ISO 9001:2000

Cert. n. 3614/1

Quality System Certified Cancelli Automatici Shed Infissi Telecomandati

Page 1 of 14 EQ2006 R.1.5 Rev. 02 dated 09/11/2007

Stab.: Strada Pietra Alta 1 – C.a.p. 10040 CASELETTE (TO) Italy

Tel. 011/9688230 - 9688170 Fax 011/9688363 –

Partita IVA 0050659.001.7

Reg. Trib. Torino N.654/62 - C.C.I.A.A. 333122 - M: T0024777

EQ2006

CONTROL BOX GATE’S OPENING - 2 MOTORS SINGLEPHASE 230VAC

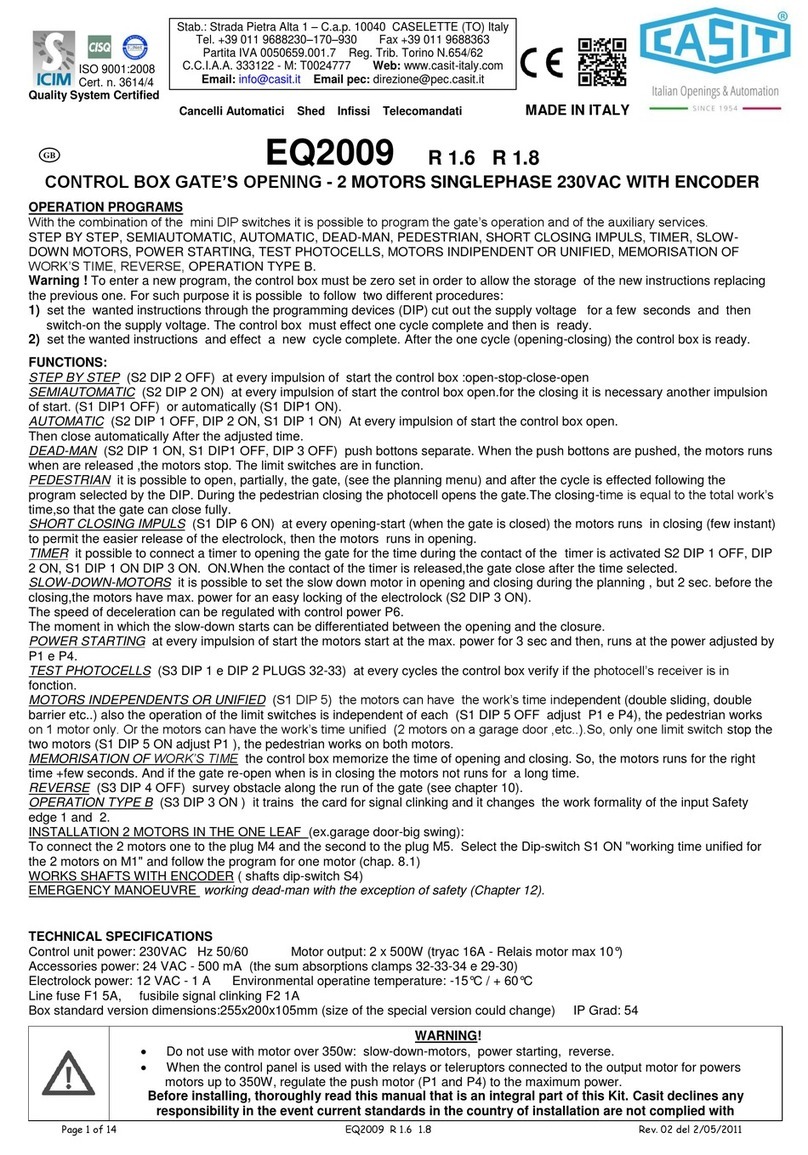

OPERATION PROGRAMS

With the combination of the mini DIP switches it is possible to program the gate’s operation and of the auxiliary services.

STEP BY STEP, SEMIAUTOMATIC, AUTOMATIC, DEAD-MAN, PEDESTRIAN, SHORT CLOSING IMPULS, TIMER, SLOW-

DOWN MOTORS, POWER STARTING, TEST PHOTOCELLS, MOTORS INDIPENDENT OR UNIFIED, MEMORISATION OF

WORK’S TIME, REVERSE, OPERATION TYPE B.

Warning ! To enter a new program, the control box must be zero set in order to allow the storage of the new instructions replacing

the previous one. For such purpose it is possible to follow two different procedures:

1) set the wanted instructions through the programming devices (DIP) cut out the supply voltage for a few seconds and then

switch-on the supply voltage. The control box must effect one cycle complete and then is ready.

2) set the wanted instructions and effect a new cycle complete. After the one cycle (opening-closing) the control box is ready.

FUNCTIONS:

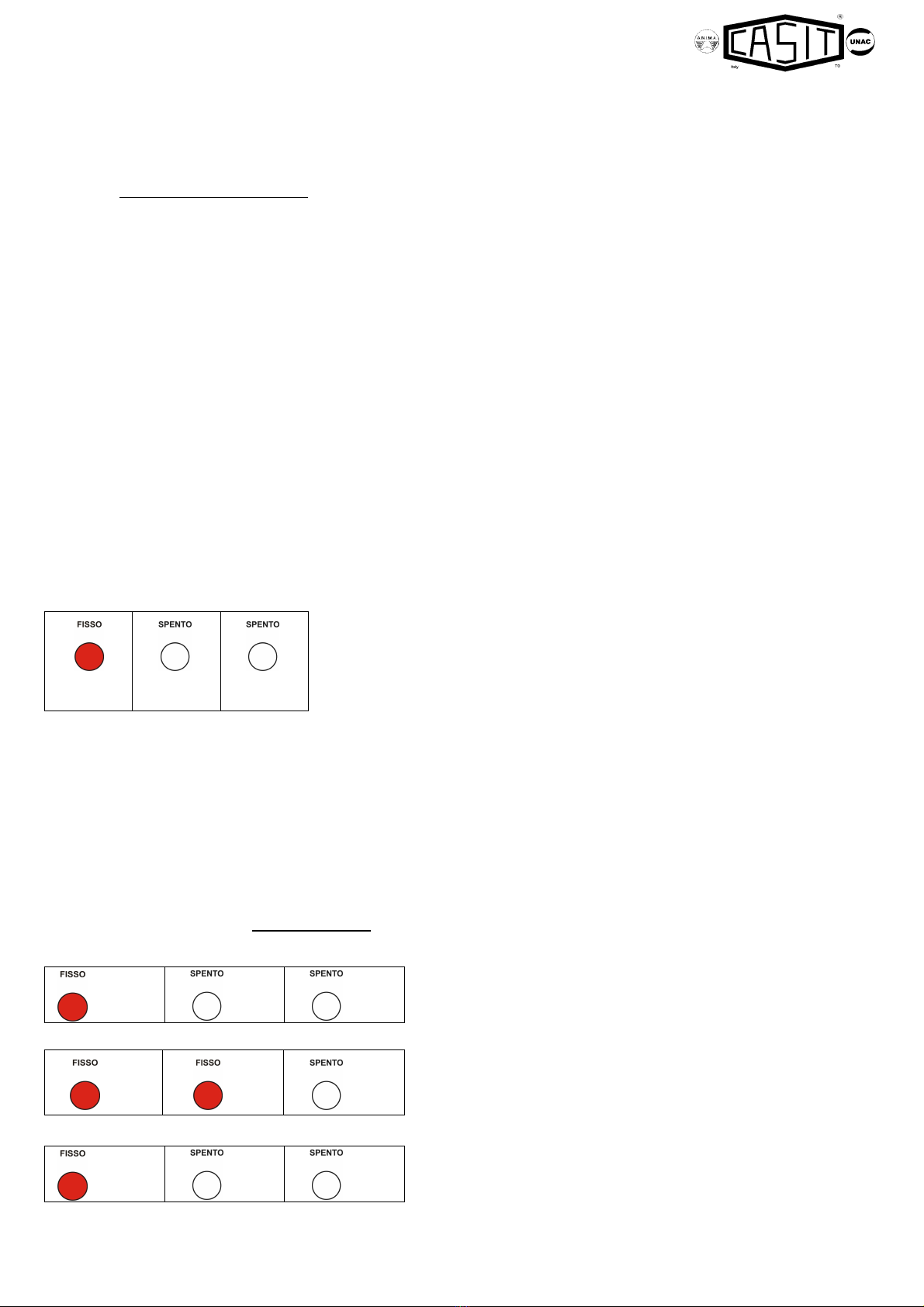

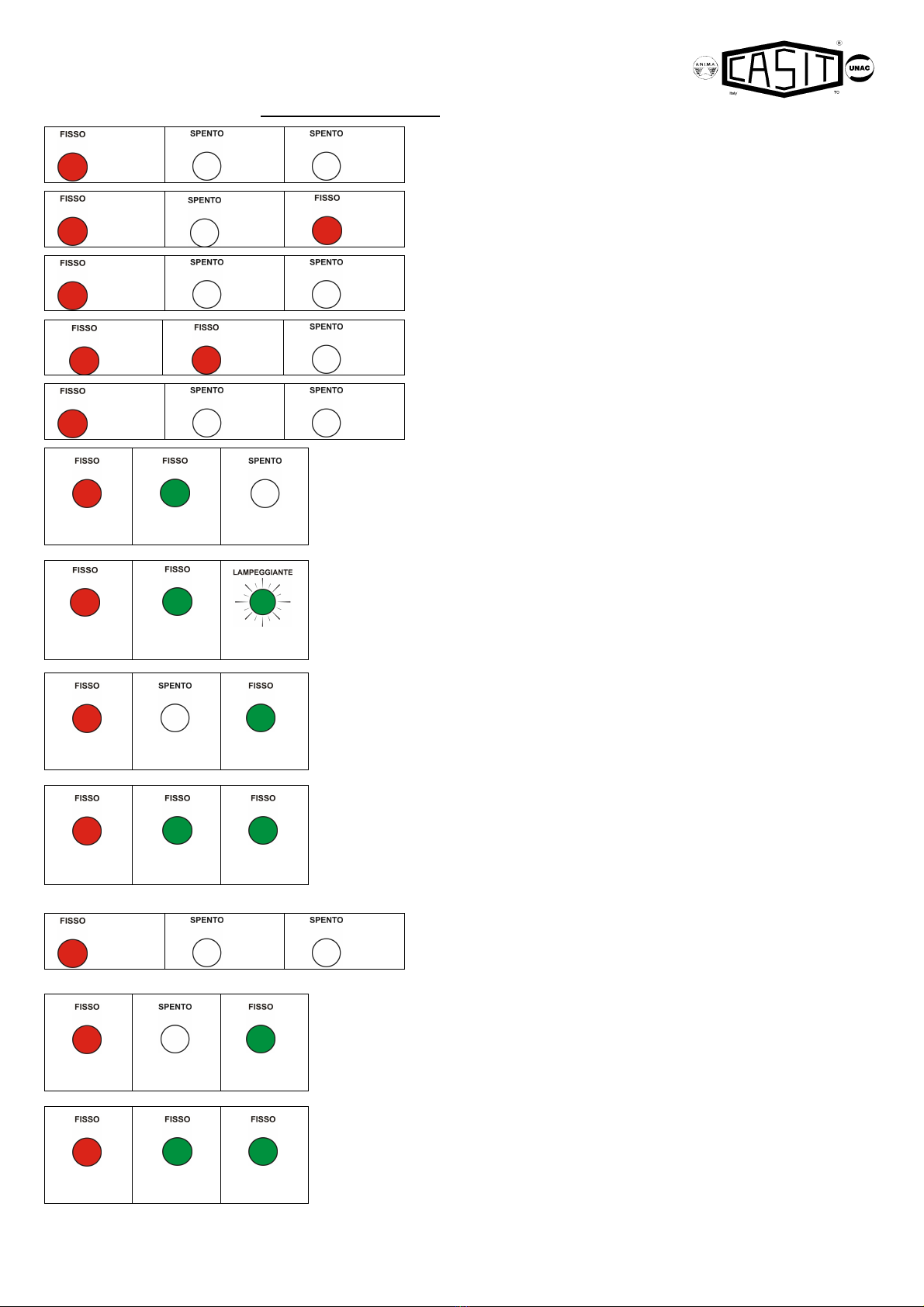

STEP BY STEP (S2 DIP 2 OFF) at every impulsion of start the control box :open-stop-close-open…….

SEMIAUTOMATIC (S2 DIP 2 ON) at every impulsion of start the control box open.for the closing it is necessary another impulsion

of start. (S1 DIP1 OFF) or automatically (S1 DIP1 ON).

AUTOMATIC (S2 DIP 1 OFF, DIP 2 ON, S1 DIP 1 ON) At every impulsion of start the control box open.

Then close automatically After the adjusted time.

DEAD-MAN (S2 DIP 1 ON, S1 DIP1 OFF, DIP 3 OFF) push bottons separate. When the push bottons are pushed, the motors runs

when are released ,the motors stop. The limit switches are in function.

PEDESTRIAN it is possible to open, partially, the gate, (see the planning menu) and after the cycle is effected following the

program selected by the DIP. During the pedestrian closing the photocell opens the gate.The closing-time is equal to the total work’s

time,so that the gate can close fully.

SHORT CLOSING IMPULS (S1 DIP 6 ON) at every opening-start (when the gate is closed) the motors runs in closing (few instant)

to permit the easier release of the electrolock, then the motors runs in opening.

TIMER it possible to connect a timer to opening the gate for the time during the contact of the timer is activated S2 DIP 1 OFF, DIP

2 ON, S1 DIP 1 ON DIP 3 ON. ON.When the contact of the timer is released,the gate close after the time selected.

SLOW-DOWN-MOTORS it is possible to set the slow down motor in opening and closing during the planning , but 2 sec. before the

closing,the motors have max. power for an easy locking of the electrolock (S2 DIP 3 ON). Do not use with motor over 350W. The

speed of deceleration can be regulated with dip-switch 9 S1, DIP9 ON high speed, DIP 9 OFF low speed.

The moment in which the slow-down starts can be differentiated between the opening and the closure.

POWER STARTING (S2 DIP 4 ON, S1 DIP 6) at every impulsion of start the motors start at the max. power for 1,5 sec (S1 DIP 6

OFF) or for 3 sec. (S1 DIP 6 ON) and then, runs at the power adjusted by P1 e P4.

TEST PHOTOCELLS (S3 DIP 1 e DIP 2 PLUGS 32-33) at every cycles the control box verify if the photocell’s receiver is in

fonction.

MOTORS INDEPENDENTS OR UNIFIED (S1 DIP 5) the motors can have the work’s time independent (double sliding, double

barrier etc..) also the operation of the limit switches is independent of each (S1 DIP 5 OFF adjust P1 e P4), the pedestrian works

on 1 motor only. Or the motors can have the work’s time unified (2 motors on a garage door ,etc..).So, only one limit switch stop the

two motors (S1 DIP 5 ON adjust P1 ), the pedestrian works on both motors.

MEMORISATION OF WORK’S TIME the control box memorize the time of opening and closing. So, the motors runs for the right

time +few seconds. And if the gate re-open when is in closing the motors not runs for a long time.

REVERSE (S3 DIP 4 OFF motor 1, S3 DIP 5 OFF motor 2) survey obstacle along the run of the gate (see chapter 7).

OPERATION TYPE B (S3 DIP 3 ON ) it trains the card for signal clinking and it changes the work formality of the input Safety

edge 1 and 2.

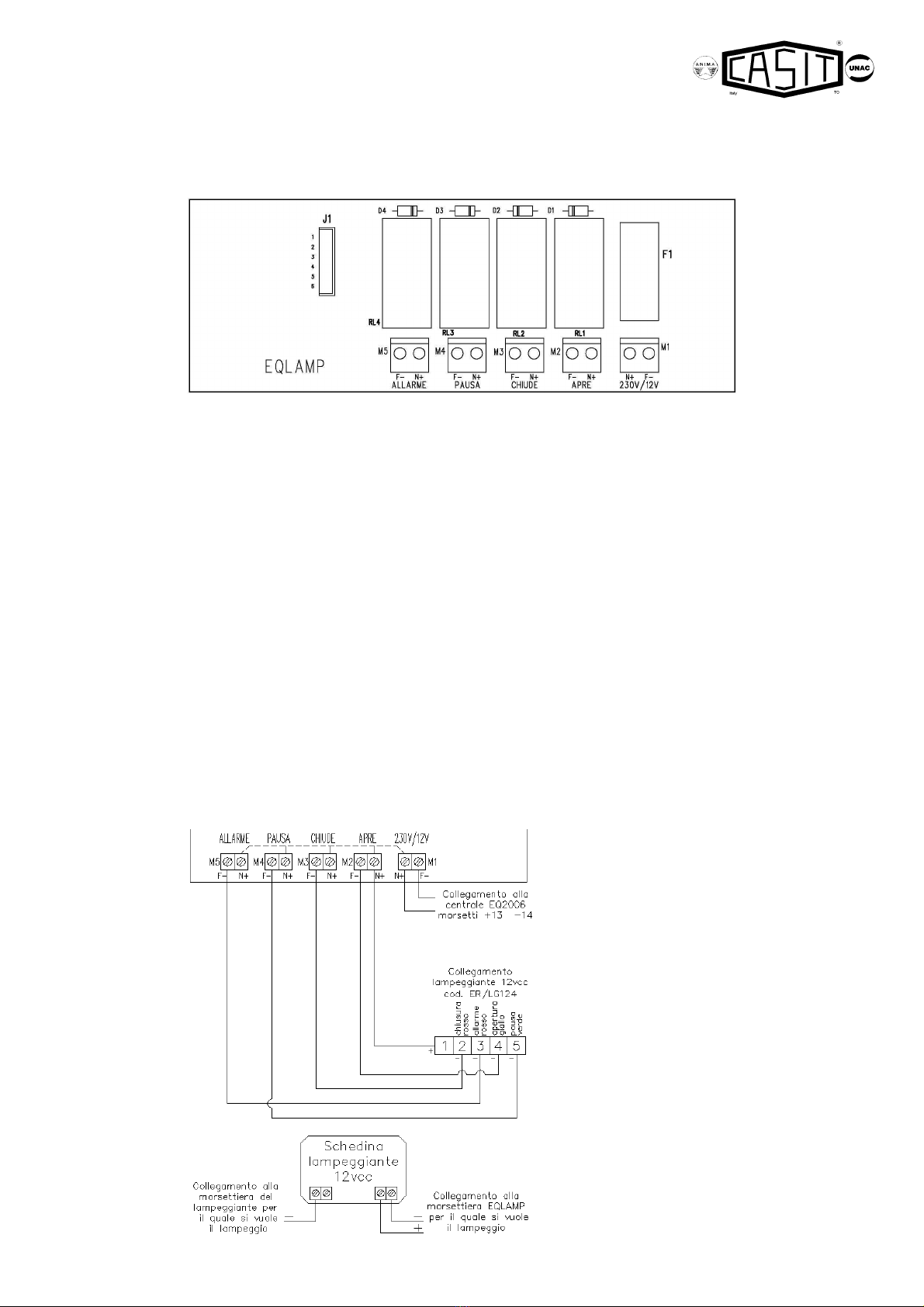

INSTALLATION 2 MOTORS IN THE ONE LEAF (ex.garage door-big swing):

To connect the 2 motors one to the plug M4 and the second to the plug M5. Select the Dip-switch S1 ON "working time unified for

the 2 motors on M1" and follow the program for one motor (chap. 6.1)

TECHNICAL SPECIFICATIONS

Control unit power: 230VAC Hz 50/60

Motor output: 2 x 500W (tryac 16A - Relais motor max 10°)

Accessories power: 24 VAC - 500 mA (the sum absorptions clamps 32-33-34 e 29-30)

Electrolock power: 12 VAC - 1 A

Environmental operatine temperature: -5°C / + 60 °C

Warning !

•Do not use with motor over 350w: slow-down-motors, power starting, reverse.

•When the control panel is used with the relays or teleruptors connected to the output motor for powers motors up to 350W,

regulate the push motor (P1 and P4) to the maximum power.

WARNING!

Before installing, thoroughly read this manual that is an integral part of this Kit. Casit declines any

responsibility in the event current standards in the country of installation are not complied with