© Danfoss | DCS (rm) | 2020.11

032R9602

032R9602

3

-40 0

Bar

°C

45.2 bar

49 bar

32 bar

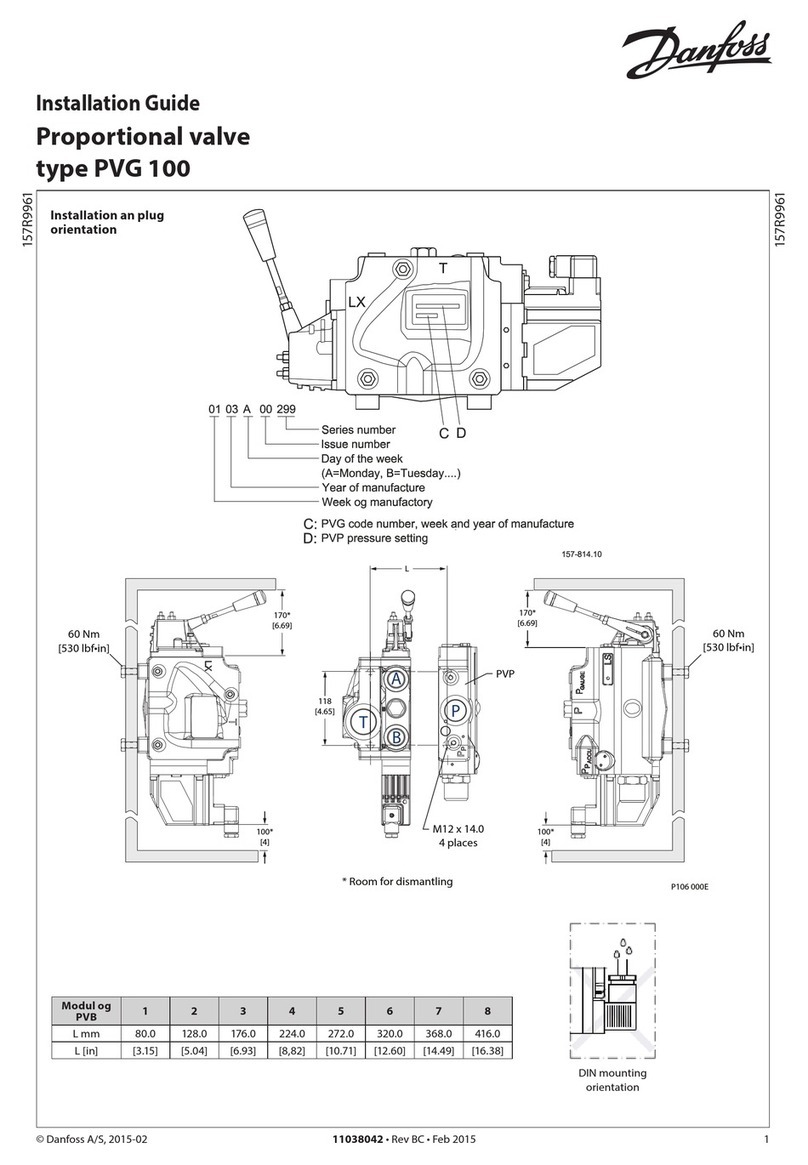

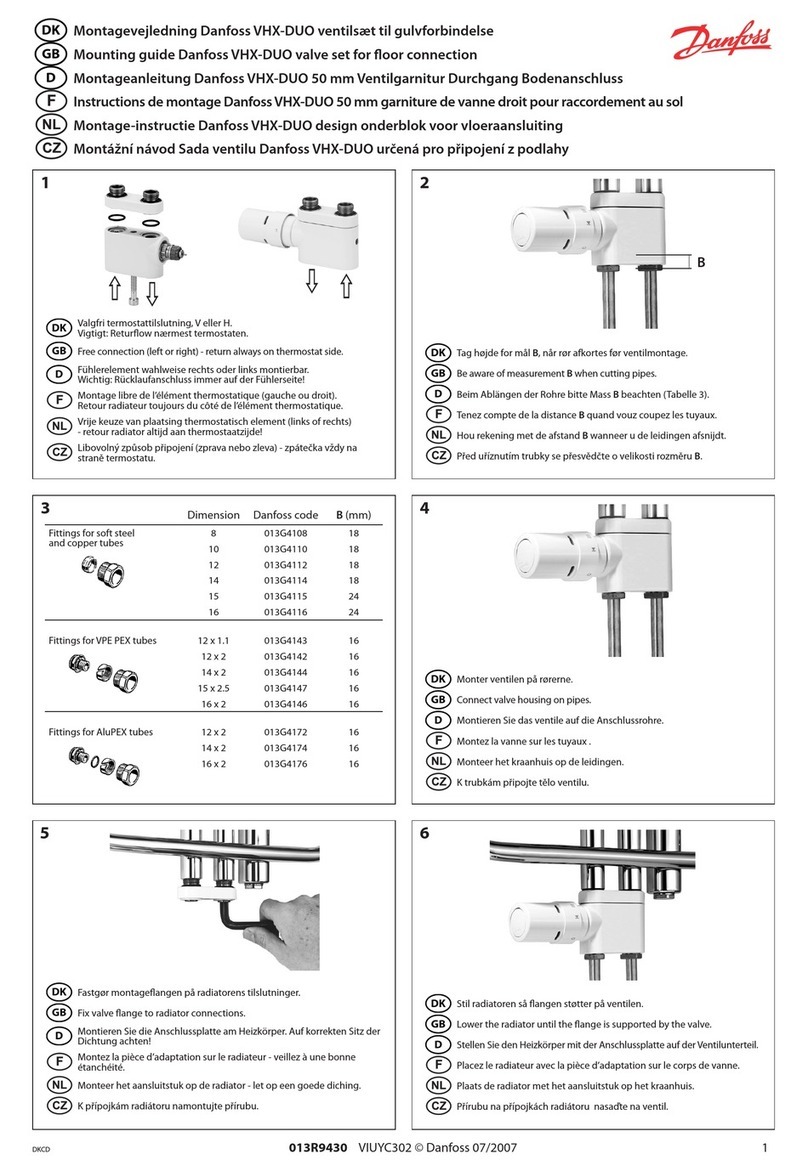

Installation guide

Solenoid valve

Types EVR 2 – EVR 22 (Version 2)

AN238486497127en-000704 | 1

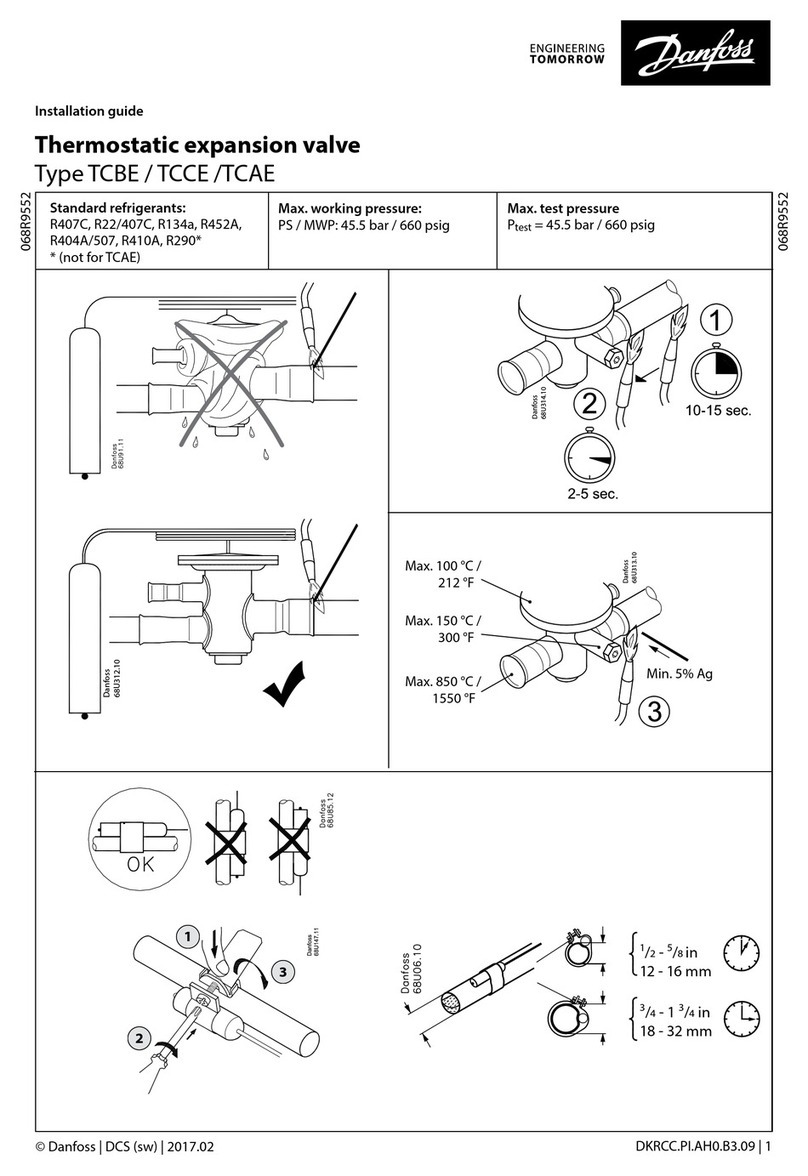

Max. 700 °C / 1300 °F

NC solder NC flare NC flange NO solder

Note:

tube design

Refrigerants

R1234yf, R1234ze(E), R125, R134a, R152a, R22, R290, R32, R404A, R407C,

R407F, R407H, R410A, R413A, R417A, R422A, R422B, R422D, R438A,

R422A, R422B, R422D, R438A, R442A, R444B, R447A, R447B, R448A,

R449A, R449B, R450A, R452A, R452B, R454A, R454B, R454C, R455A,

R463A, R507A, R512A, R513A, R513B, R515A, R515B, R516A, R600, R600a.

For complete list of approved refrigerants, visit https://store.danfoss.com

and search for individual code numbers, where refrigerants are listed as

part of technical data.

Note

Pick up valves carefully from package.

Filter

Filter drier is always recommended in customer system.

The EVR 2 – EVR 22 with solder connections and without manual stem

is validated in accordance to ATEX, ISO 5149, IEC 60335-2-24,

IEC 60335-2-40, and UL. Ignition risk is evaluated in accordance to

ISO 5149, and IEC 60335.

NOTE 1: EVR 2-15 flare connections are only approved for A1 and A2L

refrigerants.

NOTE 2: Excluded from this EVR 22 with connections 1 3/8 inch /

35 mm related to PED requirements.

Special note for R1234yf, R1234ze, R152A, R290, R32, R444B,

R452B, R454A, R454B, R454C, R455A, R516A, R600 and

R600a:

Max. working pressure

EVR solder and flare connections: 45.2 bar.

EVR flange connections: 32 bar.

EVR PED version: 49 bar.

(Approved max. working pressure is marked on the armature tube)

Note

Avoid reverse flow in EVR (except EVRC) to avoid unstable

function or long term damage of valve.

Max. working pressure in bar in relation to media temperature in °C.

Max. 100 °C / 211 °F

Media temperature: -40 °C / -40 °F – 105 °C / 221 °F Max. opening diff. pressure (MOPD): Coil dependent

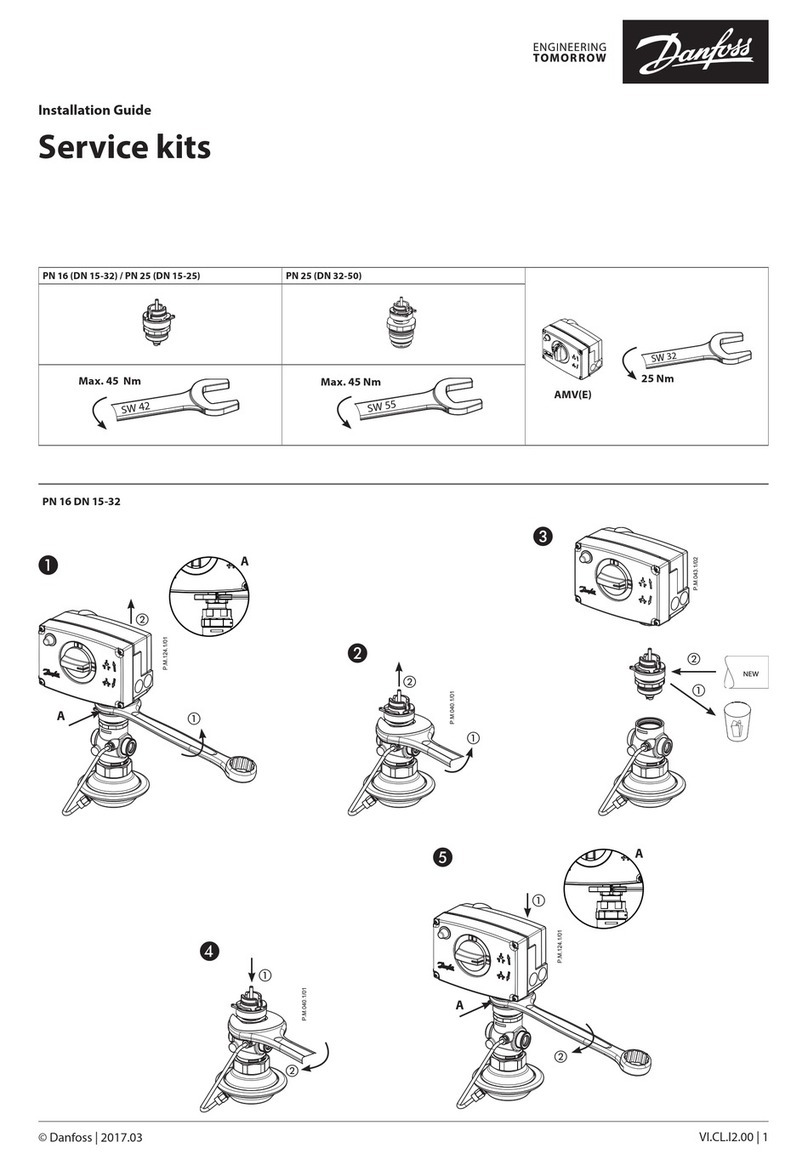

Mounting

Soldering Flare

Mounting angle

317R

Danfoss A/S 6430 Nordborg Denmark

General-Purpose Valve consists of

Body EVR 6 NC 032L1212

AND COIL BJ OR BX

TS: -40 °C/+105 °C (-40 °F/+221 °F)

MOPD: 38 bar / 550psi

PS (UL): 45.2 bar / SWP 655 psi

PS (PED): 49 bar

MADE IN DENMARK BR20 366E

Type BJ120CS

MADE IN DENMARK

Spare part no.

To be used with listed valve body

EVR•

EVRH

•EVRC•EVRP•EV2xx series

AKV•AKVA

See armature tube or label

018F4110

110-120V 60Hz 15W

110V 50Hz 16W

ID Marking - example

Valve identification and reference to UL

listed coils

Always disconnect power from the coil

when dismounted from the valve. The

coil may be damaged and there is risk of

injuries and burns.

Coil print

Danfoss

32F905.10

A

Click!

Off

O-ring

mandatory

Click!

Recommended

to reduce

vibrations, not

required for sealing

The EVR 2 – EVR 22 with solder connections and without manual stem can be applied on systems with R1234yf, R1234ze, R152A, R290, R32,

R444B, R452B, R454A, R454B, R454C, R455A, R516A, R600 and R600a as the working fluid. EVR 2-15 flare connections are only approved for

A1 and A2L refrigerants. . For countries where safety standards are not an indispensable part of the safety system Danfoss recommend the

installer to get a third party approval of the system containing flammable refrigerant. Note, please follow specific selection criteria stated in the

datasheet for these particular refrigerants.