AutoGate Shield M50 Series User manual

1.800.944.4283 AutoGate Technical Support Mar 6, 2019

AutoGate, Inc.

Installaon & Operaon Manual

Vercal Pivot Shield®Crash Systems

ASTM F2656 M30-P1, M50-1

M30 Models: VPCB-M30 & VPCM-M30SF

M50 Model: VPCB-M50

7306 Driver Road, P.O. Box 50, Berlin Heights, OH 44814

PH: 1.800.944.4283 - FAX: 419.588.3514 - www.AutoGate.com

AG#____________

1.800.944.4283 AutoGate Technical Support Mar 6, 2019

2

MANUAL

MODELS VPCB-M30, VPCB-M30SF & VPCB-M50

1.800.944.4283 AutoGate Technical Support Mar 6, 2019

3

Table of Contents

Safety & Helpful Information

Orientation

Standard Specifications

Operator Details

Operator Glossary / Terms

Basic Components of A SHIELD CRASH System Foundation

Left & Right Typical Pad Layouts

Typical Loop Configuration

Site Planning

Site Preparation

Bolster Planning & Installation

Receiving, Unloading, & Handling Your System

Preparation, Attaching the gate & Operator Installation

Gate Guards, Signs & Reflective Tape

Operator Electrical, Grounding & Battery

Genesis Control Board

Operator Wiring Diagram

Safety & Helpful Information

Genesis Board Connections

Entrapment Protection Device Functional Characteristics

Genesis Board Programing

Genesis Frequently Asked Questions (FAQ’S)

Troubleshooting the GENESIS Board

Accessory Components

Maintenance

End User / Installer Check-off List

4-5

6

7

8

9

10

11

12

13-15

16

17-20

21

22-27

28-29

30-31

32

33

34-35

36-40

41

42-48

49-50

51

52

53-57

58-60

1.800.944.4283 AutoGate Technical Support Mar 6, 2019

4

IMPORTANT SAFETY INFORMATION FOR INSTALLERS AND OWNERS

Read all of this manual and all product safety information prior to installation. AutoGate Shield CRASH Barri-

er M30 & M50 systems operators (hereafter referenced as Shield or VPCB (Vertical Pivot Crash Barrier))

move the fortified crash barrier Drop arm/gate with high force and can cause serious injury and death! All

Shield systems have fortified barrier arms. The terms barrier arm, drop arm and gate are synonymous in this

manual as some Shield systems are and can be ordered with a full size gate directly fabricated to the barrier

arm. Start the operator only when the travel path of the Shield arm is unobstructed and clear from making

any contact with personnel or any equipment. Make sure the Shield systems are installed to reduce the risks

of entrapment and are installed to comply with all safety standards, local and federal regulations, and all

manufacturer instructions.

Understand that you as the site designer, installer, maintenance crew, or owner/user must consider the risks

associated with the Shield operators. Be sure to take responsibility, read, and follow the Important Safety In-

formation in this manual and review all the literature that accompanies the product prior to installation.

Proper design is important in your system layout and installation. Entrapment protection devices must be

used at all points where injury or property damage may occur. For protection from injury to persons, use

Photo Electric Eye(s) and/or optional Pressure Sensing Edge on the leading edge of the gate and on the op-

erator housing. Loops (Vehicle Detectors) should be installed in front of and behind the gate to provide a re-

verse signal or stop signal to the gate operator. All entrapment protection and reversing devices should be

tested and inspected weekly. If any device appears to not operate correctly, the unit should be disabled until

repair can be made by a properly trained and experienced service company.

As the system installer, you must advise your customer on the correct usage of the barrier operator system

components. In providing the service of designer or installer of the operator and gate system, you are re-

sponsible for proper training of the customer as well as for the proper safe operation. All precautions to elimi-

nate hazards MUST be taken before the system can be put into operation. You MUST advise and warn your

customer of any hazards that remain. We highly recommend if they choose not to install any of the entrap-

ment protection and recommended reversing devices to not put the system into operation until safety and risk

concerns have been resolved and documented.

Check the National, State & Local Building and Fire Codes BEFORE installation as well as the project

plans and specifications.

Pedestrians must use a separate entrance/exit and never the vehicular entrance/exit gate.

This product operates under high force and serious injury and death can occur. AutoGate highly recom-

mends and strongly advises the use an proper installation of external entrapment protection devices.

If you did not order a Reversing Edge (for along the bottom rail of your gate or operator housing), or an

Photo Electric Eye(s) (Reversing Beam), you will NOT be in compliance with the intent and practices of

UL 325 Code. Consult your dealer for additional information.

NEVER activate the gate from where visibility of the gate cannot be seen. Anyone operating the gate

should always operate it in direct line of site and in a safe manner.

NEVER allow children or anyone to play on or around the gate at any time.

DO NOT attach anything to the gate over 4 pounds total weight or 4 square feet without consulting Auto-

Gate for approval and balancing instructions. The gate must remain balanced to ensure safe and reliable

operation.

1.800.944.4283 AutoGate Technical Support Mar 6, 2019

5

SECTION 1 — SAFETY

product can you to which are to the State of

or birth defects or other information to

www.P65Warnings.ca.gov

ELECTRICAL

CAUTION

WARNING

NOTE

Be aware of and follow the safety standards of the Occupational Safety and Health Administration

(OSHA), as well as any applicable Federal, State, Local Project Specification and Industry Standards or

Procedures.

Only experienced personnel are to install, operate and maintain the equipment. Serious injury or equip-

ment damage can occur if installed or operated by untrained personnel. Installers of the equipment must

follow the specific instructions and safety precautions located in this manual.

At NO time should the Drop arm/gate be modified in any way. Under NO circumstances should you drill

into the Drop arm/gate Housing with prior written authorization from AutoGate.

Do not add any additional weight to the Drop arm/gate or applicable gate panel without first contacting

AutoGate. This can affect the balancing and operation of the system.

Always keep people, equipment and objects away from all moving parts and entrapment/pinch points of

the system. NO PERSON OR OBJECT SHOULD CROSS THE PATH OF THE MOVING GATE.

Test the operator monthly. The drop arm/gate MUST reverse on contact with a rigid object or stop when

an object activates the non-contact sensors or contact sensor. After adjusting the force or the limit of trav-

el, reset the operator. Failure to adjust and reset the operator properly can increase the risk of injury or

death. Never use the gear motor release/engage lever when the gate is moving and not powered down.

This gate system is for vehicles only. PEDESTRIANS MUST USE A SEPARATE ENTRANCE!

SAVE THESE INSTRUCTIONS

The Shield can produce high levels of force. It is very important that all installers and designers are fully

aware of potential hazards that exist with incorrectly installed or designed systems. The internal safety

capabilities of a gate operator system are not enough to remove the risk of injury. The operator is only

one part of a properly installed system which when combined with correctly installed reversing devices,

will yield a system that will not only provide convenience and security, but will be safer and minimize risk

of injury. These instructions are to make you aware of potential areas that are of a safety concern. Disre-

garding any of the following may result in Serious Injury or Death!

REDUCE RISK

REVIEW

When you see these Safety Symbols and Signal Words on the following pages, they

will alert you to the possibility of serious injury or death if you do not comply with

the warnings. The hazard may be something mechanical or from electric shock.

Read the warnings carefully to avoid personal injury, they will alert you to the pos-

sibility of damage to your drop arm/gate and/or the gate operator if you do not

comply with the cauonary statements that accompany it. Read them carefully.

IMPORTNT NOTE:

BEFORE aempng to install, operate or maintain the operator, you must read and fully understand

this manual and follow all instrucons.

DO NOT aempt to repair or service your gate operator unless you are experienced service technichian

or a factory trained Service Technician.

!

1.800.944.4283 AutoGate Technical Support Mar 6, 2019

6

ORIENTATION

The Shield® VPCB (Vertical Pivot Crash Barrier) systems have many features that make it effective, reliable,

and easy to use, and some of these important features are summarized in this manual. Note that not all

systems are identical as width, gate panel implementation, finish, accessories such as lights, and other auxil-

iary component options vary order to order. The most notable visual difference in crash models are the foun-

dation and bolster design. Drop arm only or those with gates are common and optional for all models. They

can be outfitted with full gate panels are typically comprised of chain link, ornamental, industrial, high-security

and anti-climb fencing to add anti-personel entry along with your forced entry denial.

The Shield® M30 is available in two different foundation depths. Model VPCB-M30 is our standard founda-

tion and has a depth of 54”. Model VPCB-M30-SF is our Shallow Foundation and has a depth of only 20”.

The Shallow Foundation is ideal for locations with utilities that cannot be disturbed, high water tables, and

locations that cannot otherwise support our standard foundation depth. Our VPCB-M50 has one foundation

size and a depth of 66”.

Model VPCB-M30 Standard Foundation (54”

depth) with full gate panel

Model VPCB-M30 Standard Foundation (54”

depth) with Drop arm only

Model VPCB-M30-SF Shallow Foundation (20”

depth) with Drop arm only

Model VPCD-M50 (shown with full gate panel)

Standard Foundation 66”

ORIENTATION

1.800.944.4283 AutoGate Technical Support Mar 6, 2019

7

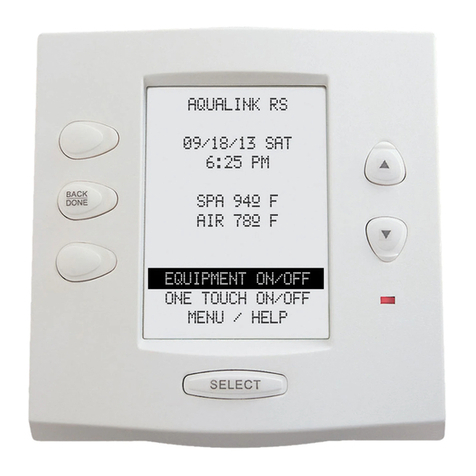

Genesis™ Control Board

Solid State coated programmable control board in an

electrical enclosure (Tested to –40° F).

Security Breach Protecon: Built in 24V brake when A/C

or baery is present. Oponal internal locking Solenoid

mechanism.

Built in sensor for real me barrier posion.

Monitored Inputs: Open - 2 inputs , Close - 2 inputs and an

addional (2) programmable inputs for Open or Close.

Programmable Inputs, Outputs, & Relays: The Genesis

board has 2 programmable inputs, 2 programmable out-

puts, and 2 built in relays for conguraon and integraon.

Control Wiring: 16 & 18 Ga. Single conductor. Copper

with electronic compression terminals n-plated for max

corrosion prevenon. Non-AutoGate components, accesso-

ries, and access control is per individual manufacturer

Instrucon. Contact AutoGate with quesons.

Delayed Closing: Programmable from 0 - 90 seconds.

Preempve outputs: 1 - 5 seconds before gate moves.

Motor & Drive System

RAD (Right Angle Drive): 1/2 HP, Gear Type, Right Angle

Locking Worm Drive, Mu Temp Synthec Lube, Equipped

with disengage lever for Manual Operaon.

Mul Belt/High torque dual reducon system, Counter Bal-

anced for smooth operaon.

Operator

Construcon: Frame - 2” Sq., 11 Ga. (.120). Mounng

pads—304 SS. Skins - 18 Ga. Galvanneal.

Gate Mounng Hardware: 304 Stainless Steel

Operator size: 68”Length, 52” Height, 39” Width

Paint: Standard Color - Black, powder coated. Spray

applied colors are Commercial Coang 2-part High Solids

Polyurethane. Standard Spray Colors: White, Brown,

Green, and Gray. Custom colors available.

VERTICAL PIVOT CRASH BARRIER SYSTEMS (VPCB)

MODEL VPCB-M30 (STD. FOUNDATION)

VPCB-M30-SF (SHALLOW FOUNDATION)

VPCB-M50 (STD. FOUNDATION)

PRODUCT SPECIFICATIONS

General Informaon

Rangs: ASTM F2656-07 Standard. M30/P1 & M50/P1 and

listed on the DoD An-Ram Vehicle Barrier List

Power Supply Opons: 120VAC—Single Phase, 20 Amp

Service. 240VAC—Single Phase, 10 Amp Service.

Baeries & Charging System: Built-in Baery Backup. Two

12v Baeries Required (Field Supplied). Recommended

Baeries: Group 24, Sealed Marine Starng

Arm Limit/Posion Sensor (LPS): Self aware of gate posi-

on at all mes. Open and Closed Limit Posions.

Open/Closing Speed: 12-14 seconds Std.

Shipping Weight: Typical (Includes Drop arm/gate system

and Bolsters) Gate & Operator wieght: 2000 lbs.

Bolsters:

VPCB-M30: 3,000 lbs.

VPCB-M30SF: 5,200 lbs.

VPCB-M50: 5,300 lbs.

Warranty: Industrial/Commercial (3 years) from date of

shipment on manufactured components workmanship.

Purchased components and accessories are covered under

their respecve warranes. (See full warranty for details)

Oponal Accessories: Loop Detectors, Gear Motor Heater,

Extreme Cold Package, MUTCD Reecve Tape, LED Warn-

ing lights, Audible Devices, and Emergency Access Systems

(SOS, Opcom, Click to Enter, Key Box/Switch, etc.)

Transport Maintenance Pin (T/M): used for transport,

maintenance to negate movement of Drop arm/gate panel)

Arm & Gate Construcon

Systems are available in barrier arm only for forced

vehicular entry denial and with a full gate panel fabricated

to the barrier arm for an-personnel capabilies.

Available clear open lengths: M30: 19’ with barrier arm

only and 17’ with gate panel fabricated to drop arm/gate.

M50: 17’ with barrier arm only and 15’ with gate panel

fabricated to drop arm/gate.

Barrier Arm Construcon: 6063 3/16” channel and 5052

3/16” plate. Locking Pins: 4140 Steel. Gate Construcon:

2 1/2” Sq. , 7 Ga. (.187) Aluminum Tubing.

Gate Max Length: 19’ Overall length (17’ clear open sec-

on).

Gate Heights: 6’ - 9’ from pad grade. Consult factory for

gates over 8’ high as they require special crang and

freight arrangements.

Picket Construcon: Aluminum—3/4” Sq. 1/8” wall is

standard. Note: Contact factory for special sizes, spacing,

and custom materials.

Chain Link Fabric: Steel 9 Ga. Alum Fabric is standard on

larger gates (Vinyl coated fabric available).

Drop Arm & Gate Paint: Spray applied colors are

Commercial Coang 2-part High Solids Polyurethane.

Standard Spray Colors: Black, White, Brown, Green, and

Gray. Custom colors available.

1.800.944.4283 AutoGate Technical Support Mar 6, 2019

8

1OPERATOR FRAME Main operator frame, 2” sq. steel tube construcon

2THROAT Area between the operator and false panel where the gate opens up

3TRANSPORT/MAINTENANCE PIN (T/M) Used for locking the arm in place with or without the gate aached

4 OPERATOR ARM Main 2” x 4” steel tube where the gate aaches

5STAINLESS STEEL FOOTPADS No messy rusty footpads

6KICK PANEL Prevents access under the operator and debris out

724VDC 90° RIGHT ANGLE DRIVE MOTOR (RAD) 1/2hp Gear motor drive to ensure safe and smooth operaon

8MANUAL OPERATION REALEASE LEVER Disengages the coupler and allows the gate to be raised by hand

9MOTOR DRIVE BELTS (3) High quality “A” Secon cogged belts...

10 MOTOR DRIVE BELT TENSIONER One shown, total of two

11 GATE BELT TENSIONER (Not shown, behind #12) Allows you to ghten the belts (Not shown behind the Drive Pulley)

12 INTERMEADITE DRIVE PULLIES Provides high torque to move the gate

13 GATE DRIVE BELTS (2) High quality V-belts to move the gate

14 MAIN GATE DRIVE PULLEY Provides high torque to move the gate

15 LIMIT/POSITION SENSOR (LPS) (behind #28) Digital Sensor that sets the open and close locaons of the gate

16 SLIDE ASSEMBLY Adjust the balancing up or down on the threaded rod (not pictured)*

17 T-BOLT ASSEMBLY Fine tuning of the balancing

18 CHAIN TENSIONING BOLT ASSEMBLY Roller chain aaches here

19 #80 ROLLER CHAIN Connects the springs to the Chain tension Bolt

20 SPRINGS (Qty. will vary on gate size and weight) Depending on gate size & weight, you can have 2 to 8 springs

21 REAR SPRING BARS Aaches the springs, Qty. will vary on the # of springs

22 BATTERIES ((2) required, not supplied) Min. 7Ah baeries, recommend Group 24 100Amp Marine Starng

23 BATTERY TRAY/POWER SUPPLY (Under Baery tray) Main Power Supply is mounted under the Baery Tray

24 3Amp AC Fuse AC Supply fuse

25 AC/DC MAIN ON/OFF SWITCH Turns on both the AC and DC power in one switch

26 INCOMING AC VOLTAGE JUNCTION BOX Normally 120Vac, 240Vac compable

27 FAULT LIGHT Three ash modes: 1. Fault, 2: DC Power issue, 3: AC power issue

28 CONTROL BOX Houses the Genesis control board and other accessory items

29 GENESIS CONTROL BOARD State of the art control board with 4-line digital display

30 UL325 SIREN Will be acvate upon an UL fault

* See Balancing Instrucons for Slide details

6

10

7

8

9

14

16

26

4

25

24

27

28

29

30

23

22

21 20 19

17

12

13

15

18

2

3

1

5

OPERATOR DETAILS

1.800.944.4283 AutoGate Technical Support Mar 6, 2019

9

he to low-

er) the Drop arm/gate.

he member of the operator the Drop arm/gate is

bolted to and lifts the Drop arm/

the

attach to and by adjusting up and or down

or subtracts tension to the of

of the Drop arm/ .

the public of

the protection from the

.

to the there no Drop arm/

A

installation work.

HP Motor The

motor shaft and output drive shaft are oriented at 90°

from each other. This type of drive for smoother

the movement not

drivable.

to the from the belt

or of the Drop arm/

(Limit/Position An electronic position sensor mounted on the main pulley

drive shaft that provides Drop arm/gate position feedback to

the control board. This component two a fea-

tures:

entrapment protection

obstructions that block stop the travel.

“open” limit positions

SECTION 2 — TERMS

1.800.944.4283 AutoGate Technical Support Mar 6, 2019

10

Operator End Bolster

Operator End Foundation

Yoke End Bolster

Yoke End Foundation

(rebar not shown in foundations)

Operator

Drop arm/gate (shown without optional gate

Operator End Bolster

Yoke End Bolster

1.800.944.4283 AutoGate Technical Support Mar 6, 2019

11

LEFTHAND OPERATOR

CONDUIT LOCATION/STUB-UP ON OUTSIDE OF OPERATOR PAD 12”

PUBLIC/ UNSECURE

SIDE

PRIVATE/SECURE

SIDE

PRIVATE/SECURED SIDE

120Vac, Minimum 20Amp Circuit

“Entrance” Keypad/Reader

“Exit” Keypad/Reader

Reversing Loop(s)

Free Exit Loop(s)

Oce Communicaon

Reversing Beam

Oponal

NOTES:

1) Pad Dimensions can vary per site

2) Leave at least 3” between Anchors and edge of pad

3) All pads must be level and below local frost line

RIGHTHAND OPERATOR

CONDUIT LOCATION/STUB-UP ON OUTSIDE OF OPERATOR PAD 12”

PUBLIC/ UNSECURE

SIDE

1.800.944.4283 AutoGate Technical Support Mar 6, 2019

12

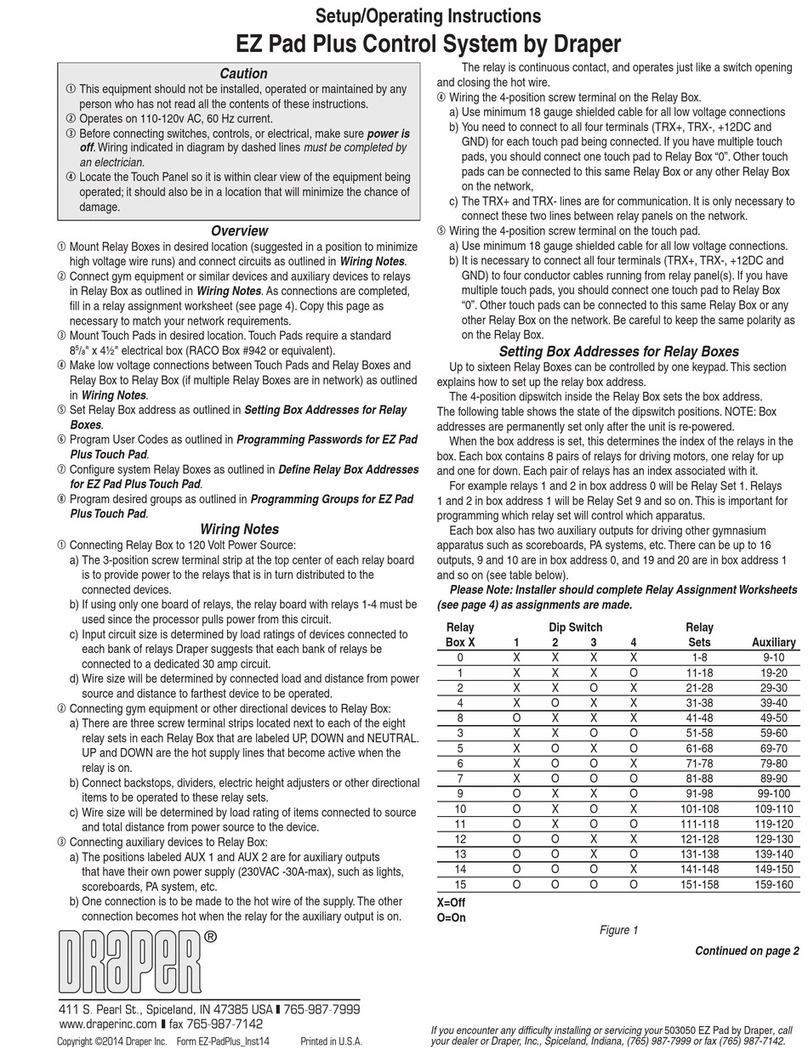

VEHICLE LOOP INSTALLATION AND PERFORMANCE

Ground vehicle sensing loops are very common to gate sites. They are used for the detection of vehicles

which then triggers the gate to do a specific action. Proper installation and placement is critical. If you

purchased Pre-formed Loops carefully follow the enclosed installation instructions and use the diagram

below for the proper placement of the ground loops. If you are constructing the loops on-site, be certain to

use D.O.T. approved materials and methods. Each site may have several loops to provide a variety of func-

tions for vehicle detection and control. Below is a simple example of a loop layout.

Test the function of the loops thoroughly by using vehicles once installed to verify correct operation.

SHIELD & LOOPS

Entrance Lane / Threat Direcon

Presence / Annunciaon

Loop

Access Control

Staon

Reversing Loop

Reversing or Close

Loop

Min 4’

Min 4’

Min 4’

1.800.944.4283 AutoGate Technical Support Mar 6, 2019

13

SITE PREPARATION & PLANNING

When you ordered your system you specified either a right-hand or left-hand system. See Pages 12-18 for

examples of a LEFTHAND and RIGHTHAND pad and operator layouts. From these illustrations and your

specific site layout, you must decide exactly where operator and crash barrier Bolsters will be finally posi-

tioned. You also need to determine the trenching and running of conduit around the access control point,

back to the operator for power and control connectivity.

Determine if there are any accessory components to be installed with your system such as traffic lights, in-

ground loops, access control stations, etc. and factor them into your site layout and installation plan. Inspect

the site and verify there are no underground utilities, overhead wires, or other obstructions that can effect

your installation and use. If possible, keep routine foot traffic away from the system to reduce the chance of

pedestrian or site personnel coming in contact with a moving barrier system. A separate pedestrian gate or

turnstile is highly recommended so as to discourage the use of the barrier system by anything other than

vehicular traffic. This evaluation and planning, along with coordination with electricians and other on-site

SITE PLANNING

Access Control

Staon

Oponal Electrical &

Access Control

Enclosure

AC Primary Power

Photo Eye Beam

Note: Photo Eye Requires power at Yoke End

1.800.944.4283 AutoGate Technical Support Mar 6, 2019

14

Foundation Planning

The following chart will detail several important items required in a basic installation. Every site will be differ-

ent and needs to be reviewed on a job by job basis.

Typical Foundation: VPCB-M30 shown (see your order specific drawings for project specific details)

Heavy DutyFork lift with side shift if pos-

sible, Gradall, or alternative For lifting the Bolster and later for lifting the operator and Drop arm/gate

Backhoe or alternative For excavating the foundation and any needed trenching

Hammer drill, including 1/2” and 3/4” bits

x 12” long For drilling and securing expansion/anchor bolts to pad and operator

Hand tools, including hammer, screw-

drivers (flat & Phillips), 1/2” drive socket

set, open end wrench set

For component installation

Lifting straps/slings or chains rated to

safely handle the weight of the system

(See Spec sheet for weights, page 8)

For off-loading from delivery transport, moving to installation area, lowering

bolster into excavated area, and landing the operator/Drop arm/gate on the

pad

Theodolite or equivalent For trench layout accuracy, leveling the bolster accurately and positioning

within tolerances specified

Concrete finishing tools (trowels,

screeds, brooms, etc.) For concrete finishing

Soil Tamper/Concrete vibrator For tamping the soil to correct compression and removing entrapped air in

concrete

Concrete 4,000 psi with non-shrinking additives

SITE PLANNING

1.800.944.4283 AutoGate Technical Support Mar 6, 2019

15

Typical Foundation: VPCB-M30-SF shown below (see your order specific drawings for project

specific details)

Typical Foundation: VPCB-M50 shown below

Typical Bolsters: VPCB-M50 shown below

SITE PLANNING

1.800.944.4283 AutoGate Technical Support Mar 6, 2019

16

For efficiency, you may want to excavate for other components and site needs concurrently with the

foundation excavation, such as but not limited to:

Trench for the conduits for power lines running to the operator, for wires to run between the operator and

the yoke end bolster for the infrared detection device, vehicle loop detectors, or any other accessory com-

ponent at the terminal end of the Drop arm/gate.

Trench for the operator control panel cables running from locations such as central control rooms,

guardhouses, etc. to the operator enclosure.

Trench for accessory components such as signal lights, traffic lights, external PLC wiring specific to the

project.

Trench for traffic sensor loop installation wiring back to operator.

Depth, soil compaction, and concrete forming for all systems

If stone is used to level, it must be crushed and compacted to a minimum of 90% dry density. Refer to the

foundation drawings for more specific information. It is best to pour the concrete against a clean, tight exca-

vated edge opposed to forming and back filling if the road is not being replaced beyond the excavated site.

Concrete

AutoGate, recommends 4,000 psi concrete with non-shrinking additives. The approximate amount of

concrete required based on a 15’ clear drivable open system is:

M30 Standard

Operator Pad: 8.5 cubic yards, see your sign off drawing to compute exact yards.

Bolster Pad: 4.5 cubic yards, see your sign off drawing to compute exact yards.

M30 Shallow Foundation

Operator Pad: 8.5 cubic yards, see your sign off drawing to compute exact yards.

Bolster Weldment Pad: 18.2 cubic yards, see your sign off drawing to compute exact yards.

M50 Standard

Operator Pad: 9.5 cubic yards, see your sign off drawing to compute exact yards.

Bolster Pad: 5.5 cubic yards, see your sign off drawing to compute exact yards.

Create a concrete leveling pad for the Bolster per the notes Instruction found on the foundation drawings with

your order.

SITE PREPERATION

! If necessary, review system drawings that came with your order and any applicable

project drawings or construction documents.

! Make sure you are excavating and placing the Bolster to the correct Hand

Orientation. See pages 12-18 for examples and refer to your order drawing.

1.800.944.4283 AutoGate Technical Support Mar 6, 2019

17

Steel Reinforcement Bars and Rebar—M30 SHALLOW FOUNDATION INSTALLATION ONLY

With the Bolster on top of the road, slide the flat steel reinforcement bars through the I-beams Then lift the

entire Bolster into the excavated trench and level.

BOLSTER PLANNING & INSTALATION

! Pay close attention to the dimensions on your drawings and any tolerances required!

Use laser level devices for accuracy.

Use a qualified heavy equipment operator or rigger to lift and set the Bolster in place.

Improper rigging may cause injury.

The center section of the Bolster should be filled first. This will minimize the po-

tential for shifting during the pouring process.

!

1.800.944.4283 AutoGate Technical Support Mar 6, 2019

18

M30 BOLSTERS STANDARD FOUNDATION INSTALLATION ONLY

With the Bolster on top of the road, secure to crane or on-site lift equipement. Then lift the entire Bolster into

the excavated foundation and level on leveling pad.

Once leveling of both bolsters is complete and matches your provided installation drawings pour concrete to

fill the foundations.

If needed, paint above surface Bolster areas that may have been chipped or exposed during offloading and

positioning in excavation with high quality outdoor paint.

BOLSTER PLANNING & INSTALATION

! Pay close attention to the dimensions on your drawings and any tolerances required!

Use laser level devices for accuracy.

Use a qualified heavy equipment operator or rigger to lift and set the Bolster in place.

Improper rigging may cause injury.

The center section of the Bolster should be filled first. This will minimize the po-

tential for shifting during the pouring process.

!

1.800.944.4283 AutoGate Technical Support Mar 6, 2019

19

MORE SAMPLE SITE PHOTOS

BOLSTER PLANNING & INSTALATION

1.800.944.4283 AutoGate Technical Support Mar 6, 2019

20

M50 Foundation Preparation and Installation

Operator End Bolster Yoke End Bolster

BOLSTER PLANNING & INSTALATION

This manual suits for next models

4

Table of contents