Controlli S.p.A.

16010 Sant’Olcese (GE)

Tel. 010 73 06 1

Fax. 010 73 06 870/871

www.controlli.eu

MVH56EA/C

Valve Actuators

with Emergency Return Device

Feedback Signal

The actuator utilizes a 2-10V position feedback (look at DIP n. 1 set-

tings).

Calibration

The actuator has both Auto and Manual Stroke Calibration, DIP n.

7. In factory delivery the auto stroke calibration is enabled; manual

calibration is not necessary unless maintenance is required on the

valve or certain alarm functions are desired.

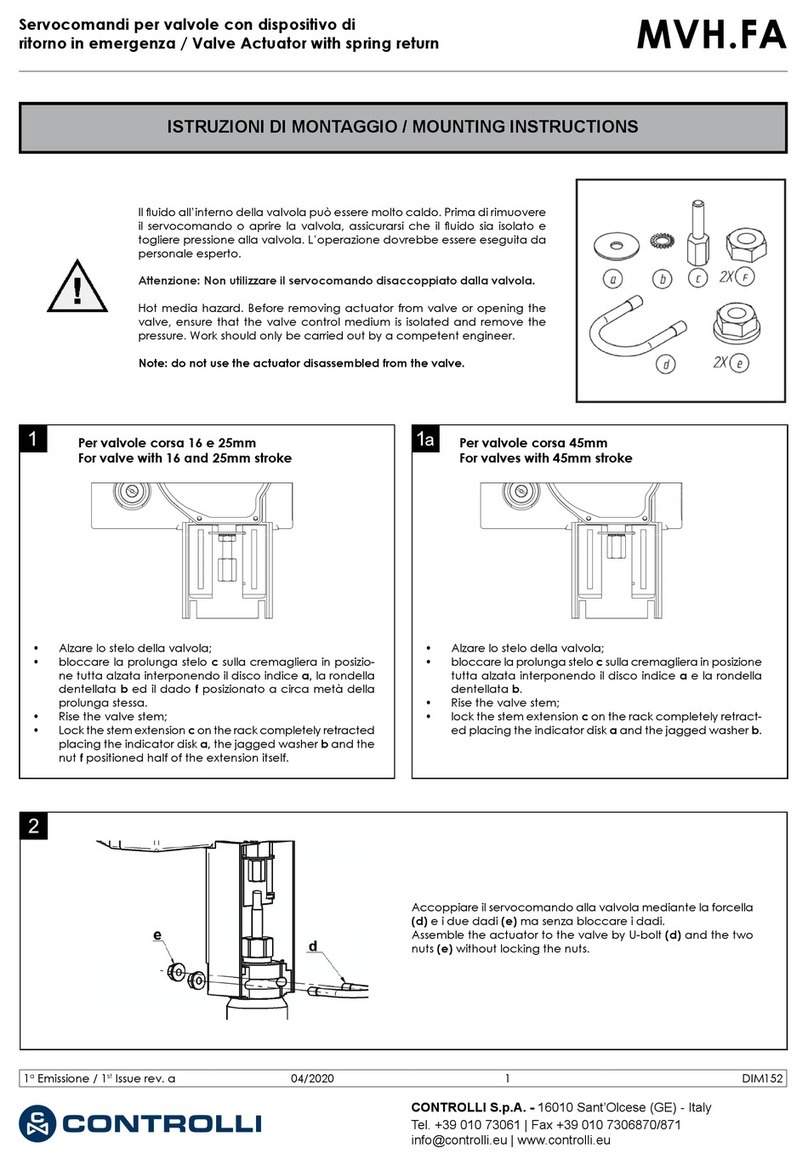

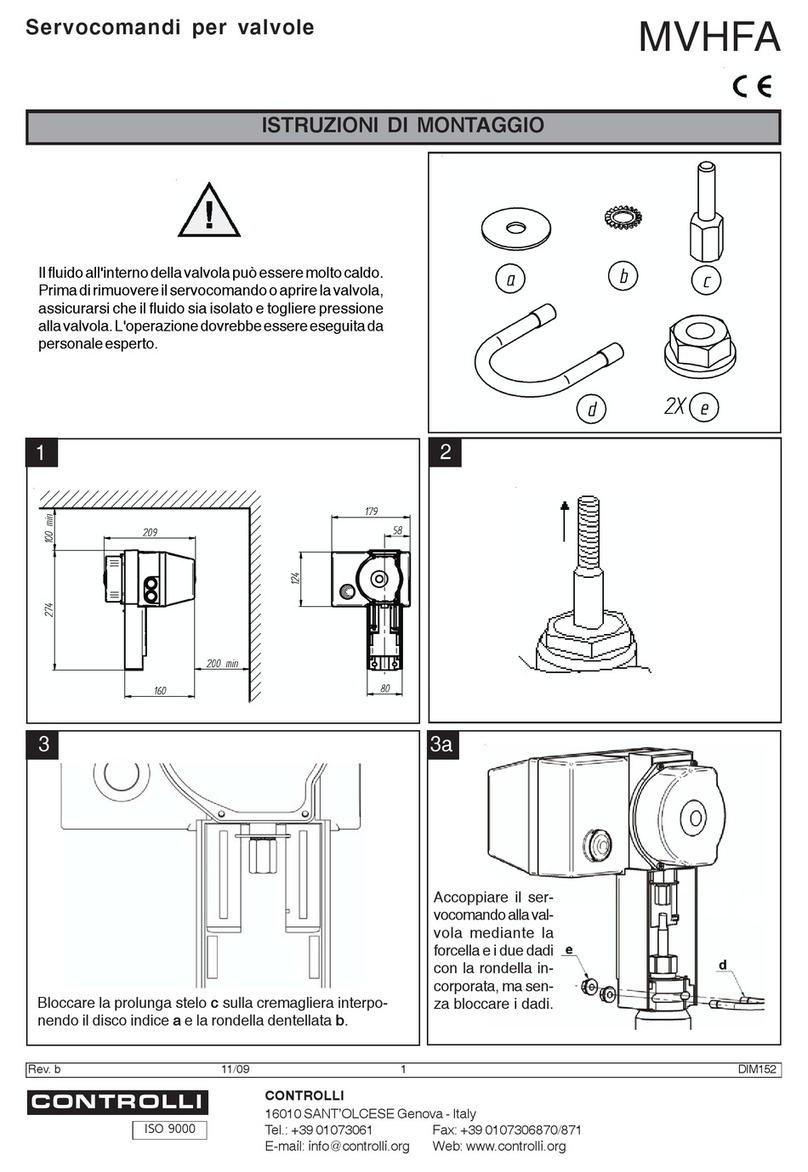

They are provided with a spring device which, in case of power loss,

makes the actuator return to the rest position.

MANUFACTURING CHARACTERISTICS

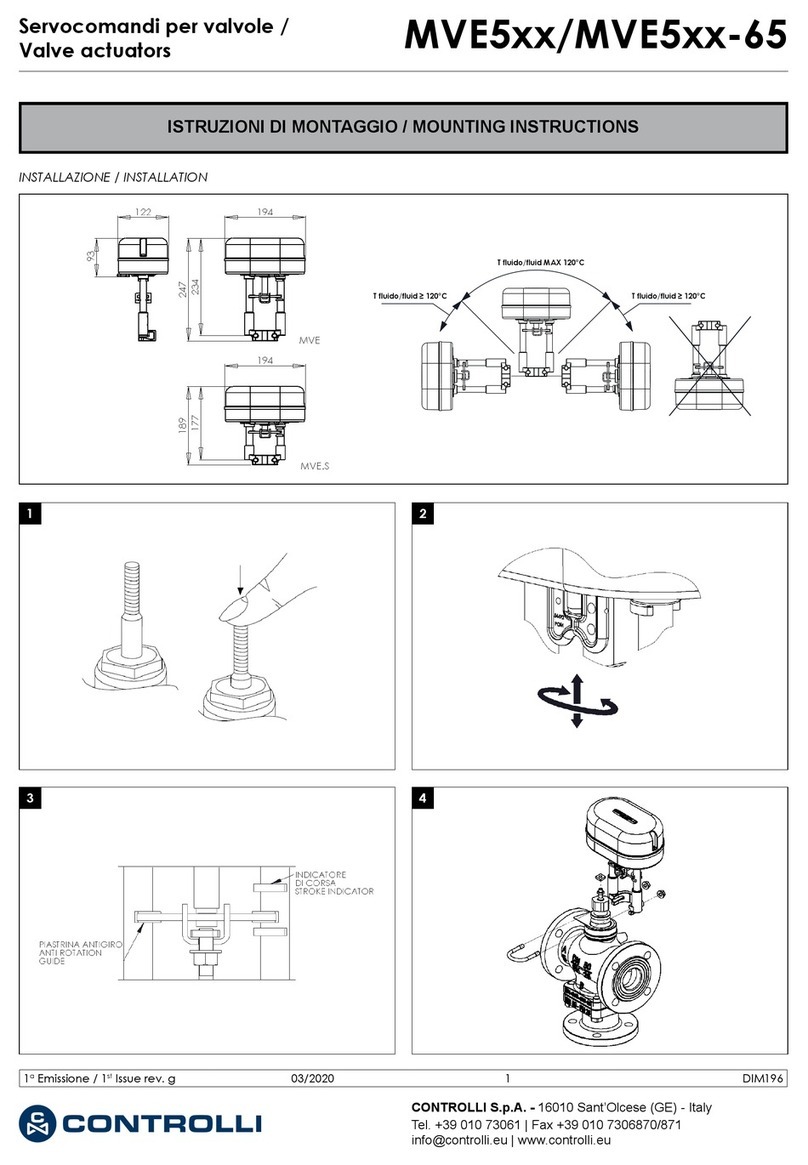

The actuator consists in a die-cast aluminium housing, which includes

the mounting bracket for connection to valve body.

Reduction gears supported by ball bearings. Movement is transmit-

ted to a rack-and-pinion mechanism connected to the valve stem

through a suitable joint.

Internal electronic card with easily accessible terminals for electrical

connections. Spring return device consisting of a at spring placed

outside the main shaft.

End Point Auxiliary Switches (accessory DMVH)

End point switches change over when the valve is fully open or clo-

sed. They are free contacts with 24Vac max voltage on terminals.

End point switches can be utilized to indicate valve stroke end posi-

tions and for relay control of additional plant equipment.

When the actuators are controlled individually or in sequence, it is

possible to use the end switches to toggle when the valve is fully

open or fully closed. The auxiliary switch position according to con-

trol signal (Y) is shown in the next table.

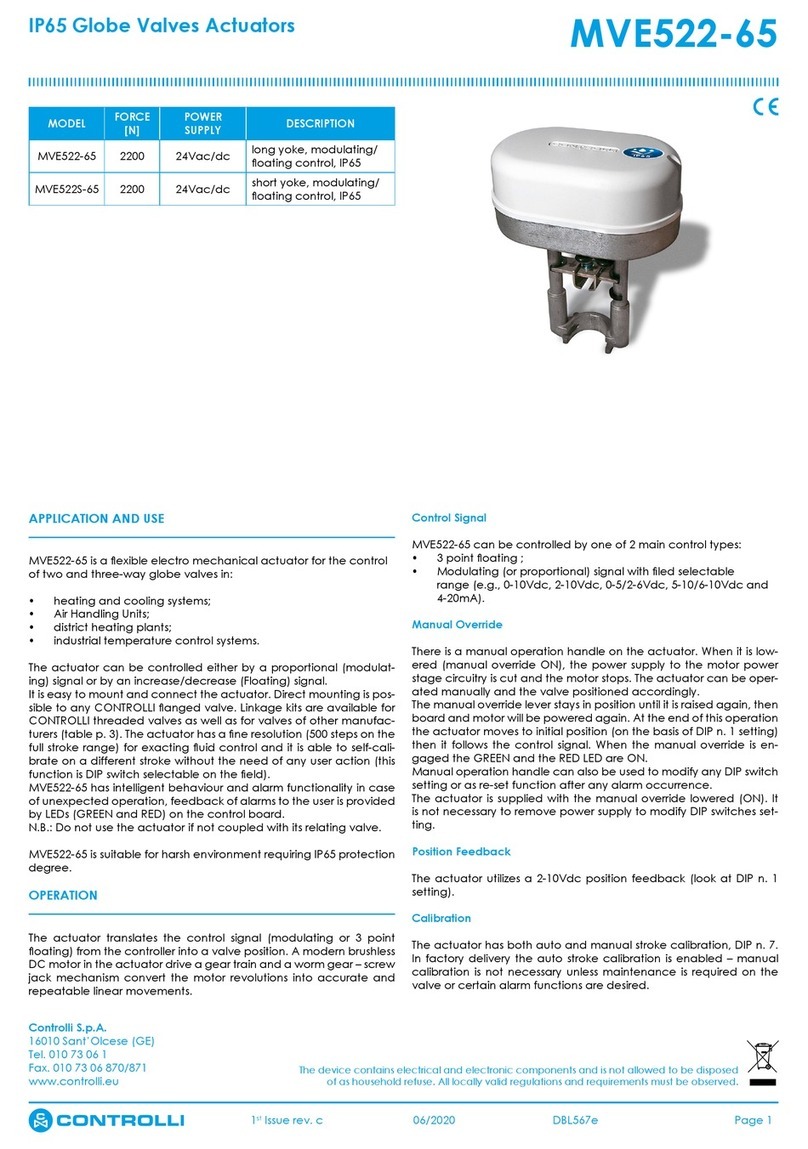

MODEL FORCE

[N]

POWER

SUPPLY DESCRIPTION

MVH56EA 700 24Vac/dc

Modulating/oating with

emergency return device

with retracted joint (valve

stem up)

MVH56EC 700 24Vac/dc

Modulating/oating with

emergency return device

with extended joint (valve

stem down)

APPLICATION AND USE

MVH56Ex is a exible electro-mechanical actuator for the control of

two and three way globe valves in:

• Heating and Cooling systems

• Air handling units

• District Heating plants

• Industrial Temperature Control systems.

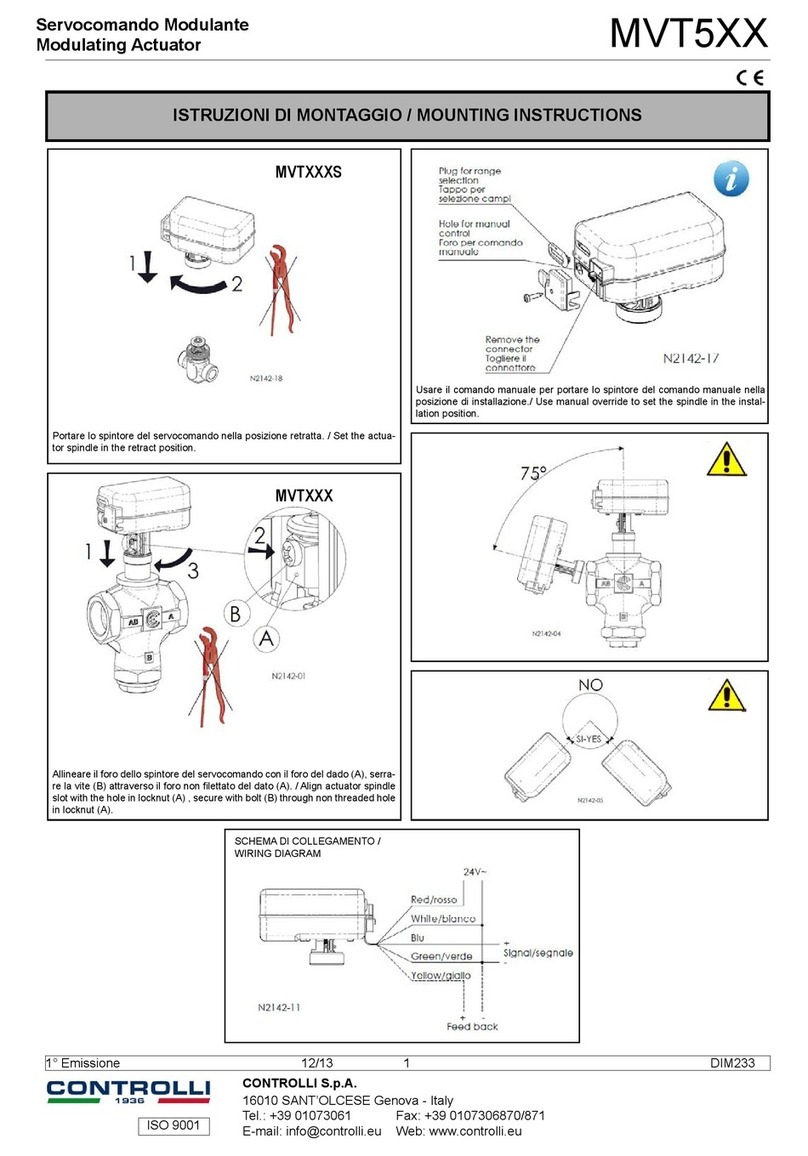

MVH56Ex can be controlled either by a proportional (modulating)

signal or by an increase/decrease (oating) signal.

It is easy to mount and connect the actuator. Direct mounting is pos-

sible to any CONTROLLI anged valve. Linkage kits are available for

CONTROLLI threaded valves as well as for valves of other manufactu-

rers (contact our technical Dept.). The Actuator has a ne resolution

(500 steps on the full stroke range) for exacting uid control and it is

able to self-calibrate on a different stroke without the need of any

user action (this function is selectable on the eld via DIP switch).

MVH56Ex has intelligent behaviour and alarm functionality in case of

unexpected operation; feedback of alarms to the user is provided

by two LEDs (GREEN and RED) on the control board.

N.B.: Do not use the actuator if not coupled with the valve.

OPERATION

The actuator translates the control signal (modulating or 3 point oa-

ting) from the controller into a valve position. A modern brushless DC

motor in the actuator drive a gear train and a worm gear – screw

jack mechanism convert the motor revolutions into accurate and

repeatable linear movements.

Control Signal

MVH56Ex can be controlled by two main control types.

• 3 point oating ;

• Modulating (or proportional) signal with led selectable range

(e.g., 0-10Vdc, 2-10Vdc, 0-5/2-6Vdc, 5-10/6-10Vdc e 4-20mA.)

1st Issue rev. d 08/2020 DBL465e Page 1

The device contains electrical and electronic components and is not allowed to be disposed

of as household refuse. All locally valid regulations and requirements must be observed.