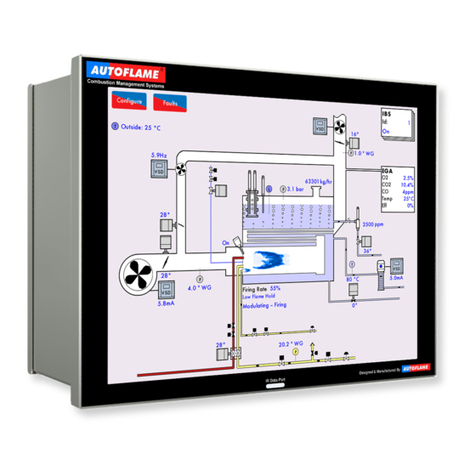

AUTOFLAME Mk8 MM User manual

Mk8 MM

Expansion Features

Installation and

Commissioning Guide

Mk8 MM

Expansion Features

Installation and Commissioning Guide

Issued by:

AUTOFLAME ENGINEERING LTD

Unit 1-2, Concorde Business Centre

Airport Industrial Estate, Wireless Road

Biggin Hill, Kent TN16 3YN

Tel: +44 (0)845 872 2000

Fax: +44 (0)845 872 2010

Email: [email protected]

Website: http://www.autoflame.com/

Registered Holder:

Company:

Department:

This manual and all the information contained herein is copyright of

Autoflame Engineering Ltd. It may not be copied in the whole or part without

the consent of the Managing Director.

Autoflame Engineering Ltd’s policy is one of continuous improvement in both

design and manufacture. We therefore reserve the right to amend

specifications and/or data without prior notice. All details contained in this

manual are correct at the time of going to print.

Important Notes

A knowledge of combustion related procedures and commissioning is essential before

embarking work on any of the M.M./E.G.A. systems. This is for safety reasons and

effective use of the M.M./ E.G.A. system. Hands on training is required. For details on

schedules and fees relating to group training courses and individual instruction, please

contact the Autoflame Engineering Ltd. offices at the address listed on the front.

Short Form - General Terms and Conditions

A full statement of our business terms and conditions are printed on the reverse of all

invoices. A copy of these can be issued upon application, if requested in writing.

The System equipment and control concepts referred to in this Manual MUST be installed,

commissioned and applied by personnel skilled in the various technical disciplines that

are inherent to the Autoflame product range, i.e. combustion, electrical and control.

The sale of Autoflame’s systems and equipment referred to in this Manual assume that

the dealer, purchaser and installer has the necessary skills at his disposal. i.e. A high

degree of combustion engineering experience, and a thorough understanding of the

local electrical codes of practice concerning boilers, burners and their ancillary systems

and equipment.

Autoflame’s warranty from point of sale is two years on all electronic systems and

components.

One year on all mechanical systems, components and sensors.

The warranty assumes that all equipment supplied will be used for the purpose that

it was intended and in strict compliance with our technical recommendations. Auto-

flame’s warranty and guarantee is limited strictly to product build quality, and design.

Excluded absolutely are any claims arising from misapplication, incorrect installation

and/or incorrect commissioning.

Contents

1TECHNICAL SPECIFICATIONS ................................................................................... 1

1.1 Mk8 Expansion Board.............................................................................................................1

1.2 Expansion Board Inputs and Outputs ......................................................................................2

1.2.1 Fuse Ratings.....................................................................................................................2

1.3 Cable Specifications ................................................................................................................3

1.4 Expansion Board Terminals Description ..................................................................................4

2EXPANSION OPTIONS ............................................................................................ 7

3WATER LEVEL CONTROL ........................................................................................ 25

3.1 Overview.............................................................................................................................. 25

3.1.1 Safety ........................................................................................................................... 25

3.1.2 Autoflame Water Level Control .................................................................................... 25

3.1.3 Water Treatment........................................................................................................... 26

3.2 Water Valve ......................................................................................................................... 27

3.2.1 Specifications................................................................................................................ 27

3.2.2 Feed Water Valve Sizing.............................................................................................. 28

3.2.3 Feed Water Control...................................................................................................... 29

3.3 Ways of Level Sensing.......................................................................................................... 30

3.3.1 Overview ...................................................................................................................... 30

3.3.2 Configuration................................................................................................................ 31

3.4 Capacitance Probes.............................................................................................................. 35

3.4.1 Overview ...................................................................................................................... 35

3.4.2 Operation..................................................................................................................... 36

3.4.3 Specification ................................................................................................................. 36

3.4.4 Installation Safety Guidelines ....................................................................................... 39

3.4.5 Capacitance Probe – Externally Mounted Pots ............................................................ 40

3.4.6 Capacitance Probe – Internally Mounted Pots ............................................................. 42

3.4.7 Capacitance Probe – Installation for a Water Tube Boiler ........................................... 44

3.4.8 External Probe Chamber Dimensions ........................................................................... 45

3.4.9 Configuration................................................................................................................ 46

3.5 2nd Low Probe........................................................................................................................ 47

3.5.1 Overview ...................................................................................................................... 47

3.5.2 Operation..................................................................................................................... 48

3.5.3 Specifications................................................................................................................ 48

3.5.4 Installation and Safety Guidelines ................................................................................ 50

3.5.5 Configuration................................................................................................................ 51

3.6 External Level Sensor ........................................................................................................... 52

3.7 Auxiliary Alarm Inputs.......................................................................................................... 53

3.8 Commissioning Procedure .................................................................................................... 54

3.8.1 Commissioning Checks.................................................................................................. 54

3.8.2 Levels............................................................................................................................ 54

3.8.3 Setting End of Probe Level............................................................................................ 55

3.8.4 Setting 2nd Low Level ..................................................................................................... 57

3.8.5 Setting 1st Low Level...................................................................................................... 58

3.8.6 Setting Control Point Level ............................................................................................ 59

3.8.7 Setting HIGH Level ....................................................................................................... 60

3.8.8 Save Commissioning..................................................................................................... 61

3.8.9 Operational Checks...................................................................................................... 63

3.8.10 Adjust Control Point ...................................................................................................... 64

3.9 Water Level Control Functions.............................................................................................. 65

3.9.1 Pre-Alarms .................................................................................................................... 65

3.9.2 Pump Bypass................................................................................................................. 65

3.9.3 Test Outputs and Shunt Switch...................................................................................... 66

3.9.4 Sudden Pressure Drop .................................................................................................. 67

3.10 Faults .................................................................................................................................... 68

4TOP BLOWDOWN ................................................................................................. 71

4.1 Overview.............................................................................................................................. 71

4.1.1 Importance of Maintaining TDS.................................................................................... 71

4.1.2 TDS, Conductivity and Temperature ............................................................................. 72

4.2 TDS Valve ............................................................................................................................. 73

4.3 TDS Probe............................................................................................................................. 74

4.3.1 Specification ................................................................................................................. 74

4.3.2 Dimensions.................................................................................................................... 75

4.3.3 Installation .................................................................................................................... 76

4.3.4 Configuration................................................................................................................ 77

4.4 Ways of Controlling TDS Level ............................................................................................. 78

4.4.1 Continuous TDS Control................................................................................................ 78

4.4.2 Solenoid and Servomotor 2-State TDS Control............................................................. 78

4.4.3 TDS Timing Diagram ..................................................................................................... 79

4.4.4 Sample Routine............................................................................................................. 80

4.5 Calibrating TDS Probe .......................................................................................................... 81

4.6 Faults .................................................................................................................................... 83

5BOTTOM BLOWDOWN.......................................................................................... 84

5.1 Overview.............................................................................................................................. 84

5.2 Bottom Blowdown Reduction ................................................................................................ 85

5.2.1 Blowdown Savings........................................................................................................ 85

5.2.2 Calculation for Bottom Blowdown Reduction................................................................ 86

5.3 Installation Guidance............................................................................................................ 88

5.3.1 Bottom Blowdown Valve............................................................................................... 88

5.3.2 Bottom Blowdown Module ........................................................................................... 89

5.4 Set-up.................................................................................................................................... 92

5.4.1 Bottom Blowdown Settings............................................................................................ 92

5.4.2 Setting Servomotor ....................................................................................................... 93

5.5 Bottom Blowdown Configuration .......................................................................................... 97

5.5.1 Bottom Blowdown Log .................................................................................................. 99

5.6 Faults .................................................................................................................................. 100

6DRAUGHT CONTROL ........................................................................................... 101

6.1 Overview............................................................................................................................ 101

6.1.1 Benefits of Draught Control ........................................................................................ 101

6.1.2 Fully Integrated Draught Control................................................................................ 101

6.2 Draught Control Operation ................................................................................................ 103

6.2.1 Overview .................................................................................................................... 103

6.2.2 Deactivation Window ................................................................................................. 103

6.2.3 Draught Control Trim .................................................................................................. 105

6.3 Set-Up ................................................................................................................................. 107

6.3.1 Configuration.............................................................................................................. 107

6.3.2 Ways of Using Draught Servomotor........................................................................... 108

6.4 Commissioning Draught Control ......................................................................................... 109

6.4.1 Commissioning Checks................................................................................................ 109

6.4.2 Commissioning Screen................................................................................................ 110

6.5 Faults .................................................................................................................................. 111

7REMOTE CONTROL .............................................................................................. 112

7.1 Overview............................................................................................................................ 112

7.2 Configuration...................................................................................................................... 113

7.3 Modbus Addresses ............................................................................................................. 114

8FIRST OUTS ......................................................................................................... 123

8.1 Overview............................................................................................................................ 123

8.2 Configuration...................................................................................................................... 124

8.2.1 Running Interlock Circuit ............................................................................................. 124

8.2.2 Interlock Option.......................................................................................................... 128

9HEAT FLOW......................................................................................................... 129

9.1 Overview............................................................................................................................ 129

9.1.1 Benefits of Steam/Hot Water Flow Metering.............................................................. 129

9.1.2 Configuration.............................................................................................................. 129

9.2 Steam Flow Metering.......................................................................................................... 130

9.2.1 Steam Flow Calculation .............................................................................................. 130

9.2.2 Steam Flow ................................................................................................................. 134

9.2.3 Steam Flow with Economiser ...................................................................................... 135

9.2.4 Steam Flow with Deaerator ........................................................................................ 136

9.2.5 Steam Flow with Deaerator and Feed Sensor ............................................................ 137

9.3 Hot Water Flow Metering................................................................................................... 138

9.3.1 Hot Water Flow Calculation ....................................................................................... 138

9.3.2 Hot Water Flow .......................................................................................................... 140

9.3.3 Hot Water Flow with Economiser................................................................................ 141

9.4 Faults .................................................................................................................................. 142

10 FULLY METERED COMBUSTION CONTROL ............................................................ 143

10.1 Overview............................................................................................................................ 143

10.1.1 Introduction................................................................................................................. 143

10.1.2 Importance of Excess Air ............................................................................................ 143

10.2 Fully Metered Combustion Control Operation ................................................................... 144

10.2.1 Philosophy .................................................................................................................. 144

10.2.2 Firing Rate .................................................................................................................. 144

10.2.3 Control Process........................................................................................................... 145

10.2.4 Mass Flow Meters....................................................................................................... 146

10.2.5 Volume Flow Meters ................................................................................................... 146

10.3 Set-Up ................................................................................................................................. 147

10.3.1 Configuration.............................................................................................................. 147

10.3.4 Limitations ................................................................................................................... 148

10.3.5 Commissioning............................................................................................................ 149

10.4 Faults .................................................................................................................................. 153

1 Technical Specifications

04.09.2016 Mk8 MM Expansion Features Installation and Set-Up Guide Page 1

1 TECHNICAL SPECIFICATIONS

1.1 Mk8 Expansion Board

1 Technical Specifications

Page 2 Mk8 MM Expansion Features Installation and Set-Up Guide 04.09.2016

1.2 Expansion Board Inputs and Outputs

Outputs: 120/230 V All outputs with the exception of PF are switched neutrals

BFW 250mA Must be connected through contactor

BB 250mA Must be connected through contactor

HWV 100mA (alarm indicator)

2LA 100mA (alarm indicator)

2LV 100mA (alarm indicator)

H1A 100mA (alarm indicator)

1LV 100mA (alarm indicator)

79 100mA (alarm indicator on MM board)

TB 250mA Solenoid only, must be connected through contactor

PF Maximum 2A (load currents for above terminals)

Note: Max number of alarm indicators on at any time is 3 (1LV, 2LA, 2LV)

Main Voltage Signal Inputs:

At 120V current loading is approximately maximum 0.7mA per input.

At 230V current loading is approximately maximum 1.5mA per input.

1.2.1 Fuse Ratings

Fuse Rating Spare Part Number

1 6.3A (T) FU10026

Fuse 1 protects the mains input to the MM, including the mains output terminals 50 – 64.

2 2A (T) FU10034

Fuse 2 protects the power supply (terminal 69) for the servomotors, alarm and 2 port valve. If this

fuse blows, the error ‘Triac Power Supply Error (Check F2)’ will occur.

3 500mA FU10040

Fuse 3 protects the 13.5V power supply to the oil pressure sensor and IR scanner on terminal 49. If

this fuse blows, the error ‘Fused 13.5V Supply Error (Check F3)’ will occur.

4 500mA 500mA

Fuse 5 protects the power supply (terminal PF) for the expansion servos and alarm outputs. If fuse

5 blows, the error ‘Expansion PF Output (Check F5)’ will occur.

5 2A (T) FU10034

Fuse 5 protects the power supply (terminal PF) for the expansion servos and alarm outputs. If fuse

5 blows, the error ‘Expansion PF Output (Check F5)’ will occur.

6 2A FU10027

Fuse 6 protects the DC circuits. If this fuse blows, the display will be off and both LEDs adjacent to

fuse 7 and 8 will be off.

7 4A FU10050

Fuse 7 protects the internal 5V supply. If this fuse blows the display will be off and the LED

adjacent to the fuse will be off.

8 2.5A FU10042

Fuse 8 protects the internal 12V supply. If this fuse blows the display will be off and the LED

adjacent to the fuse will be off.

1 Technical Specifications

04.09.2016 Mk8 MM Expansion Features Installation and Set-Up Guide Page 3

1.3 Cable Specifications

High/ Control Voltage

Screened cable should not exceed 10m and unscreened cable should not exceed 1m. The ionisation/

flame rod cable must be shielded to prevent interference with other cables, as it is a high voltage and

high frequency signal.

Low Voltage

The screened cable used from the MM to the servomotors and detectors must conform to the following

The screened cable used for low voltage wiring from the MM to the servomotors, detectors and

variable speed drive must conform to the following specification:

16/0.2mm PVC insulated overall braid, screened, PVC sheathed.

Sixteen wires per core

Diameter of wires in each core 0.2mm

Rated at 440V AC rms at 1600Hz

DEF 61-12 current rating per core 2.5A

Maximum operating temperature 70oC (158oF)

Nominal conductor area 0.5sq mm per core

Nominal insulation radial thickness on core 0.45mm

Nominal conductor diameter per core 0.93mm

Nominal core resistance at 20oC. 40.1Ω/1000m

Nominal overall diameter per core 1.83mm

Fill factor of braid screen 0.7

Equivalent imperial conductor sizes 14/0.0076

Use the number of cores suitable for the application. A universal part numbering system appears to

have been adopted for this type of cable as follows:

16-2-2C 2 Core

16-2-3C 3 Core

16-2-4C 4 Core

16-2-6C 6 Core

(5 Core not readily available)

Note: If using 4 Core cable and interference is detected, use 2 sets of 2 Core.

Data Cable

Data cable must be used for connections between MMs for sequencing applications and between MMs

and EGAs and for connection between MMs and DTI

Types of data cable that can be used:

1 Beldon 9501 for 2-core shielded cable (1 twisted pair)

2 Beldon 9502 for 4-core shielded cable (2 twisted pairs)

3 STC OS1P24

Samples are available upon request. Low voltage and data cable can be ordered directly from

Autoflame Engineering, please contact Autoflame Sales.

1 Technical Specifications

Page 4 Mk8 MM Expansion Features Installation and Set-Up Guide 04.09.2016

1.4 Expansion Board Terminals Description

S All terminals marked S are internally connected. They are provided for connections

to the various screened cables.

P- 0V supply to top blowdown and feed water servomotors

FW Signal from feed water servomotor, indicating position

P+ +12V supply to top blowdown and feed water servomotors

- Common for terminals T1, T2 and T3

T1 Signal input from T1 temperature sensor

T2 Signal input from T2 temperature sensor

- Common for terminal T1, T2 and T3

T3 Signal input from T3 temperature sensor

TW Signal from top blowdown servomotor, indicating position

F- Common for terminals MF and CF

MF Current input, 4-20mA for cold water make up flow meter

CF Current input, 4-20mA for condensate return flow meter

I+ Current output, 4-20mA to feed water VSD

V+ Voltage output, 0-10V to feed water VSD

IV- Common for terminals I+ and V+

EX- Common for terminal EX+

EX+ Current input, 4-20mA for external water level probe or fuel flow feedback

DT+, DT- Digital communications from draught control pressure sensor

DP- 0V supply to draught control pressure sensor and draught control servomotor

DP+ +12V supply to draught control pressure sensor and draught control servomotor

DPW Signal from draught control servomotor, indicating position

5T+, 5T- Digital communications from bottom blowdown module and 2nd low probe

4P- 0V supply to 2nd low resistance probe

4P+ +12V supply to 2nd low resistance probe

6T+, 6T- Communications port connections I/O module RS485

3P+ +9V supply to TDS probe

1 Technical Specifications

04.09.2016 Mk8 MM Expansion Features Installation and Set-Up Guide Page 5

3P- 0V supply to TDS probe

3T+, 3T- Digital communication connections from TDS probe

1P+ +9V supply to capacitance probe 1

1P- 0V supply to capacitance probe 1

1T+, 1T- Digital communications connections from capacitance probe 1

2P+ +9V supply to capacitance probe 2

2P- 0V supply to capacitance probe 2

2T+, 2T- Digital communications connections from capacitance probe 2

FO1 First Out annunciation line voltage input 1

FO2 First Out annunciation line voltage input 2

FO3 First Out annunciation line voltage input 3

FO4 First Out annunciation line voltage input 4

FO5 First Out annunciation line voltage input 5

FO6 First Out annunciation line voltage input 6

FO7 First Out annunciation line voltage input 7

FO8 First Out annunciation line voltage input 8

FO9 First Out annunciation line voltage input 9

FO10 First Out annunciation line voltage input 10

FO11 First Out annunciation line voltage input 11

FO12 First Out annunciation line voltage input 12

PF Power feed 2A output (230V/110)

FO13 First Out annunciation line voltage input 13

FO14 First Out annunciation line voltage input 14

FO15 First Out annunciation line voltage input 15

HAI External high water auxiliary input

1AI External 1st low water auxiliary input

2AI External 2nd low water auxiliary input

M/R System alarm mute/reset

TST System test alarm inputs/ shunt switch

1 Technical Specifications

Page 6 Mk8 MM Expansion Features Installation and Set-Up Guide 04.09.2016

NC Unused – do not connect

TB Switched neutral – top blowdown contactor

TBI Switched neutral – drives top blowdown servomotor clockwise

1LV Switched neutral – 1st low water visual alarm

H1A Switched neutral – 1st low/ high water audible alarm

2LV Switched neutral – 2nd low water visual alarm

2LA Switched neutral – 2nd low water audible alarm

HWV Switched neutral – High water visual alarm

BB Switched neutral – Bottom blowdown contactor

BFW Switched neutral – Feed water pump contactor

MVI Switched neutral – drives feed water servomotor clockwise

MVD Switched neutral – drives feed water servomotor counter clockwise

TBD Switched neutral – drives top blowdown servomotor counter clockwise

DCI Switched neutral – drives draught control servomotor clockwise

DCD Switched neutral – drives draught control servomotor counter clockwise

2 Expansion Options

04.09.2016 Mk8 MM Expansion Features Installation and Set-Up Guide Page 7

2 EXPANSION OPTIONS

The Options, Parameters and Expansion Options must only be changed by factory

trained and certified technicians who have a thorough appreciation of the Autoflame

combustion systems and the combustion process in general. Any person changing these

settings without the correct factory training and understanding of the boiler plant may

place themselves and others in a potentially dangerous situation.

CH1, CH2, CH3, CH4, CH5, CH6 and CH7 refer to the rows of buttons respectively

start with CH1 at the top.

The options, parameters and expansion options are all viewable while the MM is in run mode. In

commissioning mode, all of the options, parameters and expansion options can be adjusted according

to the application. Non safety-critical options, parameters and expansion options can be adjusted

through Online Changes.

Press in the Commission Mode screen to access the Expansion Options. Any number of

expansion options can be changed at on time. By pressing WLC, TBD, BBD, DC, Modbus FO and Flow

at the bottom of the screen, the expansion options can be grouped together by feature.

When the changes have been made to suit the application’s needs, press Exit to go back to the

Commission Mode screen.

To set all the options, parameters and expansion options to the default values and erase the

commissioning data, set option/ parameter 160 to 5. The MM will then automatically restart.

Note: The Expansion Feature must be unlocked by sending the code for that MM via

Download Manager. Please see PC Software Guide on unlocking Expansion Features.

Unlockable Software Feature Part Number

Autoflame Water Level MK8001

Analogue Water Level (requires Autoflame Water Level) MK8002

Top Blowdown MK8003

Bottom Blowdown MK8004

Draught Control MK8005

Direct Modbus MK8006

First Out Annunciation MK8007

Fully Metered Combustion System MK8008

Heat Flow (Steam Flow + Hot Water Flow) MK8009

2 Expansion Options

Page 8 Mk8 MM Expansion Features Installation and Set-Up Guide 04.09.2016

Exp

Option Default Range Description

1 0 Water Level Control Function

Expansion feature 1 must be unlocked on the MM For setting 1, there must

be a minimum of two level sensing elements or a conflict will appear. For

the possible water level sensing device combinations, please see section

3.3. The capacitance probes with/without external level sensor will be

commissioned at end of probe, second low, first low, control point and high

water.

0 Water level control disabled

1 Water level control enabled

2 0 Feedwater Control Element

The feedwater pump will turn on and off at the according to the levels set

relative to the control point, through expansion options 10, 11 and 12. For

setting 0, water going to the boiler is only controlled by the feedwater

pump output terminal BFW. For settings 1 and 2 the MM controls the

feedwater via a PID loop, see expansion options 13, 14, 15, and 16. For

setting 1 the MM uses the servomotor on terminals P-, FW, P+, MVI and

MVD. For setting 2 the MM uses the VSD on terminals I+, V+ and IV-.

0 Pump on/off only

1 Pump on/off and servomotor control

2 Pump on/off and VSD control

3 0 Capacitance Probes

If water level control is enabled, the MM will require a minimum of two

level sensing elements. For the possible water level sensing device

combinations, please see section 3.3.

0 Capacitance probes disabled

1 One capacitance probe

2 Two capacitance probes

4 0 External Level Sensor

The external level sensor is wired to terminals EX- and EX+ and will give a

4-20mA signal. The readings can be scaled in expansion options 30 and

31. If an external level sensor is used, then a 4-20mA signal for fuel flow

feedback cannot be enabled (option 57) and fully metered combustion

control cannot be enabled (expansion option 140). For the possible water

level sensing device combinations, please see section 3.3.

0 Disabled

1 Enabled

5 0 Auxiliary Alarm Inputs

For setting 1, the auxiliary alarm mains inputs terminals HAI, 1AI and 2AI

are used in addition to the capacitance probes with/without external level

sensor readings. For the possible water level sensing device combinations,

please see section 3.3.

0 Auxiliary alarm inputs disabled

1 Auxiliary alarm inputs enabled

6 0 Second Low Probe

For setting 0, it is recommended that an auxiliary second low mains input is

wired to terminals 2AI. For setting 1, the Autoflame conductive second low

probe is wired to terminals 4P-, 4P+, 6T- and 6T-. Please see local codes/

regulations for second low probe and auxiliary second low alarm setup.

For the possible water level sensing device combinations, please see

section 3.3.

0 Second low probe disabled

1 Second low probe enabled

2 Expansion Options

04.09.2016 Mk8 MM Expansion Features Installation and Set-Up Guide Page 9

Exp

Option Default Range Description

7 0 Pre-High Alarm Percentage

The pre-high alarm level is at percentage between the control point and

high water, with the control point being referring to 0% and the high water

referring to 100%. For setting 0 there is no pre-high alarm and for settings

higher than 1, the MM will generate an alarm if the water level reaches this

% value between the commissioned control point and high water. For

example, if this is set to 45%, then a pre-high alarm will occur if the water

level rises to 45% between the control point and high water level.

0 Disabled

1 – 99 1% - 99%

8 0 Pre-First-Low Alarm Percentage

The pre-first-low alarm level is at percentage between the control point and

first low, with the control point being referring to 0% and the first low

referring to 100%. For setting 0 there is no pre-first-low alarm and for

settings higher than 1, the MM will generate an alarm if the water level

reaches this % value between the commissioned control point and first low.

For example, if this is set to 45%, then a pre-first-low alarm will occur if the

water level drops to 45% between the control point and first low level.

0 Disabled

1 – 99 1% - 99%

9 0 Burner Operation at High Water

For setting 0, the burner will continue to fire at high water. For setting 1 the

burner will stop firing at high water. Expansion option 10 sets whether the

pump turns off above the control point or high water.

0 Burner runs at high water

1 Burner stops at high water

10 0 Pump Turn Off Point

The water level at which the pump turns off is set as a percentage above

the control point for setting 0, or above the high water for setting 1, see

expansion option 11.

0 Pump turns off above control point

1 Pump turns off above high water

11 30 Pump Turn Off Percentage

When the water level reaches this percentage of the control point or high

water, depending on how expansion option 11 is set, the pump will turn

off. If expansion option 11 is set to 0, then this percentage will be between

the control point and high water. If expansion option 11 is set to 1, then

then this percentage is above high water, and should not be set more than

a safe top of the probe level.

0 – 100 0% - 100%

12 10 Pump Turn On Percentage

When the water level dro

p

s the control

p

oint, the

p

um

p

will turn on

at this percentage in between the control point and first low.

0 – 100 0% - 100%

2 Expansion Options

Page 10 Mk8 MM Expansion Features Installation and Set-Up Guide 04.09.2016

Exp

Option Default Range Description

13 50 Feedwater Control Proportional Band

The proportional band is set as a percentage between the control point and

first low where the PID control will make corrections to the feedwater going

to the boiler to maintain the control point. The feedwater control will act on

servomotor or VSD depending on how expansion option 2. The control

point represents 0% and first low represents 100%, so it is possible to set

the feedwater control proportional band to a water level below the first

low. If the water level is outside of the proportional band, then the

feedwater servomotor will remain fully open.

0 Disabled

1 – 200 1% - 200%

14 20 Feedwater Control Integral Time

The integral element in the feedwater control will make corrections to the

feedwater via the servomotor or VSD, depending on expansion option 2.

For a slower response, increase the integral time. For a quicker response in

critical steam applications to avoid the water level reaching first low,

decrease the integral time. However if overshoot occurs and the water level

rises to above the control point and this is not desired, then the derivative

element will need to be enabled, see expansion option 15.

0 Disabled

1 – 1000 Seconds

15 0 Feedwater Control Derivative Time

The derivative element in the feedwater control is suitable for applications

requiring a quick response but the water level should not rise too high

above the control point. For example, if the burner is set to stop firing at

high water in expansion option 9 and high water is commissioned not too

far above from control point, then overshoot is undesirable in a critical

steam application, as the burner would stop firing.

0 Disabled

1 – 1000 Seconds

16 900 Feedwater Servo Open Angle

The feedwater servomotor closed position is set by zeroing the

potentiometer in commissioning mode. As default the servomotor is set as

fully open, however this setting can be decreased to shorten the

operational movement range of the servomotor.

100 – 900 10.0O– 90.0O

17 0 Pump Bypass Operation

The pump bypass (terminal TB) will turn on at the switch point set as a % of

the open range of the valve, and will turn off at an offset from the switch

point, set as the bypass hysteresis, see expansion options 18 and 19.

However if the pump is turned off, then the pump bypass will also be turned

off. For setting 1, the pump bypass hysteresis is below the switch point, so

the pump bypass will turn off at an offset below the switch point. For setting

2, the pump bypass hysteresis is above the switch point, so the pump

bypass will turn off at an offset above the switch point.

0 Pump bypass disabled

1 Pump bypass on above switch point

2 Pump bypass on below switch point

18 20 Pump Bypass Switch Point

The bump bypass switch point is set as a percentage of the valve open

range set in expansion option 16.

5 – 95 5% - 95%

Other manuals for Mk8 MM

3

Table of contents

Other AUTOFLAME Controllers manuals