AutoGate 2490 Guide

FWI-0001-A –RIGHT ANGLE GEARMOTOR FIELD REPLACEMENT INSTRUCTIONS

READ INSTRUCTIONS PRIOR TO STARTING

REQUIRED TOOLS: Workbench or other suitable flat work surface, tape measure, 9/16” wrench, 9/16” socket, 10mm

socket, ratchet, 1/8” hex key, two (2) 2x4 wood blocks approximately 9 inches long, 2” x 4” x 1/8” spacer plate or any

other flat wide tool, pen or pencil and paper.

FWI-0001-A –RIGHT ANGLE GEARMOTOR FIELD REPLACEMENT INSTRUCTIONS

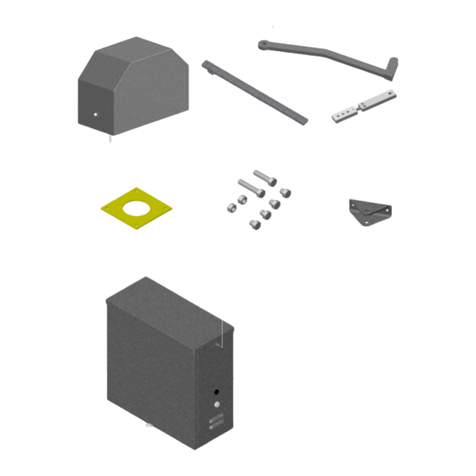

Parts Included in this kit:

#8 –4 pcs. M6 x 1 x 40mm carriage bolt

#9 –4 pcs. M6-1.0 nylon lock nut

#10 –4 pcs. 1” flat washer – 18-8 SS

#20 –1 pc. Gear motor –24v / 90 GC

FWI-0001-A –RIGHT ANGLE GEARMOTOR FIELD REPLACEMENT INSTRUCTIONS

1.) Lock the gate in the open or closed position using the T/M Safety Pin (see the operator details page (#10) in the

installation and operation manual or contact AutoGate.

Example: CLOSED position

2.) Remove four (4) “Tek” screws retaining the operator top panel then remove the top panel.

3a.) Turn off the DC and AC power switches. 3b.) Disconnect the motor power wires.

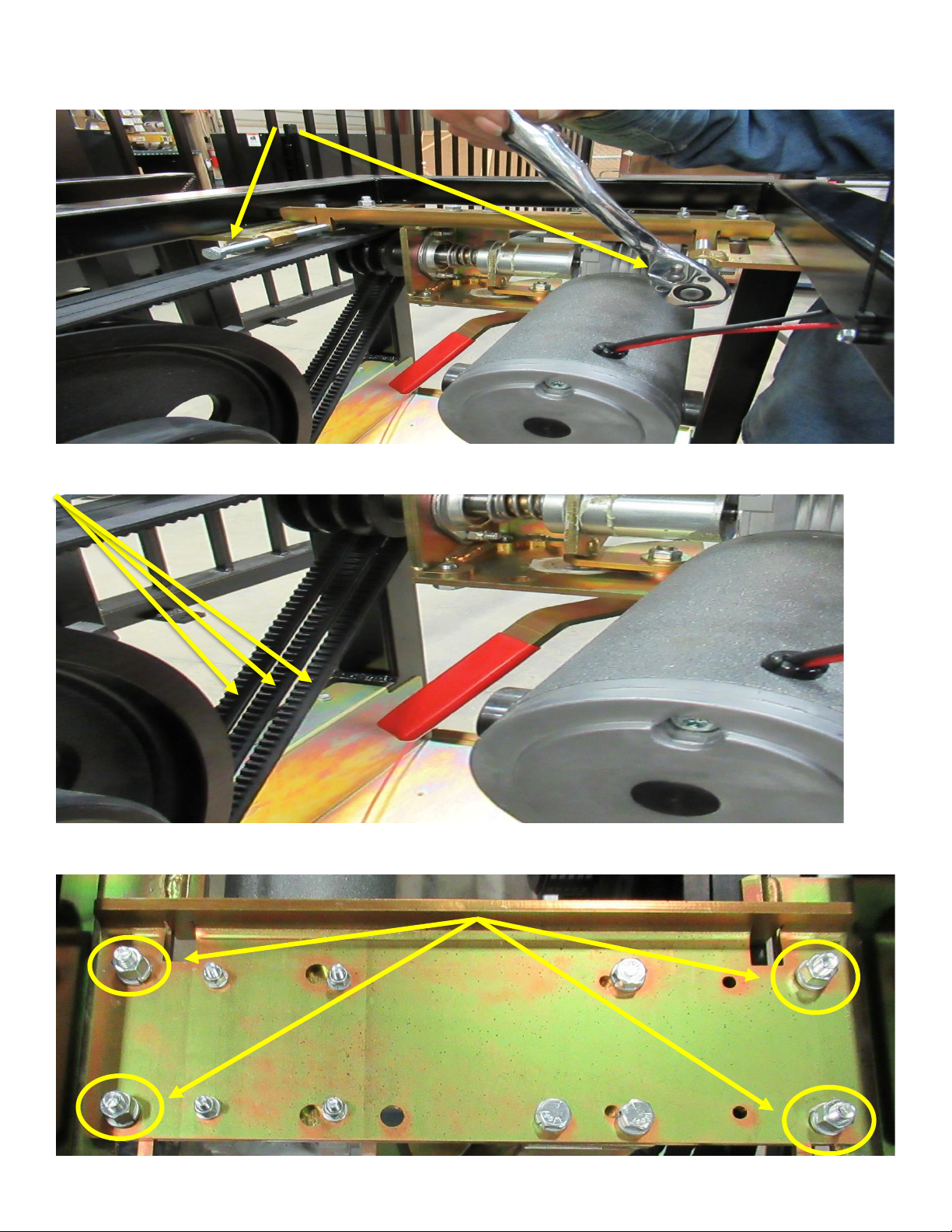

3c.) LOOSEN the four (4) 3/8-16 hex nuts (DO NOT REMOVE at this Time).

FWI-0001-A –RIGHT ANGLE GEARMOTOR FIELD REPLACEMENT INSTRUCTIONS

3d.) Remove two (2) 3/8-16 Belt Tension bolts.

3e.) Remove three (3) Drive Belts.

3f.) Remove ALL four (4) 3/8-16 hex nuts, four (4) 3/8” split lock washers, and four (4) 3/8-16 carriage bolts.

FWI-0001-A –RIGHT ANGLE GEARMOTOR FIELD REPLACEMENT INSTRUCTIONS

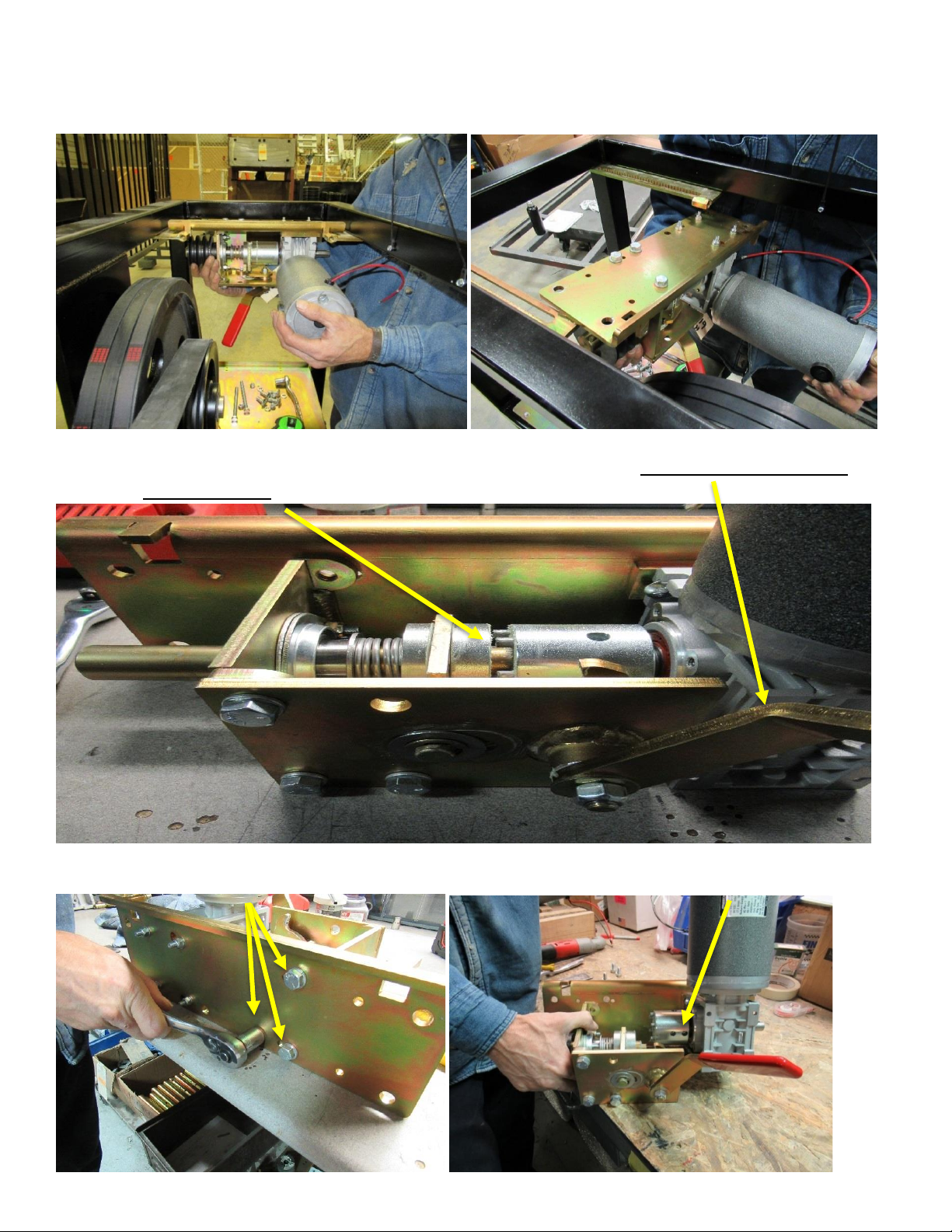

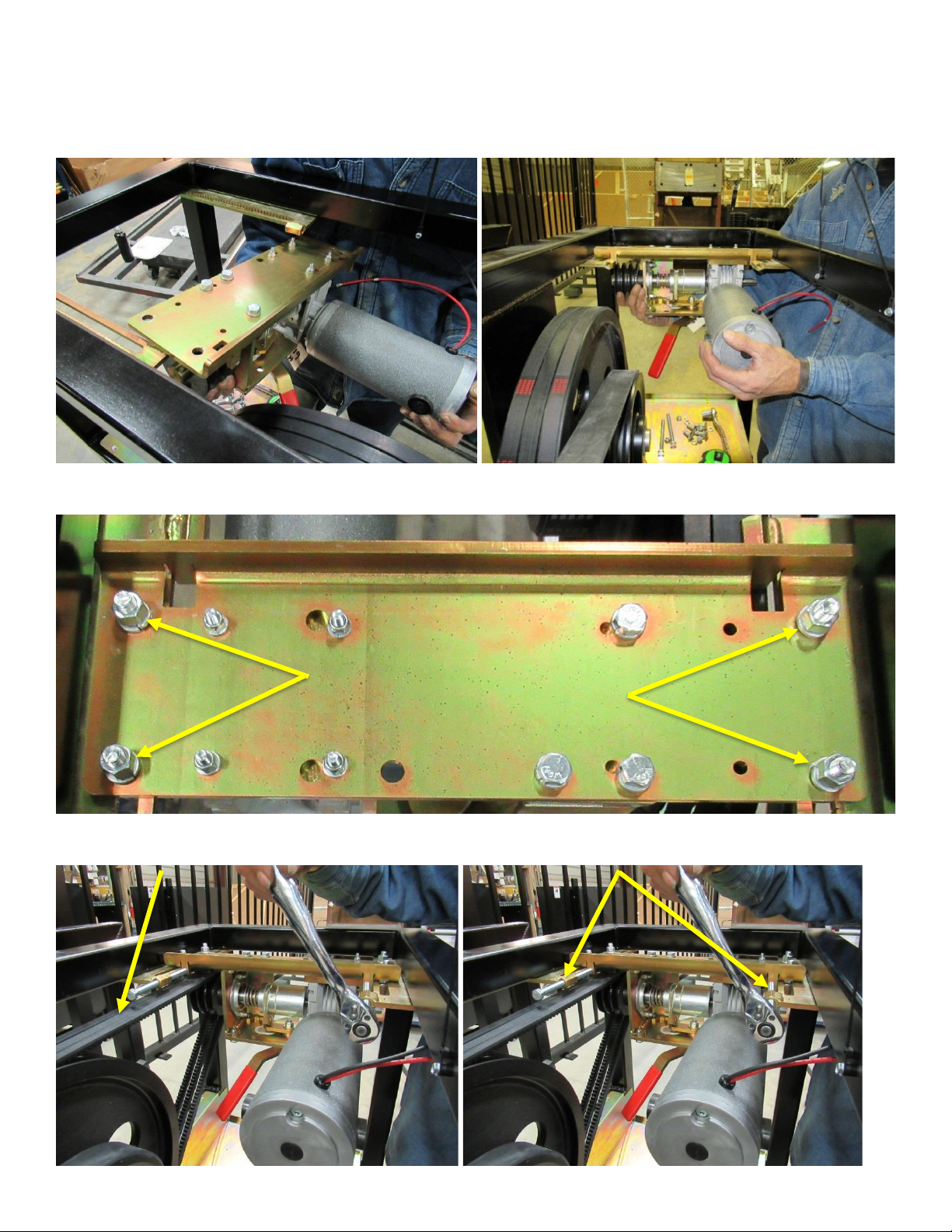

4.) Lift the Motor Assembly and move it toward the center of the operator then lower the Motor Assembly out of the

operator and place on a workbench or other suitable work surface.

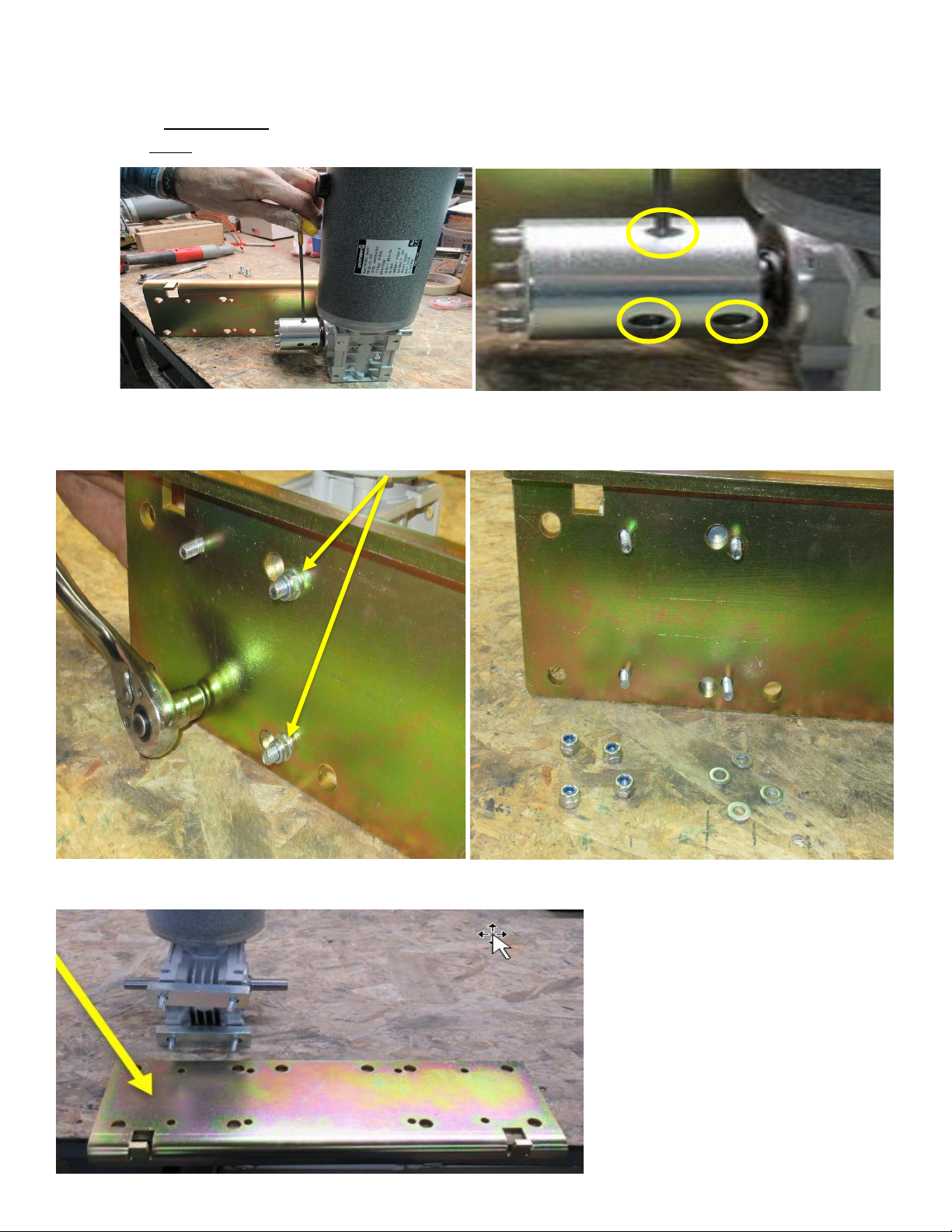

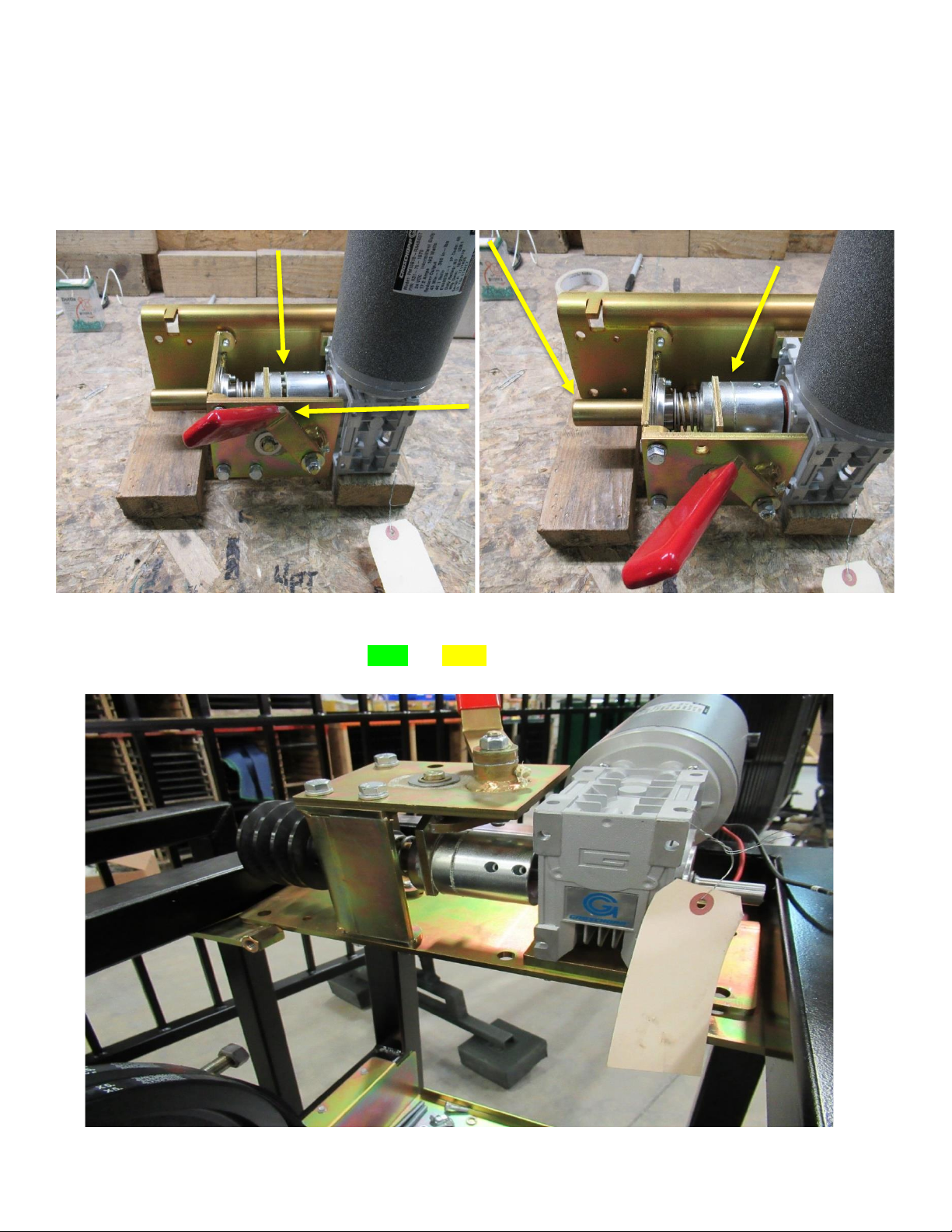

5.) Orient the Motor Assembly as shown (RH model shown, LH opposite). Using the 90 DM Retractor Cam Handle

Position the RAD Slide Coupler in the open position.

6.) Remove three (3) 3/8-16 bolts securing the RAD Bearing Mounting Bracket then remove the assembly.

FWI-0001-A –RIGHT ANGLE GEARMOTOR FIELD REPLACEMENT INSTRUCTIONS

7.) Loosen, but do not remove three (3) set screws securing the RAD Fixed Coupler to the gearbox shaft then remove

the coupler. (retain for use on the replacement motor and gearbox assembly)

8.) Remove and discard four (4) M6-1.0 nylon hex nuts and four (4) M6 x 12mm flat washers used to retain the motor

and gearbox assembly to the mounting plate.

9.) Remove mounting plate. (Retain)

FWI-0001-A –RIGHT ANGLE GEARMOTOR FIELD REPLACEMENT INSTRUCTIONS

10a.) Remove and retain two (2) spacer blocks

10b.) Remove and discard four (4) M6-1.0 x 40mm carriage bolts. They can be difficult to remove and may have to be cut

off.

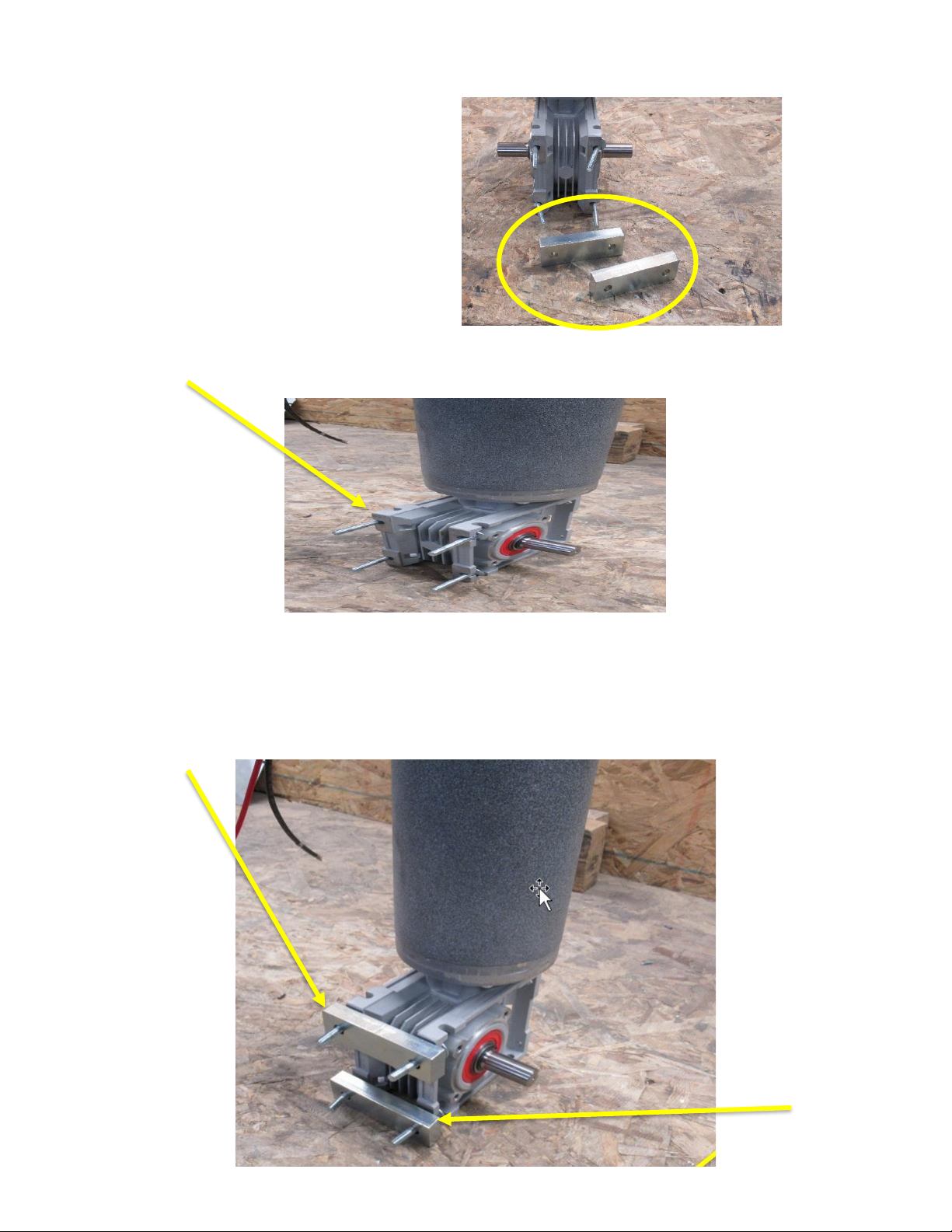

11.) Place the replacement motor and gearbox assembly on a work bench or other suitable work surface

12a.) Insert four (4) supplied M6-1.0 x 40mm carriage bolts into the slots on the motor and gearbox assembly.

12b.) Place two (2) retained spacers on the four (4) M6-1.0 x 40mm carriage bolts

FWI-0001-A –RIGHT ANGLE GEARMOTOR FIELD REPLACEMENT INSTRUCTIONS

12c.) Install the Mounting Plate onto the replacement motor and gearbox assembly

12d.) Install four (4) (supplied) M6 x 12mm flat washers and four (4) supplied M6-1.0 nylon hex nuts, (do not tighten

them.)

FWI-0001-A –RIGHT ANGLE GEARMOTOR FIELD REPLACEMENT INSTRUCTIONS

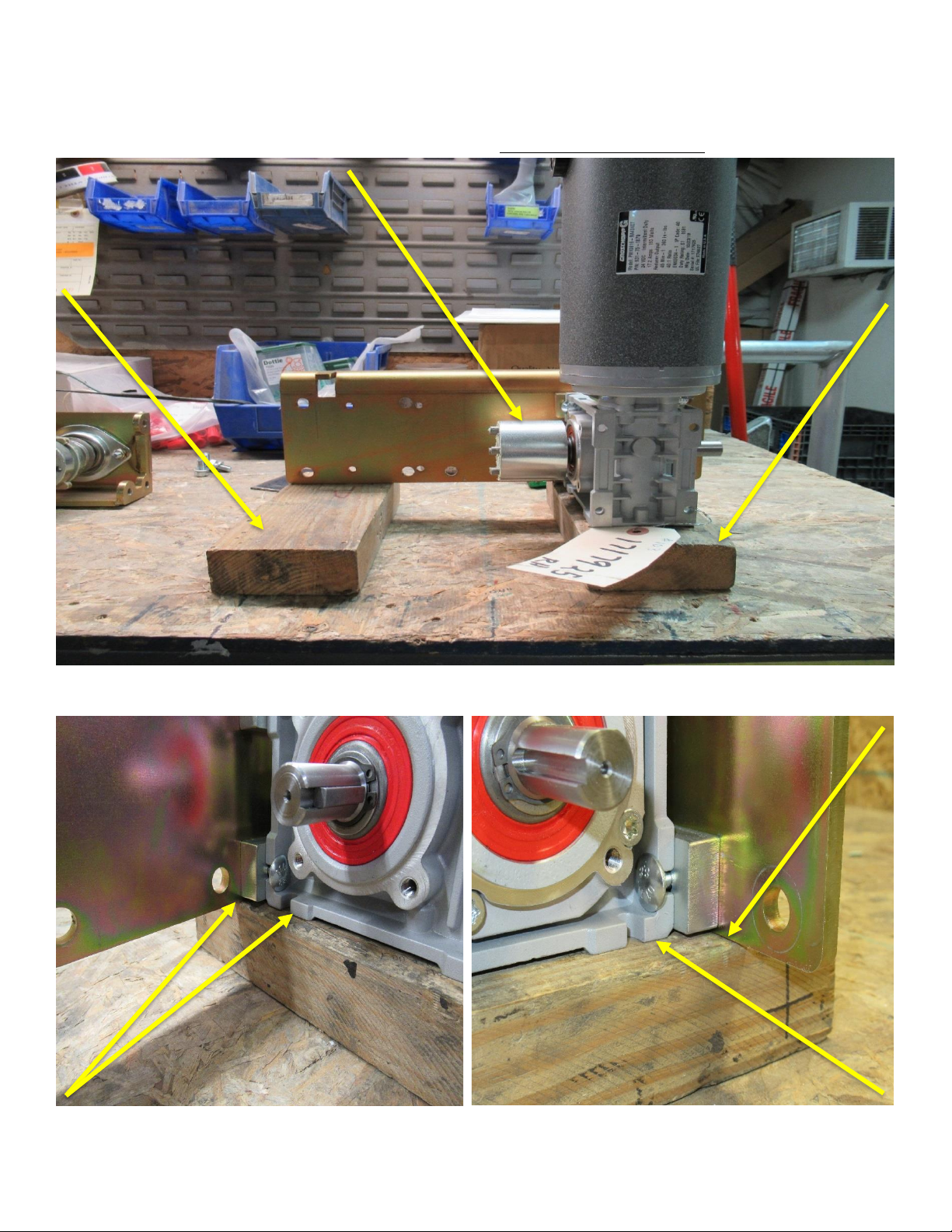

13a.) Place two (2) wood blocks on a workbench or other suitable work surface

13b.) Place the new motor and gearbox assembly and mounting plate on the wood blocks

13c.) Install the RAD Fixed Coupler on to the gear box shaft but do not tighten the set screws

14.) Ensure the motor and gear box assembly and the plate are fully seated on the wood blocks (no gaps present)

FWI-0001-A –RIGHT ANGLE GEARMOTOR FIELD REPLACEMENT INSTRUCTIONS

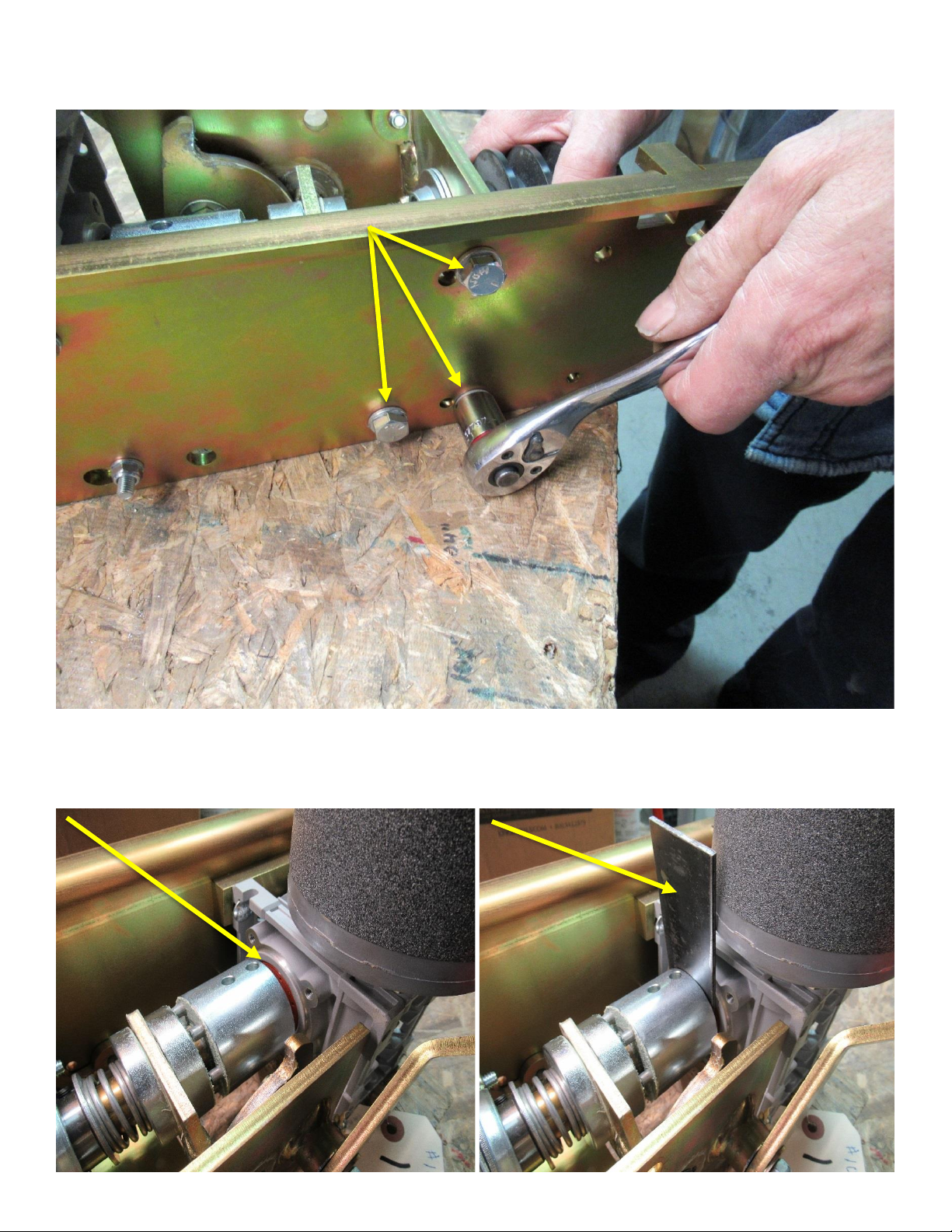

15.) Tighten four (4) M6-1.0 nylon hex nuts (ensure the mounting plate and gearbox stay seated against wood blocks)

16a.) Install the RAD Bearing Mounting Bracket assembly ensuring the pilot end of the RAD 1” Main Drive Shaft is

seated into the bearing in the RAD Fixed Coupler.

FWI-0001-A –RIGHT ANGLE GEARMOTOR FIELD REPLACEMENT INSTRUCTIONS

16b.) Secure the RAD Bearing Mounting Bracket assembly with three (3) 3/8-16 bolts

17.) Insert the 2” x 4” x 1/8” spacer plate or other flat wide tool between the gearbox and RAD Fixed Coupler and push

the fixed coupler toward the RAD Slide Coupler to ensure the RAD 1” Main Drive Shaft is fully seated in the bearing then

tighten the set screw/screws that are visible.

FWI-0001-A –RIGHT ANGLE GEARMOTOR FIELD REPLACEMENT INSTRUCTIONS

18a.) Close the RAD Slide Coupler using the 90 DM Retractor Cam Handle. Turn the shaft, by hand, until the RAD Slide

Coupler closes fully then inspect for a gap between the two (2) couplers. If a gap is present repeat steps 18 and 19 until

the gap is no longer present.

18b.) Open the RAD Slide Coupler, turn the shaft then close the RAD Slide Coupler. Turn the shaft until the RAD Slide

Coupler closes fully then inspect for a gap between the two (2) couplers. Repeat this step 3 to 4 times checking for gaps

each time. If a gap is present repeat step 18 and 19 until the gap is no longer present.

19.) Place the Motor Assembly on top of the slide side plates. Reconnect the motor power wires. Turn the AC and DC

power switches on. Run the motor using the OPEN and CLOSE buttons on the control board. As the motor runs, observe

the couplers and ensure there is no wobble and/or gaps. Repeat steps 18 –20 to eliminate all wobble and/or gaps.

FWI-0001-A –RIGHT ANGLE GEARMOTOR FIELD REPLACEMENT INSTRUCTIONS

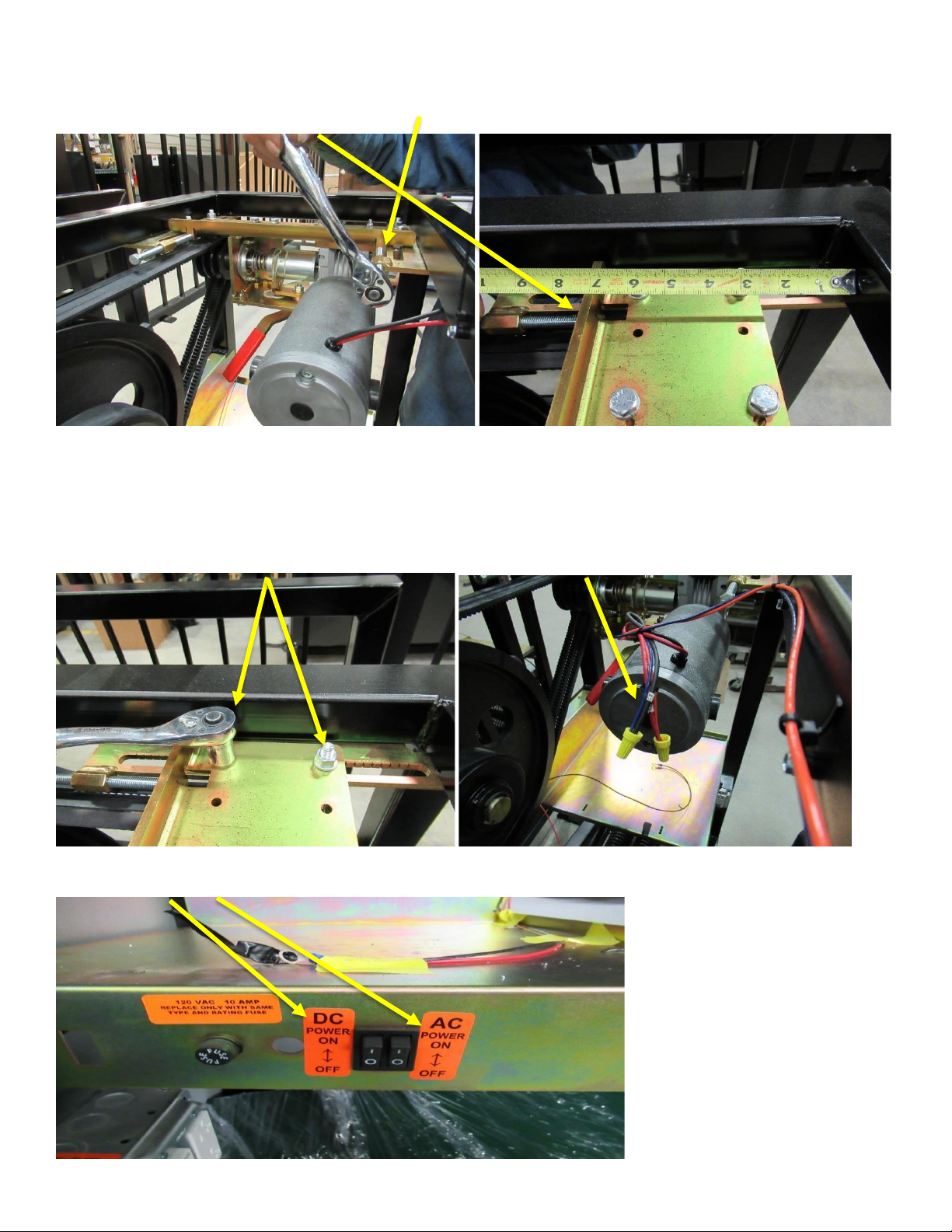

20.) Turn off the AC and DC power switches

21.) Disconnect the motor power wires

22.) Install the Motor Assembly into the operator

23a.) Install four (4) 3/8-16 carriage bolts, lock washers and hex nuts finger tight

23b.) Install three (3) Drive Belts 23c) Install two (2) 3/8-16 Belt Tension bolts

FWI-0001-A –RIGHT ANGLE GEARMOTOR FIELD REPLACEMENT INSTRUCTIONS

24.) Use Belt Tension bolts to adjust the RAD Mounting Plate back to the measurement taken in Step 4 or to the correct

belt tension, (7 ¼” in this example).

25. Take the time to inspect the belts before reinstalling them. Proceed if they are good, by tightening the (3) small

Belts down with ¼” of deflection and the Larger Belt with ½” of deflection by adjusting the Belt Tension bolts.

(This should be sufficient to operate your VPG system.)

26.) Tighten four (4) 3/8-16 hex nuts 27.) Reconnect the motor power wires

28.) Turn the DC and AC power switches on

FWI-0001-A –RIGHT ANGLE GEARMOTOR FIELD REPLACEMENT INSTRUCTIONS

29a.) Ensure the RAD Slide Coupler is locked in the open position

29b.) Jog the motor using the OPEN and CLOSE buttons on the control board to bring the remaining set screws to a more

accessible location for tightening

29c.) Turn the AC and DC power switches off then finish tightening the set screws

30.) Remove the T/M Safety Pin to unlock the gate

31.) Turn the AC and DC power switches on

32.) The operator is now ready to run

33.) Cycle the gate several times to ensure the alignment is correct

34.) Test all entrapment devises for proper operation

35.) Check Maintenance log to verify no preventative maintenance is needed.

36.) Re-Install the top panel

Other AutoGate Gate Opener manuals

Popular Gate Opener manuals by other brands

Merlin

Merlin G740A Instructions for installation & use

Beninca

Beninca DU.35L Operating instructions and spare parts catalogue

cedamatic

cedamatic CD.S20 operating instructions

Cardin Elettronica

Cardin Elettronica TECHNOCITY SL1524 Replacement procedure

Merlin

Merlin Swing A 200 Quick reference guide

Casit

Casit EQ2006 manual