm

Nominal core resistance at 20oC. 40.1Ω/1000m

Nominal overall diameter per core 1.83mm

Fill factor of braid screen 0.7

Equivalent imperial conductor sizes 14/0.0076

Use the number of cores suitable for the application. A universal part numbering system appears to

have been adopted for this type of cable as follows:

16-2-2C 2 Core

16-2-3C 3 Core

16-2-4C 4 Core

16-2-6C 6 Core

16-2-8C 8 Core

(5 Core not readily available)

Note: If using 4 Core cable and interference is detected, use 2 sets of 2 Core.

Data Cable

Data cable must be used for communication connections between MMs for sequencing applications as

well as between MMs to EGAs, MMs to a DTI and DTI to BMS systems.

Communication cable should not exceed 1km.

Types of data cable that can be used:

1 Beldon 9501 for 2-core shielded cable (1 twisted pair)

2 Beldon 9502 for 4-core shielded cable (2 twisted pairs)

3 STC OS1P24

Samples are available upon request. Low voltage and data cable can be ordered directly from

Autoflame Engineering, please contact Autoflame Sales.

When using a VSD, please review the manufacturer’s guidelines on installations to prevent EMC

including the recommendations for reactors and filters.

22.05.2017 Mk8 MM End User Guide Page 8

3 End User Operation

3 END USER OPERATION

3.1 Home Screen

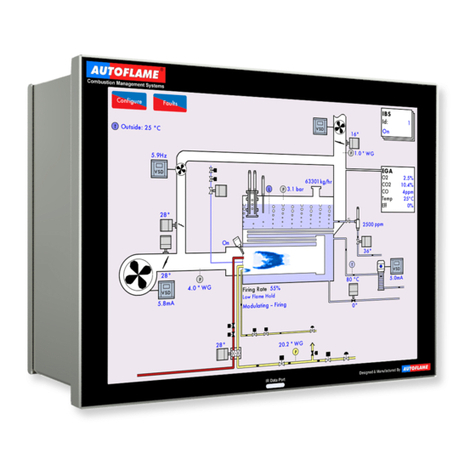

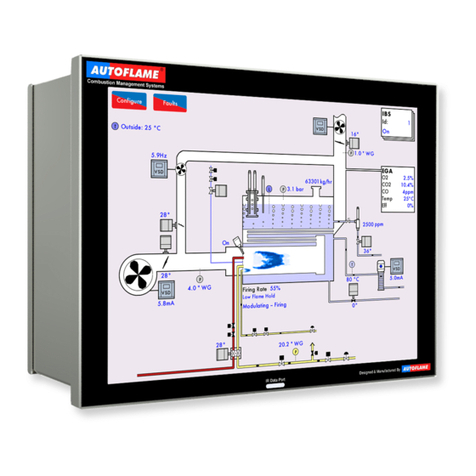

Figure 3.1.i Home Screen

The home screen shown in Figure 3.1.i displays the current boiler setup. It provides operation

information for each component of the burner/boiler in real time. Pressing on components will display

further information e.g. pressing on the servomotor image will show the servomotor position history.

This boiler room setup can be configured to display what is actually on site, please see section 3.19.5

Boiler Room Configuration.

22.05.2017 Mk8 MM End User Guide Page 9

3 End User Operation

3.1.1 Home Screen Components

Servomotor Variable

speed drive

Flame

scanner Oil pressure

sensor

Air pressure

sensor/

boiler steam

pressure

detector

Gas pressure

sensor

Boiler

temperature

detector/

outside

temperature

sensor

Feed water

temperature

sensor

Main fuel

valve open Main fuel

valve closed

Pilot gas

valve open

Pilot gas

valve closed

Control fuel

valve open

Control fuel

valve closed

Main gas

regulator Pilot gas

regulator

Gas flowing

No gas

flowing

Oil flowing

No oil

flowing

Combustion

air fan

Induced

draught fan

Gas flame Oil flame

#

Capacitance

probes

2nd Low

conductivity

probe

External level

sensor for

water level

Steam

header

TDS probe Feed water

pump

Page 10 Mk8 MM End User Guide 22.05.2017

3 End User Operation

IBS

Information

Three Pass

Fire Tube

22.05.2017 Mk8 MM End User Guide Page 11

3 End User Operation

3.1.2 Faults

Figure 3.1.2.i Lockouts

Press in the Home screen to view the faults, which are categorised into lockouts, errors,

alarms, warning and first out alarms, and are access by pressing on the corresponding tabs.

Fault Type Shuts Down Burner Reset By

Lockout Burner control fault Yes Reset button or input on T56

Error Internal or hardware fault Yes Power cycle

Alarm Critical system fault Yes Reset button or input

Warning Non-critical fault No Reset button

First out Configurable fault Optional Reset button/ auto

Page 12 Mk8 MM End User Guide 22.05.2017

3 End User Operation

3.2 Status Screen

3.2.1 Status

Figure 3.2.1.i Status

Press on the boiler load detector or the boiler image in the Home screen (Figure 3.1.i) to display the

Status screen, which gives the following information:

Burner rating

Current fuel selected and type

Burner starts and run hours

Current firing rate

Control method – internal PID control, external modulation or DTI/remote firing rate

Actual temperature/pressure reading from load detector

Current setpoint – required, reduced, DTI or external

Stat status – running interlock T53/ internal stat

Burner switch on/off offset

Reduced setpoint

Indication if MM is firing to meet required or reduced setpoint (red = active, grey = inactive)

Arrows for adjusting setpoint

Press the arrows to change the required or reduced setpoints. If these arrows are not

displayed, then either the user setpoint change has been disabled (option 15), the DTI is controlling the

setpoint (option 16), external setpoint is enabled (parameter 72), or OTC is enabled (option 80).

Note: Use parameters 29 and 30 to adjust the load detector reading if required.

22.05.2017 Mk8 MM End User Guide Page 13

3 End User Operation

3.2.2 Status – History

Figure 3.2.2.i Status – History

Press in the Status screen in Figure 3.2.1.i to show the Status History. The setpoint, actual

temperature/pressure and firing rate are displayed graphically.

This data is logged for 24 hours on the MM. Use the buttons to change the timescale of the

data displayed, and press and drag on the axis to zoom in/out of the graph.

This information is logged for 2 years on the DTI when connected with the MM.

Note: Power cycling the MM or changing fuel will reset the 24 hour history data log on the MM.

Page 14 Mk8 MM End User Guide 22.05.2017

3 End User Operation

3.2.3 Status – Burner Enable/Disable

Figure 3.2.3.i Status – Burner Enable/Disable

Press and hold for 3 seconds in the Status screen in Figure 3.2.1.i to disable the burner.

Press and hold this same button to enable the burner.

22.05.2017 Mk8 MM End User Guide Page 15

Other manuals for Mk8 MM

3

Table of contents

Other AUTOFLAME Controllers manuals