2 310531

Table of Contents

Warnings 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

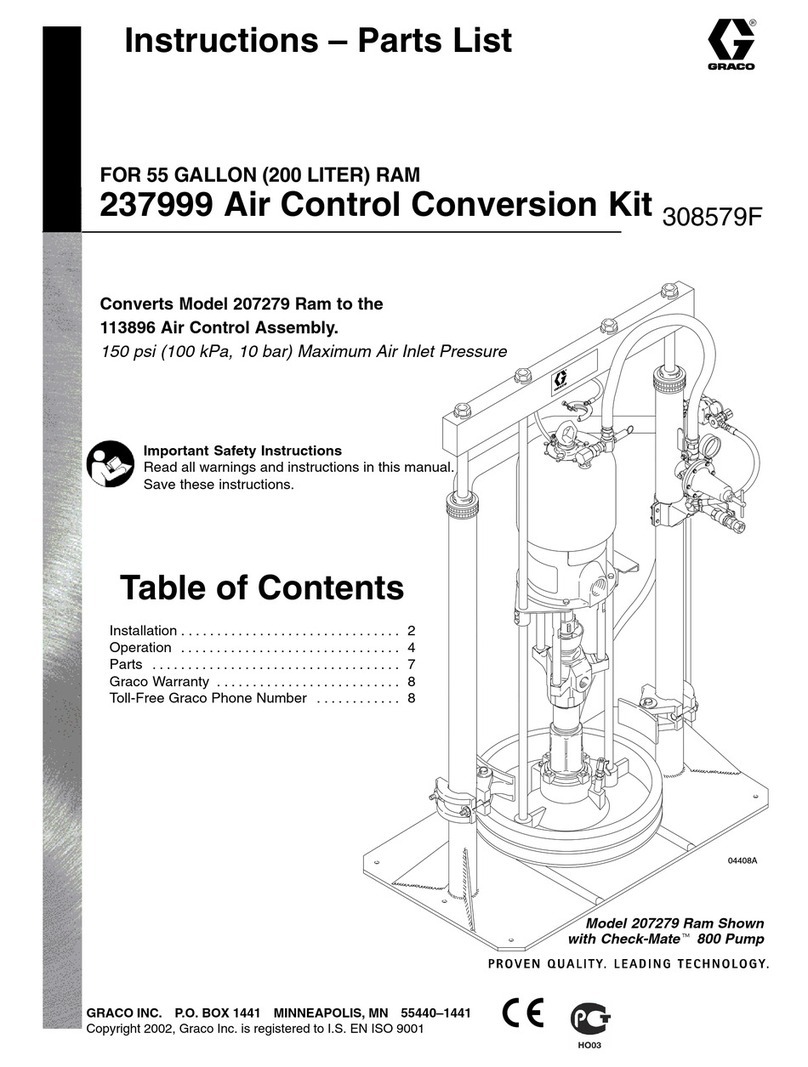

PrecisionFlo Module Overview 6. . . . . . . . . . . . . . . . .

What This Manual Includes 6. . . . . . . . . . . . . . . . . .

PrecisionFlo Module Description 6. . . . . . . . . . . . . .

PrecisionFlo Module Capabilities 7. . . . . . . . . . . . . .

Typical Fluid Applications 7. . . . . . . . . . . . . . . . . . . .

PrecisionFlo Features 7. . . . . . . . . . . . . . . . . . . . . . .

PrecisionFlo Options 8. . . . . . . . . . . . . . . . . . . . . . . .

Instruction Manual Conventions 8. . . . . . . . . . . . . . .

PrecisionFlo Definitions 8. . . . . . . . . . . . . . . . . . . . . .

Installation 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Control Assembly Hardware 11. . . . . . . . .

Installing the Control Assembly Enclosure 11. . . . .

Grounding Control Assembly 918463 13. . . . . . . . .

Grounding Control Assembly 918644 14. . . . . . . . .

Verifying Ground Continuity 15. . . . . . . . . . . . . . . . .

Connect PrecisionFlo Control Assembly

to Power Source 15. . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Resistance Between the

Control Assembly and the

True Earth Ground 15. . . . . . . . . . . . . . . . . . . . . . . . .

Connecting Fluid Lines, Air Lines, and Cables 16.

Loading Material into PrecisionFlo Module 18. . . . .

Material Loading Procedure 18. . . . . . . . . . . . . . . . .

Configuring Pressure Sensors 19. . . . . . . . . . . . . . .

Entering Nominal Values for Kp and Kd 21. . . . . . .

Calibrating PrecisionFlo Module 21. . . . . . . . . . . . .

Dispensing in Manual Mode 22. . . . . . . . . . . . . . . . .

Configuring the PrecisionFlo Module 23. . . . . . . . . .

Adjusting the Kp and Kd to Ensure

Accuracy and Repeatability of

Metering Valve Operation 24. . . . . . . . . . . . . . . . . . .

Using the Control Pendant to Modify

Kp and Kd Parameters 33. . . . . . . . . . . . . . . . . . . . .

Setting the Flow-Meter K-Factor 34. . . . . . . . . . . . .

Calibrating Flow Rate and Setting

Module Operation Mode 34. . . . . . . . . . . . . . . . . . . .

Setting the Flow-Meter K-Factor 32. . . . . . . . . . . . .

Calibrating Flow Rate and Setting

Module Operation Mode 32. . . . . . . . . . . . . . . . . . . .

Setting Flow Calibration 35. . . . . . . . . . . . . . . . . . . .

Setting PrecisionFlo On and Off Delays 37. . . . . . .

Controlling Volume Compensation 40. . . . . . . . . . .

Fine Tuning 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Scale Analog In 41. . . . . . . . . . . . . . . . . . . . .

PrecisionFlo Module Operation 42. . . . . . . . . . . . . . .

Pressure Relief Procedure 42. . . . . . . . . . . . . . . . . .

Starting the Module 43. . . . . . . . . . . . . . . . . . . . . . . .

Restarting the Module 43. . . . . . . . . . . . . . . . . . . . . .

Reading the PrecisionFlo

Control Panel Indicators 44. . . . . . . . . . . . . . . . . . . .

Setting Operation Modes 45. . . . . . . . . . . . . . . . . . .

Shutting Down the PrecisionFlo Module 46. . . . . . .

Maintenance 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintaining the PrecisionFlo Module 47. . . . . . . . .

Testing the Metering Valve’s Motor 47. . . . . . . . . . .

Troubleshooting and Fault Recovery 48. . . . . . . . . .

Restarting the Module After a Fault 48. . . . . . . . . . .

Warnings 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarms 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Selection Map 51. . . . . . . . . . . . . . . . . . . . . . . . . .

PrecisionFlo Module I/O 52. . . . . . . . . . . . . . . . . . . . . .

PrecisionFlo Module I/O Schematic 52. . . . . . . . . .

I/O Rack Layout 53. . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Module Description 54. . . . . . . . . . . . . . . . . . . . .

Theory of Operation 55. . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Mode 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic Mode 55. . . . . . . . . . . . . . . . . . . . . . . . . . .

Volume Compensation 61. . . . . . . . . . . . . . . . . . . . .

Parts 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model 918463 Control Assembly 62. . . . . . . . . . . . .

Model 918644 Control Assembly 64. . . . . . . . . . . . .

PrecisionFlo Control Interface Signals 66. . . . . . . . .

Digital Input 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Output 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Input 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Internal Interface Signals 68. . . . . . . . . . . . . .

Digital Input 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Output 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Input 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Panel Operator Interface 70. . . . . . . . . . . . . .

PrecisionFlo Module Control Panel 70. . . . . . . . . . .

Connector Pin-outs 71. . . . . . . . . . . . . . . . . . . . . . . . . .

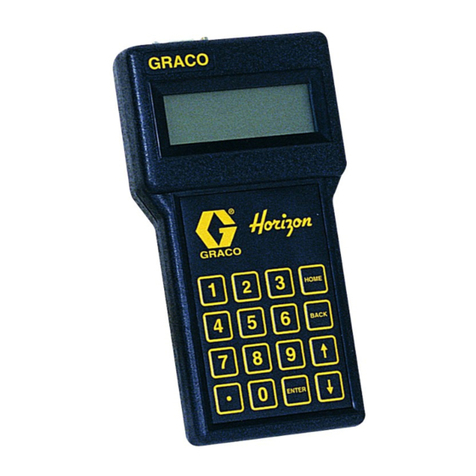

Appendix A. Hand Pendant Operation 73. . . . . . . . .

Appendix B. Configuring the Hand Pendant 74. . . .

Appendix C. Changing the Software Chips 75. . . . .

Installing the New Software 75. . . . . . . . . . . . . . . . .

Checking for Control Panel

DC Voltage Problems 76. . . . . . . . . . . . . . . . . . . . . .

Appendix D. Door Pendant Operation 77. . . . . . . . . .

Appendix E. Configuring the Door Pendant 78. . . .

Technical Data 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 79. . . . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 80. . . . . . . . . . . . . . . . . . . . .

Graco Phone Number 80. . . . . . . . . . . . . . . . . . . . . . . .