AutoGate VPG2490 Reference manual

1

2490/GENESIS Introduction

MODEL VPG2490

FULL SIZE MANUAL AVAIALBLE TO DOWNLOAD AND PRINT AT WWW.AUTOGATE.COM

2

VPG2490 OPERATOR

TheVPG2490isAutoGate’snewUL325Rev7ListedVercalPivotGateOperator.TheVPG2490em-

ploysa90°,(RightAngleDrive)gearmotor,andanewlydesigned24VDCcontroller(GenesisBoard)and

ulizesanewLimit/PosionSensor(LPS)todetectgateposion.Theframeforthismodelis2”tallerthan

thepreviousmodeltoallowforclearancebetweenthewindbracingandtheendpaneloftheoperatorcab-

inetwhenthegateisfullyopen.Thisallowstheaddionof“OPENEDGE”contactbumpstripstobe

mountedaroundthegatethroatasrequiredbyUL325.InaddiontotheGateThroattheenre

“EntrapmentArea”isrequiredtohave“OPENOBSTRUCTION”proteconperUL325.

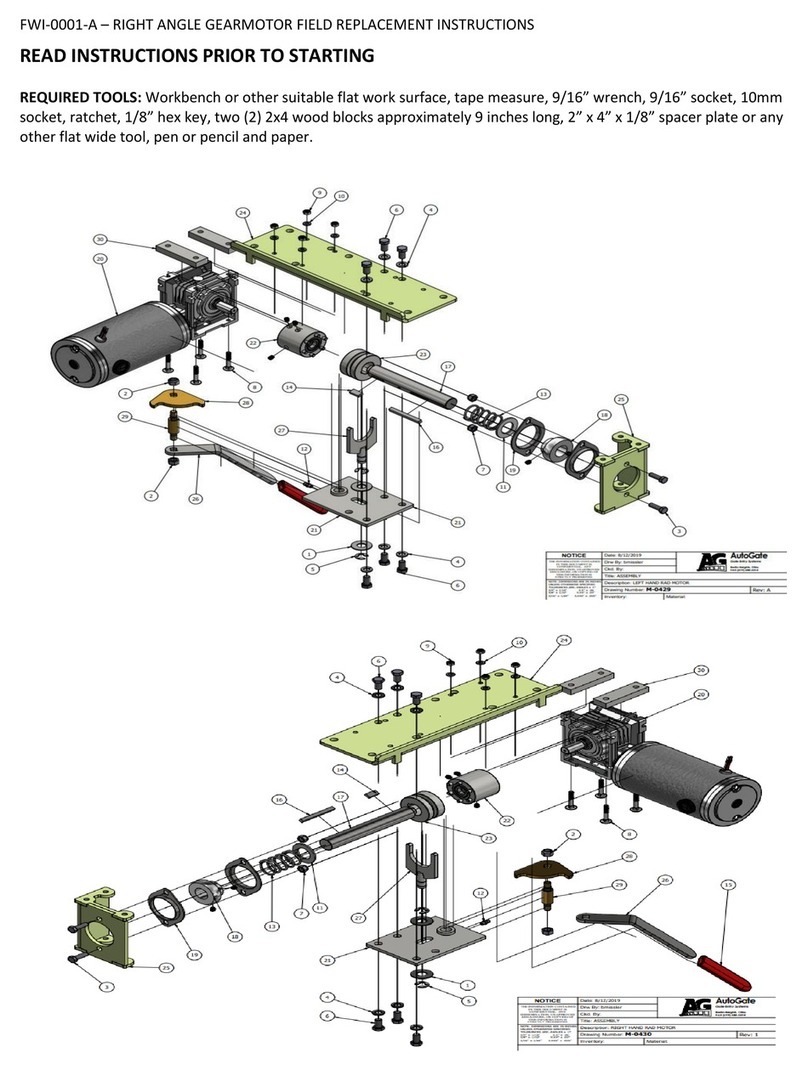

VPG2490 BELTS

Thenew90°gearmotorisa½horsepowermotorwithanon-backdrivableright-angledrivegearbox,anda

redesignedsheaveandbeltconfiguraon.Thenewconfiguraonwillprovidebeercontrolofthegatemo-

onandwillpreventthegatefrom"OVERRUNNING"themotor.Therewillbe2driveconfiguraonsused.

Thestandardspeedwillopenorclosethegatein8to10seconds,includingslowdown.Forlargerorextra

heavygatesthespeedwillbereducedslightlytopreventexcessiveweartothedrivemechanismandto

allowforsafercontrolofgatemoon.Thesesystemswillopenorclosein13to15seconds,includingslow-

down.

Adjustmentstothedrivebeltsareacricalpartofthegateoperatorfuncon.Withtheintroduconof

the½horsepowerrightangledrivegearmotor,the'MOTOR'drivebeltshavebeenchangedto"A"secon

belts.Thisnowrequires3beltstohandlethetorque.Anotherreasonforthesizechangefrom"B"to"A"

isitallowsustogetbeergripwithlessbeltwearonthesmallmotordrivesheave.The'GATE'drivebelts

willsllbethe"B"seconbelt.Thiswillconnuetobea"Banded"stylebeltbutwillbethe"Notched"

beltforbeertorqueandgrip.

3

The following are the recommended belt tension adjustments:

Toobtainthemeasurementsplacealongstraightedgeacrossthespanasshownbythedoedlineand

pressdownonthebeltwithasmallforcescaleorfingerpatmidspanbetweenthecontactpointsofthe

beltandsheaves.

Theprimary'MOTOR'driveadjustmentisanaverageofthe3belts.Adjustto.25"defleconwith6to7lbs.

offorce.Also,whenadjusngthe'MOTOR'drivebelttension,makesuretokeepthemotormounngas-

semblysquare,eitherusingatapemeasureorthenotchesinthemounngslides.Whenproperlyaligned

belttensionshouldbethesameinallthreebelts.

The'GATE'drivebelt,onastandardspeedsystem,fromtheintermediatesheavesettothefinaldrive

sheaveisasfollows;defleconof.3"witha5to6lbs.offorceforindividualbeltsor.3"with11to13lbs.of

forceforbandedbelts.

The"GATE"drivebeltonaslowspeedsystem,fromtheintermediatesheavesettothefinaldrivesheave

willhaveadefleconof.3"witha9to11lbs.offorce.

For complete BELT CHANGING instrucons refer to page 14 in this document.

2490 BELTS (cont.)

4

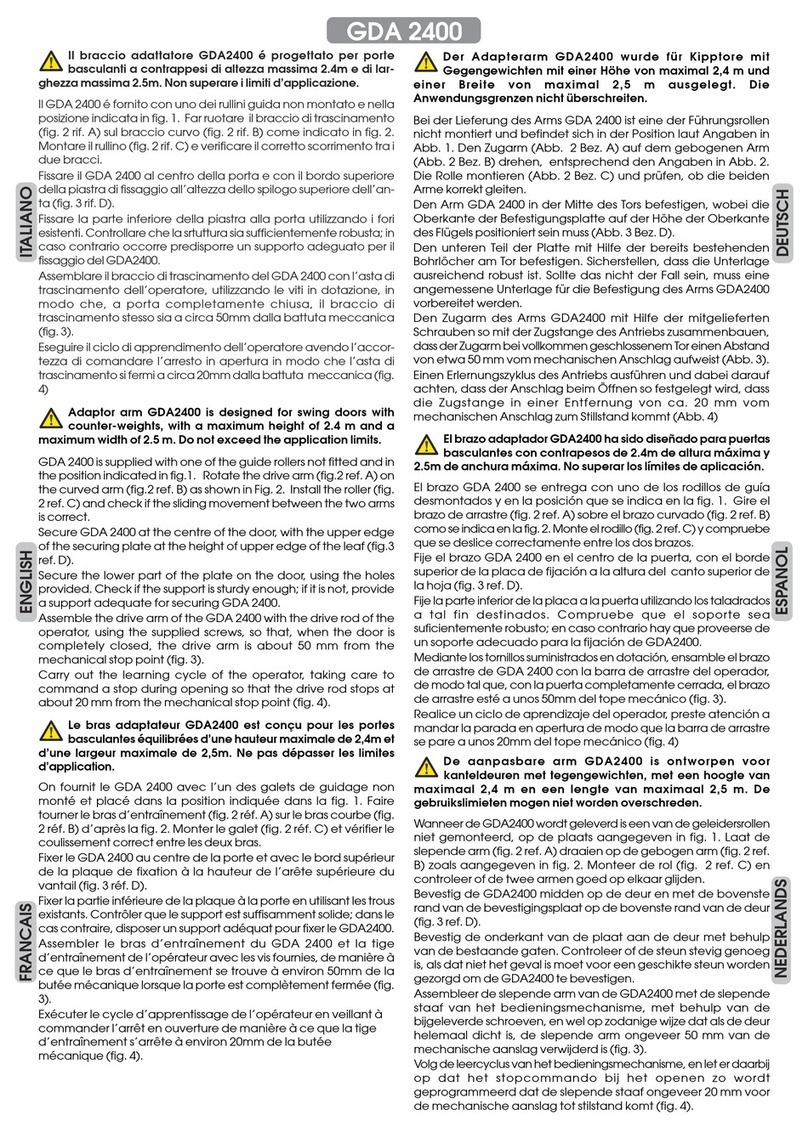

AutoGateisintroducingthe“GENESIS”controlboard.

Genesisisa24VoltDCboardcapableofcontrollingmo-

torsratedupto20Amps.Theboardhasa4line,20

charactersperlinedisplayforinformaonandprogram-

ming.

TheGenesisboardoperatesonDCpower.Ourstandard

systemwillbesuppliedwitha24to28-voltDC/18.8-

amppowersupplyandthePowerSupplysengwillbe

“NORMAL”.Thiswillpowerallfunconsofthegate.

Thereisaninternalbaerycharger/maintainercircuit

ontheGenesisboard.Thesystemwillrequiretwo(2)

12-voltbaerieswiredinseriesorasingle24-volt

baeryconnectedtothebaeryterminalsforback-up

capabilies(HighlyRecommended).Baeriesneedto

bethesamephysicalsize,andthesamecapacityrang.

Thepowersupplyhas(2)voltageinputsengswhichis

controlledbyaswitchonthesideofthecase.Thesengsare115and230.The115-voltsengisfor90

–132voltsACat10Amps.The230-voltsengisfor180-264-voltACat6Amps.

Thereare2morepowerinputsengsontheGenesisboard.Bothsengswillrequire(2)12-volt

baeriesor(1)24-voltbaeryforgateoperaon.OneistheSOLARseng.WhensetforSOLAR,anysolar

arraythatisdesignedfor24-voltchargingcanbedirectlyconnectedtotheGenesisboardinplaceofthepow-

ersupply.Theboardwillsllcontrolthegateasnormal,butthemotorwill

runfromthebaery/baeries.Theon-boardchargingsystemwillnowcharge

thebaeriesfromthesolarpanelswheneverthereisenoughlighttoacvate

thepanels.

NOTE:(2)12-voltsolarpanelswiredinseries,or(1)24-voltpanel,(2

24-voltpanelswiredinparalleltomaximizeoutputcurrent),willproducebe-

tween31VDCand45VDC.Whenthevoltagefallsbelow31volts,thecircuit

willstopchargingandpreventcurrentfrombackfeedingtothepanels.Make

surethatthepropersengischosen.Ifusingthenormalpowersupplyand

theboardissetfor“SOLAR”,thebaerieswillnevergetchargedbecausethe

powersupplyissetto26.5VDC,andthereforewillneverreachthelev-

elrequiredforchargingperthe“SOLAR”program.

Theothernon-standardsengiscalled“CHARGE”.Thiswill

mostlybeusedforbackwardscompabilityonsystemsthatcurrently

useatransformerwhenupgradingtotheGenesis.SincetheGenesis

boardonlyusesDCvoltage,theACtransformerwillnotwork.Byusing

a36-volt4-amppowersupply,the“CHARGE”sengwillworksimilar

tothe“SOLAR”seng.Thepowersupplywilloutput36voltsand

chargethebaeriesandthebaerieswillrunthegate.Butunlikesolar

panels,becausethepowersupplywillalwaysbeon,thechargingcircuit

willalwayswork.Thissetupiseasytoconvertonouroldersystems

usingthetransformerasapowersource.

Genesis Controller

5

GENESIS CONTROLLER (cont.)

TheGenesisboardisprogrammedtomonitortheinputpowerinall3scenarios.Innormaloperaon,

usingtheregularpowersupply,iftheACpowertothesupplyorthepowersupplyitselffails,theREDLEDindi-

catorlightonthedrivewayoperatorendpanelwillflash.Ifthe‘solar’panelsorthe‘charge’supplyfailto

chargethebaeriesformorethan24hours,againtheindicatorLEDwillflash,andawarningscreenwillshow

onthe4-linedisplayindicangthatthereisaproblemwiththesolarpanels,wiring,orthatthereisanissue

withtheACpowertothechargingpowersupplyorthepowersupplyitself.

Ifeitherthe‘NORMAL”orthe“CHARGE”powersupplyhaveanooutputcondion,firsttryturningoff

theACpowerswitch,thenaerafewsecondsturntheACswitchbackon.IftheGenesisdisplayshowspower

supplyvoltageasnormal,thentherewaseitheranovervoltageinputoranoverloadoftheampdrawonthe

output.Thepowersupplieshaveabuilt-inoverloadprotecontopreventdamagetoitselforthecontrol

board.Ifthepowersupplyoverheats,itwillshutdownunlthetemperaturereturnstonormalthenitwillre-

startautomacallyifACpowerispresent.

The12VDCterminalsarefor12-voltaccessories.Justlikethe24-voltterminals,thecommonsinthe

middleoftheblockareusedforthecircuit.Again,bothterminalscombinedhavea2-amploadrang.

Boththe24-voltandthe12-voltterminalsareprotectedbya2-ampfuse.Itishighlyrecommendedthat

thetotalloadoneithersetofterminalsdoesnotexceed1.75Amps.Currentdrawthatequalsthefuserang

couldblowthefuseundernormaluseduetofluctuaonsinequipment.

Thelastsetofterminalsontheboardarehighcurrentloadconnecons.Letorightare,BATT+,BATT-,

24VDC+,24VDC-,MOTOR“A”&“B”.

BATT+=Baeryposivewire

BATT-=Baerynegavewire

24VDC+=Powersupplyposiveinput

24VDC-=Powersupplynegaveinput

MOTOR“A”=WiredtotheREDmotorwire

MOTOR“B”=WiredtotheBLACKmotorwire

6

Note: P1 is NOT USED on the VPG2490 model. The VPG2490 uses a Limit Posion Sensor

(LPS). P1 would only be used if you were to install the GENESIS board in an older operator

with limit switches.

P14– Loop Rack Accessory Wiring harness port: Used with our LR‐3 Loop Rack board

J1‐USB For data connecon (future use)

P6‐Program Plug: Used to update board soware

(cont.)

P4 & P5/Pg. 7‐8

P1/Pg. 6

P11/Pg. 4

P3/Pg. 10

P12/Pg.11

P13/Pg. 11

P8/Pg. 12

P10/Pg. 12 P9/Pg. 11

POWER Indicator. If

the GREEN light is

flashing, there is

power to the board.

J1/Pg. 23

P14/Pg. 23

P1

P6/Pg. 23

P2/Pg. 9

7

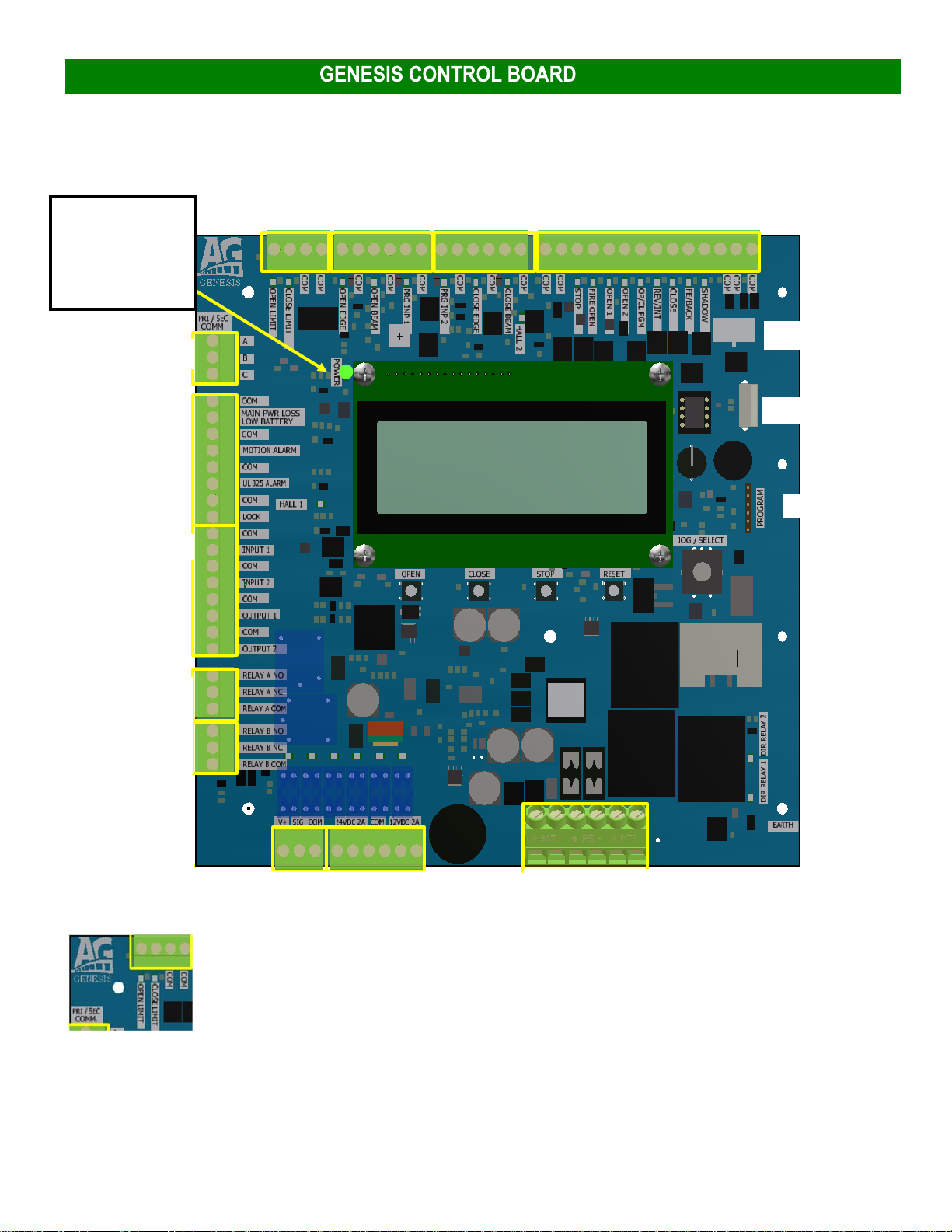

TheGENESISboardisoneofthemostadvancedboardsonthemarkettomeetalltherequirementsforen-

trapmentforUL-325.Yourgatewillnotoperatewithoutwiringinthenecessary“reversingprotecon”

equipment.

Theboardhasbeendesignedtomeetjustaboutanyaccessorydeviceandapplicaonyoucanthinkof.

PleasereviewthenextfewpagesfordetailsoneachboardINPUT,OUTPUT,POWERandFUSINGdetails.

Standard INPUTS for OPEN, CLOSE, STOP, Loops, Access Controls, Pushbuttons, etc.

6 “MONITORED” 10K entrapment device INPUTS for OPEN and CLOSE obstruction

Dedicated 1 BEAM and 1 EDGE “OPEN” obstruction

Dedicated 1 BEAM and 1 EDGE “CLOSE” obstruction

Two additional programmable for either OPEN or CLOSE obstruction

Additional Programmable Relays

Additional Programmable INPUTS

Additional Programmable OUTPUTS

24VDC Fused Accessory Power

12VDC Fused Accessory Power

SPECIALNOTE:TheGENESISboardcanberetrofitintoolderoperators.IfaGenesisboardistobeusedinnon-

monitoredentrapmentdevicegatesystem,therequiredOPEN&CLOSEmonitoredinputscanbedeacvated.

Thiswillrequireaspecialpasscodetoallowtheservicingdealer24-houraccesstoprogrammingthatcanbypass

theULRev.6code.Togetthepasscode,aphonecalltoAutoGatewiththegateserialnumberorAG#andthe8

-charactercodedisplayedontheaccessscreen.TheAutoGaterepresentavewillreadbacka5-charactercode

thatwillneedtobeenteredonthedisplay.Again,thiswillallow24-houraccesstothisspecialprogramming

funcon.Aerthat,iftherewouldeverbeareasontoaccessthespecialprogrammingfuncons,anew

passcodewouldbeneeded.

See the following pages for definitions of each terminal on the GENESIS control board.

Genesis Controller (cont.)

P4 & P5

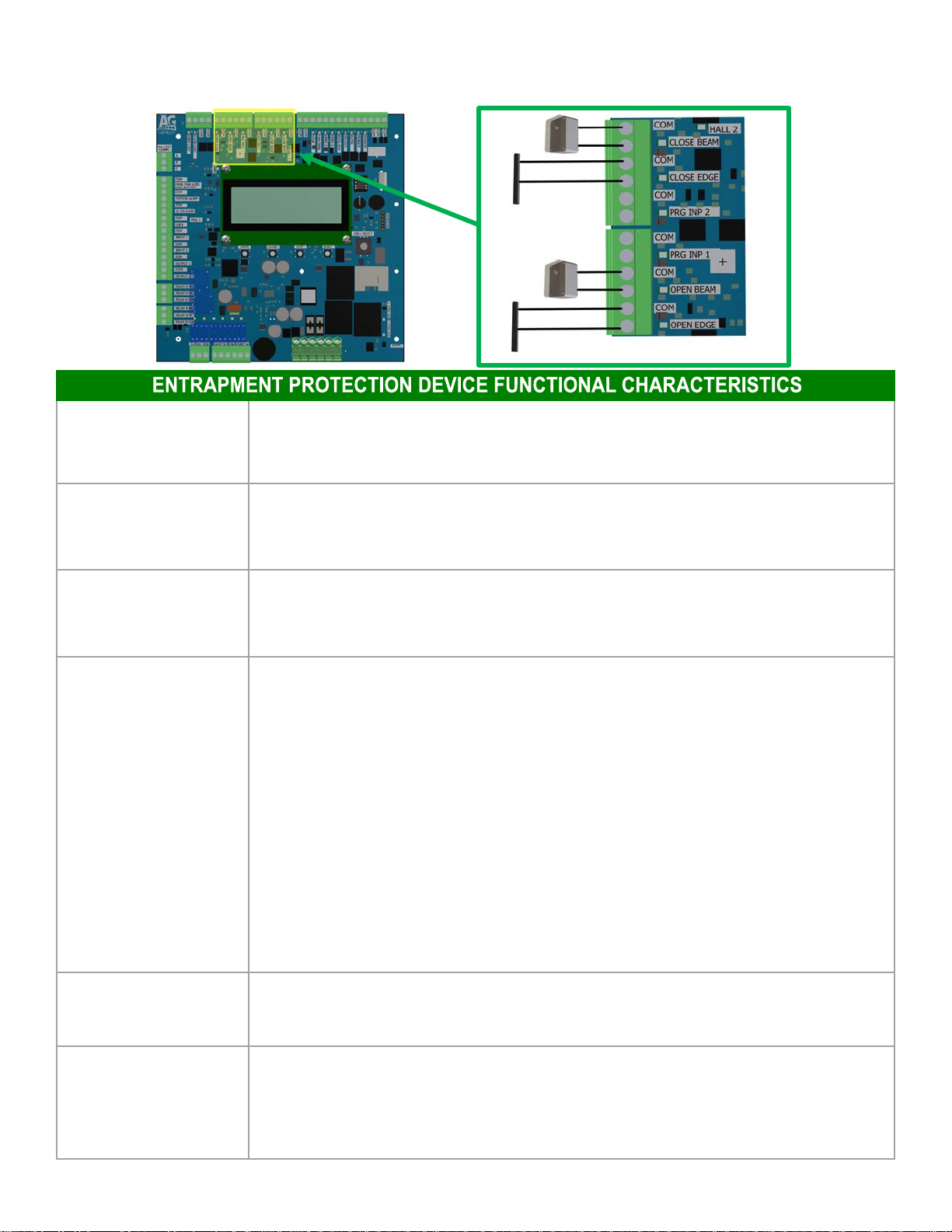

MONITORED DEVICE CONNECTIONS POINTS

GENESIS INPUT & OUTPUT DETAILS

8

MONITORED DEVICE CONNECTIONS POINTS

P4 & P5

Monitored Open Edge

Whenacvated,thegatewillstop,(inlessthan2seconds),andthenreverseandgotoafullclose

securedposion.Gatewillremainclosedunlitreceivesan“INTENDED”INPUT(Keypad/Reader/

PushBuon/FreeExit)ortheboardismanuallyreset(NotfromanEntrapmentinput).

Monitored Open Beam

Whenacvated,thegatewillstop,(inlessthan2seconds),andthenreverseandgotoafullclose

securedposion.Gatewillremainclosedunlitreceivesan“INTENDED”INPUT(Keypad/Reader/

PushBuon/FreeExit)ortheboardismanuallyreset(NotfromanEntrapmentinput).

Monitored Programmable

Input 1 & 2

ChoiceofOpenorClosedireconbyMenu,choiceofEdgeorBeamandthen10Kor2wirebyMenu.

(Refer to PROGRAMMABLE INPUT FUNCTIONAL descripƟons for required acƟon.

Monitored Close Edge

Whenacvatedthefirstme,thegatewillstopinlessthan2seconds,andreversetofullopenand

allowthe‘TimerToClose’tobeacvateduponopenlimit.Uponthesecondacvaonclosing,be-

forereachingthecloselimit,thegatewillagainstop,(inlessthan2seconds),andreversetofull

openandthe‘TimerToClose’willbedeacvated.Thegatewillremainatfullopenunlan

“INTENDED”INPUTisacvated(Keypad/Reader/PushBuon/FreeExit).Theclosecommandwill

closethegateandcleartheholdcommand.An‘Open’commandora“Reverse”command,(notthe

CloseBeaminput)willtriggertheresetofthe‘TimerToClose’acvaon.Also,anyoftheacon

buonsonthecontrolboardcanacvatethegate,(ClosebuonwillclosegateandtheOpen&Stop

buonswillresetthe‘TimerToClose’tobeacve).

Note:Uponthesecondacvaonbeforereachingthecloselimit,whenthegateisinthe“HOLD”

condion,anyinputthatwasbeingmaintainedatthemeofthesecondacvaonshallbeignored

unlthegateisenabledbyadifferentinput!IftheCLOSEEDGEremainsacvated,noinputwillre-

leasethegateforoperaon.

Monitored Close Beam Whenacvated,thegateshallstopinlessthan2seconds,andthenreversetofullopen.The‘Timer

toclose’willbecomeacveonlyaerallinputsareclear.

UL Alarm

Intheeventthegatereceivessequenalobstrucons,theULAlarmwillacvate.Toclear,verifythat

therearenoobstruconsinthemovementpathofthegate.ResetthegatebypressingtheSTOP

buonontheboardorpulsetheSTOPaccessorybuoninput.Ifthegatekeepsstoppingwithalarm

acvaon,checkthebalance,verifythattheOVERCURRENTsengishighenoughtoallownormal

operaonofthegate.Ona2490system,makesuretheLPSisfunconingproperly.

9

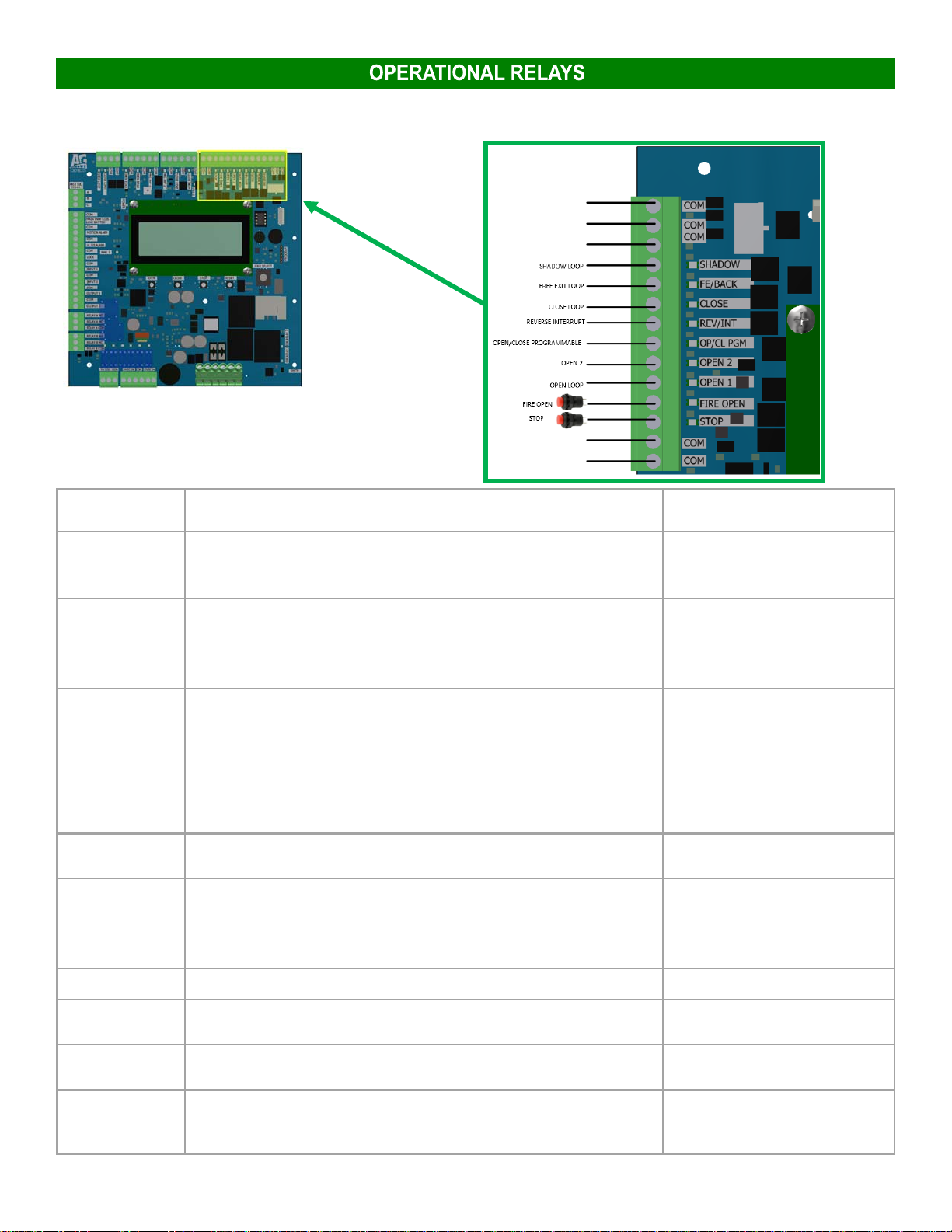

Inaddiontotheentrapmentsensorinputsthereareoperaonalinputsforvehicledetecon,communicaonwithanothergate

orsimilardeviceaswellaspushbuonsforcontrolofvariousmodesofoperaon.

Shadow Loop Whileatopenlimit,holdopen,ignoreonceoffoftheopenlimitswitch.(Not com-

mon on VerƟcal Pivot Gate)HoldOpen

FE/Back (Free Exit/

Back Away)

OpensgateasOpen1,butwhensignalisremoved,gateisgivencommandtoclose.

(ClosecommandoverriddenbyanyotheropenorReverse/Interruptcommandor

stopcommand)(PrimarilydesignedtoworkwithFE/BackonBarrierArms)

Startsopeningmovementfromany

posion

Close Loop

Startclosingmovementfromanyposion,Opencommandscanoverride.Ifgateis

closingwhenacvated,gatestopsunlclearandthenconnuestoclose.

Closeinputrespondsonreleaseoftheinputnormally.

Closeinputwillholdthegateopenwhileinputismaintainedwiththegateinthe

openposion.

Wheninconstantpressuremode,closeinputrespondsoninialpress.(Notcom-

mononVercalPivotGate)

Ifheldinupwardmoon,noeffect.

Ifheldindownwardmoon,gate

movementispausedunlreleasedand

connuesdownwardonrelease

Reverse/Interrupt Whenclosing,stopsandre-opens.Ifheld,stayopen

Open / Close PGM

Whenmenuoponnotenabled,Input=open1only.Whenenabled,input=Open

1unlesstheopenlimitisreached,itthenturnstoClose.Ifinputisheldduring

OPEN,gateholdsopen.InputneedstocycleoffbeforeinputcanCLOSEgate.

Ifhelditremainsinitsstate

Open 1 startsopeningmovementfromanyposionstartsopeningfromanyposion

Open 2 startsopeningmovementfromanyposionSameasabove

Fire Open Absoluteopen,unltheboardishardpowerreset,orlocalresetbuonpushedLocksgateopenunlreleased

Stop Stopsgateatanypointandcancelscurrentinputs.Inputswillbeignoredunlstop

isreleased.Astopinputwilldisabletheauto-closemer

Ifheld,nogatemovement,inputsig-

nored.

INPUT NAME FUNCTION AFTER MOMENTARY TRIGGER FUNCTION DURING

CONTINUOUS TRIGGER

P2

10

Warning Light

Four States

OFF: Nofaults

FAST Blink:Lowbaeryvoltage

DOUBLE PULSE Blink:LossofACpower

SLOW Blink:Anyotherfault

priority for the signals are:

1-Lowbaery

2-LossofAC

3-Anyotherfault

Moon Alarm

Acveforfullcycle(ON‐OFFmenuselectable).Programmableforpre-movement

opening(0-5secondsmenuselectable).Programmableforpre-movementclosing(0-

5secondsmenuselectable).

UL325 Alarm AcveforcondionsrelatedtoUL325specificaons

Lock

Programmable/Selectable:

Magnec lock opon-Acvewhenthegateisclosed.

Solenoid Interlock opon-Momentaryacvaontoopentheboltthatmechanically

latchesthegateclosed.

Input 1 OPTIONS: OFF,OPEN,CLOSE,SingleBuon,Reverse,Fire,Shadow,AutoOpen,

HoldOpen,EmergencySecure,AuxiliaryPulse1&2,AuxiliaryHold1&2

Input 2 SameasINPUT1

Output 1 (24VDC)

OPTIONS: OFF,PulseonOpenorCloseLimit,HoldonOpenor&CloseLimit,Pulse

onmotorOpenorClose,HoldonMotorOpenorClose,HoldonULAlarm,Holdon

MotorRun

Output 2 (24VDC) SameasOutput1

P3

11

AUXILIARY RELAYS A & B

OPTIONS:

OFF

PulseonOPENLimit:2-secondRelayAcvaon

PulseonCLOSELimit:2-secondRelayAcvaon

HoldonOPENLimit:LatchesRelayONduringOPENLimit

HoldonCLOSELimit:LatchesRelayONduringCLOSELimit

PulseonMotorOPEN:2-secondPulsewhengatestartstomoveOPEN

PulseonMotorCLOSE:2-secondPulsewhengatestartstoCLOSE

HoldonMotorOPEN:LatchesRelayonwhengateisOPENING

HoldonMotorCLOSE:LatchesRelayONwhengateisCLOSING

P12

P13

AUX Relays A & B: Areprogrammableforoperaonbasedongateaconorposion.Bothrelays

TheGenesisboardhas(2)24VDCoutputsand(2)12VDCoutputstopowerexternaldevices.Eachisfusedat2Amps.

24VDCACCESSORYPower(2)Fusedat2Ampstotal

12VDCACCESSORYPower(2)Fusedat2Ampstotal

P9

12

Primary/SecondarycommunicaonsallowforcommunicaonsbetweengatesforDualGateconfiguraons.

Whenusingtwogatestocoveradrivewayandtheybothneedtocycle

togetheronanopeninput.Connectthetwoboardswitha4-conductor

SHIELDED18ga.wire(3required,1-spare)andsetthefollowingboard

parameters:

P/S:SetforPrimary/Secondarycommunica-

on.Gatesneedtocommunicatewitheach

othertoworkproperly.

YourgateisequippedwithaLIMIT/POSITIONSENSOR.Itwillbeproperlysetwhen

itleavesthefactory.Ifyouneedtoadjustit,refertotheinstruconsbelow.Ifyou

needtoreplace,contactAutoGate.

ADJUSTING THE LIMIT/POSITION SENSOR

1.Inprogrammingmode,SetyourcursortotheGATE(line2)andenter(>Gate).

UsingtheJogknobyoucanslightlyadjusttheOPENorCLOSEposionbyturn-

ingitleorright.

2.Onceyouhavereadjustedyourgateposion,“enter”againtobackoutofthe

GatelineandgouptotheOp:lineordowntotheCl:linetosetyournewnum-

bers.

3.“Enter”(oporCL)andturnthejogknobtothenewnumbersandtestyour

gate.

>Dual Gate Mode:

Off

>Op:4500 Ramp:4000

Gate 1

P8

P10

WARNING! This screen requires a PASSCODE to access.

13

MAINTENANCE

Thebasicelectricalandmechanicalsystemsrequireonlyminimumrounemaintenance.Thefollowingitemsshould

becheckedandservicedperiodicallydependingonamountofuse.Eachitembelowhassupporngillustraonsand/

orinstruconsinthismanual.ContactAutoGateforanyquesonsorissues.Maintenance is important to any gate

system and can affect safety, warranty, quality operaon, and life‐cycle of the system.

ITEM RECOMMENDED MAINTENANCE

GreaseLinkageAssembly(“LUBRIPLATE‘R’LOWTEMP”Grease)10,000cyclesor6months

Greaseallbearings:two(2)OperatorArm,four(4)BullwheelShas10,000cyclesor6months

GreaseChainTensionBoltandLubeChain&lightlycoatsprings

(Useanon-evaporangcableandchainspray)

10,000cyclesor6months

Checkbeltsforwearandghtness.(Seepage44forinstrucons)Every6months

Chargevoltageforbaeriesshouldbe27.5VDCwithbaeriesdisconnected

checkatbaeryinmaintenancemenu.Every6months

Checkbaerywaterlevel,usedislledwateronly(Notrequiredonmainte-

nance-freeorAGMstylebaeries)Every6months

ChecktomakesureallWARNINGsignsareslldisplayedEverymonth

Lubricate(GraphiteOil)alldoorlatch,lockcylindersandmechanismsEvery6months

CleanlensesonPhotoelectricsensors/beamsorReflectorsAsneeded

Cleansnow/iceoffofgate(Balancedcorrectly,gatewilltemporarilytolerate

anaddional10lb.ofwt.)Asneeded

Checkgatebalance(seepage16)Fourmonthsaerinstall,thenannually

CheckandverifyproperoperaonofallExternal monitored entrapmentpro-

tecondevices.

Everymonth

CheckandverifyproperoperaonoftheInternal(TYPEA)entrapmentpro-

tecondevice(LPS)bywalkingtotheendofthegateandstopthegate,it

shouldreverse.

Everymonth

14

ChangingthebeltsonanAutoGateVercalPivotoperatoriseasybyfollowingthestepbystepprocedureoutlinedbelow.Asal-

ways,weareonlyaphonecallawayshouldyouneedassistanceat800-944-4283.

1.Removethe(4) TekScrewsontheTop Panelusinga5/16”nutdriver,removeandsetaside.

2.RemovetheSTIFFENER PLATE(#1)fromthePOISITION SENSOR bracket.Thisallowsaspacetoremovebelts.

3.ReleasetheMOTOR DRIVE BELT(#2)tensionbylooseningthe(4) 3/8” CARRIAGE BOLT nutssecuringtheGEAR MOTOR

bracket (#3)totheSIDE SLIDEplates (#4)witha9/16”wrench.Nowusinga9/16”wrench,backoffthe(2) Gear Motor

FORCING screws(#5)sothatonly1”remainsthroughthecouplingnut.

4.SlidetheGEAR MOTOR assemblytocreateslackinthebelts.

5.Onthecenterofthepulleys.LoosentheFLANGE BEARING bolts(#6)aboutoneturnthatsecuretheshabearingsusinga

15/16”wrench.

6.LoosentheMIDDLE FORCING screw(#7) whichisapplyingtensionontheGATE DRIVE belts(#8) byusinga15/16”wrench.

Thistooneedstobefullyloosenedtoallowenoughroomtoremovethebelts.

7.Removeoldbeltsandinstallnewbeltsloosely.

8.ApplysnugpressuretotheMOTOR DRIVE beltsbyusingthe(2) GEAR MOTOR FORCING screws.Thisshouldalsosnugthe

GATE DRIVE belts.Do not overghten!

9.ThreadtheMIDDLE FORCING screwtofingerght.

10.Re-AssembletheSTIFFNER PLATEtothePOSITION SENSOR bracket.

11.Operatethegateupanddownfor(5)metoseatthebelts.

12.TightentheMIDDLE FORCING screwtoghtentheGATE DRIVE belts.SEE PAGE 3 FOR BELT TENSION INFORMATION

13.TightentheFLANGE BEARING boltsonthemiddlesetofpulleys.

14. TightentheGEAR MOTOR FORCING screwSEE PAGE 3 FOR BELT TENSION INFORMATION

15.Tightenthe(4) CARRIAGE boltstosecuretheGEAR MOTOR brackettotheSIDE SLIDE plates.

16.Operatethegateupanddown5-10mestocheckforproperoperaon.

17.ReplacetheTop Panelusingthe(4)Tekscrews.

1.SffenerPlate

2.MotorDriveBelt

3.GearMotor

4.SideSlide

5.GearMotorForcingScrews

6.FlangeBearingBolts

7.MiddleForcingScrew

8.GateDriveBelts

12

436578

15

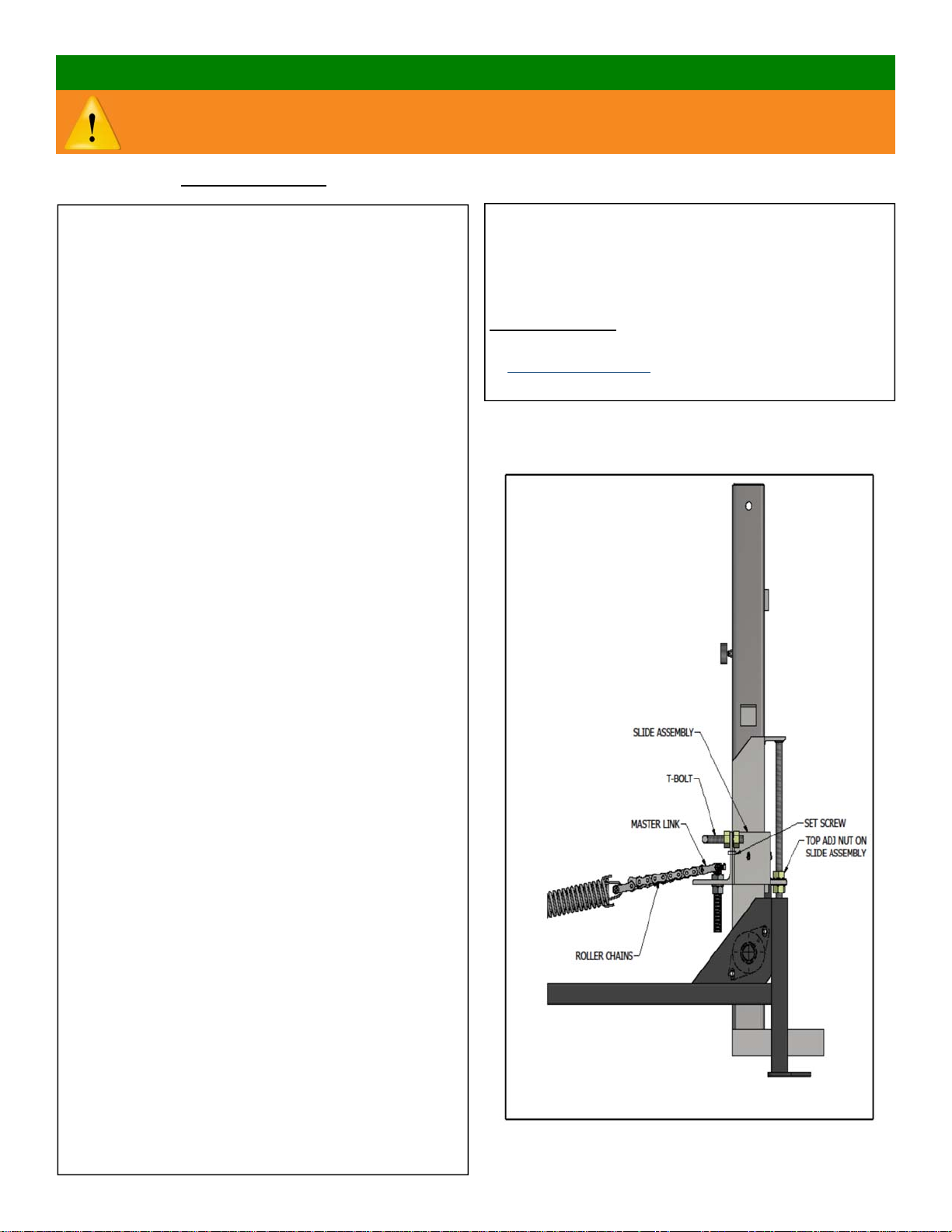

SPRING CHANGING INSTRUCTIONS

STEPS:

1. For ease of access, remove the door and end panel

nearest the gate.

2. Disable the photoelectric sensor/beam if equipped.

3. Remove any upper “T” bolts completely and loosen

the slide assembly screws.

4. Loosen the top adjusting nut of the slide assembly.

Thread the nut up to within four (4”) inches of the top of

slide mechanism.

5. You will now raise the gate. (DO NOT release the

disengage lever!) Initiate the gate to open, immediately

move to the gate and help raise it open, once the slide

moves up, hold on the bottom rail of the gate until fully

open. The gate may bounce slightly, there will be a loud

bang but no damage will occur.

6. Turn Off AC/DC Power before gate “times out” and

tries to close. Insert T/M Pin.

7. Using a 1 5/16 wrench, loosen and remove the chain

tension bolt with the damaged spring.

8. Replace damaged spring

9. Replace chain tension bolt. NOTE: Grease fitting

must point down! Tighten bottom nut. NOTE: Chain

MUST remain level and not twisted once tightened.

10. Remove T/M pin and restore AC/DC power.

11. Lowering the gate. Initiate the gate to close and at

the same time, assist the gate down by pulling on the

bottom rail of the gate. The slide will move down and

another loud bang as the gate is lowered.

12. Turn off AC/DC power.

13. Thread the slide nut back down to the slide assem-

bly and tighten.

14. Replace the T-Bolts to their original location and

tighten and tighten the slide assembly screws.

15. Restore AC/DC power and hook photoelectric sen-

sor/beam back up.

16. Cycle gate.

17. Spray all springs with a chain lube to prevent corro-

sion.

18. Grease Chain Tension bolts, Linkage Arm & Bear-

ings

RECOMMENDED: Always check and adjust the balance

after any spring change. Refer to balancing instructions

at www.AutoGate.com or the instructions on Page 16

TOOLS REQUIRED: 5/16” (Nut Driver), 1/2”, 1 1/8”, 1 5/16” Open End Wrenches

WARNING: SPRINGS ARE UNDER A TREMENDOUS LOAD. TAKE EXTREME CAUTION WHEN REMOV-

ING AND REPLACING THEM.

16

BALANCING

TESTING AMPERAGE

1.ConnectAMPmeterinseriesbyremovingthewirenutfromtheREDmotorlead.

2.Cyclegateupanddownrecordingthehighestamperageinthespaceprovidedandadjustinnecessary.high-

estUPandDOWNreadingsshouldnotexceeda1AMPdifference.Forexample:Ifyourhighestreadingis6.5

UPand6>0DOWN,thatwouldbeacceptable.Unacceptablewouldbe3.1UPand8.0)down.

ADJUSTING:

1.LoosenthesetscrewsontheSlideAssemblyaswellasthe11/8”nutsonbothsides(top&boom)ofthe

SlideAssemblyAngle.

2.Onlyadjustthenuts3to4turns(1/4”)atameandcheckyouramperagereadingsaereachadjustment.

NOTE:yourAmpsintheOPENmodeshouldbeapproximately.5(1/2)amphigherthentheCLOSEamperage.

3.IfthegateopenstooslowandisdrawinghighAmps,raisetheSlideAssemblyandrecheck.Ifthegatewill

NOTclose,lowertheSlideAssemblyandre-check.Ifyourgatestallsinetherdirecon,youhaveover-

adjusted.Backoffthelastadjustmentandre-check.

4.Ifthegateisslowstarngtoclosefromtheopenposion,increasethelengthoftheT-Bolt(s).

5.TightenSetScrewsand11/8”nuts.

UP: 10% _____ 55% _____ 85% _____

Down: 10% _____ 55% _____ 85% _____

Table of contents

Other AutoGate Gate Opener manuals

Popular Gate Opener manuals by other brands

Byan System

Byan System 600A Installation and technical manual

BFT

BFT DAMPY B Installation and user manual

Shark

Shark 500KG Manual for installation and operation

Platinum Access Systems

Platinum Access Systems BLSW1016 Installation instruction and owenrs manual

Gatekeeper

Gatekeeper YG-5602/1U/E owner's manual

Beninca

Beninca BULL 20T Operating instructions and spare parts catalogue