AUTOFLAME Mini Mk8 M.M. User manual

Combustion Management Systems

AUTOFLAME MK8

FLAME SAFEGUARD

CONTROLLER MANUAL

MM80001/FSG

08 FEB 2024

COMBUSTION MANAGEMENT SYSTEMS

Autoflame Engineering Ltd.

Unit 1-2 Concorde Business Centre

Airport Industrial Estate

Wireless Road, Biggin Hill

Kent TN16 3YN

United Kingdom

Tel:

+44 (0)1959 578 820

Email:

technicalsupport@autoflame.com

Web:

www.autoflame.com

AUTOFLAME MK8

FLAME SAFEGUARD

MANUAL

MM80001/FSG

08 FEB 2024

This manual and all the information contained herein is copyright of Autoflame Engineering Ltd. It may not be

copied in the whole or part without the consent of the Managing Director.

Autoflame Engineering Ltd’s policy is one of continuous improvement in both design and manufacture. We

therefore reserve the right to amend specifications and/or data without prior notice. All details contained in this

manual are correct at the time of going to print.

Important Notes

A knowledge of combustion related procedures and commissioning is essential before embarking work on any of

the MM / EGA systems. This is for safety reasons and effective use of the MM / EGA system. Hands on training

is required. For details on schedules and fees relating to group training courses and individual instruction, please

contact the Autoflame Engineering Ltd. offices at the address listed herein.

Short Form - General Terms and Conditions

A full statement of our business terms and conditions are printed on the reverse of all invoices. A copy of these

can be issued upon application, if requested in writing.

The System equipment and control concepts referred to in this Manual MUST be installed, commissioned and

applied by personnel skilled in the various technical disciplines that are inherent to the Autoflame product range,

i.e. combustion, electrical and control.

The sale of Autoflame’s systems and equipment referred to in this Manual assume that the dealer, purchaser and

installer has the necessary skills at his disposal. i.e. A high degree of combustion engineering experience, and a

thorough understanding of the local electrical codes of practice concerning boilers, burners and their ancillary

systems and equipment.

Autoflame’s warranty from point of sale

•Two years on all electronic systems and components.

•One year on all mechanical systems, components and sensors.

The warranty assumes that all equipment supplied will be used for the purpose that it was intended and in strict

compliance with our technical recommendations.

Autoflame’s warranty and guarantee is limited strictly to product build quality, and design. Excluded absolutely

are any claims arising from misapplication, incorrect installation and/or incorrect commissioning.

CONTENTS

1

AUTOFLAME FLAME SAFEGUARD OVERVIEW, SPECIFICATIONS AND WIRING...............................13

1.1 Autoflame Flame Safeguard Overview..................................................................................................13

1.1.1

Autoflame Flame Safeguard Main Features..................................................................................14

1.1.2

Fixing Holes and Dimensions ........................................................................................................15

1.2 Installation..............................................................................................................................................16

1.2.1. Humidity.........................................................................................................................................16

1.2.2. Vibration.........................................................................................................................................16

1.2.3. Weather .........................................................................................................................................16

1.2.4. Environmental Classification..........................................................................................................17

1.3 Wiring.....................................................................................................................................................18

1.3.1

Servo Motor Control Schematic Main Board.................................................................................19

1.3.2

On/Off Burner Control Schematic..................................................................................................20

1.3.3

Expansion Board............................................................................................................................21

1.3.4

Fuse Ratings..................................................................................................................................22

1.4 Electrical Specifications .........................................................................................................................23

1.4.1

Classifications................................................................................................................................23

1.4.2

Inputs and Outputs.........................................................................................................................23

1.4.3

Internal Hardware Status Monitoring.............................................................................................23

1.4.4

Input Checks..................................................................................................................................23

1.4.5

Expansion Board Inputs and Outputs............................................................................................24

1.4.6

Cable Specifications ......................................................................................................................25

1.4.7

Terminals Description....................................................................................................................26

1.4.8

Expansion Board Terminals Description........................................................................................28

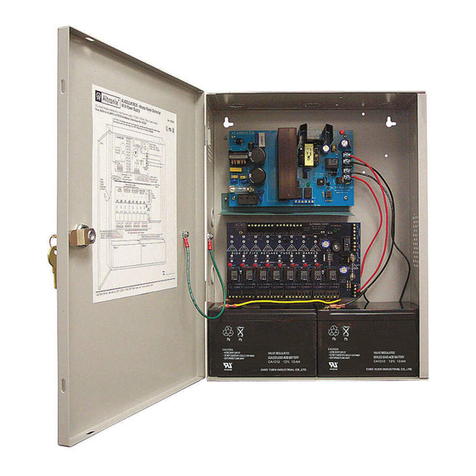

1.5 Relay Box...............................................................................................................................................29

1.5.1

Relay Box Terminal Description ....................................................................................................29

1.6 Converting a Flame Safeguard unit to an Autoflame Flame Safeguard................................................31

1.6.1

Converting Honeywell Flame Safeguard Units..............................................................................31

1.6.2

Converting Fireye Flame Safeguard Units ....................................................................................33

1.7 Standards...............................................................................................................................................34

2

OPTIONS AND PARAMETERS....................................................................................................................35

2.1 Options...................................................................................................................................................35

2.2 Parameters ............................................................................................................................................59

2.3 Language...............................................................................................................................................69

2.4 Set Clock................................................................................................................................................70

3

CONFIGURING THE AUTOFLAME FLAME SAFEGUARD UNIT ..............................................................71

3.1 Overview................................................................................................................................................71

3.1.1

Single Servo Burner Set up...........................................................................................................72

3.1.2

On/Off Burner Set up.....................................................................................................................72

3.1.3

Wiring Checks................................................................................................................................72

3.2 Installation Checks.................................................................................................................................73

3.2.1

Configuration Checks ....................................................................................................................73

3.2.2

Operational Checks .......................................................................................................................73

3.2.3

Installation Precautions..................................................................................................................73

3.2.4

Maintenance and Servicing ...........................................................................................................73

4

GENERAL FEATURES.................................................................................................................................74

4.1 No Pre-Purge.........................................................................................................................................74

4.2 Autoflame Flame Safeguard Flame Detection Using Flame Switch......................................................75

4.3 Terminals 80 and 81 Functions .............................................................................................................76

4.3.1

T80 Functions................................................................................................................................76

4.3.2

T81 Functions................................................................................................................................76

4.4 Valve Proving with Autoflame Gas Sensor............................................................................................77

5

EXPANSION FEATURES .............................................................................................................................78

6

DIRECT MODBUS ........................................................................................................................................79

6.1 Overview................................................................................................................................................79

6.2 Direct Modbus Expansion Options ........................................................................................................80

6.3 Setup and Configuration........................................................................................................................81

6.4 Modbus Addresses................................................................................................................................82

6.4.1

Modbus Address for MM Status (30102).......................................................................................91

7

FIRST OUTS..................................................................................................................................................92

7.1 Overview of First Outs...........................................................................................................................92

7.2 First Outs Expansion Options................................................................................................................92

7.3 First Outs Configuration.........................................................................................................................93

7.3.1

Enabling First Outs ........................................................................................................................93

7.3.2

Accessing First Outs......................................................................................................................93

7.3.3

First Out Function ..........................................................................................................................94

7.3.4

Edit First Out Label........................................................................................................................95

7.3.5

First Outs Interlock.........................................................................................................................96

8

OPERATION..................................................................................................................................................98

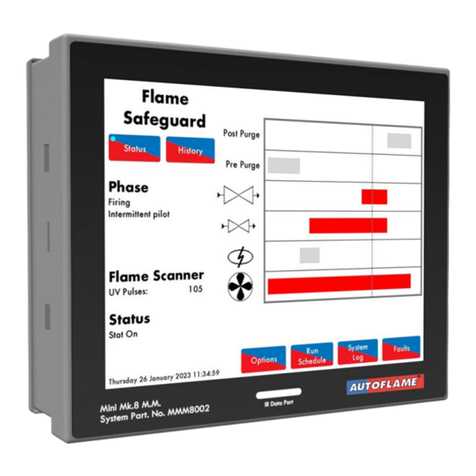

8.1 Home Screen.........................................................................................................................................98

8.1.1

Flame Safeguard - History.............................................................................................................99

8.1.2

Options.........................................................................................................................................100

8.1.3

Parameters ..................................................................................................................................101

8.1.4

Expansion....................................................................................................................................102

8.1.5

Run Times....................................................................................................................................103

8.1.6

System Log..................................................................................................................................106

8.1.7

First Outs .....................................................................................................................................107

8.1.8

Faults...........................................................................................................................................108

9

BURNER START-UP SEQUENCE.............................................................................................................109

9.1 Recycle................................................................................................................................................110

9.2 Standby................................................................................................................................................111

9.3 Internal Relay Tests.............................................................................................................................112

9.4 CPI Input..............................................................................................................................................113

9.5 Valve Proving.......................................................................................................................................114

9.6 Wait for Air Switch ...............................................................................................................................118

9.7 Purge ...................................................................................................................................................119

9.8 Ignition .................................................................................................................................................122

9.9 Pilot......................................................................................................................................................124

9.10 Proving.................................................................................................................................................127

9.11 Firing....................................................................................................................................................128

9.12 Post Purge...........................................................................................................................................129

10

UNLOCKING THE AUTOFLAME FLAME SAFEGUARD UNIT TO A MK8 MM.......................................130

10.1 Fully Unlocking the Autoflame Flame Safeguard Controller................................................................130

11

ERRORS AND LOCKOUTS .......................................................................................................................133

11.1 Errors...................................................................................................................................................133

11.2 Lockouts...............................................................................................................................................137

11.3 Alarms and Warnings...........................................................................................................................142

11.4 Settings Conflicts.................................................................................................................................150

1

Autoflame Flame Safeguard Overview, Specifications and Wiring

Flame Safeguard (MM80001/FSG) Manual

Page | 12

VERY IMPORTANT SAFETY NOTES

Please fully read and understand the following notes before commencing with any

work related to the Mk8 MM Flame Safeguard Controller. Failing to do so can

result in serious injury or even death, and can cause serious equipment and

substantial property damage.

Any person working on a boiler must be adequately trained and have a

thorough understanding and appreciation of the boiler plant.

It is the responsibility of the technician working on the plant to ensure that the system

operation meets all local codes and regulations.

Options, Parameters and Expansion Options must only be changed by an Autoflame-trained

and certified technician who has thorough understanding of the Autoflame combustion

control systems and boiler/combustion control in general. Any person changing these

settings without undergoing the necessary training and gaining an understanding of the

boiler plant may place themselves and others in a potentially dangerous situation or cause

permanent equipment damage.

Modification to the Autoflame system settings should only ever be carried out by qualified

combustion engineers. Changes to the Autoflame control system setuphas the potential

to make the controller operate in an unstable and potentially unsafe manner.

Commissioning or burner start-up must only be carried out by a an Autoflame- trained and

certified technician.

The commissioning procedure as described must be strictly adhered to. Anybody

commissioning an Autoflame system must be trained in operating combustion equipment

safely.

Autoflame products must only be installed, set up, commissioned and adjusted by an

Autoflame certified technician.

The fundamental idea of the system is to set a fuel valve position and then set a

corresponding air damper position. Care must be taken when adjusting the fuel and air

positions so as not to create any unstable or hazardous combustion conditions, e.g. moving

the fuel valve to the open position without increasing the air damper position. Improper use

may result in property damage, serious physical injury or death.

Electrical connections are live, make sure to fully and safely isolate the mains power before

carrying out any work related to the wiring connections, failure to do so may result in

serious physical injury or death.

If you are unclear about anything related to the Autoflame system, please contact

Autoflame for technical advice.

1

Autoflame Flame Safeguard Overview, Specifications and Wiring

Flame Safeguard (MM80001/FSG) Manual

Page | 13

1

AUTOFLAME FLAME SAFEGUARD OVERVIEW, SPECIFICATIONS AND

WIRING

1.1 Autoflame Flame Safeguard Overview

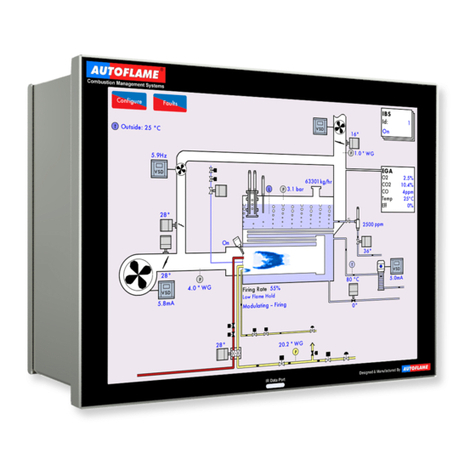

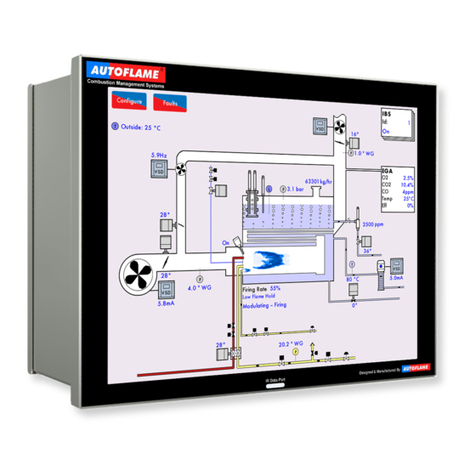

The Autoflame Flame Safeguard unit or MM80001/FSG is a version of the Micro-Modulating system that provides

an easily programmable and flexible means of providing the flame safeguard aspects of controlling a

boiler/burner.

This control module encompasses all the functions required for reliable flame safeguard management. Built into

this system is a fully automated flame safeguard, valve proving system and a 12.1” multi-touch screen interface.

MODBUS (MK8006) connectivity & First Outs (MK8007) requires unlock codes to use these features.

With the Mk8 MM, it is possible to control all boiler processes from a single 12.1” multi-touch screen interface

without any added module.

This system monitors the flame safeguard, as it checks on the flame of the burner from the use of a UV, Flame

Switch, or IR Scanner.

Additional expansion features include:

•Direct Modbus connectivity

•First out annunciation

1

Autoflame Flame Safeguard Overview, Specifications and Wiring

Flame Safeguard (MM80001/FSG) Manual

Page | 14

1.1.1

Autoflame Flame Safeguard Main Features

•12.1” Full colour touch screen

•120V or 230V standard operation 50/60Hz

•4 independent fuel programmes

•Internal flame safeguard –full flame supervision with self-check UV, IR & Flame switch.

•Dual flame scanner operation (IR and UV scanners)

•Gas valve train leak supervision via Autoflame gas pressure sensor as a low gas pressure limit

•Air pressure proving and monitoring via Air switch

•128 lockouts, errors, alarms and warnings stored with date, time, phase and reset

•1000 entry system log stored with date, time and status

•Burner control safety times user selectable

•Password protection of all safety related functions

•Infra-red port for upload/download of commission data

•First out annunciation inputs

•Download / upload all commissioning data and controller settings from MM module to a PC via

Bluetooth or IR

•Direct Modbus communications to BMS or remote monitoring and control

•Flame Safeguard mode, which allows the MM to operate as a standard Flame Safeguard.

1

Autoflame Flame Safeguard Overview, Specifications and Wiring

Flame Safeguard (MM80001/FSG) Manual

Page | 15

1.1.2

Fixing Holes and Dimensions

1

Autoflame Flame Safeguard Overview, Specifications and Wiring

Flame Safeguard (MM80001/FSG) Manual

Page | 16

1.2 Installation

When Installing this Flame Safeguard Controller

Read these instructions carefully. Failure to follow them could damage the product or cause a hazardous

condition.

Check the ratings given in the instructions and marked on the product to ensure the product is suitable for

your application.

The installer must be an Autoflame trained, experienced, flame safeguard service technician.

After installation is complete, check out the product operation as detailed in these instructions.

Never update the software on the Flame Safeguard Controller without consulting Autoflame first. Using

wrong software can damage equipment.

Warning

Fire or Explosion Hazard. Can cause severe injury, death or property damage.

To prevent possible hazardous burner operation, perform verification of safety requirements

each time a Flame Safeguard controller is installed on a burner.

IMPORTANT

For on-off gas-fired systems, some authorities, who have jurisdiction, prohibit the wiring of any limit or

operating contacts in series between the flame safeguard control and the main fuel valve(s).

Two flame detectors can be connected if necessary (see the latest Autoflame Flame Scanners Guide)

This equipment generates, uses and can radiate radio frequency energy, and if not installed and used in

accordance with the instructions, may cause interference to radio communications. It has been tested and

found to comply with the limits for a Class B computing device of part 15 of FCC rules, which are designed

to provide reasonable protection against such interference when operated in a commercial environment.

Operation of this equipment in a residential area may cause interference, in which case the users, at their

own expense, may be required to take whatever measures are required to correct this interference.

This digital apparatus does not exceed the Class B limits for radio noise of digital apparatus set out in the

Radio Interference Regulations of the Canadian Department of Communications.

1.2.1. Humidity

The Autoflame Flame Safeguard controller is designed to operate in a maximum 90 percent relative humidity,

continuous, noncondensing moisture environment.

Condensing moisture can cause a shutdown.

1.2.2. Vibration

Do not install the Flame Safeguard controller where it could be subjected to vibration in excess of 0.5G continuous

maximum vibration.

1.2.3. Weather

The Flame Safeguard controller is not designed to be watertight. If installed outdoors it must be protected by an

approved watertight enclosure. See protection rating in section 1.2.4.

1

Autoflame Flame Safeguard Overview, Specifications and Wiring

Flame Safeguard (MM80001/FSG) Manual

Page | 17

1.2.4. Environmental Classification

The Flame Safeguard Controller meets the following climate specification:

Climate:

Min. Temperature

0°C (32°F)

Recommended Temperature

Less than 40°C (104°F)

Max. Temperature

60°C (140°F)

Humidity

0 to 90% non-condensing

Storage:

Temperature

-20 to 85°C (-4 to 185°F)

Protection

Rating:

The unit is designed to be panel mounted in any orientation and the front

facia is IP65, NEMA4. The back of the unit is IP20, NEMA1.

1

Autoflame Flame Safeguard Overview, Specifications and Wiring

Flame Safeguard (MM80001/FSG) Manual

Page | 18

1.3 Wiring

1. For the internal block diagram of the Autoflame Flame Safeguard controller, see section 1.3.1, 1.3.2

& 1.3.3.

2. Disconnect the power supply before beginning installation to prevent electrical shock and

equipment damage. More than one power disconnect may be involved.

3. All wiring must comply with all applicable electrical codes, ordinances and regulations. Wiring,

where required, must comply with NEC Class 1 wiring.

4. Recommended wire size and type is defined in section 1.4.6 Cable Specifications. For high

temperature installations, use wire selected for a temperature rating above the maximum operating

temperature. All wiring must be moisture resistant.

5. Do not connect more than two wires per terminal. If more than two wires need to be connected to a

terminal, wire into a suitable terminal block in the panel first and from there to the unit terminal with

a single wire.

6. Recommended wire routing for Autoflame Flame Scanners:

a. Do not run high voltage ignition transformer wires in the same conduit with the flame scanner

wiring.

b. Do not route flame scanner wires in a conduit with line voltage circuits.

c. Enclose flame scanner wires in metal conduit.

d. Follow directions given in the Autoflame Flame Scanners Guide.

7. Do not exceed the terminal ratings. Refer to the wiring diagram in section 1.3.1, 1.3.2 & 1.3.3 or to

the ratings in the section 1.4 Electrical Specifications.

8. The voltage tolerance of the power supply must match those of the Flame Safeguard controller. A

separate power supply circuit may be required for the Flame Safeguard controller with the required

disconnect and overload protection added.

9. Check all wiring circuits and complete all the checks before installing the plug-in connectors to the

flame safeguard controller; see section 1.3.1, 1.3.2 & 1.3.3.

10. Install all electrical connectors.

11. Restore power to the panel.

Electrical Shock Hazard

Can cause severe injury, death or property damage.

1. To prevent electrical shock and equipment damage, disconnect the power supply before beginning

installation. More than one power supply disconnect may be involved.

2. Wiring connections for the Autoflame Flame Safeguard controller are unique; therefore, refer to

sections 1.3 and 1.4 for the correct specifications and connections.

3. Wiring must comply with all applicable codes, ordinances and regulations.

4. Wiring, where required, must comply with NEC Class 1 wiring.

5. Loads connected to the Flame Safeguard controller must not exceed those listed on the wiring label

or the specifications (see section 1.4.2 & 1.4.5 of this manual).

6. Limits and interlocks must be rated to carry and break current simultaneously to the ignition

transformer, pilot valve, and main fuel valve(s).

7. All external timers must be listed or component recognized by authorities who have jurisdiction for

the specific purpose for which they are used.

1

Autoflame Flame Safeguard Overview, Specifications and Wiring

Flame Safeguard (MM80001/FSG) Manual

Page | 19

1.3.1

Servo Motor Control Schematic Main Board

72

CALL FOR HEAT

BURNER ON/OFF

AIR PROVING SWITCH

GAS VALVES C.P.I./POC

LOCKOUT RESET

PILOT VALVE

MAIN FUEL VALVE 1

MAIN FUEL VALVE 2

IGNITION TRANSFORMER

GREEN

YELLOW

22

21

N

LIVE/HOT

NEUTRAL

EARTH

BURNER MOTOR 58

BLUE

51

50

51

50

RED

* LIMIT STAT

51

50

S

55

53

52

54

56

57

VENT VALVE

60

59

61

63

62

64

67

66

68

70

69

71

FLAME SWITCH

AT NO FLAME STATE.

78

75

73

74

76

77

80

79

81

83

82

84

FUEL 2

FUEL 1

LINE V

0 V

FUEL 4

FUEL 3

90

87

85

86

88

89

92

91

93

95

94

11

4

2

1

S

3

6

5

7

S

9

8

10

14

S

12

13

S

15

17

16

20

S

18

19

22

21

S

29

26

24

23

25

S

28

27

S

35

30

34

31

49

48

41

38

S

37

S

S

39

40

43

42

45

44

47

46

S

PRE-IGNITION

SAFETY INTERLOCK CIRCUIT

RUNNING INTERLOCK

NON-RECYCLING INTERLOCK

GREEN

YELLOW

BLACK

RED

YELLOW

GREEN

LINE VOLTAGE

LOW VOLTAGE

I.R. SCANNER

MODBUS

27

28

6A FUSED SUPPLY

*NOTE:

HIGH LIMIT STAT

MUST BE

MANUAL RESET

TYPE

U.V. DETECTOR

SELF CHECK

U.V. DETECTOR

EXTERNAL AUXILIARY

DELAY TO PURGE

OUTLET

PRESS.

(OPTIONAL)

GAS

BOOSTER

INLET

PRESS.

6.3A T

T50 TO T64

ALL LOW VOLTAGE WIRING TO THE CONTROL IS TO BE WIRED AS PART OF A CLASS 1 CIRCUIT

BLUE

RED

S

32

33

F4

500mA

F3

500mA

FUSE 1

2A T

SERVO SHORT

CIRCUIT

FUSE 2

LF/20.06.23/MK8 MM FLAME SAFEGUARD ISS3

IF IN DOUBT ASK AUTOFLAME TECHNICAL DEPARTMENT

80

81

HIGH FIRE / PURGE SWITCH

RELAY BOX

HIGH/LOW INITIATE

RELEASE TO MODULATE

B

R

W

69

R1

W1

B1

B

R

W

R

W

B

PRESSURE

CONTROLLER

MOTOR

HF

LF

LOW FIRE / START SWITCH

R1

R2

POWER

COMMON ALARM RELAY 79

BROWN

PURPLE

BLUE

RED

GAS PRESSURE

SENSOR

1

Autoflame Flame Safeguard Overview, Specifications and Wiring

Flame Safeguard (MM80001/FSG) Manual

Page | 20

1.3.2

On/Off Burner Control Schematic

72

CALL FOR HEAT

BURNER ON/OFF

AIR PROVING SWITCH

GAS VALVES C.P.I./POC

LOCKOUT RESET

PILOT VALVE

MAIN FUEL VALVE 1

MAIN FUEL VALVE 2

IGNITION TRANSFORMER

GREEN

YELLOW

22

21

N

LIVE/HOT

NEUTRAL

EARTH

BURNER MOTOR 58

BLUE

51

50

51

50

RED

* LIMIT STAT

51

50

S

55

53

52

54

56

57

VENT VALVE

60

59

61

63

62

64

67

66

68

70

69

71

FLAME SWITCH

AT NO FLAME STATE.

78

75

73

74

76

77

80

79

81

83

82

84

FUEL 2

FUEL 1

LINE V

0 V

FUEL 4

FUEL 3

90

87

85

86

88

89

92

91

93

95

94

11

4

2

1

S

3

6

5

7

S

9

8

10

14

S

12

13

S

15

17

16

20

S

18

19

22

21

S

29

26

24

23

25

S

28

27

S

35

30

34

31

49

48

41

38

S

37

S

S

39

40

43

42

45

44

47

46

S

PRE-IGNITION

SAFETY INTERLOCK CIRCUIT

RUNNING INTERLOCK

NON-RECYCLING INTERLOCK

GREEN

YELLOW

BLACK

RED

YELLOW

GREEN

LINE VOLTAGE

LOW VOLTAGE

I.R. SCANNER

MODBUS

27

28

6A FUSED SUPPLY

*NOTE:

HIGH LIMIT STAT

MUST BE

MANUAL RESET

TYPE

U.V. DETECTOR

SELF CHECK

U.V. DETECTOR

EXTERNAL AUXILIARY

DELAY TO PURGE

OUTLET

PRESS.

(OPTIONAL)

GAS

BOOSTER

INLET

PRESS.

6.3A T

T50 TO T64

ALL LOW VOLTAGE WIRING TO THE CONTROL IS TO BE WIRED AS PART OF A CLASS 1 CIRCUIT

BLUE

RED

S

32

33

F4

500mA

F3

500mA

FUSE 1

2A T

SERVO SHORT

CIRCUIT

FUSE 2

LF/14.07.23/MK8 MM FLAME SAFEGUARD

(ON/OFF BURNER) ISS1

IF IN DOUBT ASK AUTOFLAME TECHNICAL DEPARTMENT

80

81

HIGH FIRE / PURGE SWITCH

LOW FIRE / START SWITCH

COMMON ALARM RELAY 79

BROWN

PURPLE

BLUE

RED

GAS PRESSURE

SENSOR

TR1

70

69

ON DELAY TIMER RELAY

SET DELAY TO 5 SEC.

1

Autoflame Flame Safeguard Overview, Specifications and Wiring

Flame Safeguard (MM80001/FSG) Manual

Page | 21

1.3.3

Expansion Board

LF/20.06.23/MK8 MM FLAME SAFEGUARD ISS3

IF IN DOUBT ASK AUTOFLAME TECHNICAL DEPARTMENT

1-12 FIRST OUT ANNUNCIATION

LINE VOLTAGE INPUTS.

LABELS AND OPERATION, SETUP ON MM

POWER FEED OUTPUT (230/110V) 2 Amp

13-15 FIRST OUT ANNUNCIATION

LINE VOLTAGE INPUTS.

(USER ASSIGNABLE LABELS

SAME AS FIRST OUTS 1-12)

FO1

LINE VOLTAGE

LOW VOLTAGE

ALL LOW VOLTAGE WIRING TO THE CONTROL IS TO BE WIRED AS PART OF A CLASS 1 CIRCUIT

S

P-

FW

P+

S

-

T1

T2

S

-

T3

TW

S

F-

MF

CF

S

I+

V+

IV-

EX+

S

EX-

DT+

DT-

S

DP-

DP+

DPW

S

5T+

5T-

4P-

4P+

6T+

6T-

S

S

3P+

3P-

3T+

3T-

S

1P+

1P-

1T+

1T-

S

2P+

2P-

2T+

2T-

FO2

FO3

FO4

FO5

FO6

FO7

FO8

FO9

FO10

FO11

FO12

PF

FO13

FO14

FO15

HAI

1AI

2AI

M/R

TST

NC

TB

TBI

1LV

H1A

2LV

2LA

HWV

BB

BFW

MVI

MVD

TBD

DCI

DCD

2.5A

F8

FUSE 5

2A

PF OUTPUT

4A

F7

2A

F6

1

Autoflame Flame Safeguard Overview, Specifications and Wiring

Flame Safeguard (MM80001/FSG) Manual

Page | 22

1.3.4

Fuse Ratings

Fu s e

Rating

Sp are P a rt Nu m be r

1

6.3A (T)

FU10026

Fuse 1 protects the mains input to the MM, including the mains output terminals 50 –64.

2

2A (T)

FU10034

Fuse 2 protects the power supply (terminal 69) for the servomotors, alarm and 2 port valve. If this fuse blows,

error ‘Triac Power Supply Error (Check F2)’ will occur.

3

500mA

FU10040

Fuse 3 protects the 13.5V power supply to the oil pressure sensor and IR scanner on terminal 49. If this fuse

blows, error ‘Fused 13.5V Supply Error (Check F3)’ will occur.

4

500mA

FU10040

Fuse 4 protects the 12V power supply to the gas/air pressure sensor and steam pressure detector on

terminals 34 and 39. If this fuse blows, error ‘Fused 12V Supply Error (Check F4)’ will occur.

5

2A (T)

FU10034

Fuse 5 protects the power supply (terminal PF) for the expansion servos and alarm outputs. If fuse 5 blows,

error ‘Expansion PF Output (Check F5)’ will occur.

6

2A

FU10027

Fuse 6 protects the DC circuits. If this fuse blows, the display will be off and both LEDs adjacent to fuse 7

and 8 will be off.

7

4A

FU10050

Fuse 7 protects the internal 5V supply. If this fuse blows the display will be off and the LED adjacent to the

fuse will be off.

8

2.5A

FU10042

Fuse 8 protects the internal 12V supply. If this fuse blows the display will be off and the LED adjacent to the

fuse will be off.

1

Autoflame Flame Safeguard Overview, Specifications and Wiring

Flame Safeguard (MM80001/FSG) Manual

Page | 23

1.4 Electrical Specifications

1.4.1

Classifications

Classification according to BS EN298:2012

Mains Supply:

Single phase 230V, +10%/-15%}

47-63 Hz, unit max. consumption 140W

Single phase 120V, +10%/-15%}

1.4.2

Inputs and Outputs

Output Terminal

Rating (230V)

Rating (120V)

Notes

57

250mA

250mA

Must be connected through contactor

58

250mA

250mA

Must be connected through contactor

59

1A

2A

0.6 power factor

60

1A

2A

0.6 power factor

61

1A

2A

0.6 power factor

62

1A

2A

0.6 power factor

63

1A

2A

0.6 power factor

79

100mA

100mA

To drive relay/lamp only –switched neutral

Max. Load

6A

6A

Electrical Shock Hazard

Can cause severe injury, death or property damage.

•

The high and low voltage connections are not safe to touch. Protection against electric shock is provided by

correct installation.

•

Control voltage cabling should be maximum 10m, screened (if not screened then less than 1m, however

servomotors can be unscreened up to 10m)

•

Any cabling over 10m must have additional surge protection.

•

Low voltage cables should be screened (shielded) cable as specified in section 1.4.6.

•

The burner ‘High Limit Stat’ must be a manual reset type.

•

All external safety devices that require manual reset must be reset external to the Autoflame system and prior

to completing the recycling interlock.

The cover (back plate) of the Flame Safeguard controller must always be re-fitted after the wiring is completed to

prevent access to the electric shock hazard areas, unauthorised wiring modifications or fuse replacement.

1.4.3

Internal Hardware Status Monitoring

The Flame Safeguard controller analyses the integrity of the internal hardware and diagnostics values for key

parameters are available.

The relay safety checks are carried out during every startup sequence and their progress will be displayed on the

screen.

1.4.4

Input Checks

All system input circuits are examined to assure that the Flame Safeguard controller is capable of recognising the

true status of external controls, limits and interlocks. If any input fails this test, a safety shutdown occurs and the fault

will be logged.

1

Autoflame Flame Safeguard Overview, Specifications and Wiring

Flame Safeguard (MM80001/FSG) Manual

Page | 24

1.4.5

Expansion Board Inputs and Outputs

Outputs:

120/230 V

All outputs with the exception of PF are switched neutrals

79

100mA

(alarm indicator on MM board)

PF

Maximum 2A

(load currents for above terminal)

Main Voltage Signal Inputs:

At 120V current loading is approximately maximum 0.7mA per input.At

230V current loading is approximately maximum 1.5mA per input.

1

Autoflame Flame Safeguard Overview, Specifications and Wiring

Flame Safeguard (MM80001/FSG) Manual

Page | 25

1.4.6

Cable Specifications

Low Voltage

The screened cable used for low voltage wiring from the Flame Safeguard unit to the detectors, must conform to

the following specification:

UV scanner cable length should not exceed 25m, all other screened cables should not exceed 50m.

•16/0.2mm PVC insulated overall braid, screened, PVC sheathed.

•Sixteen wires per core

•Diameter of wires in each core 0.2mm

•Rated at 440V AC rms at 1600Hz

•DEF 61-12 current rating per core 2.5A

•Maximum operating temperature 70oC (158oF)

•Nominal conductor area 0.5sq mm per core

•Nominal insulation radial thickness on core 0.45mm

•Nominal conductor diameter per core 0.93mm

•Nominal core resistance at 20oC. 40.1Ω/1000m

•Nominal overall diameter per core 1.83mm

•Fill factor of braid screen 0.7

•Equivalent imperial conductor sizes 14/0.0076

Use the number of cores suitable for the application. A universal part numbering system appears to havebeen

adopted for this type of cable as follows:

•16-2-2C 2 Core

•16-2-3C 3 Core

•16-2-4C 4 Core

•16-2-6C 6 Core

•16-2-8C 8 Core

(5 Core not readily available)

Note: If using 4 Core cable and interference is detected, use 2 sets of 2 Core.

Data Cable

Data cable must be used for communication connections between MM to BMS systems of Modbus RS485.

Communication cable should not exceed 1km.

Types of data cable that can be used:

•

Belden 9501 for 2-core shielded cable (1 twisted pair)

•

Belden 9502 for 4-core shielded cable (2 twisted pairs)

•

STC OS1P24

Samples are available upon request. Low voltage and data cable can be ordered directly from Autoflame

Engineering, please contact Autoflame Sales.

1

Autoflame Flame Safeguard Overview, Specifications and Wiring

Flame Safeguard (MM80001/FSG) Manual

Page | 26

1.4.7

Terminals Description

S

All terminals marked S are internally connected. They are provided for connections to the various

screened cables

21, 22

Connections to an Autoflame self-check UV sensor

27, 28

Communications port connections for Modbus

29, 30

Digital communications connections to an Autoflame IR scanner

31, 32

Digital communications connections to an Autoflame gas pressure sensor

33

0V supply to an Autoflame gas pressure sensor

34

+12V supply to an Autoflame gas pressure sensor

48

0V supply to an Autoflame IR scanner

49

+15V supply to an Autoflame IR scanner

50, 51

Connections to an Autoflame UV scanner

52

Mains voltage input –external auxiliary delay to purge/ secondary proving set in option/parameter

157

53

Mains voltage input –burner on/off signal, running interlock circuit

54

Mains voltage input –air proving switch

55

Mains voltage input - proving circuits, e.g. gas valve proof of closure

56

Mains voltage input - lockout reset

57

Mains voltage output –call for heat

58

Mains voltage output –burner motor

59

Mains voltage output –start/pilot valve

60

Mains voltage output –main fuel valve 1

61

Mains voltage output –main fuel valve 2

62

Mains voltage output –vent valve

63

Mains voltage output –ignition transformer

66

Mains supply –earth

67

Main supply –neutral

68

Mains supply –live/hot

69

Mains voltage output, power to Relay Box (SP80070, SP80070/110)

70

Switched neutral –High/Low Initiate output.

71

Switched neutral –Release to Modulate output.

79

Switched neutral –alarm output for MM lockout/MM error.

80

Low Fire / Start position interlock.

81

High Fire / Purge position interlock.

Other manuals for Mini Mk8 M.M.

2

Table of contents

Other AUTOFLAME Controllers manuals

Popular Controllers manuals by other brands

Kencove

Kencove AG M4 operating instructions

ABB

ABB Totalflow mflo Series Startup guide

Becker

Becker CentralControl CC51 Commissioning instructions

ITT

ITT Conoflow GB50 Series Instruction and maintenance manual

Rosenberg

Rosenberg H42 Series operation instruction

Controlli

Controlli MVH56EA quick start guide