Automatic Heating BCM User manual

Operating Instructions

Modulex Boiler

Communications

Module - BCM

1. BOILER COMMUNICATIONS

MODULE (BCM)

When installed and enabled, the BCM enhances the range of

control functions offered by the Modulex Boilers. These

additional control functions include the following:

• BCM provides a fault relay which energizes when a global

fault (all burners off), or a fault on the inserted burner or a

fault that can not achieve the required target setpoint

occurs.

• BCM serves as a Back-up Controller in the event that the

primary E8 Controller fails.

• BCM can be selected as the Primary Controller instead

of the E8.

• BCM can function as a “Slave” to a “Master” Energy

Management System (EMS), Building Automation System

(BAS).

Paragraph 1.1 through 1.7 which follow provide detailed

descriptions of the BCM and each of the additional control

functions listed above.

1.1 BOILER COMMUNICATIONS MODULE

(BCM) DESCRIPTION

1.1 BOILER COMMUNICATIONS MODULE (BCM)

The BCM is installed on the front of the Modulex Boiler,

behind the removable front panel.

Two Control Switches are mounted on the clear plastic

cover on the front of the BCM. Three LED Status Indicators

are mounted directly on the BCM PCB and can be viewed

through the clear plastic cover. In addition, the PCB

contains an on-board, screwdriver-adjustable address

switch. The control and indicator functions are illustrated

and described in Figure 1-2.

The Modulex Boiler is shipped with the BCM, a third Control

Switch is mounted above the BCM. This switch is used to

enable/disable the e-Bus connection between the E8 and

BCM Controllers. Refer to paragraph 1.4.3 for details.

Figure 1-2. BCM Controls and Indicators

CONTROL /

INDICATOR

ENABLE/DISABLE

SWITCH (I/0)

RESET SWITCH

DL1 (Yellow) LED

DL2 (Red) LED

DL3 (Green) LED

SW1

FUNCTION

DL1 STATUS

Momentary two-position rocker

switch resets (clears) fault relay

and LED when activated.

Two-position rocker switch enables

the BCM to act as a Back-Up

Controller when placed in the ON (I)

position.

Communication Status Indicator

functions as follows:

DESCRIPTION

OFF No devices detected by

either communication

interface

BLINKING Only one communication

device detected at one

communication interface

(input or output) ON Both

communication interfaces

(input & output) are active

ON Both communication

interfaces (input &

output) are active

Alarm Status LED lights when a fault

is detected by the BCM. Activating the

Reset Switch will clear the faults

Pump Status Indicator lights when

Pump is running.

Screwdriver-adjustable rotary switch

labeled0–9.Thisswitchisusedto

set the corresponding address of the

Modulex Boiler on the input Modbus or

Ebus Network.

OUTPUT

COMMUNICATIONS

(Ebus)

SW1

ENABLE/DISABLE

SWITCH

INPUT

COMMUNICATIONS

(Modbus/Ebus)

RESET

SWITCH

DL1

(WYELLO )

DL2

(RED)

DL3

(GREEN)

FRONT VIEW

Modulex Controller Operation

2

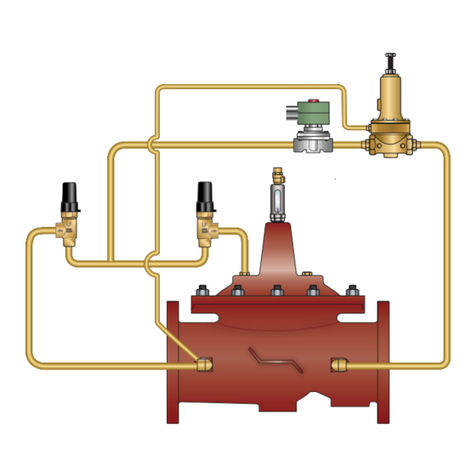

Figure 1-3. BCM Fault Relay & Reset Switch Wiring

1.2 BCM FAULT RELAY

The BCM Fault Relay is activated (energized) when a

fault (see par. 1) condition occurs in the Modulex Boiler.

When activated, the Fault Relay provides contact closure

across pins 3 and 4 of connector Y4 on the BCM board.

In addition, the red LED on the BCM board will light

continuously.

1.2.1 BCM FAULT RELAY WIRING

If desired, pins 3 and 4 of connector Y4 (Figure 1-3) can be

wired to an external source to provide a remote alarm

indication when the BCM Fault Relay is activated.

1.2.2 CLEARING FAULTS

A fault can be cleared by pressing and releasing the black

Reset Switch on the front cover of the BCM. However, if the

cause of the fault has not been corrected, the Fault Relay

will again be activat

Figure 1-4. BCM Back-Up Controller Wiring

1.3 BCM CONFIGURED AS BACK-UP

CONTROLLER

When the BCM is configured as the Back-Up Controller

for the E8, it will assume control of the Modulex Boiler if

the E8 fails. In the event of an E8 Controller failure, the

BCM will operate the Modulex Boiler in the Constant

Setpoint Mode (default setpoint = °C). The primary Boiler82

Pump must also be wired to the BCM so it will run when

the BCM assumes control in the Back-Up Mode.

If a setpoint temperature lower than °C is desired, the82

setpoint can be changed prior to boiler start-up. Refer to

paragraph 1.3.1 for details.

1.3.1 BCM BACK-UP CONTROLLER

WIRING

The Primary Boiler Pump must be wired to BCM

Connector Y4 as shown in Figure 1-4. Also, if a

Constant Setpoint temperature lower than the default

setting of °C) is desired in the event of an E8 failure,82

the appropriate resistor must be connected across

terminals 6 and 7 of BCM Connector Y2 as shown in

Figure 1-5.

3

Modulex Controller Operation

4

Figure 1-5. Installing Resistor to Change Default Setpoint

Ext sens

Open

47

22

Set point

82°C

71

60

49

38

°C

°C

°C

°C

27°C

1.4 BCM CONFIGURED AS PRIMARY

CONTROLLER UTILIZING MODBUS

The BCM can be configured as the Primary Controller, instead

of the E8, when it is connected to a Modbus Network. However,

the E8 must be disconnected from the e-Bus connection on

the BCM Board (see para. 1.4.3). All Modbus Networks are

implemented utilizing a “Master – Slave” scenario where only

one device, the “Master”, can initiate a communication

sequence. However, BCMs can only function as “Slave”

devices on a Modbus Network. Therefore, the BCM must be

interfaced to an external controlling “Master”. The “Master”

can be an Energy Management System (EMS)/Building

Automation System (BAS) developed by other manufacturers.

The following subordinate paragraphs provide descriptions

of Modbus Network operation and required wiring connections

between the BCM “Slaves and the controlling “Master” (EMS,

BAS).

Detailed information on the Modbus Function Codes, Input/

Holding Register Assignments and other Modbus

requirements supported by the BCM are provided in Appendix

B of this document.

1.4.1 OPERATING SCENARIO

Each Modulex Boiler is equipped with its own BCM to

allow Modbus Network monitoring and control. The Master

can control the Networked Modulex Boilers utilizing either

Remote Setpoint or Modulation Level signaling.

In the event that the external control signal from the EMS

or BAS is lost, the BCM will assume control of the Modulex

Boilers if enabled by switch. When this occurs, the BCM

will maintain the boiler at a constant setpoint based on

the resistor installed between terminals 6 and 7 of

connector Y2 (see Figure 7-5). If the event occurs and the

2 positions switch is on 0 (disabled), the BCM Fault Relay

will be activated and the red Fault LED (DL2) will light.

1.4.2 PHYSICAL MODBUS RS485 WIRING

Modbus RS485 devices should be wired in a “Daisy-Chain”

configuration similar to the example shown Figure 7-6. DO

NOT wire the units in a “Star” configuration where all devices

are connected to a central point (node).

Figure 1-6. Typical Daisy-Chain Modbus/RS485 Network

The physical wiring connections for a Modbus Network should

be made using shielded twisted-pair wire.

Modbus wiring connections are made at terminals 1 and 2 of

BCM connector Y2 as shown in Figure 7-7.

1-7. BCM Modbus (RS485) Connections

BCM FRONT VIEW

MASTER

SLAVE

#1 SLAVE

#2 SLAVE

#3 SLAVE

#4 SLAVE

#5

7.4.3 DISCONNECTING E8 FROM E-BUS ON

BCM BOARD.

The Modulex Boiler is shipped with the BCM factory-installed,

it will contain a 3-position switch mounted above the BCM

TABLE 1-1. 3 - POSITION BCM SWITCH FUNCTIONS

NOTES:

1. DO NOT set the 3-Position Switch to Position I.

2. Set the 3-Position Switch to Position OONLY

when controlling Boilers from an external

Controller via Modbus Communication.

3. Position II is the Default position for the 3-

Position Switch. Ensure it is set to this position

when it arrives from the Factory

(Figure 7-8). Refer to the switch matrix in Table 7-1 for

descriptions of how the factory-installed 3-position switch

functions with respect to the 2-position ON/OFF switch on the

BCM.

BCM

2 Postion ON/OFF

Switch

I

(1b)

(See NOTE 1 Below)

O

(0)

(See NOTE 2 Below)

II

(1a)

(See NOTE 3 Below)

The BCM is the Gate-way for Mo-

dbus and external control.The E8

does not control the boiler and

the BCM will not take over the

boiler if the Modbus signal fails.

The BCM is the Gate-way for Mo-

dbus and external control.The E8

does not control the boiler and

the BCM will take over the boiler

if the Modbus signal fails.

The E8 is the primary controller

and the BCM will allow monito-

ring through Modbus but will not

take over boiler if the E8 fails.

The E8 is the primary controller

and the BCM will allow monito-

ring but the BCM will take over

running the boiler if the E8 fails

DO NOT USE

BCM 3 Position Switch (Equivalent Terminal in Modulex Wiring Diagram)

DO NOT USE

O (OFF)

I(ON)

Figure 1-8. Location of 2-Position and 3-Position Switches

5

Modulex Controller Operation

6

When a third-party EMS or BAS Master is used, the

Modbus Network connections will depend on the

available communication port(s) on the EMS/BAS.

Many EMS/BAS Models contain only a RS232 (DB9)

port, while others contain either a 2-Wire or 4-Wire RS485

port. In addition, some EMS/BAS models contain both a

RS232 and a RS485 port. If the EMS or BAS is equipped

with only a RS232 port, a RS232-to-RS485 converter will

be required.

A terminating resistor (120 ohms) on each end of the RS485

loop is designed to match the electrical impedance

characteristic of the twisted-pair loop and prevent echoes

or cross-talk from corrupting data on the line. Short or

medium length Modbus/RS485 loops (less than 1000 feet)

can usually operate satisfactorily without the terminating

resistor. However, longer loop runs (over 1000 feet), may

require terminating resistors.

Bias may be necessary on the RS485 loop to minimize

noise on the circuit. accomplishedLoop bias is by

activating pull-up/pull-down resistors on the last Boiler

Communications Module (BCM) in the chain.

Modulex recommends that both terminating resistors

and bias be implemented on the RS485 circuit as

described in paragraphs 1.5 and 1.5.1 which follow.

When an EMS or BAS is used as the controlling Master,

consult the manufacturer’s Technical Manual for termination

resistor recommendations. If the EMS/BAS being used

does not provide a bias and one is needed, pull-down bias

can be implemented by installing a 1K ohm resistor (not

provided) across terminals 2 and 4 on BCM connector Y2

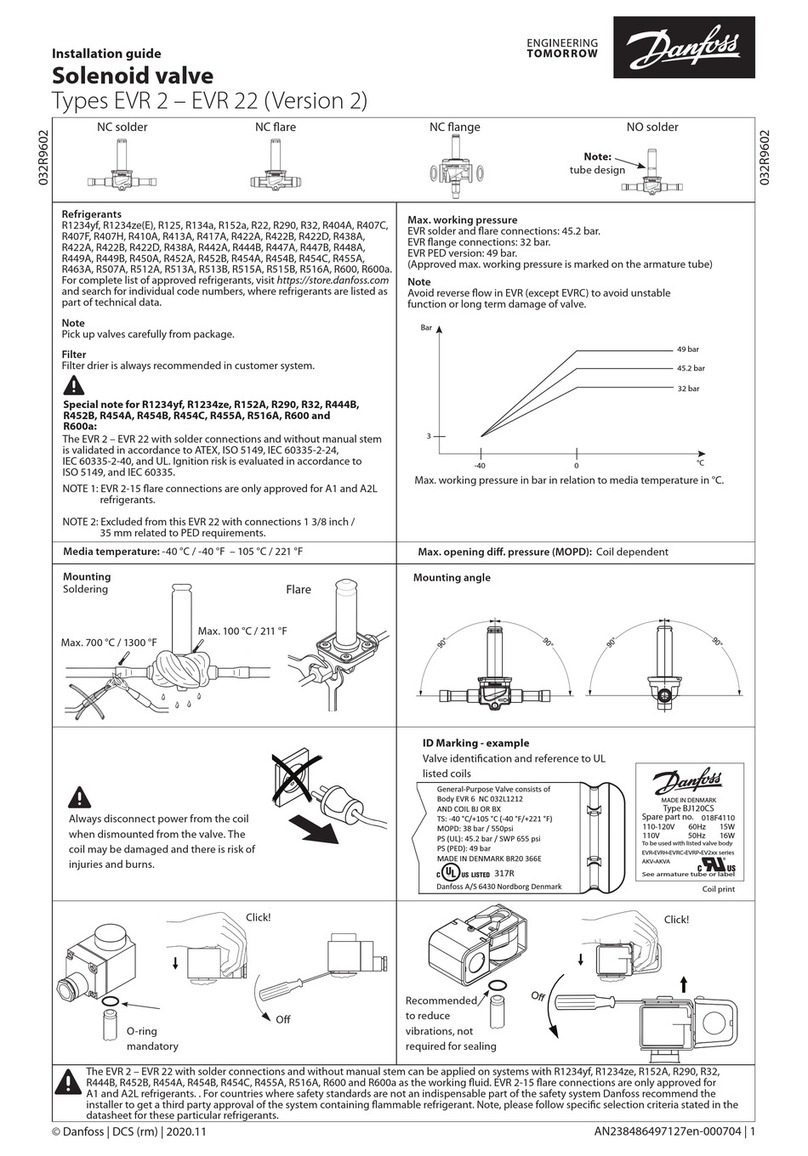

(Figure 1-9).

BCMs can function only as Slave devices on a Modbus

Network. Since the Slaves are connected in a “Daisy-Chain”

configuration, the terminating resistor must be enabled only

in the last BCM Controller in the chain. Enabling the

terminating resistor is accomplished by positioning jumper

JP1 as shown in Figure 1-9 only on the BCM Board

contained in the last BCM Controller.

As mentioned in paragraph 1.5.1, when the controlling

Master is an EMS or BAS, pull-down bias may be

implemented by connecting a 1K ohm resistor as shown

in Figure 1-9.

The last unit in the chain must be energized (even if disabled)

to enable bias.

Figure 1-9. BCM Loop Termination and Bias

Figure 1-10 shows a Sample Modbus Network wiring

for a Master EMS/BAS controlling

Figure shows an EMS or BAS Master equipped

port. If the EMS or BAS contains a 4-Wire RS485 port, refer to

Detail “A” for wiring details. If the controlling

contains only a RS232 port, a RS232-to-RS485

be required to interface with connector Y2 at each BCM

Controlle

as a guide and does not include

to the EMS/BAS manufacturer’s

any network

diagram

BCM Controller Slaves. This

with a RS485

Master EMS/BAS

converter will

r. It should be noted that this diagram is only intended

all possible scenarios. Refer

manual prior to attempting

wiring connections.

1.4.4 EMS OR BAS MASTER TO BCM

SLAVE WIRING CONNECTIONS

1.4.5 RS485 LOOP TERMINATION

RESISTORS AND BIAS

1.5 EMS/BAS TERMINATING RESISTOR

AND BIAS

1.5.1 BCM CONTROLLER TERMINATING

RESISTOR AND BIAS

1.6 MODBUS NETWORK WIRING

DIAGRAM

CAUTION

It is imperative that polarity be maintained

between all Modbus Network connections. The

Network will not operate if the proper polarity is

not maintained. Also, twisted-pair wiring shields

should only be terminated at the controlling

Master for the Modbus Network.

BCM FRONT VIEW

7

Modulex Controller Operation

8

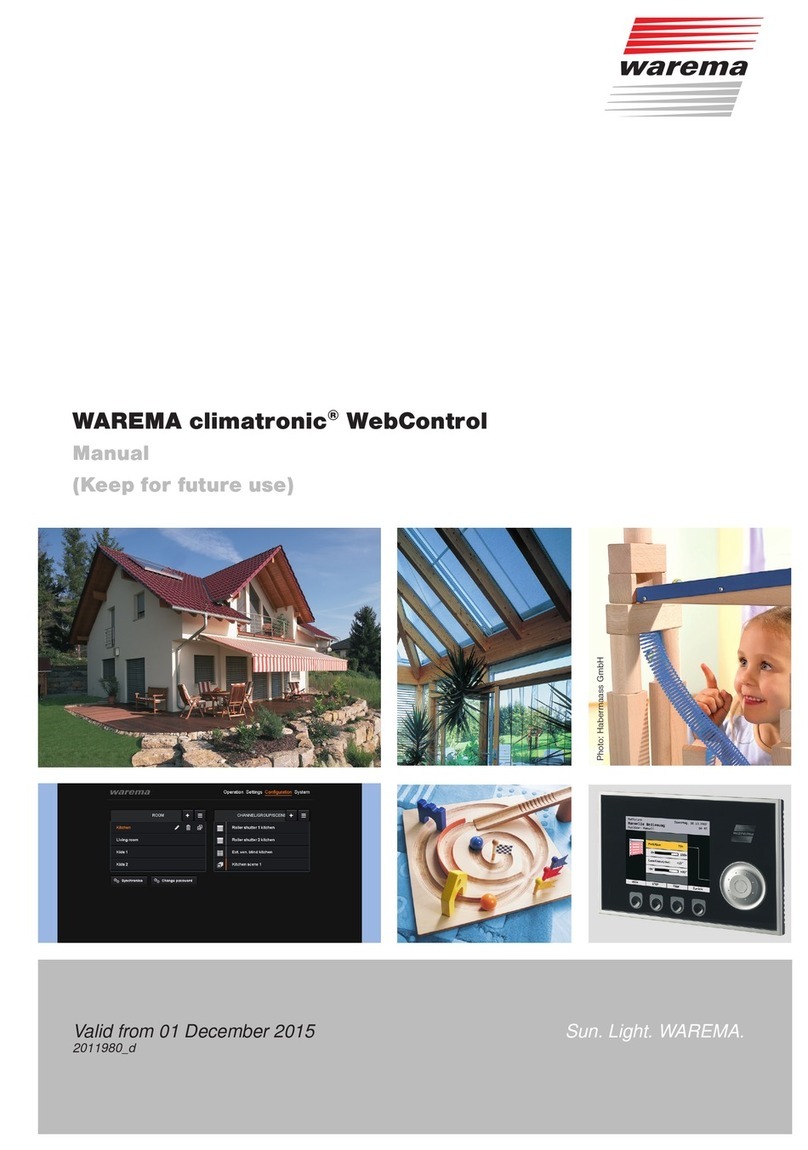

Figure 1-11. Location of BCM Address Selection Switch SW1

1.7.2 MONITORING AND CONFIGURATION

ONLY

For monitoring and configuration only, set the 3-position switch

to position II when the E8 is controlling the boiler. The boiler

operation can be monitored via the Modbus terminals.

1.7.3 MODBUS DIRERCT DRIVE CONTROL

AND MONITORING

The BCM’s modulation output can be directly driven by writing

to its Direct Drive register (Standard Holding Register). It

will ramp up the boiler based on the settings in the Standard

Holding Register or Setting Register 3000 to 3051. The default

maximum setpoint temperature limit is 85°C as shown in

register 3015. This value should not be increased, if possible.

The default timeout interval is 30 seconds as shown in register

3011. To prevent communication dropouts, write the direct

drive modulation value at least 3 times within the

communication timeout interval.

1.7.4 MODBUS REMOTE SETPOINT

CONTROL AND MONITORING

To send a setpoint temperature to the BCM and have it control

the boiler based on its internal settings, 3 registers need to be

adjusted:

1. the desired setpoint should be written to the Requested

Setpoint (Address 1004)in the Standard holding Registers

or Control Registers. This value should be written at least

3 times within the Communication Timeout time (Address

3011).

2. The Heat Request Command (Control Register Address

1021) should be set to 0xEE (238) to request heat.

3. If the modulation level should be allowed to go above

50%, adjust the Maximum Modulation Level setting (Ad

dress 1017).

NOTE

If power is lost, all Control Register settings re-

turn to their default values. Be sure to read them

regularly and refresh if necessary. The changes

to the Settings Registers are stored during

power-down.

1.7.5 EMS OR BAS SET-UP AS MASTER TO

BCM CONTROLLER SLAVES

Ref uer to the set-up instructions in the man facturer’s equip-

ment manual for the Energy Management System (EMS) or

Building Automation System (BAS) being used as the control-

ling Master.

1.7 MODBUS SOFTWARE SET-UP

The following paragraphs provide the information and proce-

dures necessary to configure the Boiler Communications

Modules (BCMs) to operate on a Modbus Network.

NOTE

The following paragraphs assume that between

1 and 9 Modulex Boilers are being controlled on

the Modbus Network.

7.7.1 BCM Set-Up for Modbus Operation

The BCM Controller can be set up for the following types of

Modbus operating modes:

• Monitoring and Configuration Only

• Modbus Direct Drive Control and Monitoring

• Modbus Remote Setpoint Control and Monitoring

In order for the BCM Controller to be recognized by the Mod-

bus Master, a valid address must be set at each BCM on the

Modbus Network. Address selection on each BCM is accom-

plished by setting rotary DIP switch SW1. This switch is loca-

ted in the lower right portion of each BCM as shown in Figure

1-11.

As Figure 1-11 shows, SW1 is a 10-position switch labeled 0

– 9. SW1 is set to the desired position using a small flat-tip

screwdriver. Figure 1-11 shows SW1 set to address 0 (zero)

which disables the BCM on the Modbus Network. Only Mod-

bus addresses 1 through 9 will be recognized by the Modbus

Master. SW1 must be set to a different position for each Modu-

lex Boiler being controlled on the Modbus Network.

Once the desired address has been set on each BCM, the

Modulex Boiler is configured for Modbus Network control by

the controlling Master EMS/BAS. In order for the BCM to act as

the Back-Up Controller if the Modbus Master signal is lost, the

ENABLE/DISABLE switch must be set to ENABLE (1).

See Appendix B for Modbus points for the BCM.

9

APPENDIX B

BOILER COMMUNICATIONS MODULE (BCM)

B-1 BCM MODBUS COMMUNICATION & SUPPORT REQUIREMENTS

The Modbus communication support requirements incorporated in the BCM are as follows:

B-1.1 Function Codes

The BCM supports the Modbus Function Codes SHOWN IN Table B-1.

Table B-1. Supported Modbus Function Codes

FUNCTION CODE

03

04

06

DESCRIPTION

Read up to 8 contiguous Holding Registers

Read up to 8 contiguous Address Registers

Write a single 16 bit Register

Table B-2. Modbus Support Requirements

CHARACTERISTIC

Communication Medium

EMS Master to BCM Slave

RS 485 Alowable Cable Length

Address Support From Master EMS

Trasmission Mode Support

Timing specifications:

Baud Rate:

Data Framing:

Message Framing:

Character Framing:

Heartbeat Timeout:

DESCRIPTION

B-1.2 Modbus Support Requirements

The Modb r m to the supporus Netwo k must confor t requirements listed in Table B-2.

RS485 2-Wire Differential Bus With Shield

4000 Feet Maximum

1 to 9 via Address Select Switch (SW1)

RTU (Remote Terminal Unit)

Fixed at 9600

8databits,noparity,1stopbit

Silent period of at least 3.5 character times Before first

character and After last character

No more than 1.5 character times of silence between

received and transmitted characters

Adjustable (0 or 1 – 240 seconds)

Appendix B

10

B-2. BCM CONTROLLER STANDARD HOLDING REGISTER ASSIGNMENTS

B-2.1 BCM Controller Standard Input Register Assignments

The BCM Controller has only two Read Only Input Register addresses as shown in Table B-3.

Table B-3. BCM Controller Standard Input Register Address Mapping

Modbus Data

Address

0

1

Menu Item

Status & Error Code

Unit Status

Menu Item

enum (2,8,10,18,23,32,42,38)

2 = Standby

8 = High temperature switch open

10 =Low gas pressure switch open

18 =Air flow switch open during ignition

23 =Flame loss during run

32 =Residual flame

42 =Outlet temperature sensor fault

38 = Other conditions not listed above

enum (1, 3, 5)

1 = Standby (ready to run but not fired)

3 = Remote (fired)

5 = Fault (failure detected)

B-2.2 BCM CONTROLLER STANDARD HOLDING REGISTER ASSIGNMENTS

The BCM Controller Holding Registers contain functions that are Read Only, Write Only or both Read & Write. The

address assignments for these functions are listed in Table B-4 and are grouped into the following major categories:

Control Registers, Operating Data Registers, System Data Settings and Test Registers. Functions within each group

are not necessarily in hex address order.

The Read Only, Write Only or Read/Write status for each function in Table B-4 is shown in the Default/Comments

column.

11

Table B-4. BCM Standard Holding Register Address Mapping

Modulex Controller Operation Appendix B>

12

Table B-4. BCM Standard Holding Register Address Mapping - Cont.

13

Table B-4. BCM Standard Holding Register Address Mapping - Cont.

APPENDIX B

Modulex Controller Operation Appendix B>

14

Table B-4. BCM Standard Holding Register Address Mapping - Cont.

APPENDIX B

Atyutomatic Heating P Ltd

ABN 90 446 545 923

DISTRIBUTED BY

Telephone Facsimile

Email

1800 337 959 +61 3 9310 5655

sales@automaticheating.com.au

P.O. Box 35 Epping VIC 3076 Australia

www.automaticheating.com.au

Table of contents