OVERVIEW

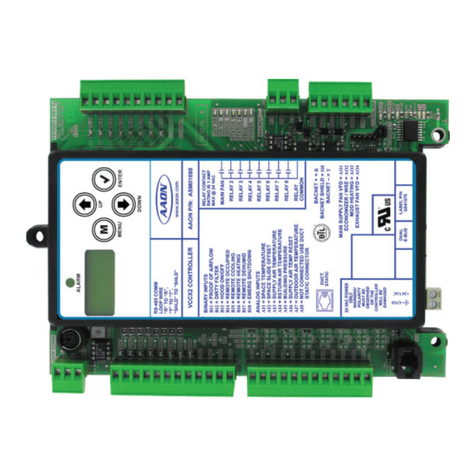

6VCCX2 Controller Technical Guide

System Features

Features

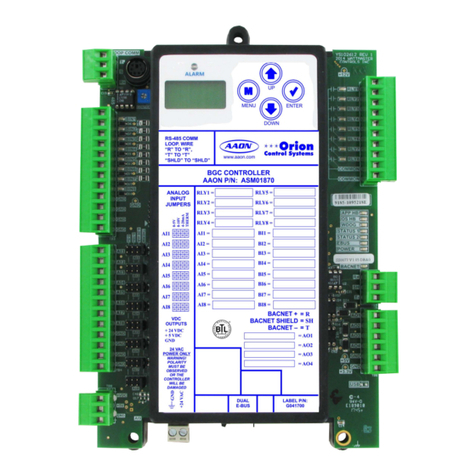

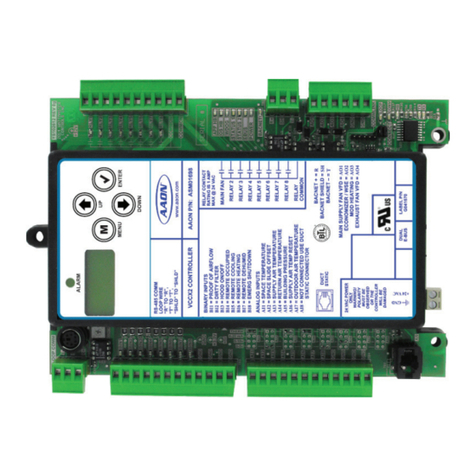

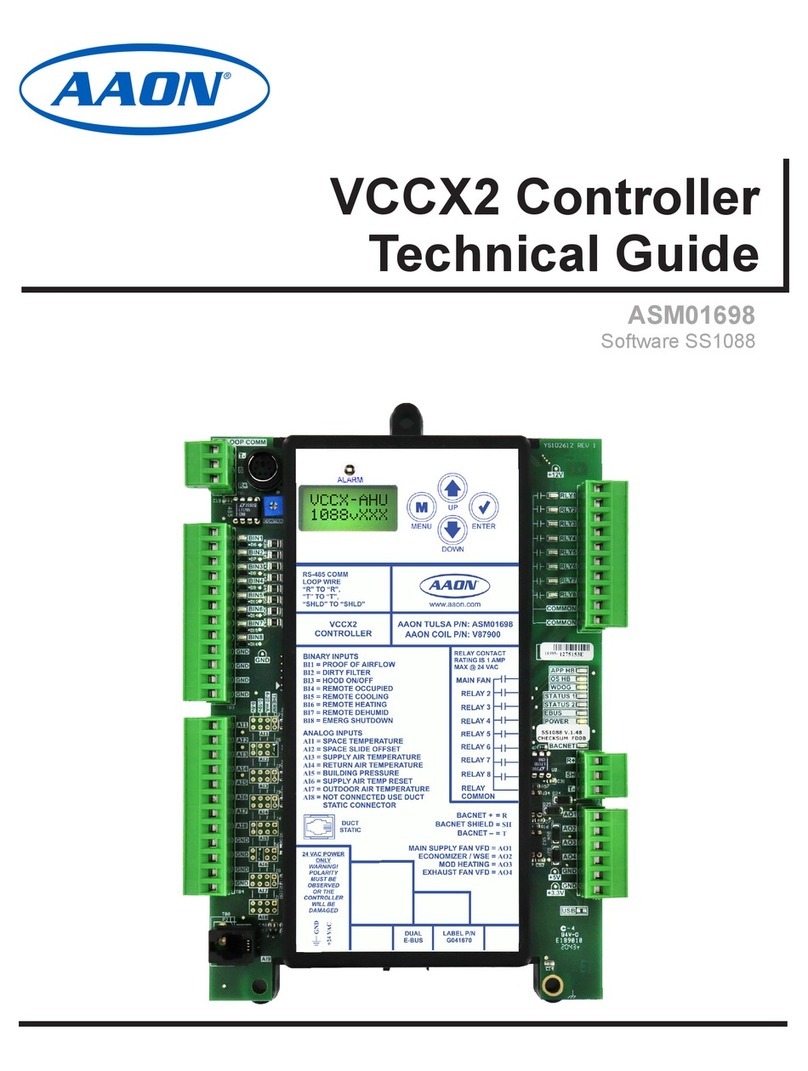

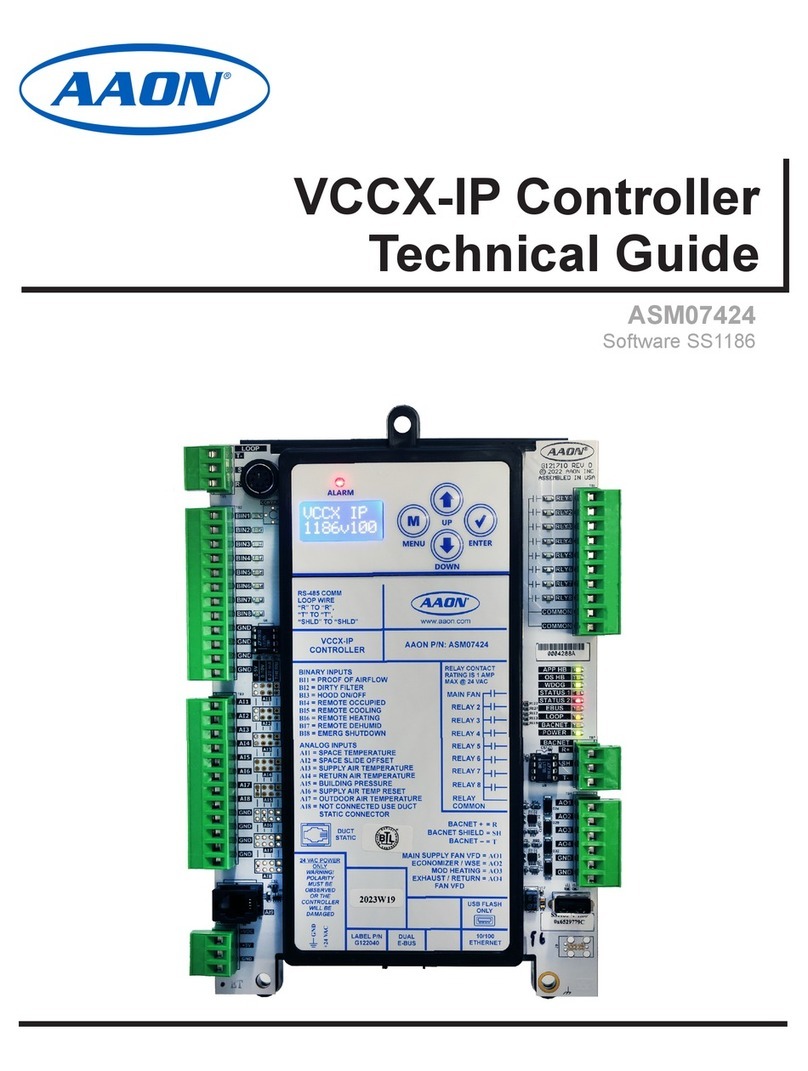

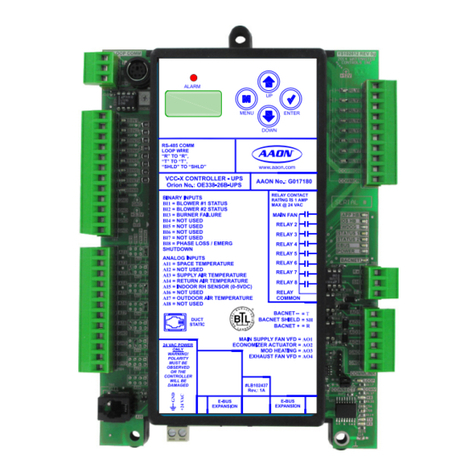

The VCCX2 Controller is designed with 8 analog inputs, 4 analog

outputs, 8 binary inputs, and 8 relay outputs (7 confi gurable). It also

has an on-board BACnet® port for connection to an MS/TP network.

The Controller contains a 2 x 8 LCD character display and 4 buttons

that allow for status and alarm display, force modes, and BACnet®

confi guration.

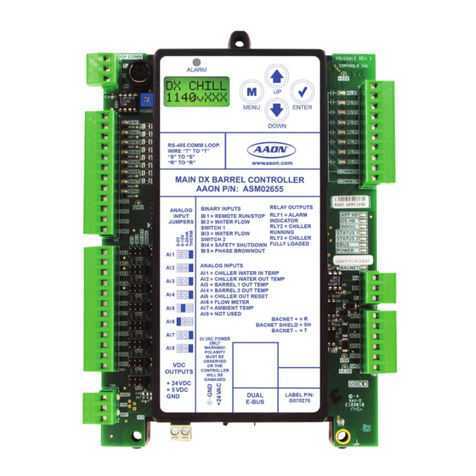

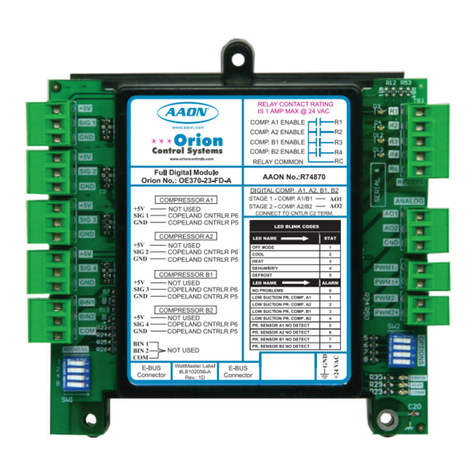

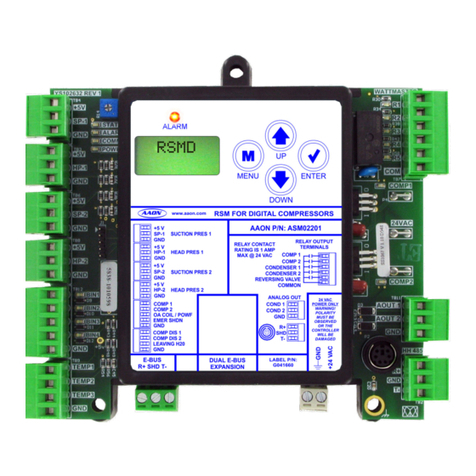

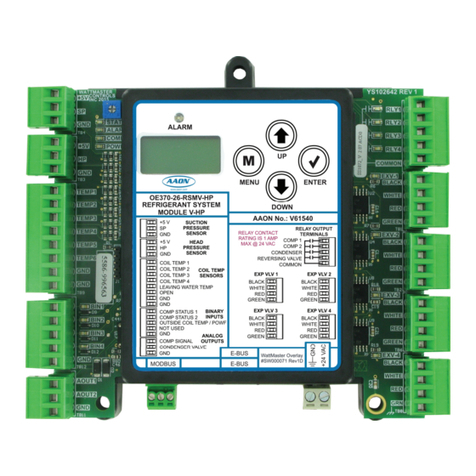

The VCCX2 Controller can communicate with the Refrigerant

System Module for VFD Compressors, Refrigerant System Module

for VFD Compressors - Heat Pump, Refrigerant System Module

for Digital Compressors, and Refrigerant System Module for a

Single Digital Compressor. In addition, the VCC-X EM1 Expansion

Module and 12 Relay E-BUS Expansion Module provides additional

specifi cally dedicated inputs and outputs.

There are also 2 E-BUS Expansion connectors on the VCCX2 which

allow for the connection of the expansion modules listed above,

as well as communicating sensors, and future E-BUS Modules

via modular E-BUS cables. There are presently 7 communicating

sensors available. Two of these sensors have LCD displays: E-BUS

Digital Space Temperature Only Sensor or E-BUS Digital Space

Temperature and Humidity Sensor. There is a communicating E-BUS

Space Temperature and Humidity Sensor with no LCD display as

well as an E-BUS Space CO2 Sensor, and E-BUS Duct CO2 Sensor,

each with no LCD display. Also available are the E-BUS Horizontal

or Vertical Outdoor Air Temperature and Humidity Sensor and the

E-BUS Return Air Temperature and Humidity Sensor.

The VCCX2 Controller provides for the following applications:

Constant Volume, VAV, Single Zone VAV, Make-up Air, and Space

Temperature Control of High Percentage Outdoor Air.

Other features of the VCCX2 include:

• Controls up to 8 Digital Compressors

• Controls up to 4 sets of tandem VFD Compressors

• Controls up to 12 stages of Heat

• Modulating Cooling Output for Chilled Water

Valve Control

• Modulating Heating Output ( Hot Water Valve,

Steam Valve, SCR Electric Heat Control)

• Full Integration with the AAON® Refrigerant

System Modules

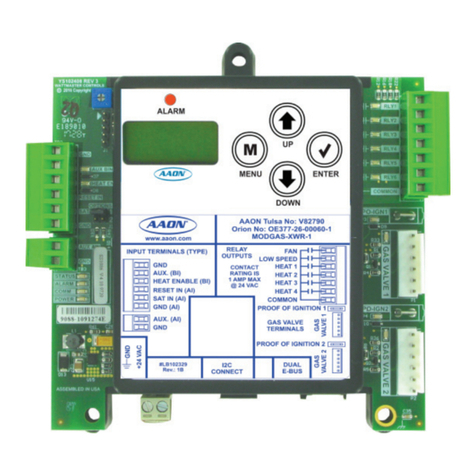

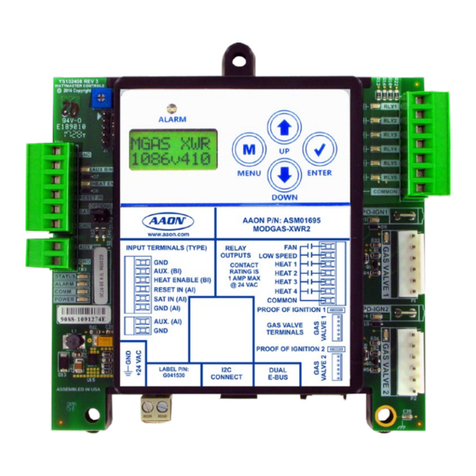

• Full Integration with the AAON® MODGAS-X

Modulating Natural Gas Controller

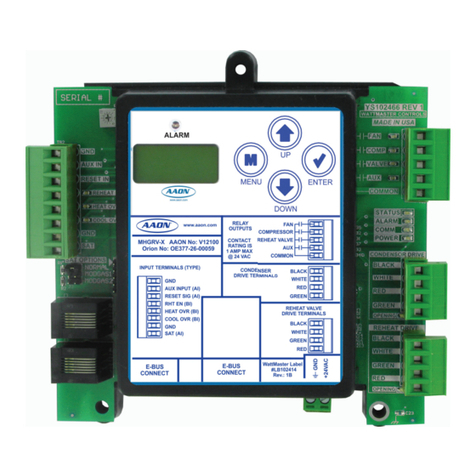

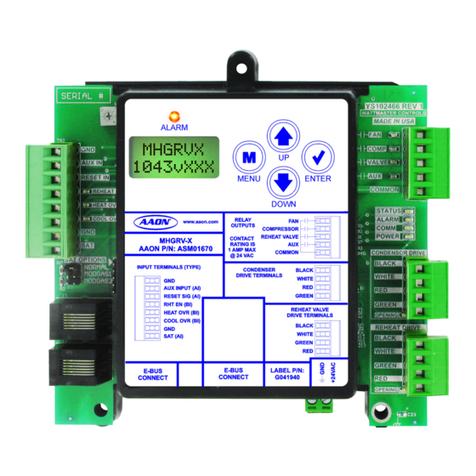

• Full Integration with the AAON® MHGRV-X

Modulating Hot Gas Reheat Valve Controller

• Full Integration with the AAON® PREHEAT-X

Controller

• Advanced Dehumidifi cation Capabilities

• Air to Air Heat Pump and Water Source Heat Pump

applications

• Air Flow Monitoring of Outdoor Air, Supply Air,

Return Air, and Exhaust Air Streams with approved

EBTRON®, GreenTrolTM, or Paragon Airfl ow

Monitoring Stations

• Air Flow Control of Outdoor Air Damper

• Single Zone VAV Control w/Optional CAV Heating

• Primary/Secondary Heating Control

• Remote Forced Cooling, Heating, and

Dehumidifi cation Control

• Remote Supply Air Temperature Reset Signal

• Adaptive Supply Air Temperature Reset

• Selectable Mode Enable Sensor

• Fan Proving Interlock

• Dirty Filter Alarm

• Emergency Shutdown Input (Smoke Detector/

Firestat or other Shutdown Conditions)

• Drybulb/Wetbulb/Dewpoint Control of Economizer

Operation

• Waterside Economizer Capability

• Building Pressure Control (Direct or Reverse

Acting)

• Exhaust Duct Static Control of Exhaust Fan

• Remote Forced Occupied Capability

• Confi gurable for AAON® Return Air Bypass

Applications

• IAQ Economizer Reset

• Title 24 Economizer Certifi ed

• 7-Day, 2-Event-per-Day Scheduling

• 14 Holiday Event Scheduling

• Daylight Savings Time Adjustment

• Trend Logging Capability

• Static Pressure Control for Filter Loading

Applications

• Heat Wheel - On/Off Control

• Head Pressure Control

• On-board BACnet® port for connection to an

MS/TP network (See Appendix C)